| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: DN6848 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Hall ICs

1

Publication date: November 2002

SPC00003CEB

DN6848SE

DN6848S

DN6848/SE/S

Wide operating temperature range

(

-40∞C to +100∞C)

One-way magnetic field operation

Overview

In each of Hall ICs, a Hall element, an amplifier circuit,

a Schmidt circuit, a stabilized power supply, and a tem-

perature compensation circuit are integrated on a single

chip by IC technique. The Hall element output is ampli-

fied by the amplifier circuit, and converted into the corre-

sponding digital signals through the Schmidt circuit so

that TTL and MOS IC are directly drivable.

Features

∑ High sensitivity and low drift

∑ Stabilized temperature characteristics owing to addi-

tional integration of temperature compensation circuit.

∑ Wide operating supply voltage range

(V

CC

= 4.5 V to 16 V)

∑ One-way magnetic field operation

∑ TTL and MOS IC are directly drivable by the output.

∑ Open collector output

Applications

∑ Speed sensor, position sensor, rotation sensor, keyboard

switch, micro switch and the like

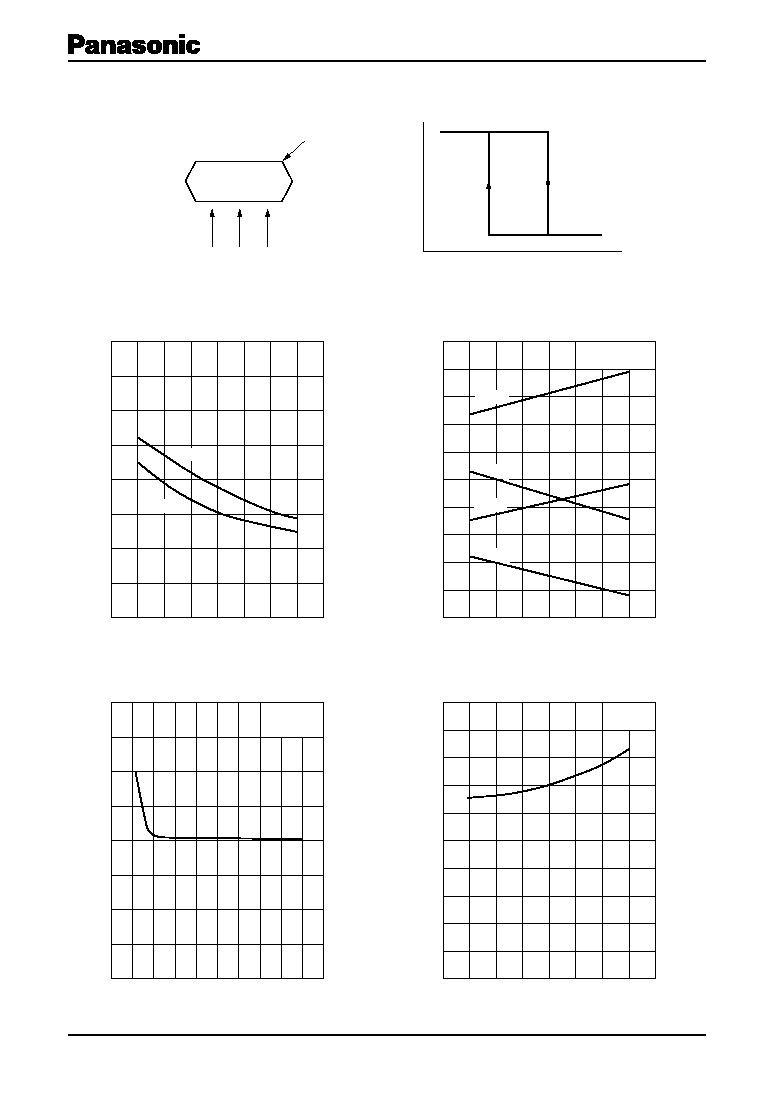

Block Diagram (DN6848/SE/S)

Note) The number in ( ) shows the pin number for the DN6848S.

SSIP003-P-0000A

Unit: mm

SSIP003-P-0000C

Unit: mm

Unit: mm

4.52±0.3

0.55±0.15

0.4±0.1

1.54±0.1

1.27

1 2 3

(0.4)

12.5±06.5

(0.72)

4.52±0.3

(1.0)

(1.0)

1 2 3

5

∞

(5

∞)

2

∞

1.27

4.0±0.2

(1.0)

(1.0)

(0.7)

4.5±0.2

0.43

+0.1

≠0.05

0.43

+0.1

≠0.05

0.55±0.15

2.0±0.2

0.8±0.1

(1.0)

10.5±0.5

ESOP004-P-0200

1.6

3.0±0.3

0.6±0.2

1

2

4

3

5.4±0.4

3.0±0.3

1.5±0.3

0.4±0.2

0.1±0.1

0.2

0.95±0.2

0.4±0.15

+0.15 ≠0.05

1 : V

CC

2 : GND

3 : Output

1 : V

CC

2 : GND

3 : Output

1 : V

CC

2 : N.C. or GND

3 : Output

4 : GND

DN6848

Power supply circuit and

temperature compensation circuit

1

V

CC

2

GND

(4)

N.C.

or

GND

(2)

3

Output

Hall element Amplifier Schmidt

trigger

Output stage

Note) The packages (SSIP003-P-0000A, SSIP003-P-

0000C and ESOP004-P-0200) of this product

will be changed to lead-free type (SSIP003-P-

0000H, SSIP003-P-0000J and ESOP004-P-

0200A). See the new package dimensions sec-

tion later of this datasheet.

DN6848/SE/S

2

SPC00003CEB

Recommended Operating Range

Parameter

Symbol

Range

Unit

Supply voltage

V

CC

4.5 to 16

V

Absolute Maximum Ratings

Parameter

Symbol

Rating

Unit

Supply voltage

V

CC

18

V

Supply current

I

CC

8

mA

Circuit current

I

O

20

mA

Power dissipation

P

D

150

mW

Operating ambient temperature

T

opr

-40 to +100

∞C

Storage temperature

T

stg

-55 to +125

∞C

Note) 1. The variation of operating magnetic flux density does not depend on supply voltage due to its built-in stabilized power

source. (V

CC

should be confined to the range of 4.5 V to 16 V.)

2. A supply current increases by approximately 1 mA when its output level varies from high to low.

Electrical Characteristics at T

a

= 25∞C

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

Operating magnetic flux density

B

1(L-H)

V

CC

= 12 V

0.5

9

21

mT

B

2(H-L)

V

CC

= 12 V

1.5

11

22

mT

Hysteresis width

BW

V

CC

= 12 V

1

2

mT

Output voltage

V

OL

V

CC

= 16 V, I

O

= 12 mA, B = 22 mT

0.4

V

V

CC

= 4.5 V, I

O

= 12 mA, B = 22 mT

0.4

V

Output current

I

OH

V

CC

= 4.5 V to 16 V, V

O

= 16 V,

10

µA

B

= 0 mT

Supply current

I

CC

V

CC

= 16 V

6

mA

V

CC

= 4.5 V

5.5

mA

Technical Data

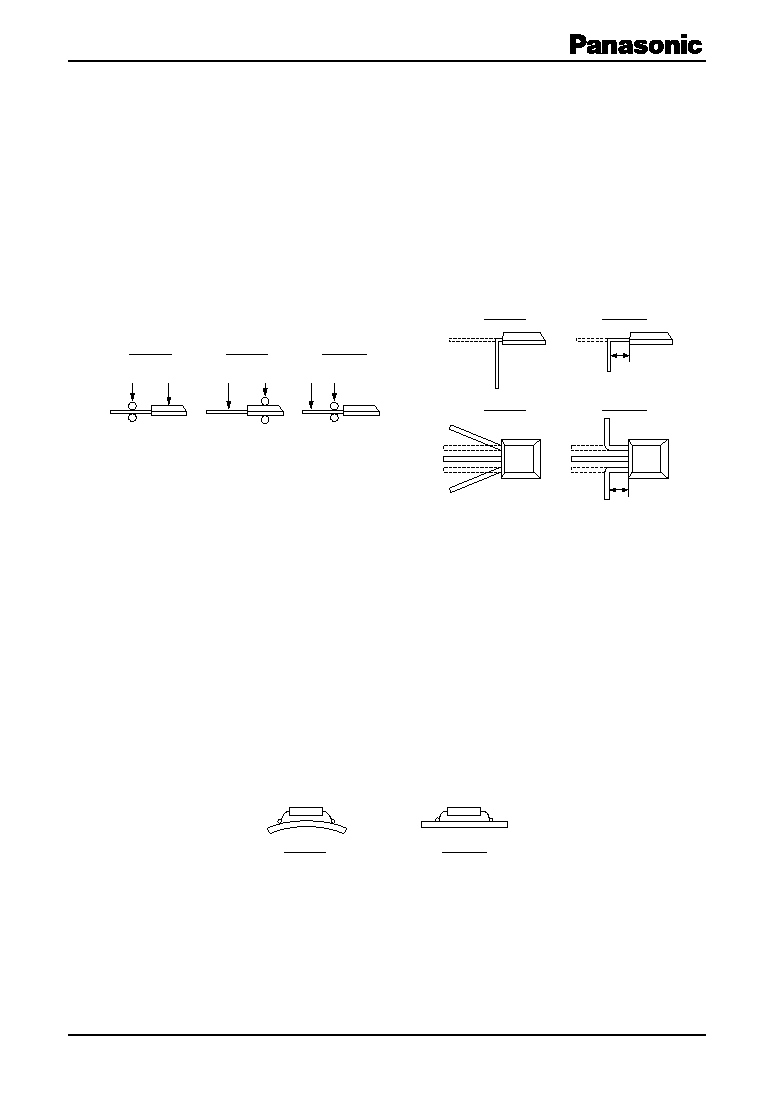

∑ Position of Hall element (unit: mm)

A Hall element is placed on the shaded part in the figure.

DN6848

DN6848SE

DN6848S

Distance from package surface to sensor part

0.7

0.42

0.65

1.0

1.0

1.5

1.5

1.0 1.63

1.0

1.25

1.0 1.75

1.0

1.3

Note) This IC is not suitable for car electrical equipment.

DN6848/SE/S

3

SPC00003CEB

Technical Data (continued)

∑ Magneto-electro conversion characteristics

Applying direction of magnetic flux

Marked face

B

H-L

B

L-H

Magnetic flux density B

Output v

oltage

V

O

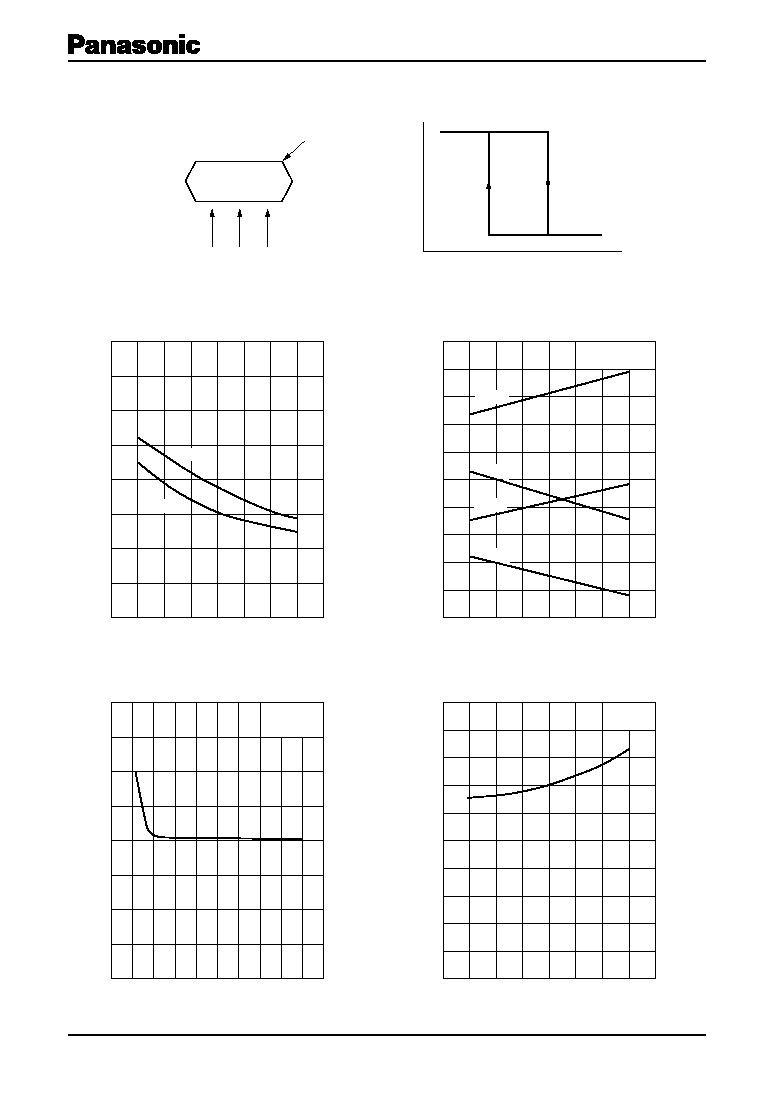

∑ Main characteristics

Supply current

Ambient temperature

Operating magnetic flux density

Ambient temperature

0

125

V

CC

= 12 V

I

O

= 12 mA

0

1

2

3

4

5

6

7

8

2.5

5.0

7.5

10.0

12.5

15.0

17.5

20.0

-50

-25

0

25

50

75

100

125

-50

-25

0

25

50

75

100

2.5

7.5

12.5

17.5

22.5

5.0

10.0

15.0

20.0

25.0

125

-50

-25

0

25

50

75

100

10

20

30

40

50

60

70

80

90

100

0

20

2

4

6

8

10

12

14

16

18

Sample 3

Sample 2

Sample 4

Sample 1

V

CC

= 4.5 V 16 V

B

H-L

V

CC

= 16 V

V

CC

= 4.5 V

T

a

= 25∞C

Ambient temperature T

a

(∞C)

Operating magnetic flux density B (mT)

Ambient temperature T

a

(∞C)

Supply current I

CC

(mA)

Ambient temperature T

a

(∞C)

Lo

w-le

v

el output v

oltage

V

OL

(mV)

Supply voltage V

CC

(V)

Operating magnetic flux density B (mT)

Operating magnetic flux density

Supply voltage

Low-level output voltage

Ambient temperature

DN6848/SE/S

4

SPC00003CEB

Caution on Use of Hall ICs

The Hall ICs are often used to detect movement. In such cases, the position of the Hall IC may be changed by

exposition to shock or vibration over a long period of time, and it causes the detection level change. To prevent this, fix

the package with adhesives or fix it on a dedicated case.

1. A case using an adhesive

Some kinds of adhesive generate corrosive gas (such as chloric gas) during curing. This corrosive gas corrodes

the aluminum on the surface of the Hall IC, and may cause a functional defect of disconnection.

If Hall IC is to be sealed after installation, attention should be given to the adhesive or resin used for peripherals

and substrate cleaner, as well as to the adhesive used for Hall IC installation. Please confirm the above matter to those

manufacturers before using.

We could not select the specified adhesive, for we find it difficult to guarantee the ingredient of each adhesive.

2. A case bending lead wire

Bend the lead wire without stressing the package.

3. Power supply line/Power transmission line

If a power supply line/power transmission line becomes longer, noise and/or oscillation may be found on the

line. In this case, set the capacitor of 0.1

µF to 10 µF near the Hall IC to prevent it.

If a voltage of 18 V or more is thought to be applied to the power supply line (flyback voltage from coil or the

ignition pulse, etc.), avoid it with external components (capacitor, resistor, Zener diode, diode, surge absorbing ele-

ments, etc.).

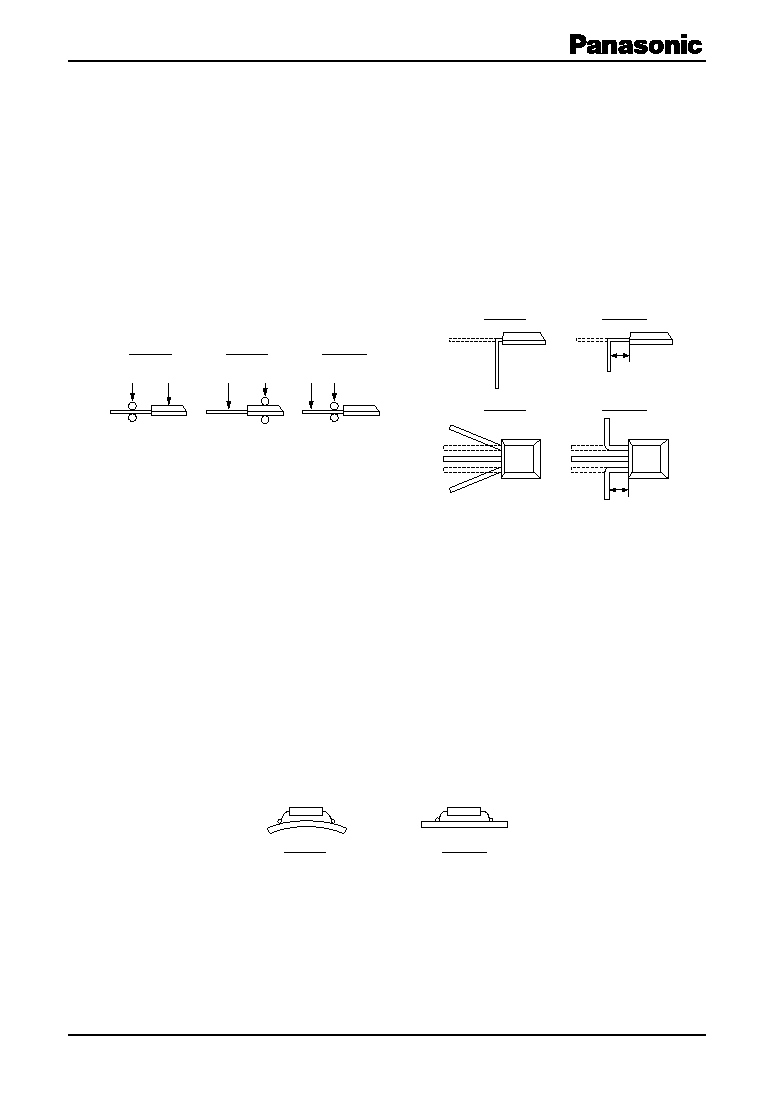

4. On mounting of the surface mount type package (ESOP004-P-0200)

Set pin 2 of the ESOP004-P-0200 package open, or connect it to GND. The IC will be damaged if it is connected

to V

CC

.

When mounted on the printed circuit board, the Hall IC may be highly stressed by the warp that may occur from

the soldering. This may also cause a change in the operating magnetic flux density and a deterioration of its resistance

to moisture.

5. V

CC

and GND

Do not reverse V

CC

and GND. If the V

CC

and GND pins are reversely connected, this IC will be destroyed. If the

IC GND-pin voltage is set higher than other pin voltage, the IC configuration will become the same as a forward

biased diode. Therefore, it will turn on at the diode forward voltage (approximately 0.7 V), and a large current will

flow through the IC, ending up in its destruction. (This is common to monolithic IC.)

6. Cautions on power-on of Hall IC

When a Hall IC is turned on, the position of the magnet or looseness may change the output of a Hall IC, and a pulse

may be generated. Therefore, care should be given whenever the output state of a Hall IC is critical when the supply

power is on.

Fixed

W

Fixed

Correct

(a)

(b)

Fixed

Bending method of lead wire

Bending position of lead wire

W

W

3 mm *

3 mm *

*: The distance can be within 3 mm, if no stress is applied

to the resin mold by tightly fixing the lead wires with a

metallic mold or the like.

Wrong

Correct

Wrong

Correct

Wrong

Wrong

Correct

Wrong

DN6848/SE/S

5

SPC00003CEB

Caution on Use of Hall ICs (continued)

7. Fixing a Hall IC

When the Hall IC of an insertion type package installed by soldering the lead wire only is to be used under

vibration, fix it firmly with a holder. Otherwise, vibration may cause metal fatigue in the lead wire of Hall IC,

resulting in wire breakage.

8. On fixing a Hall IC to holder

When a Hall IC is mounted on the printed circuit board with a holder and the coefficient of expansion of the holder

is large, the lead wire of the Hall IC will be stretched and it may give a stress to the Hall IC.

If the lead wire is stressed intensely due to the distortion of holder or board, the adhesives between the package

and the lead wire may be weakened and cause a minute gap resulting in the deterioration of its resistance to moisture.

Sensitivity may also be changed by this stress.

9. On using flux in soldering

Choose a flux which does not include ingredients from halogen group, such as chlorine, fluorine, etc. The

ingredients of halogen group may enter where the lead frame and package resin joint, causing corrosion and the

disconnection of the aluminum wiring on the surface of an IC chip.

10. In case of the magnetic field of a magnet is too strong

Output may be inverted when applying a magnetic flux density of 100 mT or more. Accordingly, magnetic flux

density should be used within the range of 100 mT.

11. On mounting , deburring and soldering of insertion type package

If the leads of a Hall IC in an insertion type package are inserted up to their root part through holes on the printed

circuit board, abnormal stress is applied to the package and the reliability of the Hall IC is likely to deteriorate. So,

when mounting each Hall IC of the insertion type, insert the leads in due degree at which the bottom face of the

package is separated at least 2 mm from the top face of the PCB.

Also note that burrs of epoxy resin may be left sticking to the lead wires. (We are trying to remove such burrs as

much as possible in the deburring process, but in some cases, they are not perfectly removable.)

12. On surface treatment of mini-mold package

Surface treatment is available in either smooth or dull finish.

13. On soldering of the surface mount type package

Surface mounting type Hall ICs are apt to change its electrical characteristics due to the stress from soldering at

mounting. Therefore, avoid the mounting by flow (dipping) and a soldering iron. Please mount it by reflow soldering

abiding by its recommended conditions.

2 mm

Printed board

Remaining burrs

When soldering the leads, remenber to separate

the soldering position by 2 mm or more from

the resin part of the package.