Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

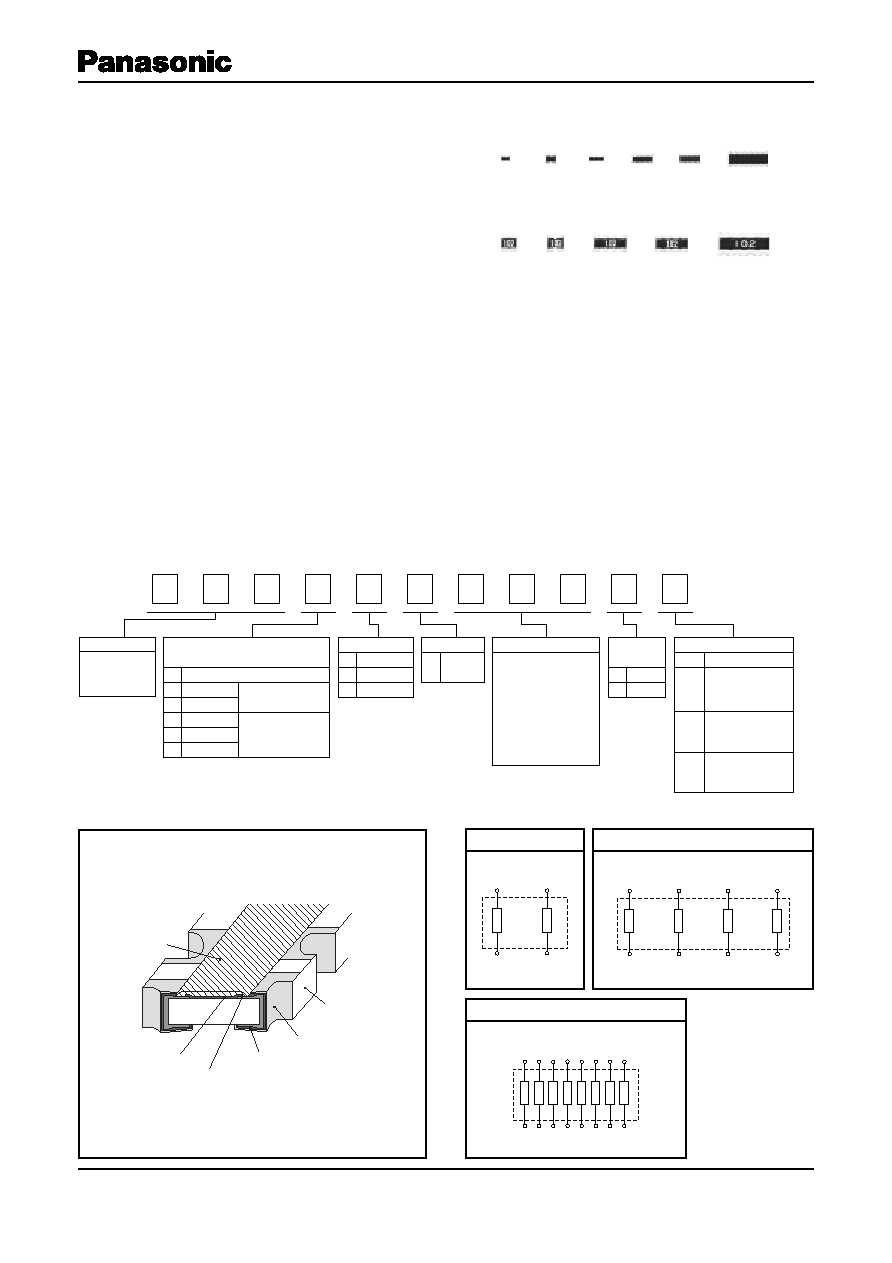

Chip Resistor Array

Design and specifi cations are each subject to change without notice. Ask factory for the current technical specifi cations before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

E

1

X

2

B

3

V

4

8

5

V

6

4

7

7

8

2

9

J

10

V

11

Thick Film

Chip Resistor

Networks

Chip Resistor Array

Type: inches

Product Code

0201 Array

0402 Array

0603 Array

0402 Array

0603 Array

0805 Array

1

2

3

N

V

S

4

8

H

4 Terminal

8 Terminal

16 Terminal

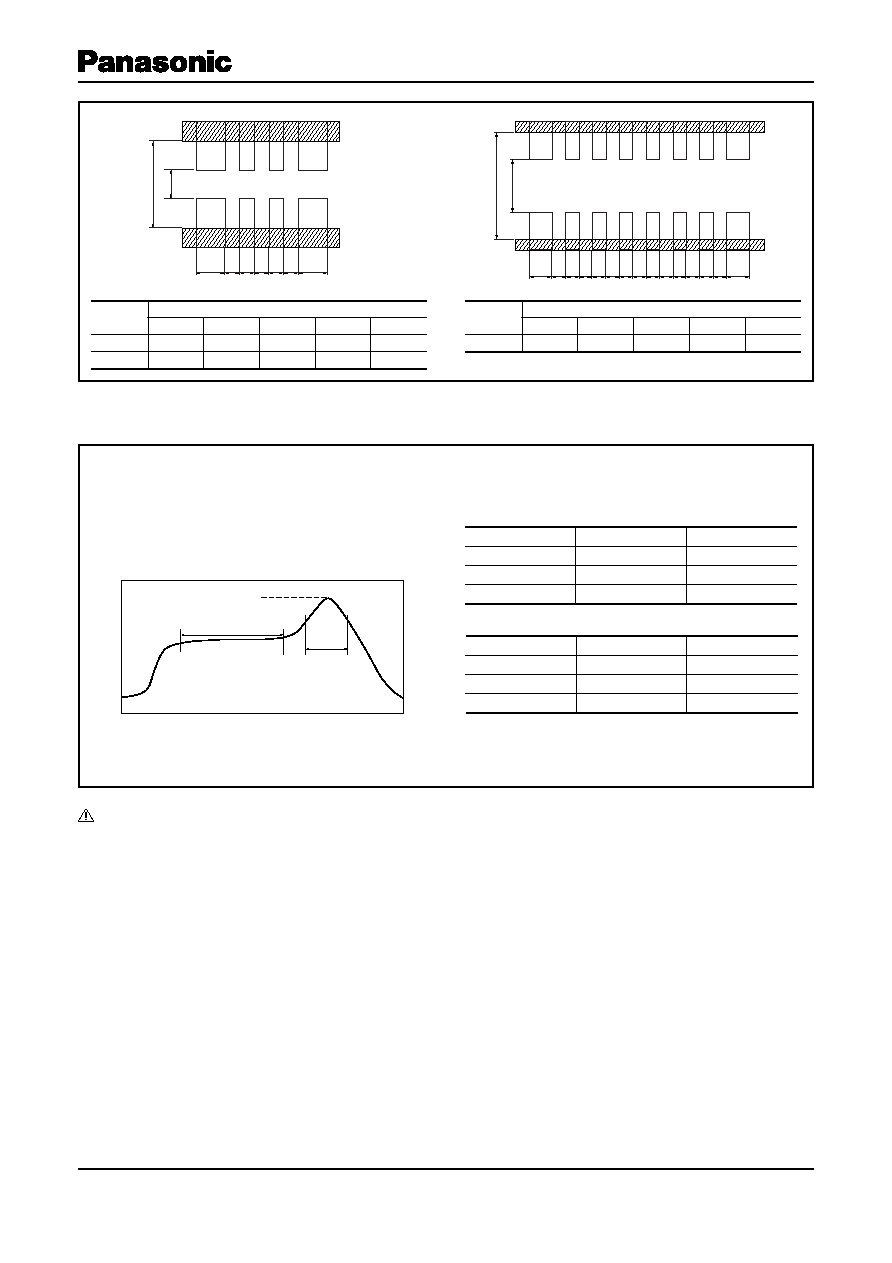

No. of Terminal

Schematics

V

Isolated

type

The first two digits are

significant figures of

resistance value and

the third one denotes

the number of zeros

following. Jumper is

expressed by R00

Resistance Value

Example: 222: 2.2 k

Resistance

Tolerance

J

0

±5 %

Jumper

Packaging Methods

Code

Nil

X

V

Embossed

Carrier Taping

(S8V)

Punched Carrier Taping

2 mm pitch

(14V, 18V, 24V, 28V, N8V)

Punched Carrier Taping

4 mm pitch

(2HV, 34V, 38V, V4V, V8V)

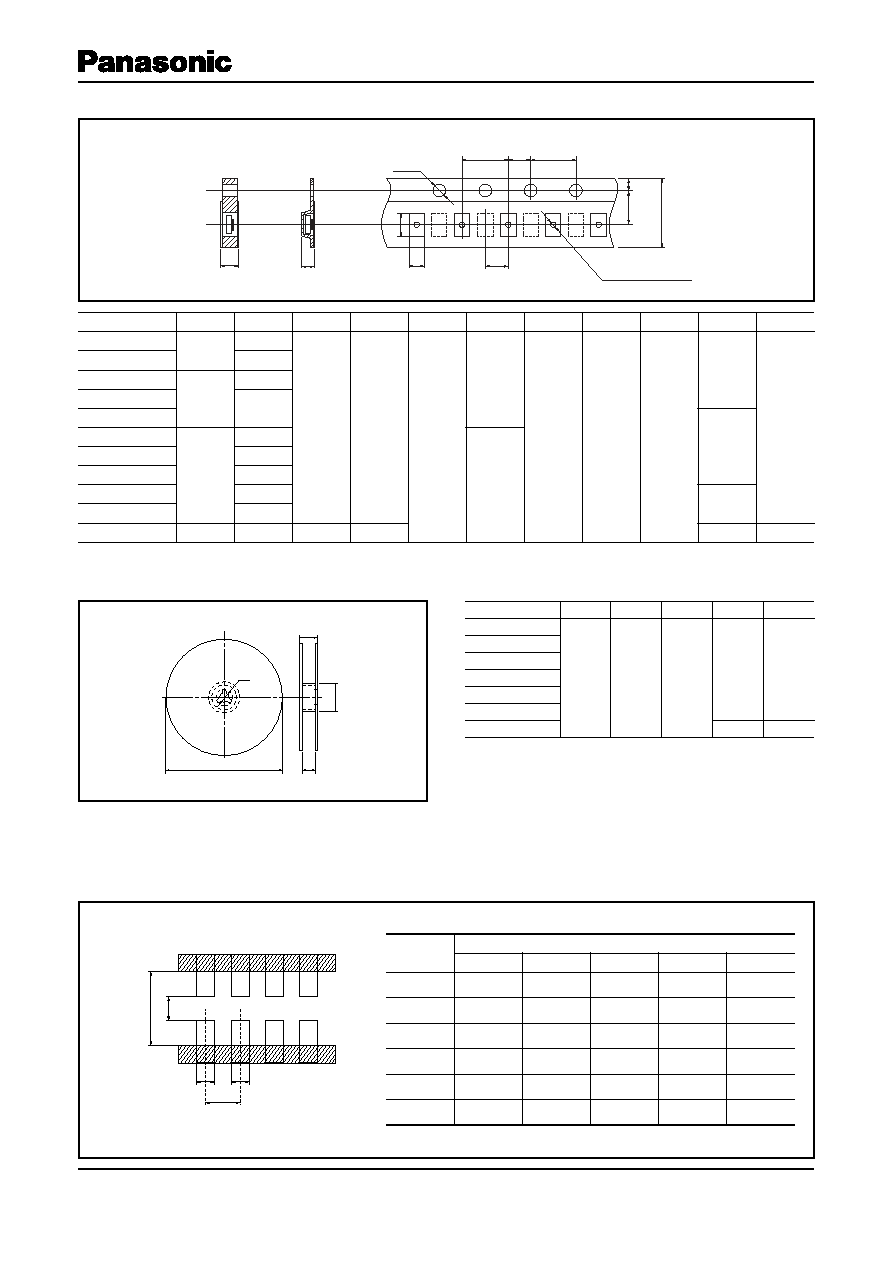

Convex Terminal

Concave Terminal

Packaging

Protective coating

Thick film

resistive element

Electrode (Inner)

Electrode (Between)

Electrode (Outer)

Alumina substrate

4

3

1

2

8

1

7

2

6

3

5

4

16

1

15

2

14

3

13

4

12

5

11

6

10

7

9

8

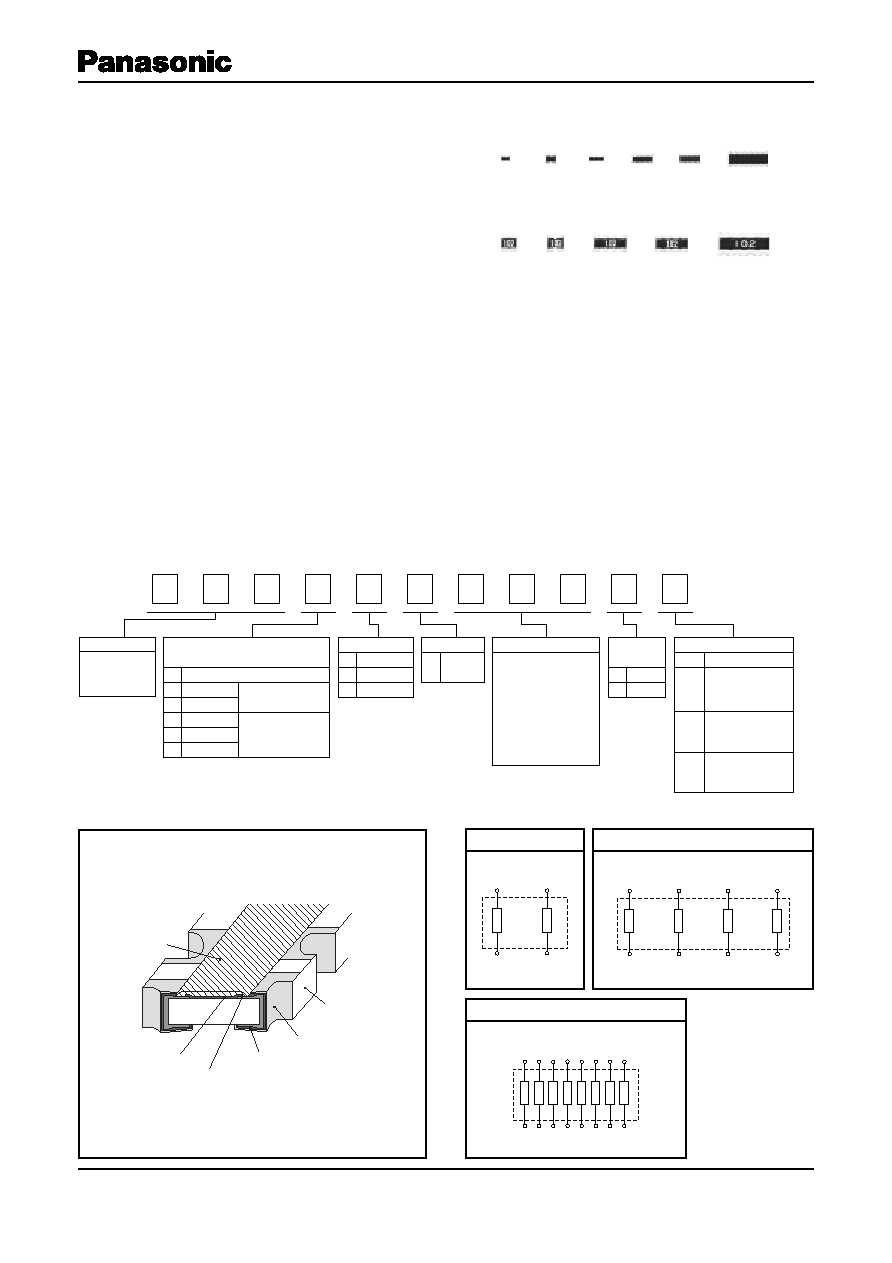

Construction (Example : Concave Terminal)

Schematics

Isolated type

14V, 24V, 34V, V4V

18V, 28V, N8V, 38V, V8V, S8V

2 resistors

4 resistors

2HV

8 resistors

Features

High density

2 resistors in 0.8 mm

0.6 mm size (EXB14V)

4 resistors in 1.4 mm

0.6 mm size (EXB18V)

2 resistors in 1.0 mm

1.0 mm size (EXB24V)

4 resistors in 2.0 mm

1.0 mm size (EXB28V, N8V)

8 resistors in 3.8 mm

1.6 mm size (EXB2HV)

2 resistors in 1.6 mm

1.6 mm size (EXB34V, V4V)

4 resistors in 3.2 mm

1.6 mm size (EXB38V, V8V)

4 resistors in 5.1 mm

2.2 mm size (EXBS8V)

Improvement of placement effi ciency

Placement effi ciency of Chip Resistor Array is two, four or eight times of the fl at type chip resistor

Type:

EXB1 : 0201 Array

EXB2 : 0402 Array

EXB3 : 0603 Array

EXBN : 0402 Array

EXBV : 0603 Array

EXBS : 0805 Array

Explanation of Part Numbers

Chip Resistor Array

May. 2005

Design and specifi cations are each subject to change without notice. Ask factory for the current technical specifi cations before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

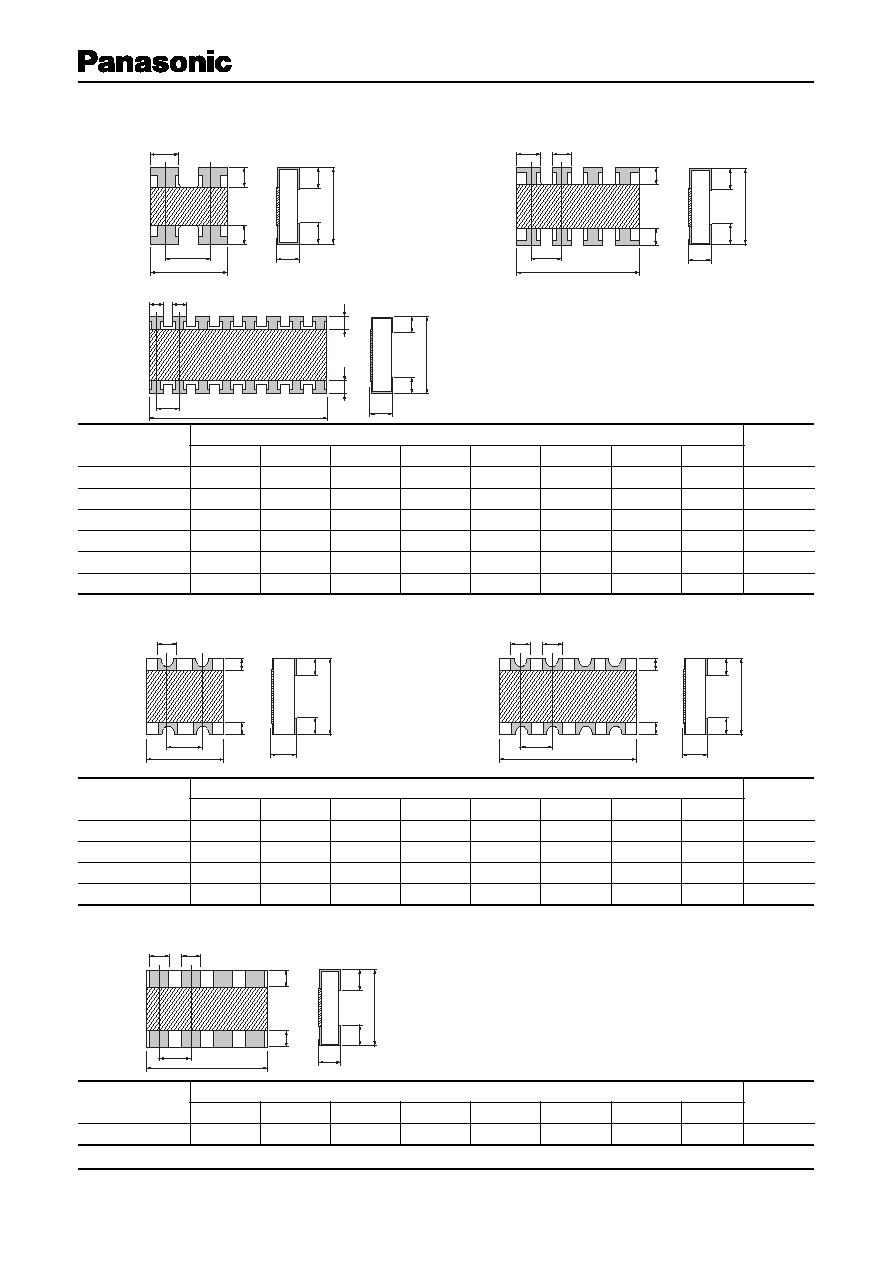

Chip Resistor Array

P

P

L

L

G

G

G

W

G

B

B

W

B

B

A1

A1

A2

EXBV4V

EXBN8V, V8V, S8V

T

T

P

L

T

G

W

G

B

B

A1

A2

EXB18V

A1

P

T

P

L

T

L

BB

G

BB

GG

W

W

G

A1

A2

EXB14V, 24V, 34V

EXB28V, 38V

P

T

L

G

W

G

BB

A1

A2

EXB2HV

Type

(inches)

Dimensions (mm)

Mass (Weight)

[g/1000 pcs.]

L

W

T

A1

A2

B

P

G

EXBN8V (0402 4)

2.00

±0.10

1.00

±0.10

0.45

±0.10

0.30

±0.10

0.30

±0.10

0.20

±0.15

(0.50)

0.30

±0.15

3.0

EXBV4V (0603 2)

1.60

+0.20

1.60

+0.20

0.60

±0.10

0.60

±0.10

--

0.30

±0.15

(0.80)

0.45

±0.15

5.0

EXBV8V (0603 4)

3.20

+0.20

1.60

+0.20

0.60

±0.10

0.60

±0.10

0.60

±0.10

0.30

±0.15

(0.80)

0.45

±0.15

10

EXBS8V (0805 4)

5.08

+0.20

2.20

+0.20

0.70

±0.20

0.80

±0.15

0.80

±0.15

0.50

±0.15

(1.27)

0.55

±0.15

30

Type

(inches)

Dimensions (mm)

Mass (Weight)

[g/1000 pcs.]

L

W

T

A1

A2

B

P

G

EXB14V (0201 2)

0.80

±0.10

0.60

±0.10

0.35

±0.10

0.35

±0.10

--

0.15

±0.10

(0.50)

0.15

±0.10

0.5

EXB24V (0402 2)

1.00

±0.10

1.00

±0.10

0.35

±0.10

0.40

±0.10

--

0.18

±0.10

(0.65)

0.25

±0.10

1.2

EXB28V (0402 4)

2.00

±0.10

1.00

±0.10

0.35

±0.10

0.45

±0.10

0.35

±0.10

0.20

±0.10

(0.50)

0.25

±0.10

2.0

EXB2HV (0402 8)

3.80

±0.10

1.60

±0.10

0.45

±0.10

0.35

±0.10

0.35

±0.10

0.30

±0.10

(0.50)

0.30

±0.10

9.0

EXB34V (0603 2)

1.60

±0.20

1.60

±0.15

0.50

±0.10

0.65

±0.15

--

0.30

±0.20

(0.80)

0.30

±0.20

3.5

EXB38V (0603 4)

3.20

±0.20

1.60

±0.15

0.50

±0.10

0.65

±0.15

0.45

±0.15

0.30

±0.20

(0.80)

0.35

±0.20

7.0

0.10

0.10

0.10

0.10

0.10

0.10

Type

(inches)

Dimensions (mm)

Mass (Weight)

[g/1000 pcs.]

L

W

T

A1

A2

B

P

G

EXB18V (0201 4)

1.40

±0.10

0.60

±0.10

0.35

±0.10

0.20

±0.10

0.20

±0.10

0.10

±0.10

(0.40)

0.20

±0.10

1.0

( ) Reference

Dimensions in mm (not to scale)

(1) Convex Terminal type

(2) Concave Terminal type

(3) Flat Terminal type

( ) Reference

( ) Reference

May. 2005

Chip Resistor Array

Design and specifi cations are each subject to change without notice. Ask factory for the current technical specifi cations before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

60 40 20

0

20 40 60 80 100 120 140 160 180

0

20

40

60

80

100

70

°C

55

°C

125

°C

Ambient Temperature (

°C)

Rated

Load

(%)

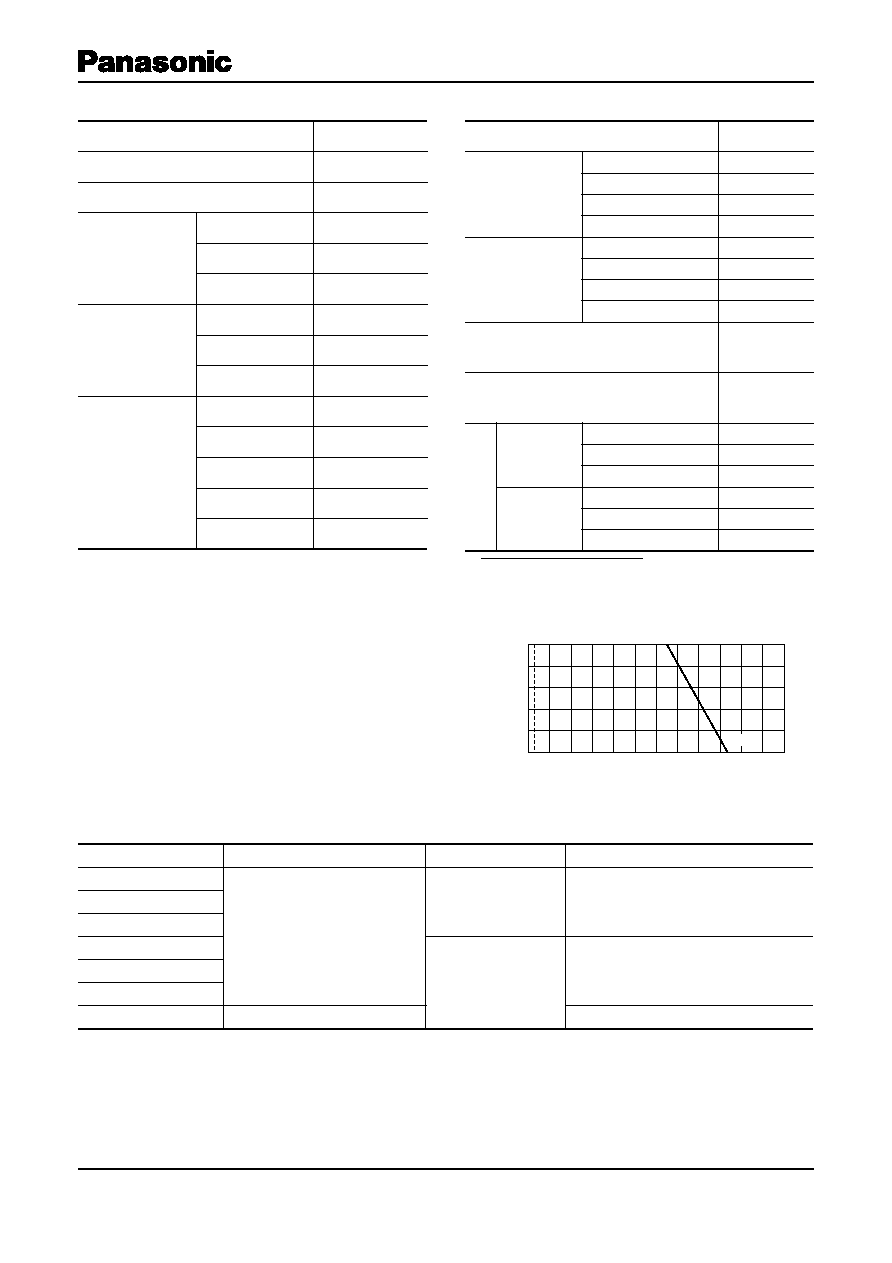

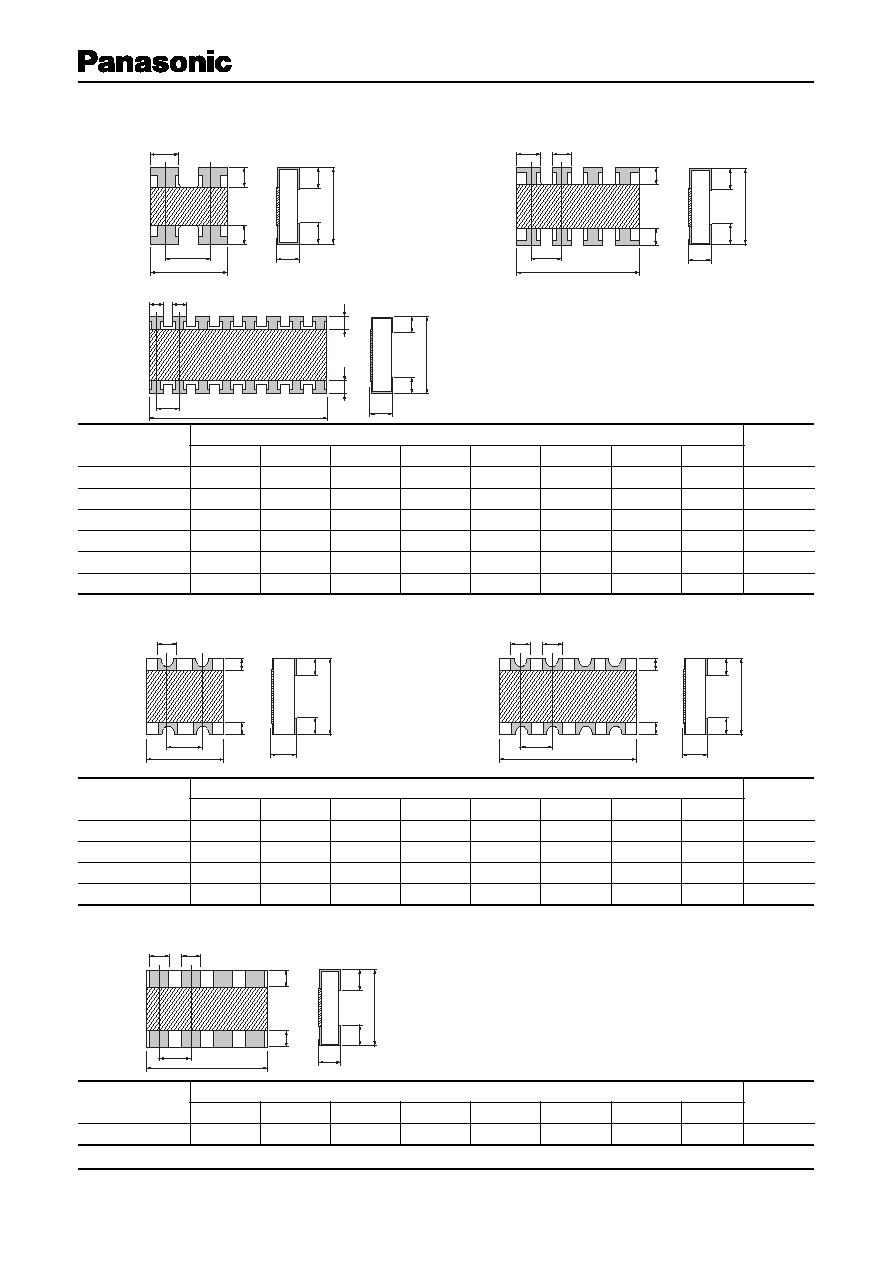

Item

Specifi cations

Resistance Range

10 to 1 M :E24 series

Resistance Tolerance

J: ±5 %

Number of Terminals

14V,24V,V4V,34V

4 terminal

18V,28V,N8V,38V,V8V,S8V 8 terminal

2HV

16 terminal

Number of Resistors

14V,24V,V4V,34V

2 terminal

18V,28V,N8V,38V,V8V,S8V 4 terminal

2HV

8 terminal

Power Rating at 70 °C

14V,28V,N8V

0.031 W/element

18V

0.031 W/element

(0.1 W/package)

24V,V4V,34V,V8V,38V

0.063 W/element

S8V

0.1 W/element

2HV

0.063 W/element

(0.25 W/package)

Type

Kind of Taping

Pitch (P

1

)

Quantity

EXB14V, 18V

Punched Carrier Taping

2 mm

10000 pcs./reel

EXB24V, 28V

EXBN8V

EXB2HV

4 mm

5000 pcs./reel

EXB34V, 38V

EXBV4V, V8V

EXBS8V

Embossed Carrier Taping

2500 pcs./reel

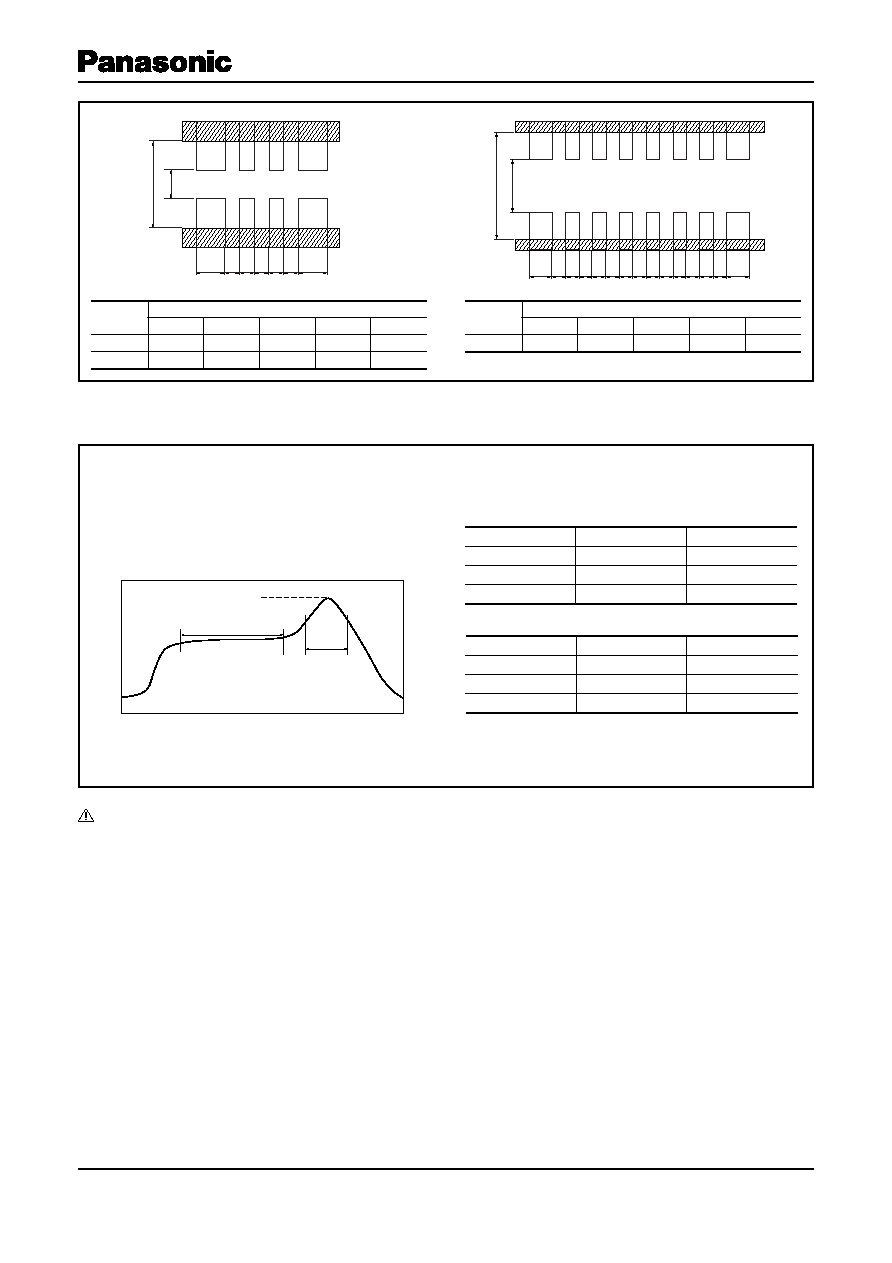

Ratings

(1) Rated Continuous Working Voltage (RCWV) shall be de ter mined from RCWV= Power Rating

Resistance Value, or Limiting Element Voltage (max.

RCWV) listed above, whichever less.

(2) Overload (Short-time Overload) Test Voltage (SOTV) shall be determined from SOTV=2.5

Power Rating or max. Overload (Voltage) list ed above whichever less.

Power Derating Curve

For resistors operated in ambient temperature above

70 °C, power rating shall be derated in accordance

with the fi gure on the right.

Packaging Methods (Taping)

Standard Quantity

Item

Specifi cations

Limiting Element Voltage

(1)

Max. Rated Continuous

Working Voltage

14V,18V

12.5 V

2HV

25 V

24V,28V,N8V,38V,34V,V4V,V8V 50 V

S8V

100 V

Max. Over-load Voltage

(2)

14V,18V

25 V

2HV

50 V

24V,28V,N8V,38V,34V,V4V,V8V 100 V

S8V

200 V

T.C.R.

±200 10

-6

/°C(ppm/°C)

Category Temperature Range

(Operating Temperature Range)

55 °C to 125 °C

Jump

er

A

r

r

a

y

Rated Current

14V,18V

0.5 A

2HV,24V,28V,N8V,38V,34V,V4V,V8V 1 A

S8V

2 A

Max, Overload Current

14V,18V

1 A

2HV,24V,28V,N8V,38V,34V,V4V,V8V 2 A

S8V

4 A

( )

Sep. 2005

Design and specifi cations are each subject to change without notice. Ask factory for the current technical specifi cations before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

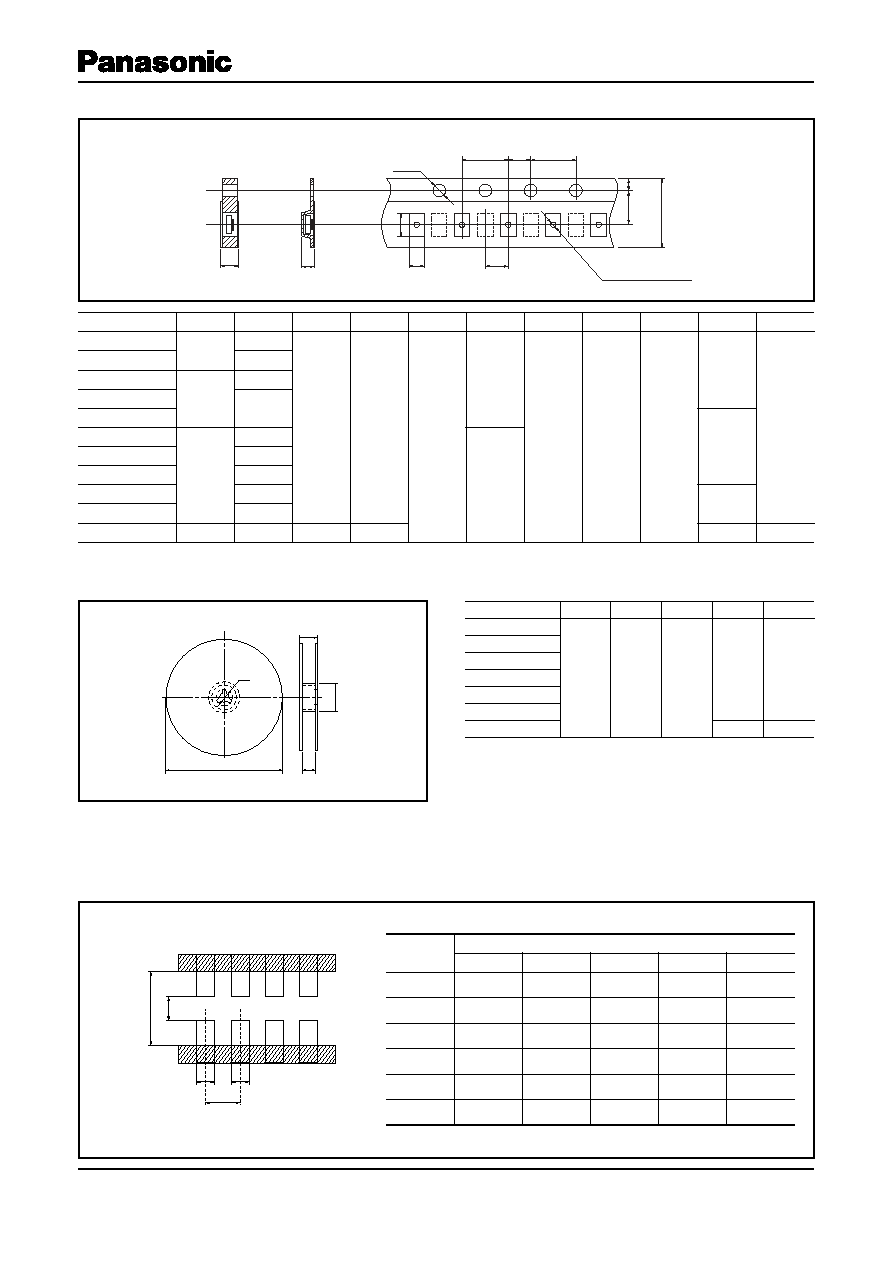

Chip Resistor Array

T

T

A

P

0

P

2

P

1

P

1

fD

0

B

F

W

E

fD

1

(Only Emboss)

(2 mm pitch)

f

B

W

T

fA

fC

f

a

b

c

p

Type

A

B

W

F

E

P

1

P

2

P

0

fD

0

T

fD

1

EXB14V

0.70

+0.10

0.90

+0.10

8.00

±0.20

3.50

±0.05

1.75

±0.10

2.00

±0.10

2.00

±0.05

4.00

±0.10

1.50

+0.10

0.52

±0.05

_

EXB18V

1.60

±0.10

EXB24V

1.20

±0.10

1.20

±0.10

EXB28V

2.20

±0.10

EXBN8V

0.70

±0.05

EXB2HV

1.95

±0.15

4.10

±0.15

4.00

±0.10

EXB34V

1.95

±0.20

EXB38V

3.60

±0.20

EXBV4V

1.95

±0.20

0.84

±0.05

EXBV8V

3.60

±0.20

EXBS8V

2.80

±0.20

5.70

±0.20

12.00

±0.30

5.50

±0.20

1.60 max. 1.50

+0.10

Type

fA

fB

fC

W

T

EXB14V,18V

180.0

+0

60 min.

13.0

±1.0

9.0

±1.0

11.4

±1.0

EXB24V,28V

EXBN8V

EXB2HV

EXB34V,38V

EXBV4V,V8V

EXBS8V

13.0

±1.0

15.4

±2.0

3.0

0

0

0.05

0.05

Type

Dimensions

Unit (mm)

a

b

c

p

f

14V

0.20 to 0.30 0.25 to 0.30 0.25 to 0.30

0.50

0.80 to 0.90

18V

0.20 to 0.30 0.15 to 0.20 0.15 to 0.20

0.40

0.80 to 0.90

24V

0.5

0.35 to 0.40 0.35 to 0.40

0.65

1.4 to 1.5

V4V,V8V

0.7 to 0.9

0.4 to 0.45

0.4 to 0.45

0.80

2 to 2.4

34V,38V

0.7 to 0.9

0.4 to 0.5

0.4 to 0.5

0.80

2.2 to 2.6

S8V

1 to 1.2

0.5 to 0.75

0.5 to 0.75

1.27

3.2 to 3.8

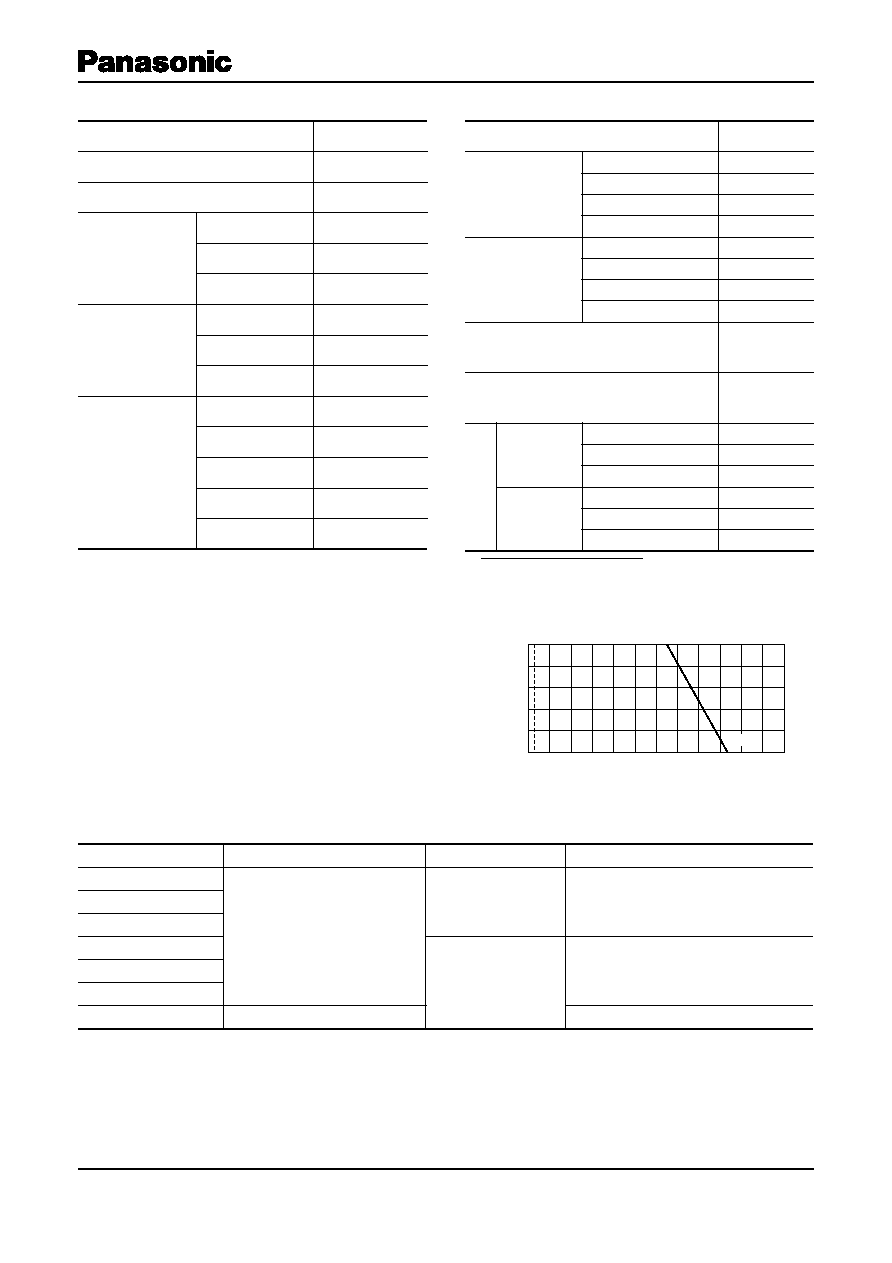

Punched Carrier Embossed Carrier

Carrier Tape

Taping Reel

Land pattern design

Recommended land pattern design for Network chip is shown below.

Unit (mm)

Unit (mm)

(Not to scale)

Sep. 2005

Chip Resistor Array

Design and specifi cations are each subject to change without notice. Ask factory for the current technical specifi cations before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

Preheating

Peak

Heating

Temperature

Time

b

b

d

d

d

d

d

d

d

c

c

c

c

c

c

a

f

f

a

b

d

b

c

c

d

d

Temperature

Time

Preheating

140 °C to 160 °C

60 s to 120 s

Main heating

Above 200 °C

30 s to 40 s

Peak

235 ± 5 °C

max. 10 s

Temperature

Time

Preheating

150 °C to 180 °C

60 s to 120 s

Main heating

Above 230 °C

30 s to 40 s

Peak

max. 260 °C

max. 10 s

Recommended Soldering Conditions

Recommendations and precautions are described below.

Recommended soldering conditions for refl ow

For soldering (Example : Sn/Pb)

For lead-free soldering (Example : Sn/Ag/Cu)

Safety Precautions

· We do not recommend fl ow soldering, because a solder bridge may form.

Flow soldering

Type

Dimensions

Unit (mm)

a

b

c

d

f

28V

0.40

0.525

0.25

0.25

1.40

N8V

0.45 to 0.50 0.35 to 0.38

0.25

0.25

1.40 to 2.00

Type

Dimensions

Unit (mm)

a

b

c

d

f

2HV

1.00

0.425

0.25

0.25

2.00

(Not to scale)

(Not to scale)

The following are precautions for individual products. Please also refer to the precautions common to Fixed Resistors

shown on page ER3 of this catalog.

1. Take measures against mechanical stress during and after mounting of Chip Resistor Array (hereafter called the

resistors) so as not to damage their electrodes and protective coatings.

Be careful not to misplace the resistors on the land patterns. Otherwise, solder bridging may occur.

2. If a transient load (heavy load in a short time) like a pulse is expected to be applied, check and eval u ate the op er a tions

of the resistors when installed in your products before use.

Never exceed the rated power. Otherwise, the performance and/or reliability of the resistors may be impaired.

3. Do not use halogen-based or other high-activity fl ux. Otherwise, the residue may impair the resistors' per for mance

and/or reliability.

4. When soldering with a soldering iron, never touch the resistors' bodies with the tip of the soldering iron. When using a

soldering iron with a high temperature tip, fi nish soldering as quickly as possible (within three seconds at 350 °C max.).

5. As the amount of applied solder becomes larger, the mechanical stress applied to the resistors increases, causing

problems such as cracks and faulty characteristics. Avoid applying an excessive amounts of solder.

6. Do not apply shock to the resistors or pinch them with a hard tool (e.g. pliers and tweezers). Oth er wise, the re sis tors'

protective coatings and bodies may be chipped, affecting their performance.

7. Avoid excessive bending of printed circuit boards in order to protect the resistors from abnormal stress.

· Refl ow soldering shall be performed a maximum of

two times.

· Please contact us for additional information when

used in conditions other than those specifi ed.

· Please measure the temperature of the terminals

and study every kind of solder and printed circuit

board for solderability be fore ac tu al use.

Mar. 2005