| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: PCA9532 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Philips

Semiconductors

PCA9532

16-bit I

2

C LED dimmer

Product data

Supersedes data of 2003 Feb 26

2003 May 02

INTEGRATED CIRCUITS

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2

2003 May 02

FEATURES

∑

16 LED drivers (on, off, flashing at a programmable rate)

∑

2 selectable, fully programmable blink rates (frequency and duty

cycle) between 0.625 and 160 Hz (6.4 seconds and

6.25 milliseconds)

∑

256 brightness steps

∑

Input/outputs not used as LED drivers can be used as regular

GPIOs

∑

Internal oscillator requires no external components

∑

I

2

C-bus interface logic compatible with SMBus

∑

Internal power-on reset

∑

Noise filter on SCL/SDA inputs

∑

Active-LOW reset input

∑

16 open drain outputs directly drive LEDs to 25 mA

∑

Controlled edge rates to minimize ground bounce

∑

No glitch on power-up

∑

Supports hot insertion

∑

Low stand-by current

∑

Operating power supply voltage range of 2.3 V to 5.5 V

∑

0 to 400 kHz clock frequency

∑

ESD protection exceeds 2000 V HBM per JESD22-A114,

150 V MM per JESD22-A115 and 1000 V CDM per JESD22-C101

∑

Latch-up testing is done to JEDEC Standard JESD78 which

exceeds 100 mA

∑

Packages offered: SO24, TSSOP24, HVQFN24

DESCRIPTION

The PCA9532 is a 16-bit I

2

C-bus and SMBus I/O expander

optimized for dimming LEDs in 256 discrete steps for

Red/Green/Blue (RGB) color mixing and back light applications.

The PCA9532 contains an internal oscillator with two user

programmable blink rates and duty cycles coupled to the output

PWM. The LED brightness is controlled by setting the blink rate high

enough (> 100 Hz) that the blinking cannot be seen and then using

the duty cycle to vary the amount of time the LED is on and thus the

average current through the LED.

The initial set-up sequence programs the two blink rates/duty cycles

for each individual PWM. From then on, only one command from the

bus master is required to turn individual LEDs ON, OFF, BLINK

RATE 1 or BLINK RATE 2. Based on the programmed frequency

and duty cycle, BLINK RATE 1 and BLINK RATE 2 will cause the

LEDs to appear at a different brightness or blink at periods up to

1.6 seconds. The open drain outputs directly drive the LEDs with

maximum output sink current of 25 mA per bit and 200 mA per

package (100 mA per octal).

To blink LEDs at periods greater than 1.6 seconds the bus master

(MCU, MPU, DSP, chipset, etc.) must send repeated commands to

turn the LED on and off as is currently done when using normal I/O

Expanders like the Philips PCF8575 or PCA9555. Any bits not used

for controlling the LEDs can be used for General Purpose Parallel

Input/Output (GPIO) expansion which provides a simple solution

when additional I/O is needed for ACPI power switches, sensors,

pushbuttons, alarm monitoring, fans, etc.

The active-LOW hardware reset pin (RESET) and Power-On Reset

(POR) initializes the registers to their default state, all zeroes,

causing the bits to be set HIGH (LED off).

Three hardware address pins on the PCA9532 allow eight devices

to operate on the same bus.

ORDERING INFORMATION

PACKAGES

TEMPERATURE RANGE

ORDER CODE

TOPSIDE MARK

DRAWING NUMBER

24-pin plastic SO

-40 to +85

∞

C

PCA9532D

PCA9532D

SOT137-1

24-pin plastic TSSOP

-40 to +85

∞

C

PCA9532PW

PCA9532

SOT355-1

24-pin plastic HVQFN

-40 to +85

∞

C

PCA9532BS

9532

SOT616-1

Standard packing quantities and other packaging data is available at www.philipslogic.com/packaging.

I

2

C is a trademark of Philips Semiconductors Corporation.

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

3

PIN CONFIGURATION -- SO, TSSOP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A0

A1

A2

LED0

LED1

LED2

LED3

LED4

LED5

LED6

LED7

V

DD

SDA

SCL

RESET

LED15

LED14

LED13

LED11

LED12

LED10

LED9

LED8

V

SS

SW00931

Figure 1. Pin configuration -- SO, TSSOP

PIN CONFIGURATION -- HVQFN

18

17

16

15

14

7

8

9

10

11

1

2

3

4

5

24

23

22

21

20

su01668

TOP VIEW

LED0

RESET

6

13

12

19

LED1

LED2

LED3

LED4

LED5

LED11

LED12

LED13

LED14

LED15

LED6

LED7

LED8

LED9

LED10

A2

A1

A0

V

SDA

SCL

DD

V

SS

Figure 2. Pin configuration -- HVQFN

PIN DESCRIPTION

SO, TSSOP

PIN

NUMBER

HVQFN

PIN

NUMBER

SYMBOL

FUNCTION

1

22

A0

Address input 0

2

23

A1

Address input 1

3

24

A2

Address input 2

4, 5, 6, 7, 8, 9,

10, 11

1, 2, 3, 4, 5, 6,

7, 8

LED0-7

LED driver 0-7

12

9

V

SS

Supply ground

13, 14, 15, 16,

17, 18, 19, 20

10, 11, 12, 13,

14, 15, 16, 17

LED8-15

LED driver 8-15

21

18

RESET

Active-LOW reset input

22

19

SCL

Serial clock line

23

20

SDA

Serial data line

24

21

V

DD

Supply voltage

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

4

BLOCK DIAGRAM

PWM0

REGISTER

PWM1

REGISTER

PRESCALER 0

REGISTER

PRESCALER 1

REGISTER

I

2

C-BUS

CONTROL

LEDx

A2

A1

A0

INPUT

FILTERS

SCL

SDA

OSCILLATOR

POWER-ON

RESET

V

DD

V

SS

SW02045

1

0

BLINK0

BLINK1

RESET

NOTE: ONLY ONE I/O SHOWN FOR CLARITY

LED SELECT (LSx)

REGISTER

INPUT

REGISTER

PCA9532

Figure 3. Block diagram

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

5

DEVICE ADDRESSING

Following a START condition the bus master must output the

address of the slave it is accessing. The address of the PCA9532 is

shown in Figure 4. To conserve power, no internal pull-up resistors

are incorporated on the hardware selectable address pins and they

must be pulled HIGH or LOW.

1

1

0

0

A2

A1

A0

SLAVE ADDRESS

su01420

FIXED

HARDWARE SELECTABLE

R/W

Figure 4. Slave address

The last bit of the address byte defines the operation to be

performed. When set to logic 1 a read is selected while a logic 0

selects a write operation.

CONTROL REGISTER

Following the successful acknowledgement of the slave address,

the bus master will send a byte to the PCA9532 which will be stored

in the Control Register. This register can be read and written via the

I

2

C-bus.

0

0

AI

B2 B1 B0

0

SW00898

B3

AUTO-INCREMENT FLAG

REGISTER ADDRESS

RESET STATE: 00h

Figure 5. Control register

CONTROL REGISTER DEFINITION

B3

B2

B1

B0

REGISTER

NAME

TYPE

REGISTER

FUNCTION

0

0

0

0

INPUT0

READ

INPUT

REGISTER 0

0

0

0

1

INPUT1

READ

INPUT

REGISTER 1

0

0

1

0

PSC0

READ/

WRITE

FREQUENCY

PRESCALER 0

0

0

1

1

PWM0

READ/

WRITE

PWM

REGISTER 0

0

1

0

0

PSC1

READ/

WRITE

FREQUENCY

PRESCALER 1

0

1

0

1

PWM1

READ/

WRITE

PWM

REGISTER 1

0

1

1

0

LS0

READ/

WRITE

LED 0-3

SELECTOR

0

1

1

1

LS1

READ/

WRITE

LED 4-7

SELECTOR

1

0

0

0

LS2

READ/

WRITE

LED 8-11

SELECTOR

1

0

0

1

LS3

READ/

WRITE

LED 12-15

SELECTOR

REGISTER DESCRIPTION

The lowest 3 bits are used as a pointer to determine which register

will be accessed.

If the auto-increment flag (AI) is set, the four low order bits of the

Control Register are automatically incremented after a read or write.

This allows the user to program the registers sequentially. The

contents of these bits will rollover to `0000' after the last register is

accessed.

When auto-increment flag is set (AI = 1) and a read sequence is

initiated, the sequence must start by reading a register different from

`0' (B3 B2 B1 B0

0

0 0 0 0)

Only the 4 least significant bits are affected by the AI flag.

Unused bits must be programmed with zeroes.

INPUT0 -- INPUT REGISTER 1

bit

I7

I6

I5

I4

I3

I2

I1

I0

default

0

0

0

0

0

0

0

0

The INPUT register 1 reflects the state of the device pins (inputs 0

to 7). Writes to this register will be acknowledged but will have no

effect.

INPUT1 -- INPUT REGISTER 2

bit

I15

I14

I13

I12

I11

I10

I9

I8

default

0

0

0

0

0

0

0

0

The INPUT register 1 reflects the state of the device pins (inputs 8

to 15). Writes to this register will be acknowledged but will have no

effect.

PSC0 -- FREQUENCY PRESCALER 0

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

PSC0 is used to program the period of the PWM output.

The period of BLINK0

+

(PSC0

)

1)

152

PWM0 -- PWM REGISTER 0

bit

7

6

5

4

3

2

1

0

default

1

0

0

0

0

0

0

0

The PWM0 register determines the duty cycle of BLINK0. The

outputs are LOW (LED on) when the count is less than the value in

PWM0 and HIGH (LED off) when it is greater. If PWM0 is

programmed with 00h, then the PWM0 output is always HIGH

(LED off).

The duty cycle of BLINK0 is:

PWM0

256

PSC1 -- FREQUENCY PRESCALER 1

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

PSC1 is used to program the period of PWM output.

The period of BLINK1

+

(PSC1

)

1)

152

PWM1 -- PWM REGISTER 1

bit

7

6

5

4

3

2

1

0

default

1

0

0

0

0

0

0

0

The PWM1 register determines the duty cycle of BLINK1. The

outputs are LOW (LED on) when the count is less than the value in

PWM1 and HIGH (LED off) when it is greater. If PWM1 is

programmed with 00h, then the PWM1 output is always HIGH

(LED off).

The duty cycle of BLINK1 is:

PWM1

256

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

6

LS0 -- LED 0-3 SELECTOR

LED 3

LED 2

LED 1

LED 0

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

LS1 -- LED 4-7 SELECTOR

LED 7

LED 6

LED 5

LED 4

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

LS2 -- LED 8-11 SELECTOR

LED 11

LED 10

LED 9

LED 8

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

LS3 -- LED 12-15 SELECTOR

LED 15

LED 14

LED 13

LED 12

bit

7

6

5

4

3

2

1

0

default

0

0

0

0

0

0

0

0

The LSx LED select registers determine the source of the LED data.

00 = Output is set Hi-Z (LED off - default)

01 = Output is set LOW (LED on)

10 = Output blinks at PWM0 rate

11 = Output blinks at PWM1 rate

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

7

POWER-ON RESET

When power is applied to V

DD

, an internal Power-On Reset holds

the PCA9532 in a reset state until V

DD

has reached V

POR

. At this

point, the reset condition is released and the PCA9532 registers are

initialized to their default states, all the outputs in the off state.

EXTERNAL RESET

A reset can be accomplished by holding the RESET pin LOW for a

minimum of t

W

. The PCA9532 registers and I

2

C state machine will

be held in their default state until the RESET input is once again

HIGH.

This input requires a pull-up resistor to V

DD

.

CHARACTERISTICS OF THE I

2

C-BUS

The I

2

C-bus is for 2-way, 2-line communication between different ICs

or modules. The two lines are a serial data line (SDA) and a serial

clock line (SCL). Both lines must be connected to a positive supply

via a pull-up resistor when connected to the output stages of a device.

Data transfer may be initiated only when the bus is not busy.

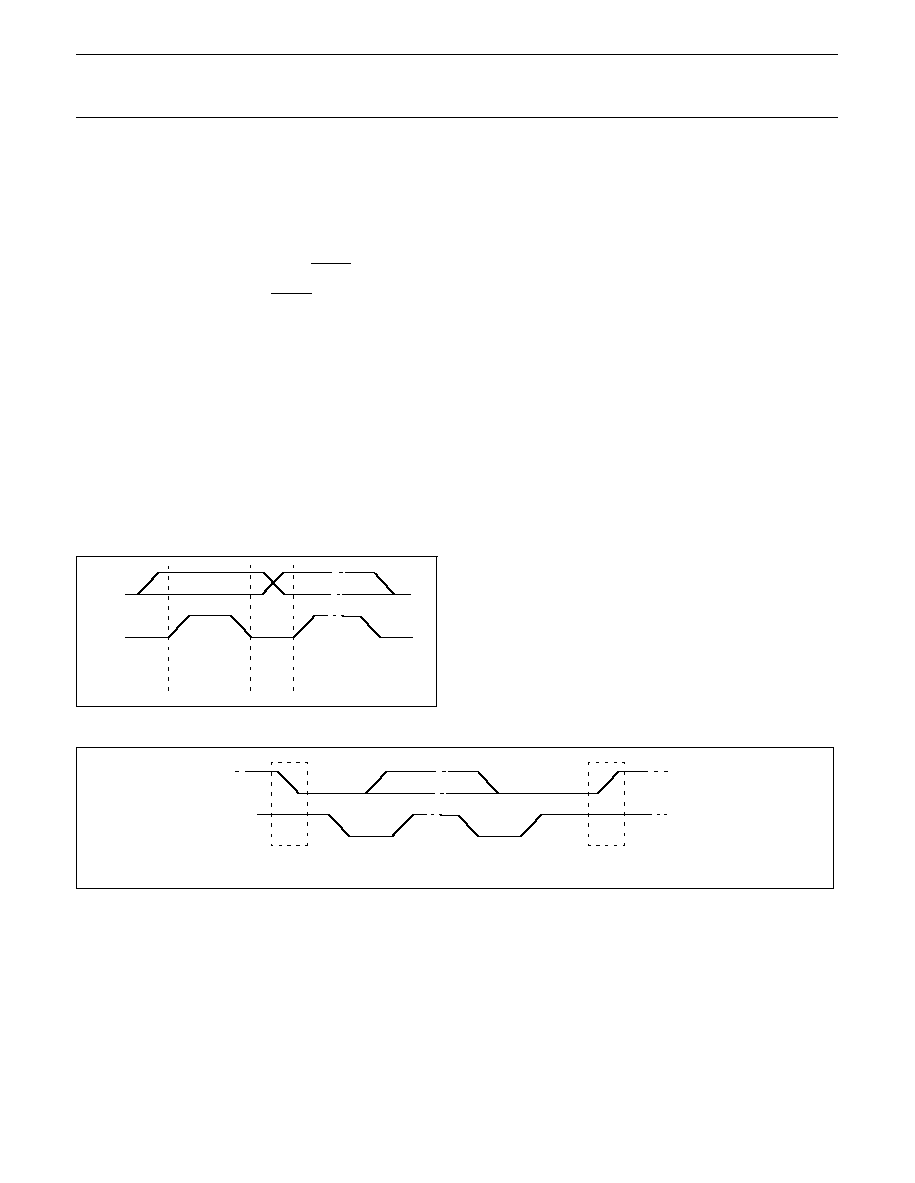

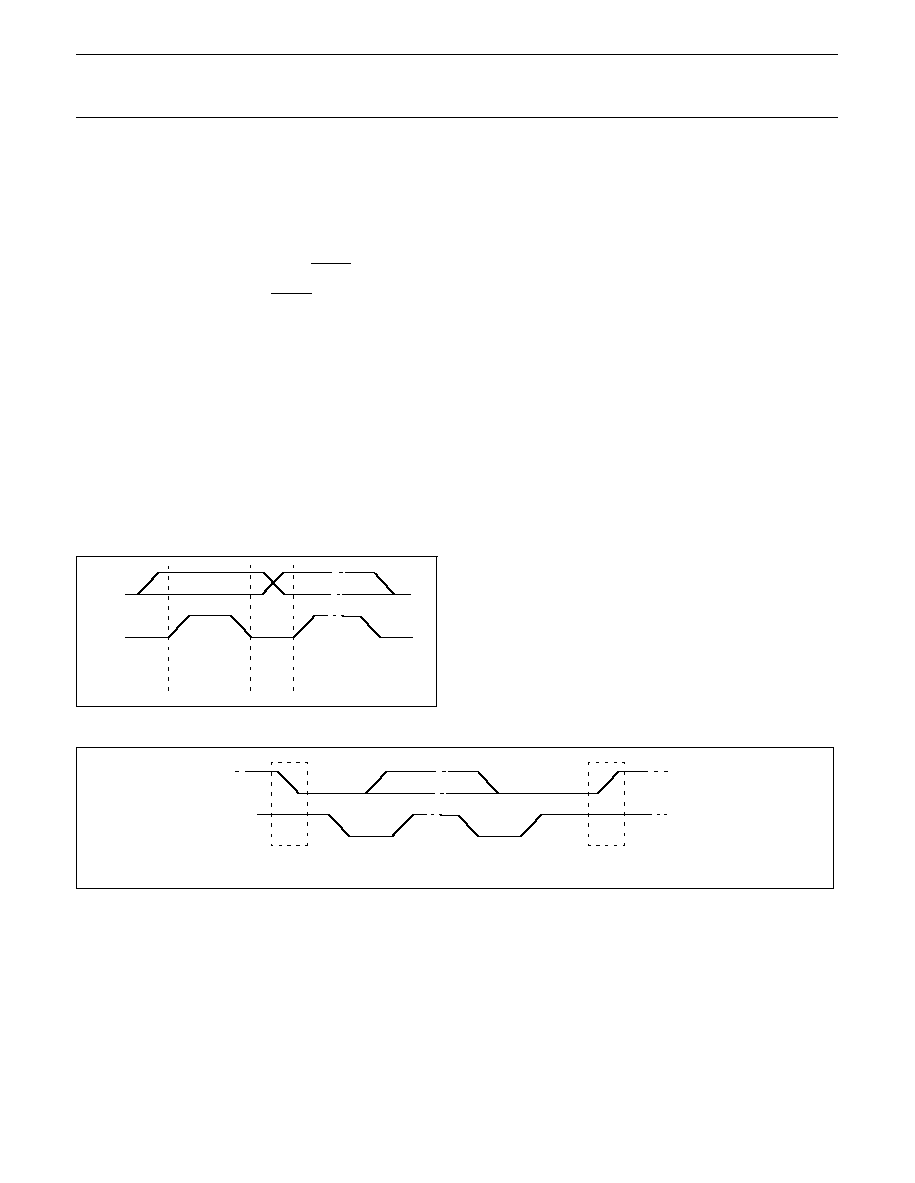

Bit transfer

One data bit is transferred during each clock pulse. The data on the

SDA line must remain stable during the HIGH period of the clock

pulse as changes in the data line at this time will be interpreted as

control signals (see Figure 6).

SDA

SCL

SW00363

data line

stable;

data valid

change

of data

allowed

Figure 6. Bit transfer

Start and stop conditions

Both data and clock lines remain HIGH when the bus is not busy. A

HIGH-to-LOW transition of the data line, while the clock is HIGH is

defined as the start condition (S). A LOW-to-HIGH transition of the

data line while the clock is HIGH is defined as the stop condition (P)

(see Figure 7).

System configuration

A device generating a message is a transmitter: a device receiving

is the receiver. The device that controls the message is the master

and the devices which are controlled by the master are the slaves

(see Figure 8).

SDA

SCL

SW00365

S

P

SDA

SCL

START condition

STOP condition

Figure 7. Definition of start and stop conditions

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

8

MASTER

TRANSMITTER/

RECEIVER

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

MASTER

TRANSMITTER

MASTER

TRANSMITTER/

RECEIVER

SDA

SCL

SW00366

I

2

C

MULTIPLEXER

SLAVE

Figure 8. System configuration

Acknowledge

The number of data bytes transferred between the start and the stop conditions from transmitter to receiver is not limited. Each byte of eight bits

is followed by one acknowledge bit. The acknowledge bit is a HIGH-level put on the bus by the transmitter whereas the master generates an

extra acknowledge related clock pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of each byte. Also a master must generate an

acknowledge after the reception of each byte that has been clocked out of the slave transmitter. The device that acknowledges has to pull down

the SDA line during the acknowledge clock pulse, so that the SDA line is stable LOW during the HIGH period of the acknowledge related clock

pulse, set-up and hold times must be taken into account.

A master receiver must signal an end of data to the transmitter by not generating an acknowledge on the last byte that has been clocked out of

the slave. In this event, the transmitter must leave the data line HIGH to enable the master to generate a stop condition.

DATA OUTPUT

BY TRANSMITTER

SCL FROM

MASTER

SW00368

DATA OUTPUT

BY RECEIVER

1

2

8

9

S

START condition

clock pulse for

acknowledgement

acknowledge

not acknowledge

Figure 9. Acknowledgement on the I

2

C-bus

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

9

Bus transactions

A1

A0

1

2

SCL

WRITE TO

REGISTER

DATA OUT

FROM PORT

3

4

5

6

7

8

SDA

S

0

A

A

A

1

1

0

0

A2

DATA 1

slave address

data to register

start condition

R/W

acknowledge

from slave

acknowledge

from slave

acknowledge

from slave

t

pv

DATA 1 VALID

SW02000

9

B0

0

0

0

AI

B3

B2

B1

command byte

Figure 10. WRITE to register

0

0

A2

A1

A0

1

1

0

0

A0

1

1

S

0

A

A

A

acknowledge

from slave

R/W

acknowledge

from slave

A

P

NA

acknowledge

from slave

acknowledge

from master

S

DATA

DATA

R/W

first byte

at this moment master-transmitter

becomes master-receiver and

slave-receiver becomes

slave-transmitter

last byte

SW01099

no acknowledge

from master

1

slave address

data from register

data from register

slave address

auto-increment

register address

if AI = 1

A1

A2

AI B3

B0

0

0

B1

B2

0

Figure 11. READ from register

1

1

0

0

A2

A1

A0

READ FROM

PORT

DATA INTO

PORT

SDA

S

1

A

A

DATA 1

DATA 4

slave address

data from port

data from port

start condition

R/W

acknowledge

from slave

acknowledge

from master

stop

condition

t

ps

DATA 4

DATA 2

P

DATA 3

t

ph

SW01096

no acknowledge

from master

NA

DATA 1

NOTE:

1. This figure assumes the command byte has previously been programmed with 00h.

Figure 12. READ input port register

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

10

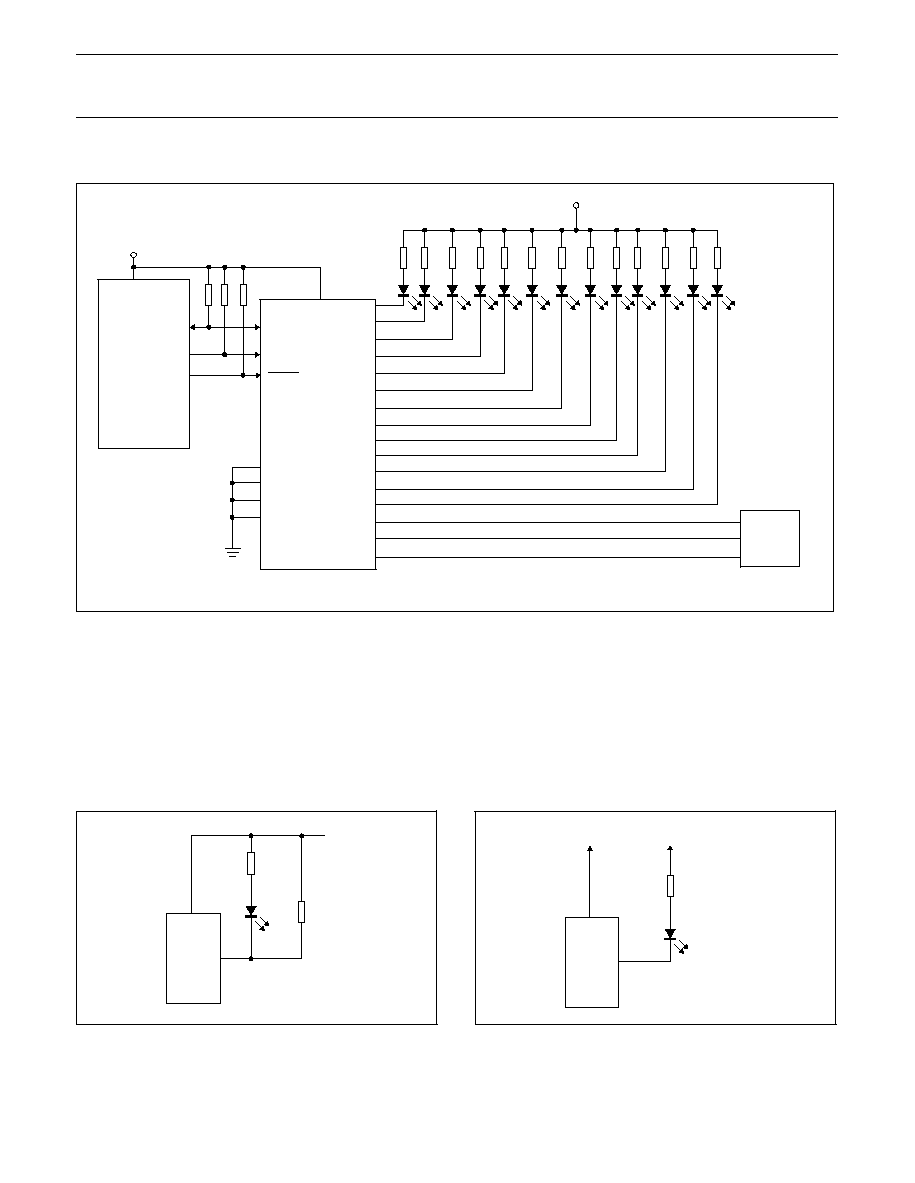

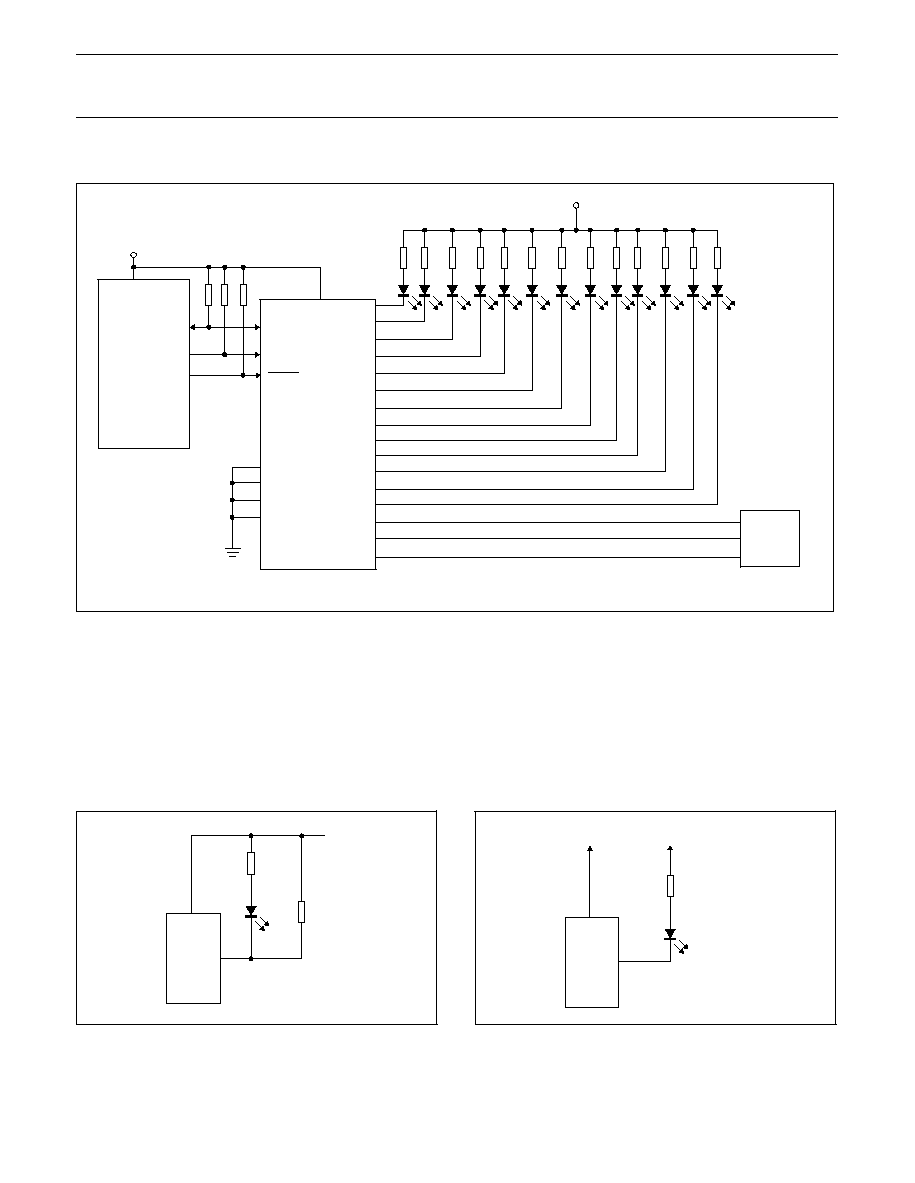

APPLICATION DATA

PCA9532

A1

A0

V

SS

SDA

SCL

RESET

V

DD

I

2

C/SMBus MASTER

SW02044

SDA

SCL

A2

LED0

LED1

LED2

LED3

LED4

LED5

LED6

LED7

5 V

5 V

LED8

LED9

LED10

LED11

LED12

LED13

LED14

LED15

GPIOs

Note: LED0 to LED12 are used as LED drivers

LED13 to LED15 are used as regular GPIOs.

Figure 13. Typical application

Minimizing I

DD

when the I/O is used to control LEDs

When the I/Os are used to control LEDs, they are normally connected to V

DD

through a resistor as shown in Figure 13. Since the LED acts as a

diode, when the LED is off the I/O V

IN

is about 1.2 V less than V

DD

. The supply current, I

DD

, increases as V

IN

becomes lower than V

DD

and is

specified as

I

DD

in the DC characteristics table.

Designs needing to minimize current consumption, such as battery power applications, should consider maintaining the I/O pins greater than or

equal to V

DD

when the LED is off. Figure 14 shows a high value resistor in parallel with the LED. Figure 15 shows V

DD

less than the LED supply

voltage by at least 1.2 V. Both of these methods maintain the I/O V

IN

at or above V

DD

and prevents additional supply current consumption when

the LED is off.

V

DD

V

DD

LEDx

LED

100 k

SW02086

Figure 14. High value resistor in parallel with the LED

V

DD

3.3 V

LEDx

LED

SW02087

5 V

Figure 15. Device supplied by a lower voltage

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

11

Programming example

The following example will show how to set LED0 to LED3 on. It will

then set LED4 and LED5 to blink at 1 Hz at a 50% duty cycle. LED6

and LED7 will be set to be dimmed at 25% of their brightness (duty

cycle = 25%). LED8 to LED15 will be set to off.

Table 1.

I

2

C-bus

Start

S

PCA9532 address with A0-A2 = LOW

C0h

PSC0 subaddress + auto-increment

12h

Set prescaler PSC0 to achieve a period of 1 second:

Blink period

+

1

+

PSC0

)

1

152

PSC0 = 151

97h

Set PWM0 duty cycle to 50%:

PWM0

256

+

0.5

PWM0 = 128

80h

Set prescaler PCS1 to dim at maximum frequency

Blink period

+

maximum

PSC1 = 0

00h

Set PWM1 output duty cycle to 25%:

PWM1

256

+

0.25

PWM1 = 64

40h

Set LED0 to LED3 on

55h

Set LED4 and 5 to PWM0, and LED6 or 7 to PWM1

FAh

Set LED8 to LED11 off

00h

Set LED12 to LED15 off

00h

Stop

P

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

12

ABSOLUTE MAXIMUM RATINGS

In accordance with the Absolute Maximum Rating System (IEC 134)

SYMBOL

PARAMETER

CONDITIONS

MIN

MAX

UNIT

V

DD

Supply voltage

-0.5

6.0

V

V

I/O

DC voltage on an I/O

V

SS

- 0.5

5.5

V

I

I/O

DC output current on an I/O

--

±

25

mA

I

SS

Supply current

--

200

mA

P

tot

Total power dissipation

--

400

mW

T

stg

Storage temperature range

-65

+150

∞

C

T

amb

Operating ambient temperature

-40

+85

∞

C

HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is desirable to take

precautions appropriate to handling MOS devices. Advice can be found in Data Handbook IC24 under "Handling MOS devices".

DC CHARACTERISTICS

V

DD

= 2.3 to 5.5 V; V

SS

= 0 V; T

amb

= -40 to +85

∞

C; unless otherwise specified. TYP at 3.3 V and 25

∞

C.

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

Supplies

V

DD

Supply voltage

2.3

--

5.5

V

I

DD

Supply current

Operating mode; V

DD

= 5.5 V; no load;

V

I

= V

DD

or V

SS

; f

SCL

= 100 kHz

--

350

550

µ

A

I

stb

Standby current

Standby mode; V

DD

= 5.5 V; no load;

V

I

= V

DD

or V

SS

; f

SCL

= 0 kHz

--

2.1

5.0

µ

A

I

DD

Additional standby current

Standby mode; V

DD

= 5.5 V; Every

LED I/O at V

IN

= 4.3 V; f

SCL

= 0 kHz

--

--

2

mA

V

POR

Power-on reset voltage

V

DD

= 3.3 V; no load; V

I

= V

DD

or V

SS

--

1.7

2.2

V

Input SCL; input/output SDA

V

IL

LOW-level input voltage

-0.5

--

0.3 V

DD

V

V

IH

HIGH-level input voltage

0.7 V

DD

--

5.5

V

I

OL

LOW-level output current

V

OL

= 0.4V

3

6.5

--

mA

I

L

Leakage current

V

I

= V

DD

= V

SS

-1

--

+1

µ

A

C

I

Input capacitance

V

I

= V

SS

--

4.4

5

pF

I/Os

V

IL

LOW-level input voltage

-0.5

--

0.8

V

V

IH

HIGH-level input voltage

2.0

--

5.5

V

V

OL

= 0.4 V; V

DD

= 2.3 V; Note 1

9

--

--

mA

V

OL

= 0.4 V; V

DD

= 3.0 V; Note 1

12

--

--

mA

V

OL

= 0.4 V; V

DD

= 5.0 V; Note 1

15

--

--

mA

I

OL

LOW-level output current

V

OL

= 0.7 V; V

DD

= 2.3 V; Note 1

15

--

--

mA

V

OL

= 0.7 V; V

DD

= 3.0 V; Note 1

20

--

--

mA

V

OL

= 0.7 V; V

DD

= 5.0 V; Note 1

25

--

--

mA

I

L

Input leakage current

V

DD

= 3.6 V; V

I

= 0 or V

DD

-1

--

1

µ

A

C

IO

Input/output capacitance

--

2.6

5

pF

Select Inputs A0, A1, A2 / RESET

V

IL

LOW-level input voltage

-0.5

--

0.8

V

V

IH

HIGH-level input voltage

2.0

--

5.5

V

I

LI

Input leakage current

-1

--

1

µ

A

C

I

Input capacitance

V

I

= V

SS

--

2.3

5

pF

NOTE:

1. Each I/O must be externally limited to a maximum of 25 mA and each octal (LED0-LED7 and LED8-LED15) must be limited to a maximum

current of 100 mA for a device total of 200 mA.

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

13

AC SPECIFICATIONS

SYMBOL

PARAMETER

STANDARD MODE

I

2

C-BUS

FAST MODE

I

2

C-BUS

UNITS

SYMBOL

PARAMETER

MIN

MAX

MIN

MAX

UNITS

f

SCL

Operating frequency

0

100

0

400

kHz

t

BUF

Bus free time between STOP and START conditions

4.7

--

1.3

--

µ

s

t

HD;STA

Hold time after (repeated) START condition

4.0

--

0.6

--

µ

s

t

SU;STA

Repeated START condition set-up time

4.7

--

0.6

--

µ

s

t

SU;STO

Setup time for STOP condition

4.0

--

0.6

--

µ

s

t

HD;DAT

Data in hold time

0

--

0

--

ns

t

VD;ACK

Valid time for ACK condition

2

--

600

--

600

ns

t

VD;DAT

(L)

Data out valid time

3

--

600

--

600

ns

t

VD;DAT

(H)

Data out valid time

3

--

1500

--

600

ns

t

SU;DAT

Data set-up time

250

--

100

--

ns

t

LOW

Clock LOW period

4.7

--

1.3

--

µ

s

t

HIGH

Clock HIGH period

4.0

--

0.6

--

µ

s

t

F

Clock/Data fall time

--

300

20 + 0.1 C

b

1

300

ns

t

R

Clock/Data rise time

--

1000

20 + 0.1 C

b

1

300

ns

t

SP

Pulse width of spikes that must be suppressed by the

input filters

--

50

--

50

ns

Port Timing

t

PV

Output data valid

--

200

--

200

ns

t

PS

Input data set-up time

100

--

100

--

ns

t

PH

Input data hold time

1

--

1

--

µ

s

Reset

t

W

Reset pulse width

10

--

10

--

ns

t

REC

Reset recovery time

0

--

0

--

ns

t

RESET

4,5

Time to reset

400

--

400

--

ns

NOTES:

1. C

b

= total capacitance of one bus line in pF.

2. t

VD;ACK

= time for Acknowledgement signal from SCL LOW to SDA (out) LOW.

3. t

VD;DAT

= minimum time for SDA data out to be valid following SCL LOW.

4. Resetting the device while actively communicating on the bus may cause glitches or errant STOP conditions.

5. Upon reset, the full delay will be the sum of t

RESET

and the RC time constant of the SDA bus.

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

14

+10%

0%

-10%

-20%

-30%

-40%

PERCENT

VARIATION

TEMPERATURE

(

∞

C)

-40

+20%

0

+25

+70

+85

MAX

AVG

MIN

SW01085

Figure 16. Typical frequency variation over process at V

DD

= 2.3 V to 3.0 V

+10%

0%

-10%

-20%

-30%

-40%

PERCENT

VARIATION

TEMPERATURE

(

∞

C)

-40

+20%

0

+25

+70

+85

MAX

AVG

MIN

SW01086

Figure 17. Typical frequency variation over process at V

DD

= 3.0 V to 5.5 V

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

15

SDA

SCL

SW01087

t

REC

t

REC

50%

30%

50%

50%

50%

t

REC

t

W

RESET

LEDx

LED OFF

ACK OR READ CYCLE

START

Figure 18. Definition of RESET timing

t

SP

t

BUF

t

HD;STA

P

P

S

t

LOW

t

R

t

HD;DAT

t

F

t

HIGH

t

SU;DAT

t

SU;STA

Sr

t

HD;STA

t

SU;STO

SDA

SCL

SU00645

Figure 19. Definition of timing

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

16

SO24:

plastic small outline package; 24 leads; body width 7.5 mm

SOT137-1

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

17

TSSOP24:

plastic thin shrink small outline package; 24 leads; body width 4.4 mm

SOT355-1

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

18

HVQFN24:

plastic thermal enhanced very thin quad flat package; no leads; 24 terminals;

body 4 x 4 x 0.85 mm

SOT616-1

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

19

REVISION HISTORY

Rev

Date

Description

_2

20030502

Product data (9397 750 11459); ECN 853-2398 29860 dated 24 April 2003.

Supersedes data of 26 February 2003 (9397 750 10874).

Modifications:

∑

Correction to voltage in typical application drawing

∑

Update note on maximum current per bit and per device

∑

Adjust minimum and maximum curves to

±

15% on frequency variation graphs.

_1

20030226

Product data (9397 750 10874); ECN 853-2398 29297 of 12 December 2002.

Philips Semiconductors

Product data

PCA9532

16-bit I

2

C LED dimmer

2003 May 02

20

Purchase of Philips I

2

C components conveys a license under the Philips' I

2

C patent

to use the components in the I

2

C system provided the system conforms to the

I

2

C specifications defined by Philips. This specification can be ordered using the

code 9398 393 40011.

Definitions

Short-form specification -- The data in a short-form specification is extracted from a full data sheet with the same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition -- Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or at any other conditions above those given

in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information -- Applications that are described herein for any of these products are for illustrative purposes only. Philips Semiconductors make no

representation or warranty that such applications will be suitable for the specified use without further testing or modification.

Disclaimers

Life support -- These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be

expected to result in personal injury. Philips Semiconductors customers using or selling these products for use in such applications do so at their own risk and agree

to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes -- Philips Semiconductors reserves the right to make changes in the products--including circuits, standard cells, and/or software--described

or contained herein in order to improve design and/or performance. When the product is in full production (status `Production'), relevant changes will be communicated

via a Customer Product/Process Change Notification (CPCN). Philips Semiconductors assumes no responsibility or liability for the use of any of these products, conveys

no license or title under any patent, copyright, or mask work right to these products, and makes no representations or warranties that these products are free from patent,

copyright, or mask work right infringement, unless otherwise specified.

Contact information

For additional information please visit

http://www.semiconductors.philips.com.

Fax: +31 40 27 24825

For sales offices addresses send e-mail to:

sales.addresses@www.semiconductors.philips.com.

Koninklijke Philips Electronics N.V. 2003

All rights reserved. Printed in U.S.A.

Date of release: 05-03

Document order number:

9397 750 11459

Philips

Semiconductors

Data sheet status

[1]

Objective data

Preliminary data

Product data

Product

status

[2] [3]

Development

Qualification

Production

Definitions

This data sheet contains data from the objective specification for product development.

Philips Semiconductors reserves the right to change the specification in any manner without notice.

This data sheet contains data from the preliminary specification. Supplementary data will be published

at a later date. Philips Semiconductors reserves the right to change the specification without notice, in

order to improve the design and supply the best possible product.

This data sheet contains data from the product specification. Philips Semiconductors reserves the

right to make changes at any time in order to improve the design, manufacturing and supply. Relevant

changes will be communicated via a Customer Product/Process Change Notification (CPCN).

Data sheet status

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at URL

http://www.semiconductors.philips.com.

[3] For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

Level

I

II

III