| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: NE5560 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1

1994 Aug 31

853-0125 13721

DESCRIPTION

The NE/SE5560 is a control circuit for use in switched-mode power

supplies. This single monolithic chip incorporates all the control and

housekeeping (protection) functions required in switched-mode

power supplies, including an internal temperature-compensated

reference source, internal Zener references, sawtooth generator,

pulse-width modulator, output stage and various protection circuits.

FEATURES

∑

Stabilized power supply

∑

Temperature-compensated reference source

∑

Sawtooth generator

∑

Pulse-width modulator

∑

Remote on/off switching

∑

Current limiting

∑

Low supply voltage protection

∑

Loop fault protection

∑

Demagnetization/overvoltage protection

∑

Maximum duty cycle clamp

∑

Feed-forward control

∑

External synchronization

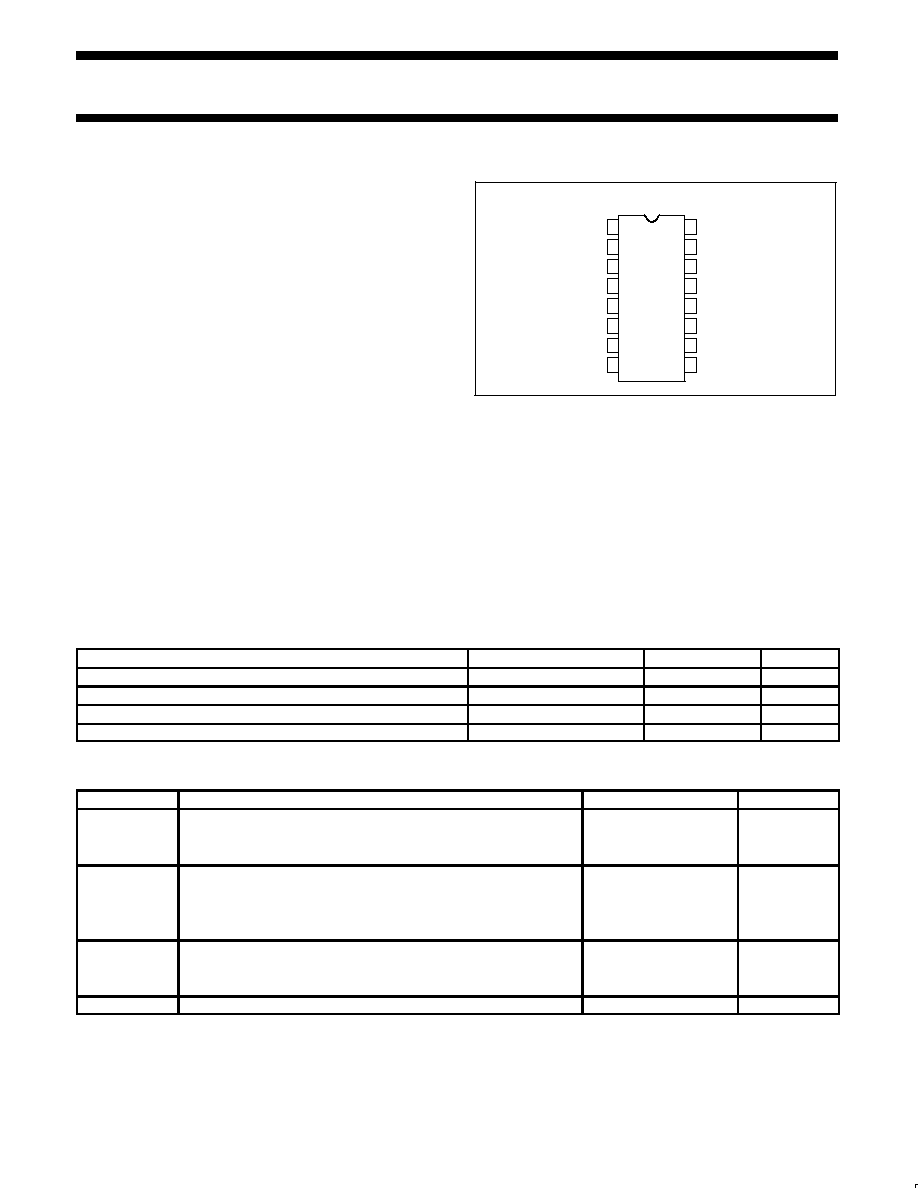

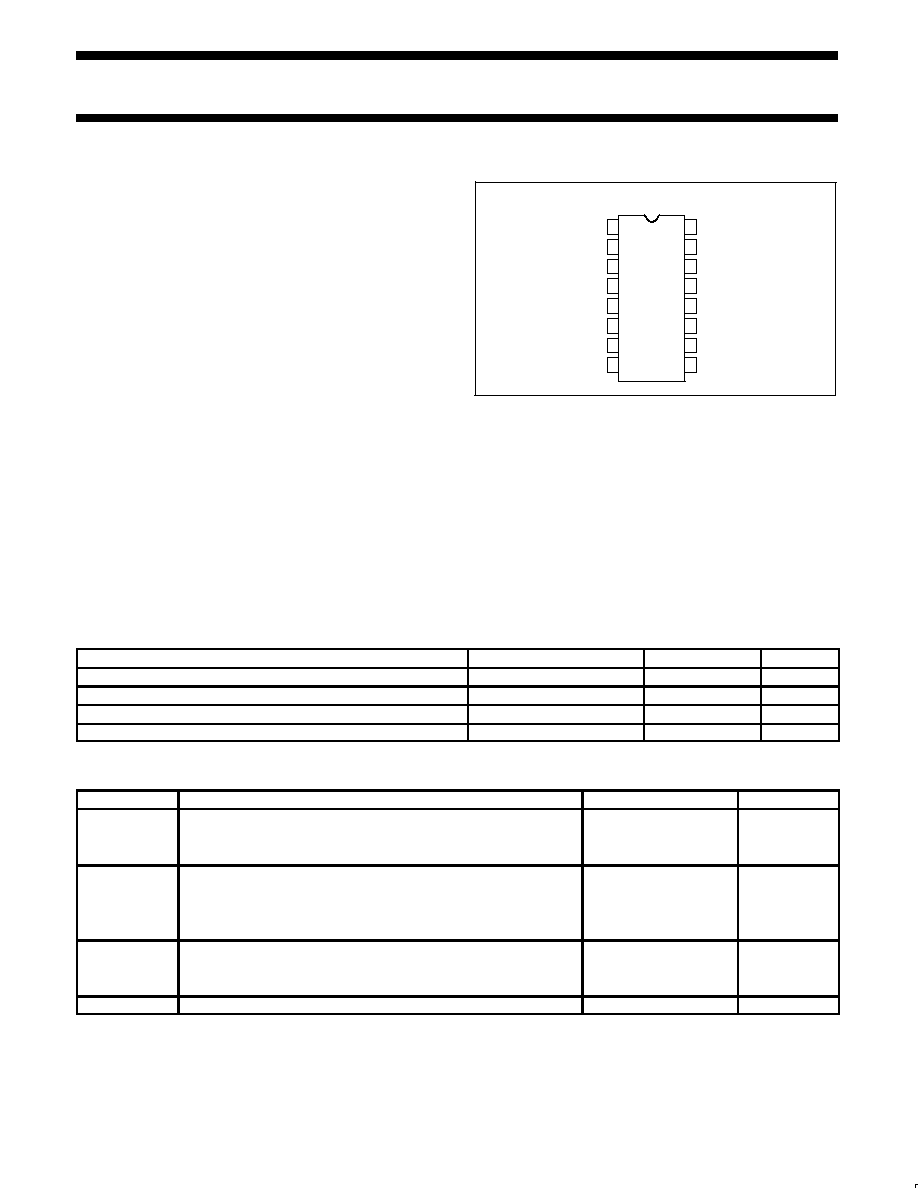

PIN CONFIGURATION

D, F, N Packages

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

VCC

VZ

FEEDBACK

GAIN

MODULATOR

DUTY CYCLE CONTROL

RT

CT

FEEDFORWARD

OUTPUT (COLL)

OUTPUT (EMIT)

DEMAG: OVERVOLTAGE

GND

CURRENT LIMITING

REMOTE ON/OFF

EXTERNAL SYNC

SL00360

Figure 1. Pin Configuration

ORDERING INFORMATION

DESCRIPTION

TEMPERATURE RANGE

ORDER CODE

DWG #

16-Pin Plastic Dual In-Line Package (DIP)

0 to 70

∞

C

NE5560N

SOT38-4

16-Pin Plastic Small Outline Large (SOL) Package

0

∞

C to 70

∞

C

NE5560D

SOT162-1

16-Pin Plastic Dual In-Line Package (DIP)

-55

∞

C to 125

∞

C

SE5560N

SOT38-4

16-Pin Cerdip Dual In-Line Package (CERDIP)

-55

∞

C to 125

∞

C

SE5560F

0582B

ABSOLUTE MAXIMUM RATINGS

SYMBOL

PARAMETER

RATING

UNIT

Supply

1

V

CC

Voltage-forced mode

+18

V

I

CC

Current-fed mode

30

mA

Output transistor (at 20-30V max)

I

OUT

Output current

40

mA

Collector voltage (Pin 15)

V

CC

+1.4V

V

Max. emitter voltage (Pin 14)

+5

V

T

A

Operating ambient temperature range

SE5560

-55 to +125

∞

C

NE5560

0 to 70

∞

C

T

STG

Storage temperature range

-65 to +150

∞

C

NOTES:

1. Does not include current for timing resistors or capacitors.

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

2

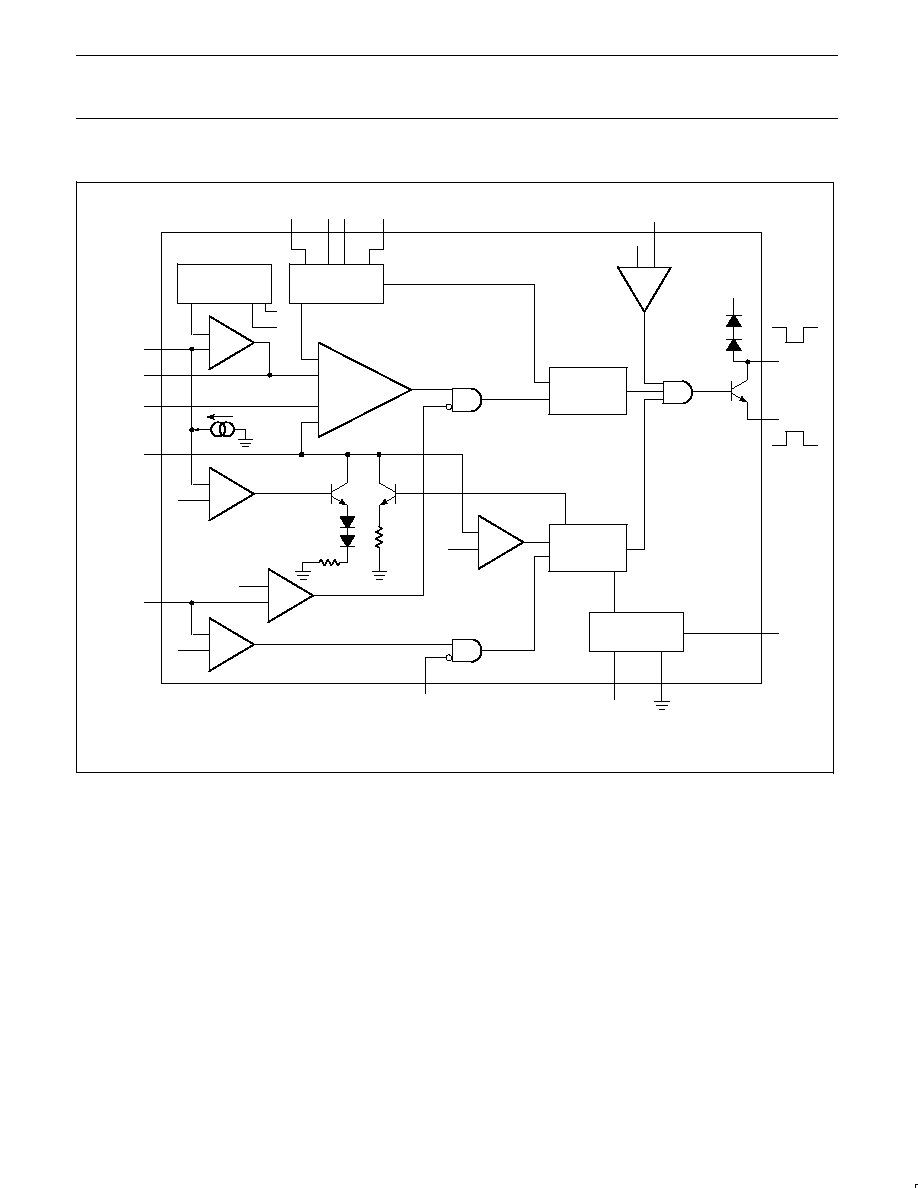

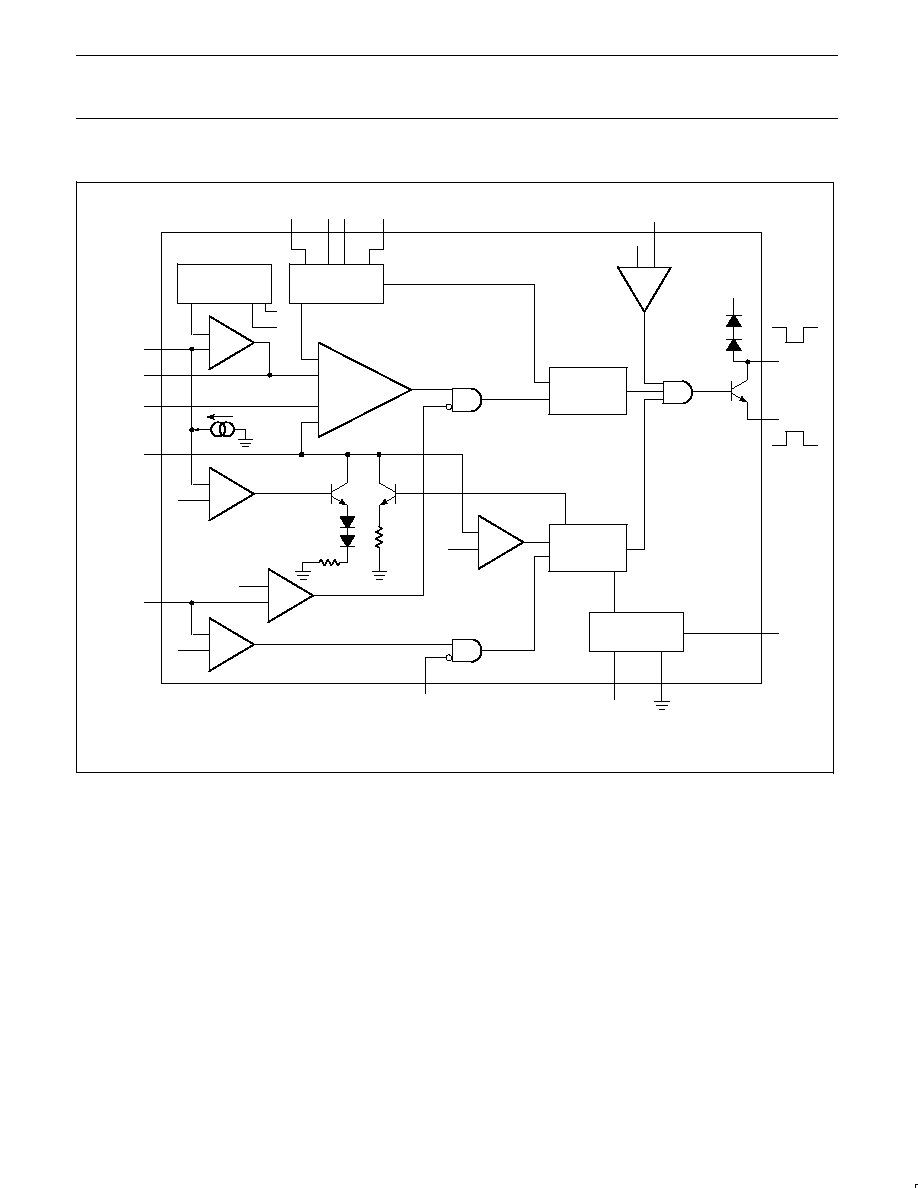

BLOCK DIAGRAM

NOTE:

1. See Voltage/Current fed supply characteristic curve.

FEED

FORWARD

EXTERNAL

SYNC INPUT

DEMAGNETIZATION

OVER-VOLTAGE PROTECTION

REFERENCE

VOLTAGE

SAWTOOTH

GENERATOR

FEEDBACK

VOLTAGE

GAIN ADJUST

MODULATOR

INPUT

CUTY CYCLE

CONTROL

CURRENT

LIMITING

+

≠

0.48V

0.6V

+

0.6V

0.6V

0.48V

+

≠

≠

+

+

≠

≠

+

PULSE WIDTH

MODULATOR

≠

+

0.6V

S

R

LATCH

Q

R

S

START

STOP

REMOTE

ON/OFF

STABILIZED

SUPPLY

+

≠

0.6V

3

4

5

8

11

10

1

12

2

14

15

13

9

8

7

16

OUTPUTS

CT

RT

VZ

VCC

1k

100

OC1

Q1

+

≠

VCC

SL00361

Figure 2. Block Diagram

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

3

DC ELECTRICAL CHARACTERISTICS

T

A

=25

∞

C, V

CC

=12V, unless otherwise specified.

SYMBOL

PARAMETER

TEST CONDITIONS

SE5560

NE5560

UNIT

SYMBOL

PARAMETER

TEST CONDITIONS

Min

Typ

Max

Min

Typ

Max

UNIT

Reference sections

V

REF

Internal reference voltage

25

∞

C

3.69

3.72

3.81

3.57

3.72

3.95

V

Over temperature

3.65

3.85

3.53

4.00

V

Temperature coefficient of V

REF

-100

-100

ppm/

∞

C

V

Z

Internal Zener reference

I

L

=-7mA

7.8

8.4

8.8

7.8

8.4

8.8

V

Temperature coefficient of V

Z

200

200

ppm/

∞

C

Oscillator section

Frequency range

Over temperature

50

100k

50

100k

Hz

Initial accuracy oscillator

R=5k

5

5

%

Duty cycle range

f

O

=20kHz

0

98

0

98

%

Modulator

Modulation input current

Voltage at Pin 5=2V Over

temperature

0.2

20

0.2

20

µ

A

Housekeeping function

I

IN`

Pin 6, input current

At 2V

I

IN`

Pin 6, input current

Over temperature

0.2

20

0.2

20

µ

A

Pin 6, duty cycle limit control

Pin 6, duty cycle limit control

For 50% max duty cycle

Pin 6, duty cycle limit control

15kHz to 50kHz/41% of V

Z

40

50

60

40

50

60

% of duty

cycle

Pin 1, low supply voltage

protection thresholds

8

9.0

10.5

8

9.0

10.5

V

Pin 3, feedback loop protection trip

threshold

400

600

720

400

600

720

mV

At 2V

Pin 3, pull-up current

-7

-15

-35

-7

-15

-35

µ

A

Pin 13,

demagnetization/over-voltage

protection trip on threshold

Over temperature

470

600

720

470

600

720

mV

At 0.25V

I

IN

Pin 13, input current

25

∞

C

-0.6

-10

-0.6

-10

µ

A

Over temperature

-20

-20

Pin 16, feed-forward duty cycle

control

Voltage at Pin 16=2V

Z

30

40

50

30

40

50

% original

duty cycle

At 16V, V

CC

=18V

*Pin 16, feed-forward input current

25

∞

C

0.2

5

0.2

5

µ

A

Over temperature

10

10

µ

A

External synchronization

Pin 9 Off

0

0.8

0

0.8

V

On

2

V

Z

2

V

Z

V

Sink current

Voltage at Pin 9=0V, 25

∞

C

-65

-100

-65

-125

µ

A

Over temperature

-125

-125

µ

A

Remote

Pin 10 Off

0

0.8

0

0.8

V

On

2

V

Z

2

V

Z

V

At 0V

Sink current

25

∞

C

-85

-100

-85

-125

µ

A

Over temperature

-125

-125

µ

A

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

4

DC ELECTRICAL CHARACTERISTICS

(Continued)

SYMBOL

PARAMETER

TEST CONDITIONS

SE5560

NE5560

UNIT

SYMBOL

PARAMETER

TEST CONDITIONS

Min

Typ

Max

Min

Typ

Max

UNIT

Current limiting

I

IN

Pin 11 Input current

Voltage at

Pin 11=250mV

-2

-20

-2

-20

µ

A

25

∞

C

Over temperature

-40

-40

µ

A

Single pulse inhibit delay

Inhibit delay time for 20%

overdrive at 40mA I

OUT

0.7

0.8

0.7

0.8

µ

s

OC2

Trip Levels: Shut down, slow start,

low level

0.500

0.600

0.700

0.500

0.600

0.700

V

OC1

Current limit, high level

0.400

0.480

0.560

0.400

0.560

0.500

V

OC

Low Level in terms of high level,

OC

2

0.750

0.800

0.850

0.750

0.800

0.850

V

Error amplifier

V

OH

Output voltage swing

6.2

9.5

6.2

9.5

V

V

OL

Output voltage swing

0.7

0.7

V

Open-loop gain

54

60

54

60

dB

R

F

Feedback resistor

10k

10k

BW

Small-signal bandwidth

3

3

MHz

Output stage

V

CE

(SAT) I

C

=40mA

0.5

0.5

V

Output current (Pin 15)

40

40

mA

Max. emitter voltage (Pin 14)

5

6

5

6

V

Supply voltage/current

1

I

CC

Supply current

I

Z

=0, voltage-forced,

V

CC

=12V, 25

∞

C

10

10

mA

Over temp.

15

15

mA

V

CC

Supply voltage

I

CC

=10mA current-fed

20

23

19

24

V

V

CC

Supply voltage

I

CC

=30mA current-fed

20

30

20

30

V

NOTES:

1. Does not include current for timing resistors or capacitors.

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

5

MAXIMUM PIN VOLTAGES

NE5560

Pin No

Function

Maximum Voltage

1

V

CC

See Note 1

2

V

Z

Do not force (8.4V)

3

Feedback

V

Z

4

Gain

5

Modulator

V

Z

6

Duty Cycle Control

V

Z

7

R

T

Current force mode

8

C

T

9

External Sync

V

Z

10

Remote On/Off

V

Z

11

Current Limiting

V

CC

12

GND

GND

13

Demagnetization/Overvoltage

V

CC

14

Output (Emit)

V

Z

15

Output (Collector)

V

CC

+2V

BE

16

Feed-forward

V

CC

NOTES:

1. When voltage-forced, maximum is 18V; when current-fed, maximum is 30mA. See voltage-/current-fed supply characteristic curve.

TYPICAL PERFORMANCE CHARACTERISTICS

60

50

40

30

20

10

0

1k

10k

100k

1M

10M

FREQUENCY (Hz)

GAIN (dB)

Open-Loop Gain

0

≠30

≠60

≠90

≠120

≠150

≠180

1k

10k

100k

1M

10M

FREQUENCY (Hz)

PHASE

ANGLE (DEG)

Open-Loop Phase

Error Amplifier

SL00362

Figure 3. Typical Performance Characteristics

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

6

TYPICAL PERFORMANCE CHARACTERISTICS

(Continued)

MAX (%)

(%)

V

CC

Pd MAX (W)

1.0

50

24

TA

OPERATING CURVE

≠60

∞

C

25

∞

C

70

∞

C

125

∞

C

SE

NE

Power Derating Curve

mA

20

10

0

0

10

20

30

V

NE5560

Voltage-/Current-Fed

Supply Characteristics

VCC

GND

12

1

VS

RVCC

VCC

Current-Fed Dropping Resistor

SEE DC ELECTRICAL

CHARACTERISTICS

FOR CURRENT FED

VCC RANGE

R

VCC

+

V

S

*

V

CC

(10 20mA)

100

90

80

70

60

50

40

30

20

10

0

1

2

3

4

5

6

V4,5,6 (V)

Transfer Curve of Pulse-Width

Modular Duty Cycle vs Input Voltage

12

R1

R2

2

6

DUTY

CYCLE

CONTROL

MAXIMUM DUTY

CYCLE (%)

100

90

80

70

60

50

40

30

20

10

0

0.1 0.2

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

R

2

R

1

*

R

2

Graph for Determining

MAX

(%)

R1 + R2

(

)

SOFT ST

ART DUTY

CYCLE %

103

104

2

3

4

5

6 7 8 9

2

80

70

60

50

40

30

20

10

MAX 90%

MAX 70%

MAX 50%

MAX 30%

≠

+

7

6

5

4

3

2

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

4

3

RS

R1

VREF(3.72V)

VO/VREF (%)

10

20

30

40

50

60

70

80

90

Regulation vs Error

Amp Closed Gain

Soft-Start Min. Duty Cycle vs R

1

+ R

2

R

f

R

S

+

20

R

f

R

S

+

100

R

f

R

S

+

500

SL00363

Figure 4. Typical Performance Characteristics

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

7

TYPICAL PERFORMANCE CHARACTERISTICS

(Continued)

DUTY

CYCLE

1000

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

1

R=10k

R=20k

R=40k

R=5k

2

2.5

3

3.5

4

4.5

CnF)

f(kHz)

Typical Frequency Plot vs R

T

and

C

T

100

90

80

70

60

50

40

30

20

10

1

1.5

2

2.5

V

16

V

Z

SL00364

Figure 5. Typical Performance Characteristics

THEORY OF OPERATION

The following functions are incorporated:

≠ A temperature-compensated reference source.

≠ An error amplifier with Pin 3 as input. The output is connected

to Pin 4 so that the gain is adjustable with external resistors.

≠ A sawtooth generator with a TTL-compatible synchronization

input (Pins 7, 8, 9).

≠ A pulse-width modulator with a duty cycle range from 0 to 95%.

The PWM has two additional inputs:

Pin 6 can be used for a precise setting of

MAX

Pin 5 gives a direct access to the modulator, allowing for real

constant-current operation:

≠ A gate at the output of the PWM provides a simple dynamic

current limit.

≠ A latch that is set by the flyback of the sawtooth and reset by

the output pulse of the above mentioned gate prohibits double

pulsing.

≠ Another latch functions as a start-stop circuit; it provides a fast

switch-off and a slow start.

≠ A current protection circuit that operates via the start-stop

circuit. This is a combined function with the current limit circuit,

therefore Pin 11 has two trip-on levels; the lower one for

cycle-by-cycle current limiting, the upper one for current

protection by means of switch-off and slow-start.

≠ A TTL-compatible remote on/off input at Pin 10, also operating

via the start-stop circuit.

≠ An inhibit input at Pin 13. The output pulse can be inhibited

immediately.

≠ An output gate that is commanded by the latches and the inhibit

circuit.

≠ An output transistor of which both the collector (Pin 15) and the

emitter (Pin 14) are externally available. This allows for normal

or inverse output pulses.

≠ A power supply that can be either voltage- or current-driven

(Pins 1 and 12). The internally-generated stabilized output

voltage VZ is connected to Pin 2.

≠ A special function is the so-called feed-forward at Pin 16. The

amplitude of the sawtooth generator is modulated in such a way

that the duty cycle becomes inversely proportional to the

voltage on this pin:

~ 1/V16.

≠ Loop fault protection circuits assure that the duty cycle is

reduced to zero or a low value for open- or short-circuited

feedback loops.

Stabilized Power Supply (Pins 1, 2, 12)

The power supply of the NE5560 is of the well known series

regulation type and provides a stabilized output voltage of typically

8.5V.

This voltage V

Z

is also present at Pin 2 and can be used for precise

setting of

MAX

and to supply external circuitry. Its max. current

capability is 5mA.

The circuit can be fed directly from a DC voltage source between

10.5V and 18V or can be current-driven via a limiting resistor. In the

latter case, internal pinch-off resistors will limit the maximum supply

voltage: typical 23V for 10mA and max. 30V for 30mA.

The low supply voltage protection is active when V

(1-12)

is below

10.5V and inhibits the output pulse (no hysteresis).

When the supply voltage surpasses the 10.5V level, the IC starts

delivering output pulses via the slow-start function.

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

8

The current consumption at 12V is less than 10mA, provided that no

current is drawn from V

Z

and R

(7-12)

20k

.

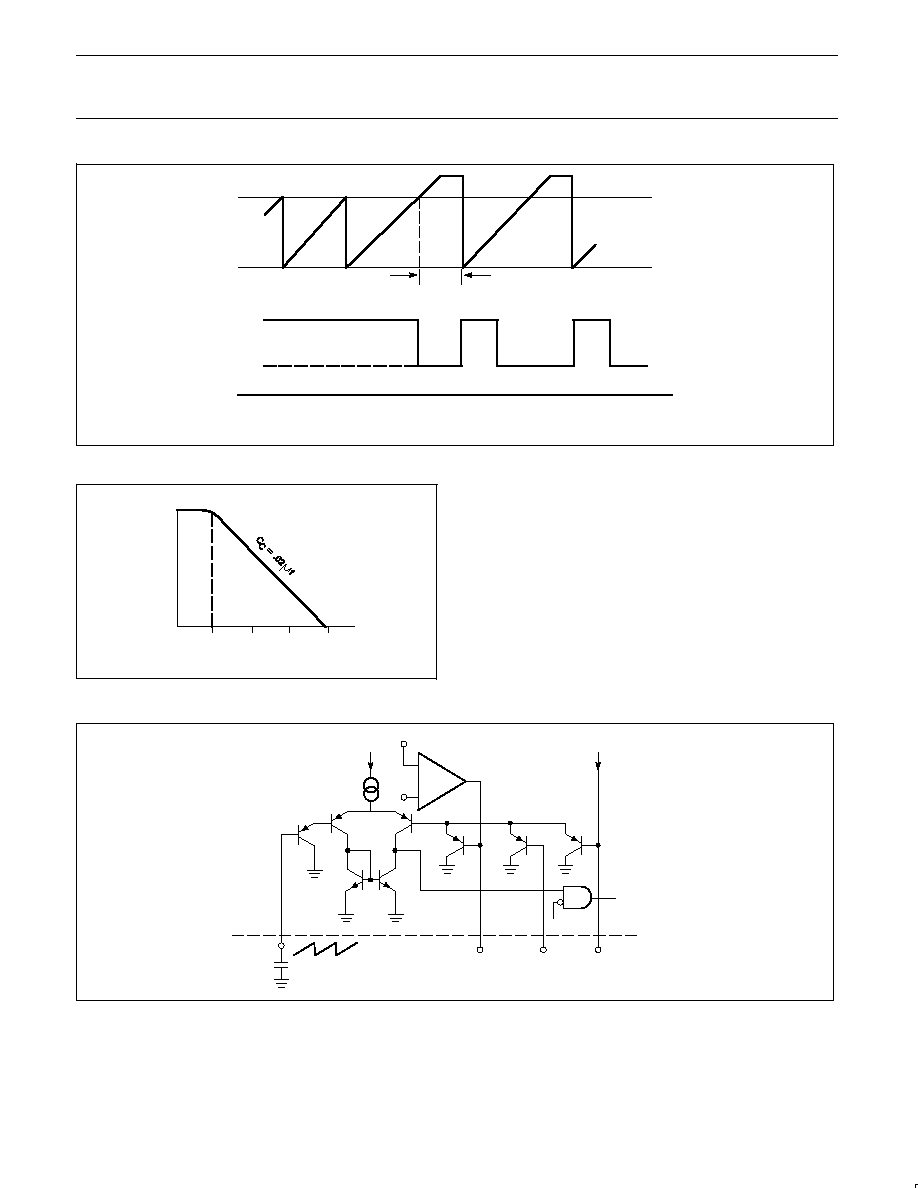

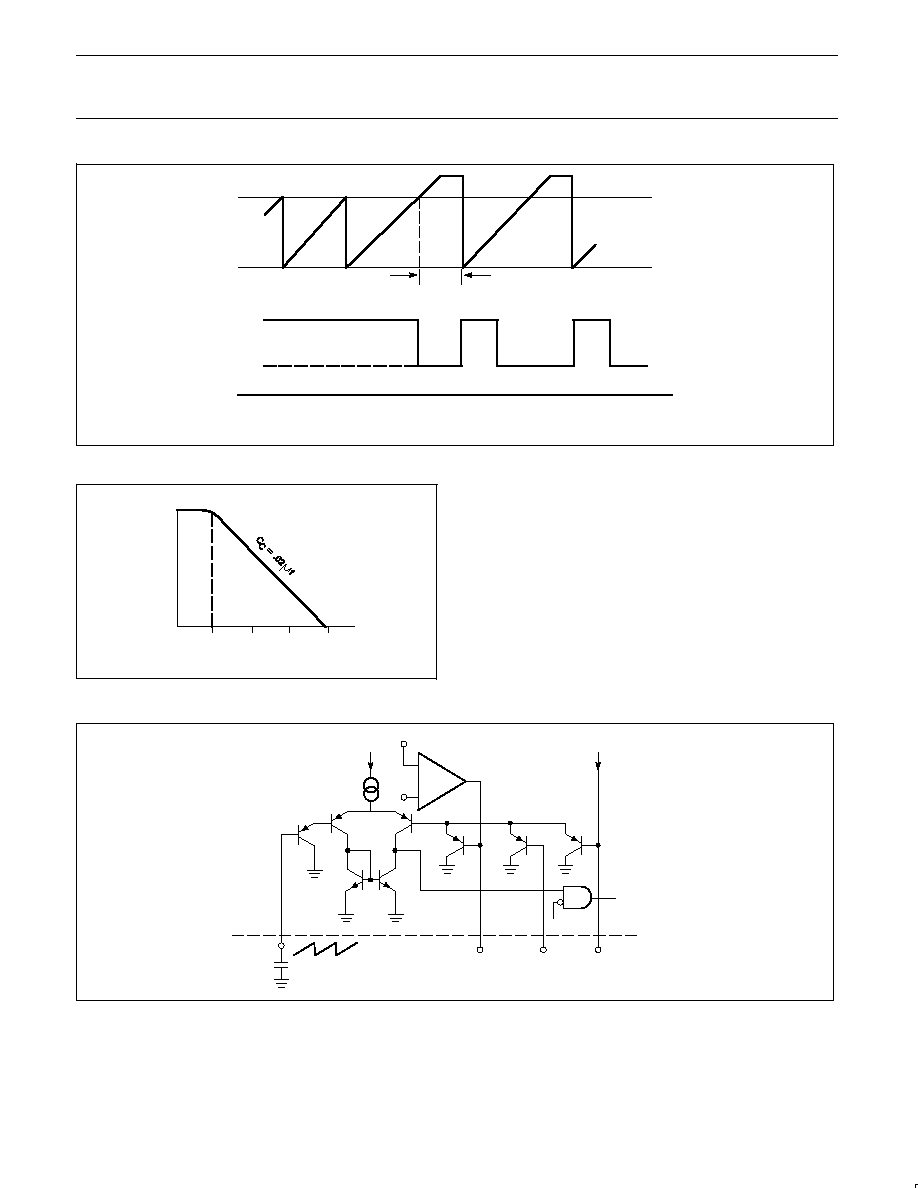

The Sawtooth Generator

Figure 6 shows the principal circuitry of the oscillator. A resistor

between Pin 7 and Pin 12 (GND) determines the constant current

that charges the timing capacitor C

(8-12)

.

This causes a linear increasing voltage on Pin 8 until the upper level

of 5.6V is reached. Comparator H sets the RS flip-flop and Q1

discharges C

(8-12)

down to 1.1V, where comparator L resets the

flip-flop. During this flyback time, Q2 inhibits the output.

Synchronization at a frequency lower than the free-running

frequency is accomplished via the TTL gate on Pin 9. By activating

this gate (V

9

<2V), the setting of the sawtooth is prevented. This is

indicated in Figure 7.

Figure 8 shows a typical plot of the oscillator frequency against the

timing capacitor. The frequency range of the NE5560 goes from

<50Hz up to >100kHz.

Reference Voltage Source

The internal reference voltage source is based on the bandgap

voltage of silicon. Good design practice assures a temperature

dependency typically

±

100ppm/

∞

C. The reference voltage is

connected to the positive input of the error amplifier and has a

typical value of 3.72V.

Error Amplifier Compensation

For closed-loop gains less than 40dB, it is necessary to add a

simple compensation capacitor as shown in Figures 8 and 9.

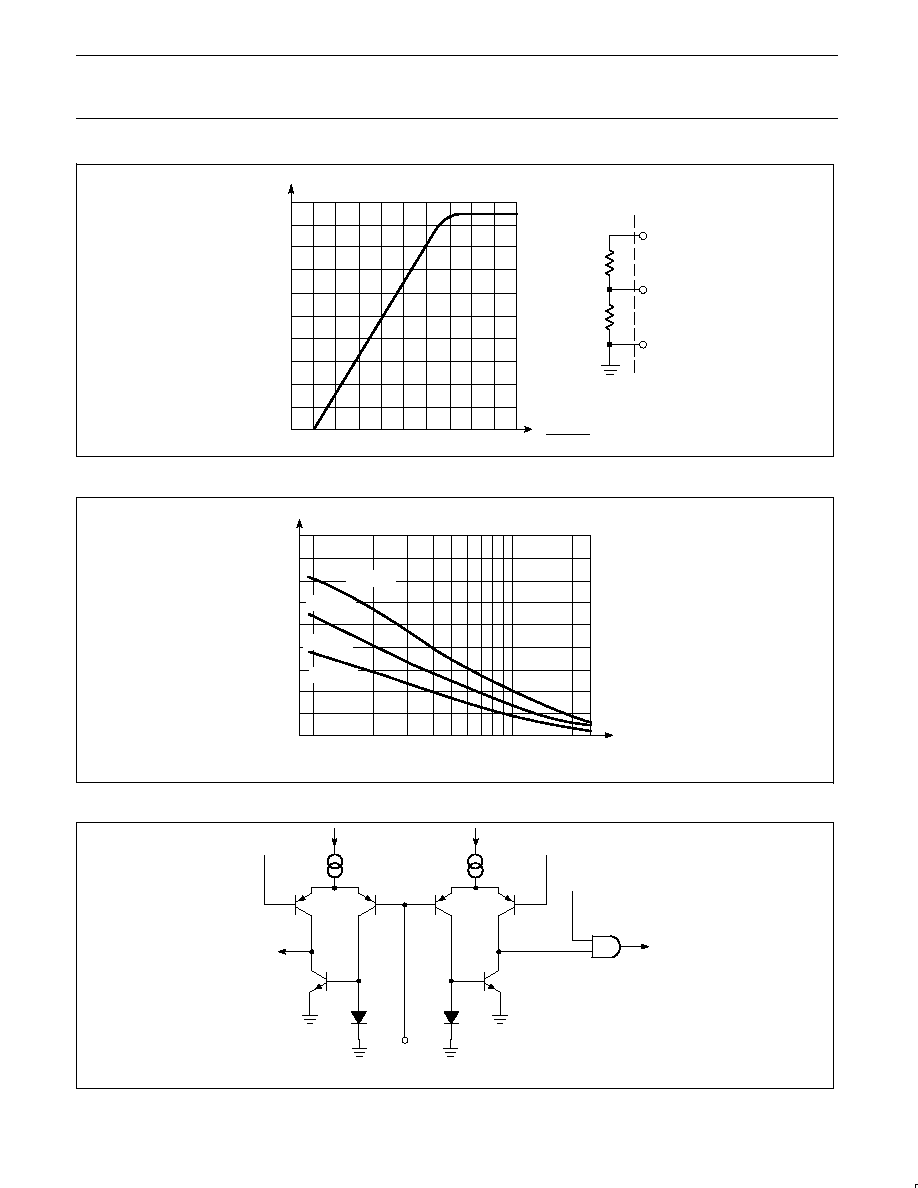

Error Amplifier with Loop-Fault Protection Circuits

This operational amplifier is of a generally used concept and has an

open-loop gain of typically 60dB. As can be seen in Figure 9, the

inverting input is connected to Pin 3 for a feedback information

proportional to V

O

.

The output goes to the PWM circuit, but is also connected to Pin 4,

so that the required gain can be set with R

S

and R

(3-4)

. This is

indicated in Figure 9, showing the relative change of the feedback

voltage as a function of the duty cycle. Additionally, Pin 4 can be

used for phase shift networks that improve the loop stability.

When the SMPS feedback loop is interrupted, the error amplifier

would settle in the middle of its active region because of the

feedback via R

(3-4)

. This would result in a large duty cycle. A current

source on Pin 3 prevents this by pushing the input voltage high via

the voltage drop over R

(3-4)

. As a result, the duty cycle will become

zero, provided that R

(3-4)

>100k. When the feedback loop is

short-circuited, the duty cycle would jump to the adjusted maximum

duty cycle. Therefore, an additional comparator is active for

feedback voltages at Pin 3 below 0.6V. Now an internal resistor of

typically 1k is shunted to the impedance on the

MAX

setting Pin 6.

Depending on this impedance,

will be reduced to a value

0

. This

will be discussed further.

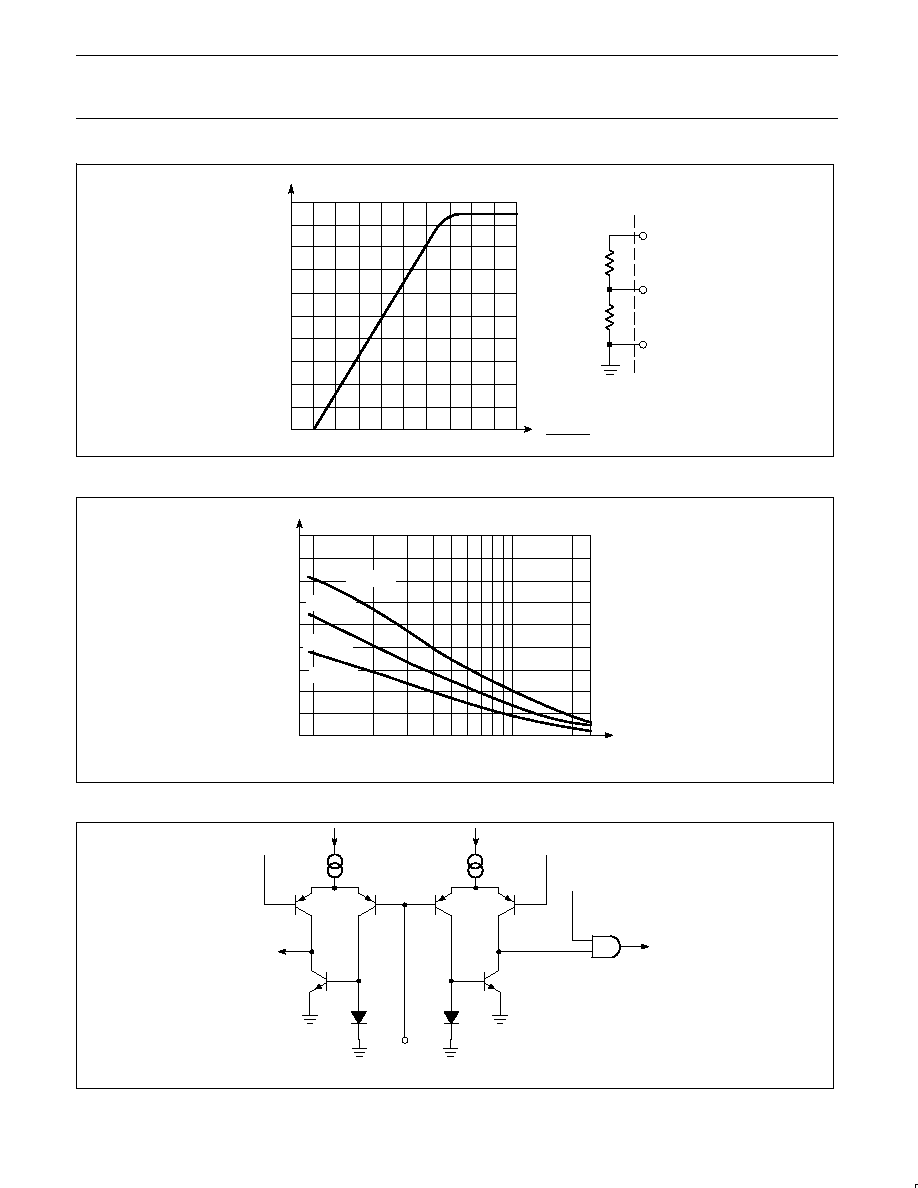

The Pulse-Width Modulator

The function of the PWM circuit is to translate a feedback voltage

into a periodical pulse of which the duty cycle depends on that

feedback voltage. As can be seen in Figure 10, the PWM circuit in

the NE5560 is a long-tailed pair in which the sawtooth on Pin 8 is

compared with the LOWEST voltage on either Pin 4 (error amplifier),

Pin 5, or Pin 6 (

MAX

and slow-start). The transfer graph is given in

Figure 11. The output of the PWM causes the resetting of the output

bi-stable.

Limitation of the Maximum Duty Cycle

With Pins 5 and 6 not connected and with a rather low feedback

voltage on Pin 3, the NE5560 will deliver output pulses with a duty

cycle of

95%. In many SMPS applications, however, this high

will

cause problems. Especially in forward converters, where the

transformer will saturate when

exceeds 50%, a limitation of the

maximum duty cycle is a must.

A DC voltage applied to Pin 6 (PWM input) will set

MAX

at a value

in accordance with Figure 11. For low tolerances of

MAX

, this

voltage on Pin 6 should be set with a resistor divider from V

Z

(Pin 2).

The upper and lower sawtooth levels are also set by means of an

internal resistor divider from V

Z

, so forming a bridge configuration

with the

MAX

setting is low because tolerances in V

Z

are

compensated and the sawtooth levels are determined by internal

resistor matching rather than by absolute resistor tolerance. Figure

12 can be used for determining the tap on the bleeder for a certain

MAX

setting.

As already mentioned, Figure 13 gives a graphical representation of

this. The value

o is limited to the lower and the higher side;

∑

It must be large enough to ensure that at maximum load and mini-

mum input voltage the resulting feedback voltage on Pin 3

exceeds 0.6V.

∑

It must be small enough to limit the amount of energy in the SMPS

when a loop fault occurs. In practice, a value of 10-15% will be a

good compromise.

SET

RESET

7

8

1.1V

5.6V

N

L

≠

+

≠

+

Q1

Q2

TO OUTPUT LATCH

TO PWM

9 SYN

VZ

RT

CT

SL00365

Figure 6. Sawtooth Generator

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

9

5.6V

1.1V

INHIBIT

`SET'

SET

RESET

>2V

<0.8V

VS

VS

SL00366

Figure 7. Sawtooth Oscillator Synchronization

60dB

SLOPE

20dB/DECADE

1kHz

10kHz

1MHz

SL00367

Figure 8. Error Amplifier Compensation Open-Loop Gain

(+)

8

3.72V

3

+

≠

ERROR

AMP

PWM

OUT

(≠)

(≠) O.C.

(≠)

START/

STOP

RESET

4

5

6

SL00368

Figure 9. Error Amplifier

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

10

a. Duty Cycle --

-- % Regulation

b. Pulse-Width Modulation

(+)

8

3.72V

3

+

≠

ERROR

AMP

PWM

OUT

(≠)

(≠) O.C.

(≠)

START/

STOP

RESET

4

5

6

≠

+

7

6

5

4

3

2

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

4

3

RS

R1

VREF(3.72V)

VO/VREF (%)

10

20

30

40

50

60

70

80

90

R

f

R

S

+

20

R

f

R

S

+

100

R

f

R

S

+

500

SL00369

Figure 10.

100

90

80

70

60

50

40

30

20

10

0

1

2

3

4

5

6

(%)

V4,5,6 (V)

SL00370

Figure 11. Transfer Curve of Pulse-Width Modulator

Duty Cycle vs Input Voltage

Extra PWM Input (Pin 5)

The PWM has an additional inverting input: Pin 5. It allows for

attacking the duty cycle via the PWM circuit, independently from the

feedback and the

MAX

information. This is necessary when the

SMPS must have a real constant-current behavior, possibly with a

fold-back characteristic. However, the realization of this feature must

be done with additional external components. When not used, Pin 5

should be tied to Pin 6.

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

11

MAX (%)

12

R1

R2

2

6

DUTY

CYCLE

CONTROL

MAXIMUM DUTY

CYCLE (%)

100

90

80

70

60

50

40

30

20

10

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

R

2

R

1

*

R

2

SL00371

Figure 12. Graph for Determining

MAX

(%)

R1 + R2

(

)

SOFT ST

ART DUTY

CYCLE %

103

104

2

3

4

5

6 7 8 9

2

80

70

60

50

40

30

20

10

MAX 90%

MAX 70%

MAX 50%

MAX 30%

SL00372

Figure 13. Soft-Start Minimum Duty Cycle vs R

1

+ R

2

0.6V

START

STOP

11

0.48V

from

PWM

RESET

OF OUTPUT

BISTABLE

SL00373

Figure 14. Current Protection Input

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

12

V11 (CURRENT LIMITING)

NORMAL OPERATING

POINT

LEVEL 1 LEVEL 2

.48

.60 (V)

RELA

TIVE I (mA)

OUT

OC1

OC2

SL00374

Figure 15. Output Characteristics

Dynamic Current Limit and Current Protection

(Pin 11)

In many applications, it is not necessary to have a real

constant-current output of the SMPS.

Protection of the power transistor will be the prime goal. This can be

realized with the NE5560 in an economical way. A resistor (or a

current transformer) in the emitter of the power transistor gives a

replica of the collector current. This signal must be connected to Pin

11. As can be seen in Figure 14, this input has two comparators with

different reference levels. The output of the comparator with the

lower 0.48V reference is connected to the same gate as the output

of the PWM.

When activated, it will immediately reset the output flip-flop, so

reducing the duty cycle. The effectiveness of this cycle-by-cycle

current limit diminishes at low duty cycle values. When

becomes

very small, the storage time of the power transistor becomes

dominant. The current will now increase again, until it surpasses the

reference of the second comparator. The output of this comparator

activates the start-stop circuit and causes an immediate inhibit of the

output pulses. After a certain deadtime, the circuit starts again with

very narrow output pulses. The effect of this two-level current

protection circuit is visualized in Figure 15.

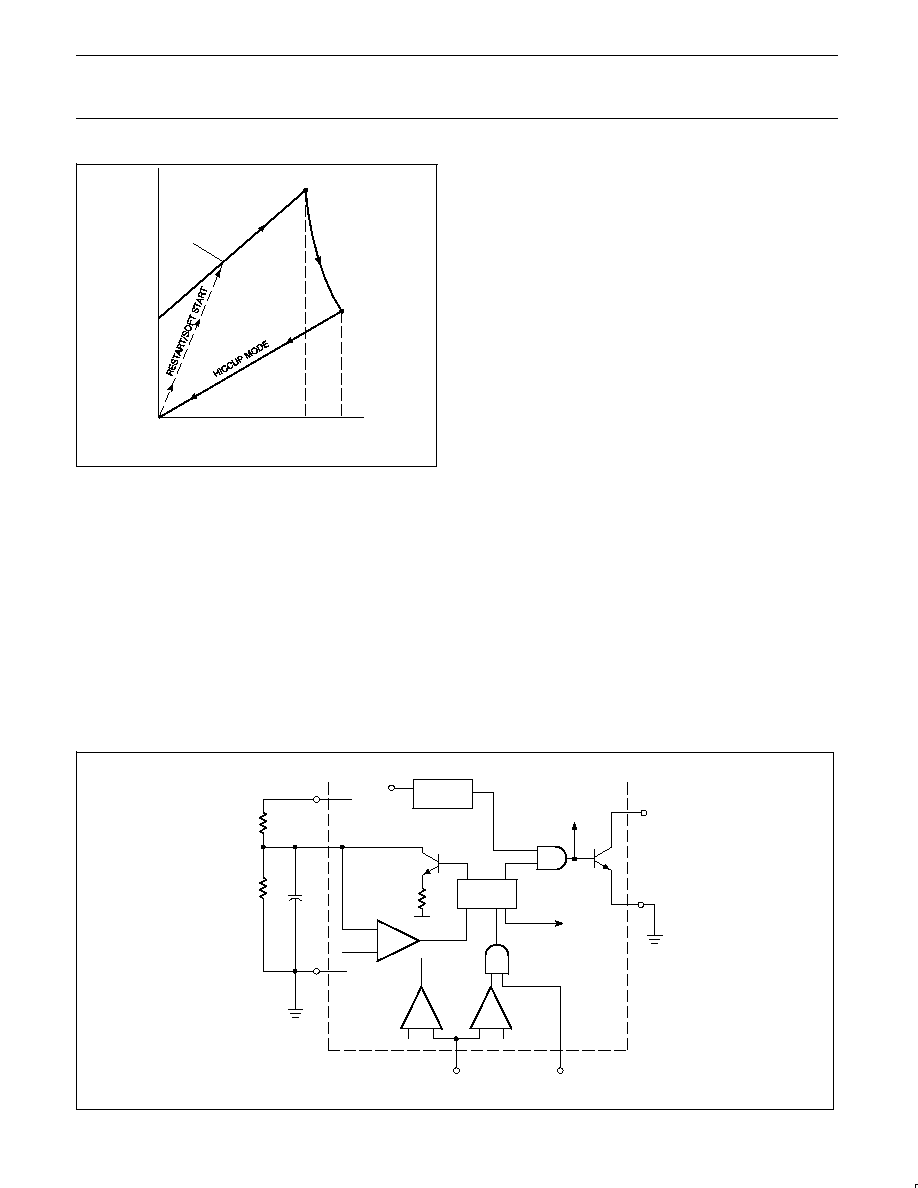

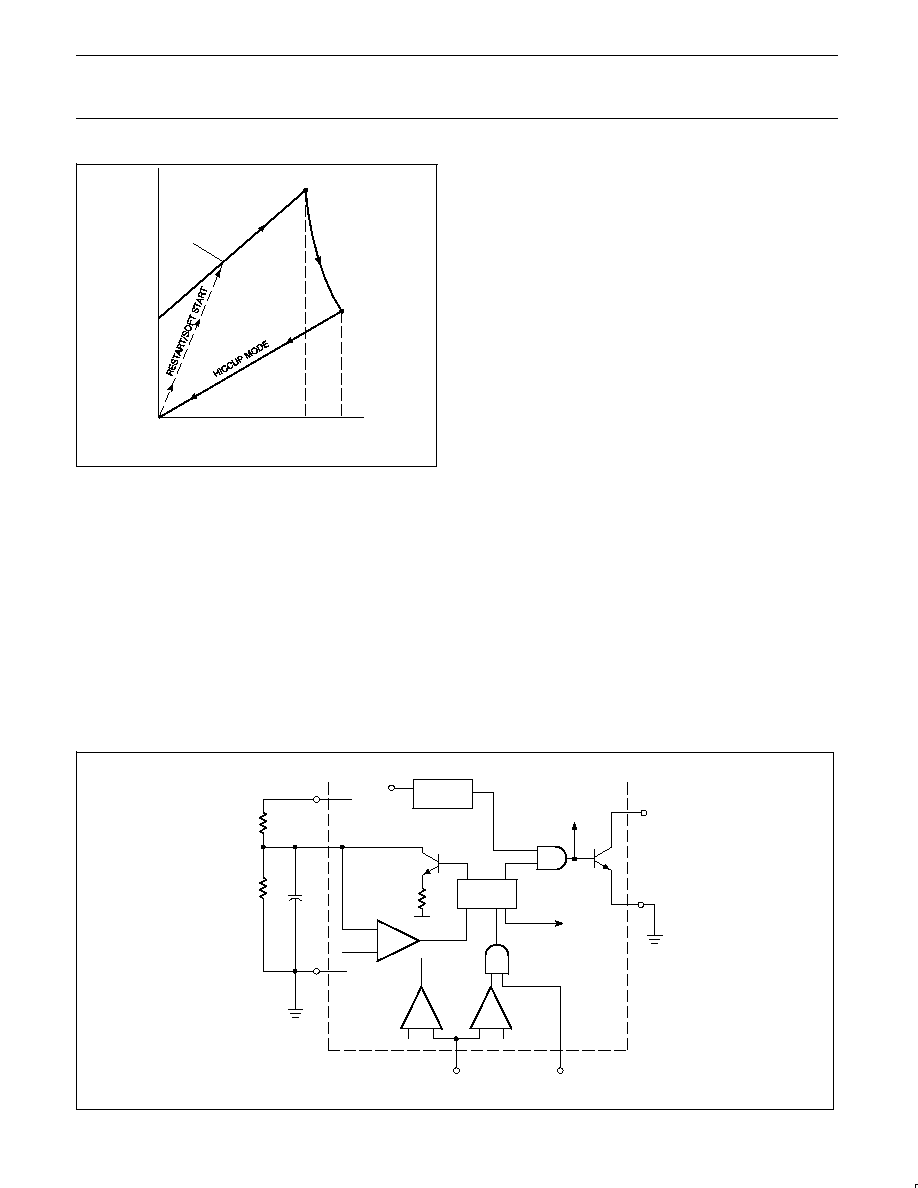

The Start-Stop Circuit

The function of this protection circuit is to stop the output pulses as

soon as a fault occurs and to keep the output stopped for several

periods. After this dead-time, the output starts with a very small,

gradually increasing duty cycle. When the fault is persistent, this will

cause a cyclic switch-off/switch-on condition. This "hiccup" mode

effectively limits the energy during fault conditions. The realization

and the working of the circuit are indicated in Figures 12 and 13.

The dead time and the soft-start are determined by an external

capacitor that is connected to Pin 6 (

MAX

setting).

An RS flip-flop can be set by three different functions:

1. Remote on/off on Pin 10.

2. Overcurrent protection on Pin 11.

3. Low supply voltage protection (internal).

As soon as one of these functions cause a setting of the flip-flop, the

output pulses are blocked via the output gate. In the same time

transistor Q1 is forward-biased, resulting in a discharge of the

capacitor on Pin 6.

The discharging current is limited by an internal 150

resistor in the

emitter of Q1. The voltage at Pin 6 decreases to below the lower

level of the sawtooth. When V6 has dropped to 0.6V, this will

activate a comparator and the flip-flop is reset. The output stage is

no longer blocked and Q1 is cut off. Now V

Z

will charge the

capacitor via R1 to the normal

MAX

voltage. The output starts

delivering very narrow pulses as soon as V6 exceeds the lower

sawtooth level. The duty cycle of the output pulse now gradually

increases to a value determined by the feedback on Pin 3, or by the

static

MAX

setting on Pin 6.

15

14

2

6

12

11

10

LATCH

START/

STOP

SET

RESET

0.6V

0.48V

0.6V

LOW SUPPLY

VOLTAGE

PROTECTION

100

R1

R2

CSS

Q1

Q2

PWM

VZ

SL00375

Figure 16. Start-Stop Circuit

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

13

INCREASES

V6

V15

SET

RESET

CHARGE

.6V

5.6V

SAWTOOTH

1.1V

DISCHARGE

DEAD

TIME

SL00376

Figure 17. Start-Stop Circuit

Remote On/Off Circuit (Pin 10)

In systems where two or more power supplies are used, it is often

necessary to switch these supplies on and off in a sequential way.

Furthermore, there are many applications in which a supply must be

switched by a logical signal. This can be done via the

TTL-compatible remote on/off input on Pin 10. The output pulse is

inhibited for levels below 0.8V. The output of the IC is no longer

blocked when the remote on/off input is left floating or when a

voltage >2V is applied. Start-up occurs via the slow-start circuit.

The Output Stage

The output stage of the NE5560 contains a flip-flop, a push-pull

driven output transistor, and a gate, as indicated in Figure 18. The

flip-flop is set by the flyback of the sawtooth. Resetting occurs by a

signal either from the PWM or the current limit circuit. With this

configuration, it is assured that the output is switched only once per

period, thus prohibiting double pulsing. The collector and emitter of

the output transistor are connected to respectively Pin 15 and Pin

14, allowing for normal or inverted output pulses. An

internally-grounded emitter would cause intolerable voltage spikes

over the bonding wire, especially at high output currents.

This current capability of the output transistor is 40mA peak for V

CE

0.4V. An internal clamping diode to the supply voltage protects the

collector against overvoltages. The max. voltage at the emitter (Pin

14) must not exceed +5V. A gate, activated by one of the set or

reset pulses, or by a command from the start-stop circuit will

immediately switch-off the output transistor by short-circuiting its

base. The external inhibitor (Pin 13) operates also via this base.

Demagnetization Sense

As indicated in Figure 18, the output of this NPN comparator will

block the output pulse, when a voltage above 0.6V is applied to Pin

13. A specific application for this function is to prevent saturation of

forward-converter transformers. This is indicated in Figure 19.

Feed-Forward (Pin 16)

The basic formula for a forward converter is

V

OUT

+

dV

IN

n

(n

+ transformer ratio)

This means that in order to keep V

OUT

at a constant value, the duty

cycle

must be made inversely proportional to the input voltage. A

pre-regulation (feed-forward) with the function

~1/V

IN

can ease the

feedback-loop design.

"I" "I" "n"

NOTES:

The signal V13 can be derived from the demagnetizing winding in

a forward converter as shown below.

FLYBACK

SET

RESET

FROM START STOP

0.6V

13

14

15

+

≠

VZ

VZ

V1

B

H

P1

P2

S1

+

≠

SL00377

Figure 18. Output Stage

This loop now only has to regulate for load variations which require

only a low feedback gain in the normal operation area. The

transformer of a forward converter must be designed in such a way

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

14

that it does not saturate, even under transient conditions, where the

max. inductance is determined by

MAX

◊

V

IN

max. A regulation of

MAX

~1/V

IN

will allow for a considerable reduction or simplification of

the transformer. The function of

~1/V

IN

can be realized by using

Pin 16 of the NE5560.

ON

ON

ON

T

T

T

1

1

2

2

3

3

(50)

SL00378

Figure 19. Output Stage Inhibit

Figure 20 shows the electrical realization. When the voltage at Pin

16 exceeds the stabilized voltage V

Z

(Pin 2), it will increase the

charging current for the timing capacitor on Pin 8.

The operating frequency is not affected, because the upper trip level

for sawtooth increases also. Note that the

MAX

voltage on Pin 6

remains constant because it is set via V

Z

. Figure 21 visualizes the

effect on

MAX

and the normal operating duty cycle

. For V

16

=2

◊

V

Z

,

these duty cycles have halved. The graph for

=f(V

16

) is given in

Figure 22.

NOTE:

V

16

must be less than Pin 1 voltage.

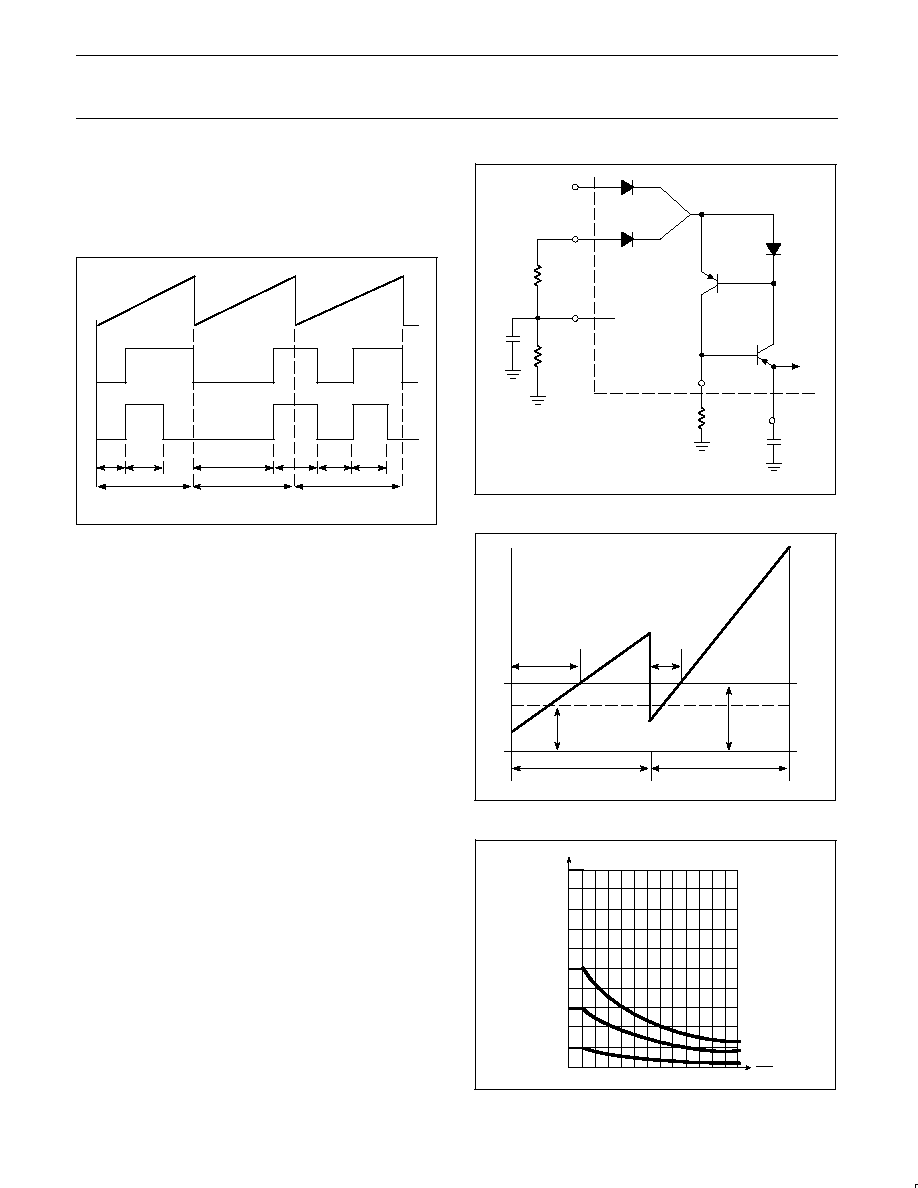

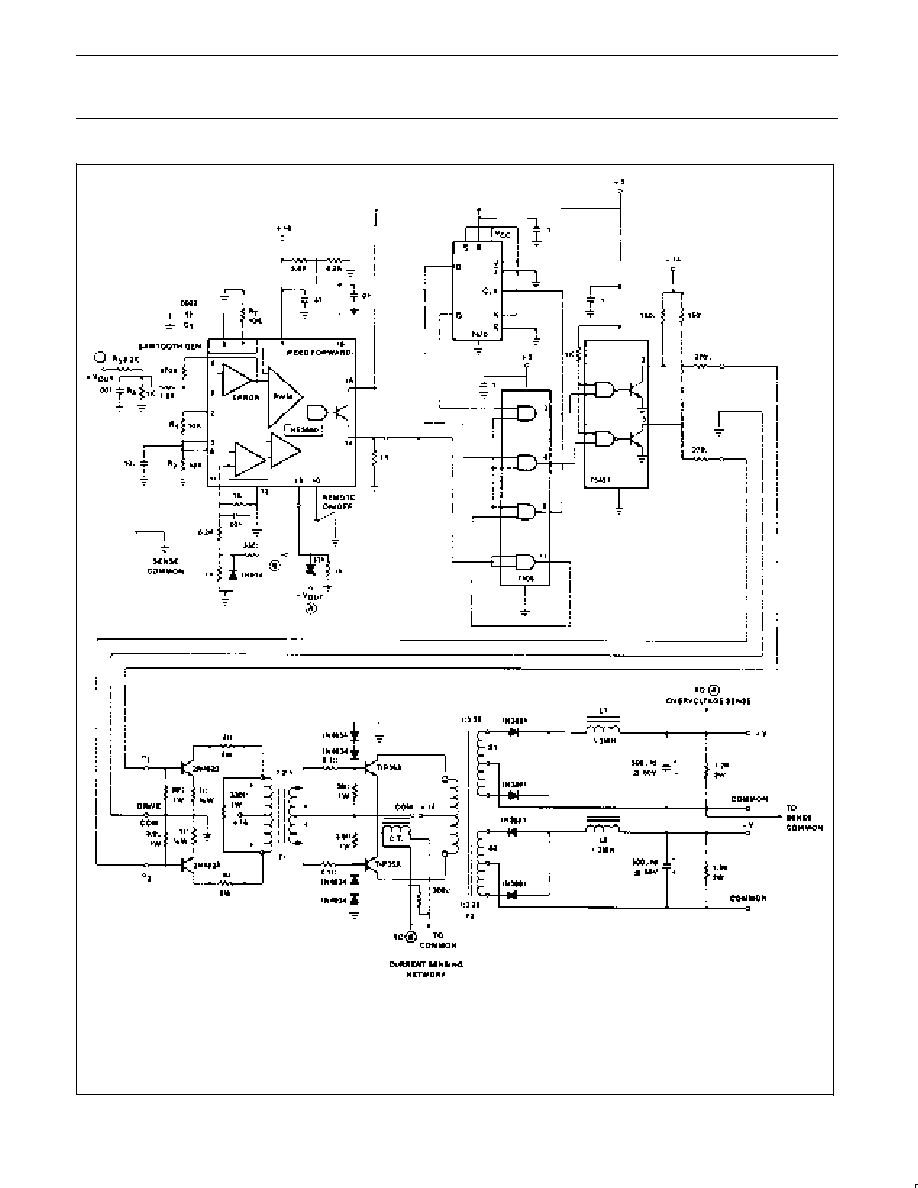

APPLICATIONS

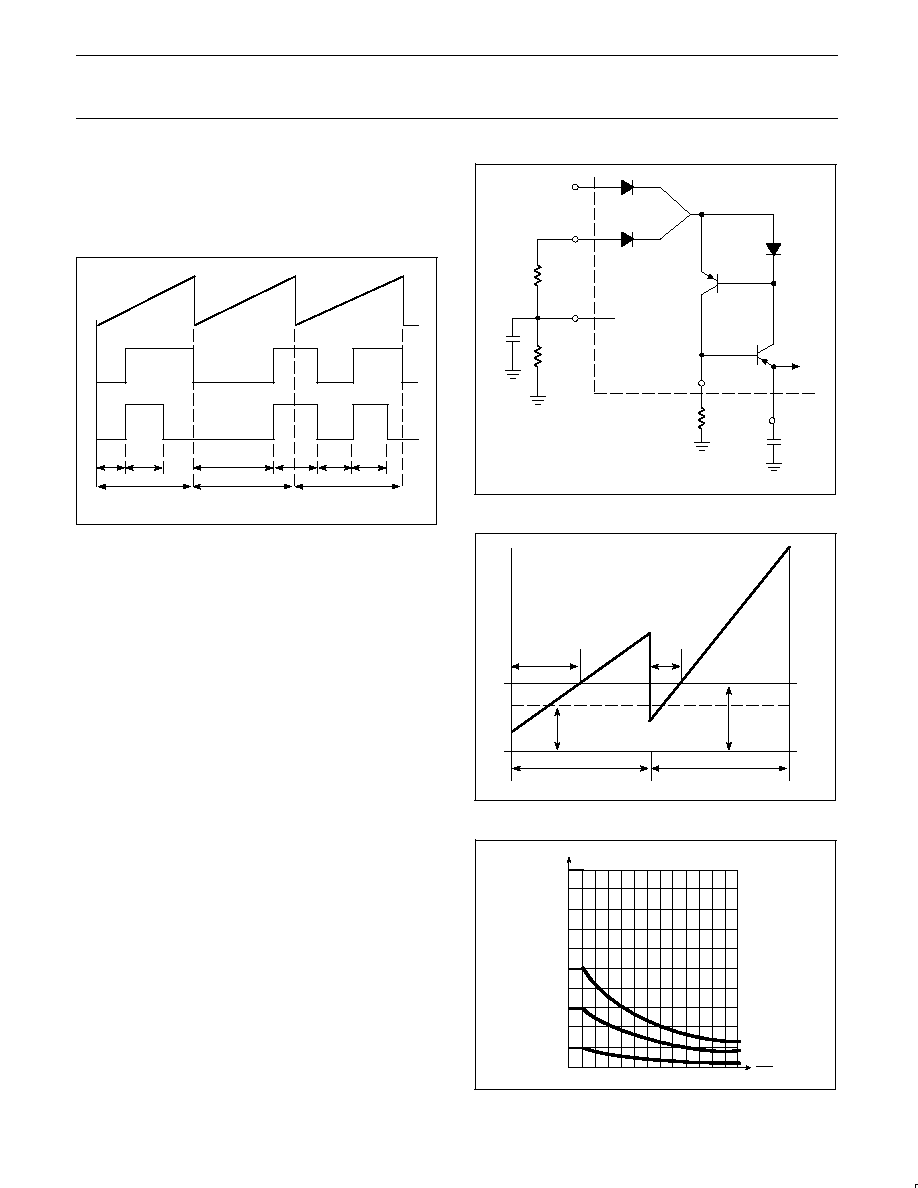

NE/SE5560 Push-Pull Regulator

This application describes the use of the Philips Semiconductors

NE/SE5560 adapted to function as a push-pull switched mode

regulator, as shown in Figures 23 and 24.

Input voltage range is +12V to +18V for a nominal output of +30V

and -30V at a maximum load current of 1A with an average

efficiency of 81%.

Features include feed-forward input compensation, cycle-to-cycle

drive current protection and other voltage sensing, line (to positive

output) regulation <1% for an input range of +13V to +18V and load

regulation to positive output of <3% for

I

L

(+) of 0.1 to 1A.

The main pulse-width modulator operates to 48kHz with power

switching at 24kHz.

FEED-FORWARD

16

2

6

7

8

DO NOT EXCEED VCC

CSS

R1

R2

RT

CT

MAX

INPUT

SL00379

Figure 20. External

Maximum Control

WORKING

LEVEL

MAX

LEVEL

d

MAX

1

d

MAX

2

VZ

V16

2XVZ

T

T

SL00380

Figure 21. Feed-Forward Circuitry

DUTY

CYCLE

100

90

80

70

60

50

40

30

20

10

1

1.5

2

2.5

V

16

V

Z

SL00381

Figure 22. Feed-Forward Regulation

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

15

NOTES:

Power ground and signal ground must be kept separated

T1, Primary = 130T (C.T.) #26

Secondary = 18T (C.T.) #22

Core = Ferroxcube 3622

3C8 material

C.T. = 50T #26 0n

Ferroxcube 2616 core (3C8)

F2D bobbin

T2, Primary = 16T (C.T.) #18 Secondaries (each) 52T (C.T.) #22

Core = Ferroxcube 4229 3C8 material

L1, L2 = 120T #20 on single gapped EC35 Ferroxcube core. 3C8 material.

SL00382

Figure 23. NE/SE5560 Push-Pull Switched-Mode Regulated Supply with CMOS Drive Conversion Logic

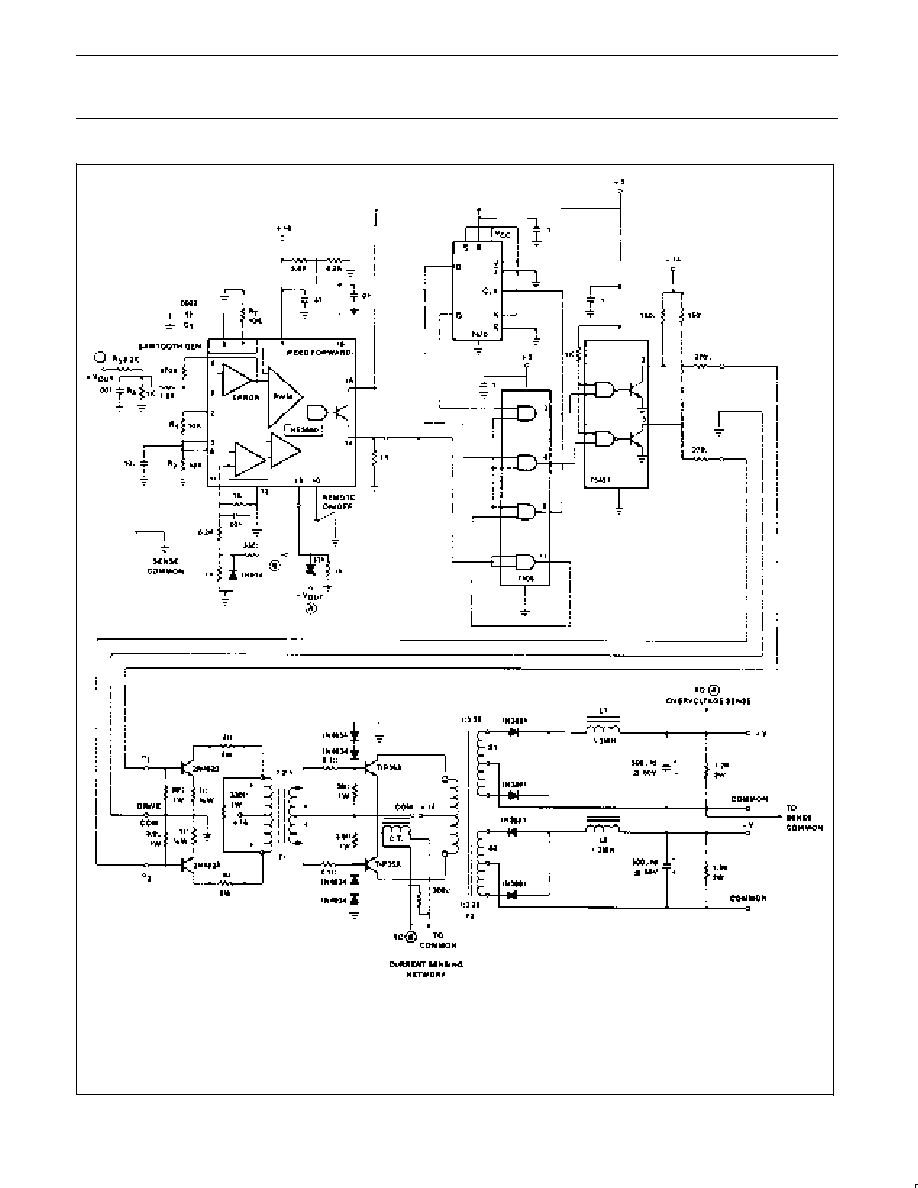

Philips Semiconductors

Product specification

NE/SE5560

Switched-mode power supply control circuit

1994 Aug 31

16

NOTES:

Power ground and signal ground must be kept separated

T1, Primary = 130T (C.T.) #26

Secondary = 18T (C.T.) #22

Core = Ferroxcube 3622

3C8 material

C.T. = 50T #26 0n

Ferroxcube 2616 core (3C8)

F2D bobbin

T2, Primary = 16T (C.T.) #18 Secondaries (each) 52T (C.T.) #22

Core = Ferroxcube 4229 3C8 material

L1, L2 = 120T #20 on single gapped EC35 Ferroxcube core. 3C8 material.

SL00383

Figure 24. NE/SE5560 Push-Pull Switched-Mode Regulated With TTL Drive Conversion Logic