| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TDA1313T | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Document Outline

- FEATURES

- GENERAL DESCRIPTION

- ORDERING INFORMATION

- QUICK REFERENCE DATA

- PINNING

- FUNCTIONAL DESCRIPTION

- LIMITING VALUES

- THERMAL RESISTANCE

- CHARACTERISTICS

- QUALITY SPECIFICATION

- TEST AND APPLICATION INFORMATION

- APPLICATION INFORMATION

- PACKAGE OUTLINES

- SOLDERING

- DEFINITIONS

- LIFE SUPPORT APPLICATIONS

DATA SHEET

Objective specification

File under Integrated Circuits, IC01

July 1993

INTEGRATED CIRCUITS

TDA1313; TDA1313T

Stereo continuous calibration DAC

(CC-DAC)

July 1993

2

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

FEATURES

∑

4/8

◊

oversampling (multiplexed/simultaneous input)

possible

∑

Voltage output (capable of driving headphone)

∑

Space saving package (SO16 or DIL16)

∑

Low power consumption

∑

Wide dynamic range (16-bit resolution)

∑

Continuous Calibration concept

∑

Easy application:

≠ single 3 to 5.5 V supply rail

≠ output voltage is proportional to the supply voltage

≠ integrated current-to-voltage converter

∑

Internal bias current ensures maximum dynamic range

∑

Wide operating temperature range (

-

40

∞

C to

+

85

∞

C)

∑

Compatible with most current Japanese input format

multiplexed/simultaneous, two's complement and

CMOS)

∑

No zero crossing distortion

∑

Cost efficient

∑

High signal-to-noise ratio

∑

Low total harmonic distortion.

GENERAL DESCRIPTION

The TDA1313; 1313T is a voltage driven digital-to-analog

converter, and is of a new generation of DACs which

incorporates the innovative technique of Continuous

Calibration (CC). The largest bit-currents are repeatedly

generated from one single current reference source. This

duplication is based upon an internal charge storage

principle having an accuracy which is insensitive to

ageing, temperature and process variations.

The TDA1313; 1313T is fabricated in a 1.0

µ

m CMOS

process and features an extremely low power dissipation,

small package size and easy application. Furthermore, the

accuracy of the intrinsic high coarse-current combined

with the implemented symmetrical offset decoding method

preclude zero-crossing distortion and ensures high quality

audio reproduction. Therefore, the CC-DAC is eminently

suitable for use in (portable) digital audio equipment.

ORDERING INFORMATION

Notes

1. SOT38-1; 1996 August 15.

2. SOT109-1; 1996 August 15.

EXTENDED TYPE NUMBER

PACKAGE

PINS

PIN POSITION

MATERIAL

CODE

TDA1313

(1)

16

DIL

plastic

SOT38GG

TDA1313T

(2)

16

SO16

plastic

SOT109AG

July 1993

3

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

QUICK REFERENCE DATA

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

V

DD

supply voltage

3.0

5.0

5.5

V

I

DD

supply current

V

DD

= 5 V; at code

0000H

-

8

9.5

mA

V

FS

full scale output voltage

V

DD

= 5 V

3.8

4.2

4.6

V

(THD

+

N)/S

total harmonic distortion

plus noise

at 0 dB signal level

-

-

88

-

81

dB

-

0.004

0.009

%

at 0 dB signal level;

see Fig.8

-

-

70

-

dB

-

0.03

-

%

at

-

60 dB signal level

-

-

36

-

28

dB

-

1.6

4.0

%

at

-

60 dB; A-weighted

-

-

38

-

dB

-

1.3

-

%

S/N

signal-to-noise ratio at

bipolar zero

A-weighted at code

0000H

93

98

-

dB

t

CS

current setting time to

±

1LSB

-

0.2

-

µ

s

BR

input bit rate at data input

-

-

18.4

Mbits/s

f

BCK

clock frequency at clock

input

-

-

18.4

MHz

TC

FS

full scale temperature

coefficient at analog outputs

(V

OL

; V

OR

)

-

400

-

ppm

T

amb

operating ambient

temperature

-

40

-

+85

∞

C

P

tot

total power dissipation

V

DD

= 5 V; at code

0000H

-

40

53

mW

V

DD

= 3 V; at code

0000H

-

15

-

mW

July 1993

4

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

handbook, full pagewidth

MGE230

32 (5-BIT)

CALIBRATED

CURRENT

SOURCES

1 CALIBRATED

SPARE SOURCE

11-BIT

PASSIVE

DIVIDER

LEFT BIT SWITCHES

LEFT INPUT REGISTER

LEFT OUTPUT REGISTER

RIGHT BIT SWITCHES

RIGHT INPUT REGISTER

RIGHT OUTPUT REGISTER

32 (5-BIT)

CALIBRATED

CURRENT

SOURCES

1 CALIBRATED

SPARE SOURCE

11-BIT

PASSIVE

DIVIDER

REFERENCE

SOURCE

CONTROL

AND

TIMING

3

16

1

2

15

4

12

11

C5

100 nF

V

DDA

V

SSA

56

C4

100 nF

V

DDO

V

SSO

13

14

C3

100 nF

V

DDD

V

SSD

TDA1313

TDA1313T

BCK

4/8FSSEL

WS

SI/LSI

LRSEL/RSI

V

REF

C6

1

µ

F

8

7

C2

1 nF

V

OR

V

REF

R2

4 k

OP2

9

10

C1

1 nF

V

OL

V

REF

R1

4 k

OP1

LIN

LOUT

RIN

ROUT

Fig.1 Block diagram.

July 1993

5

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

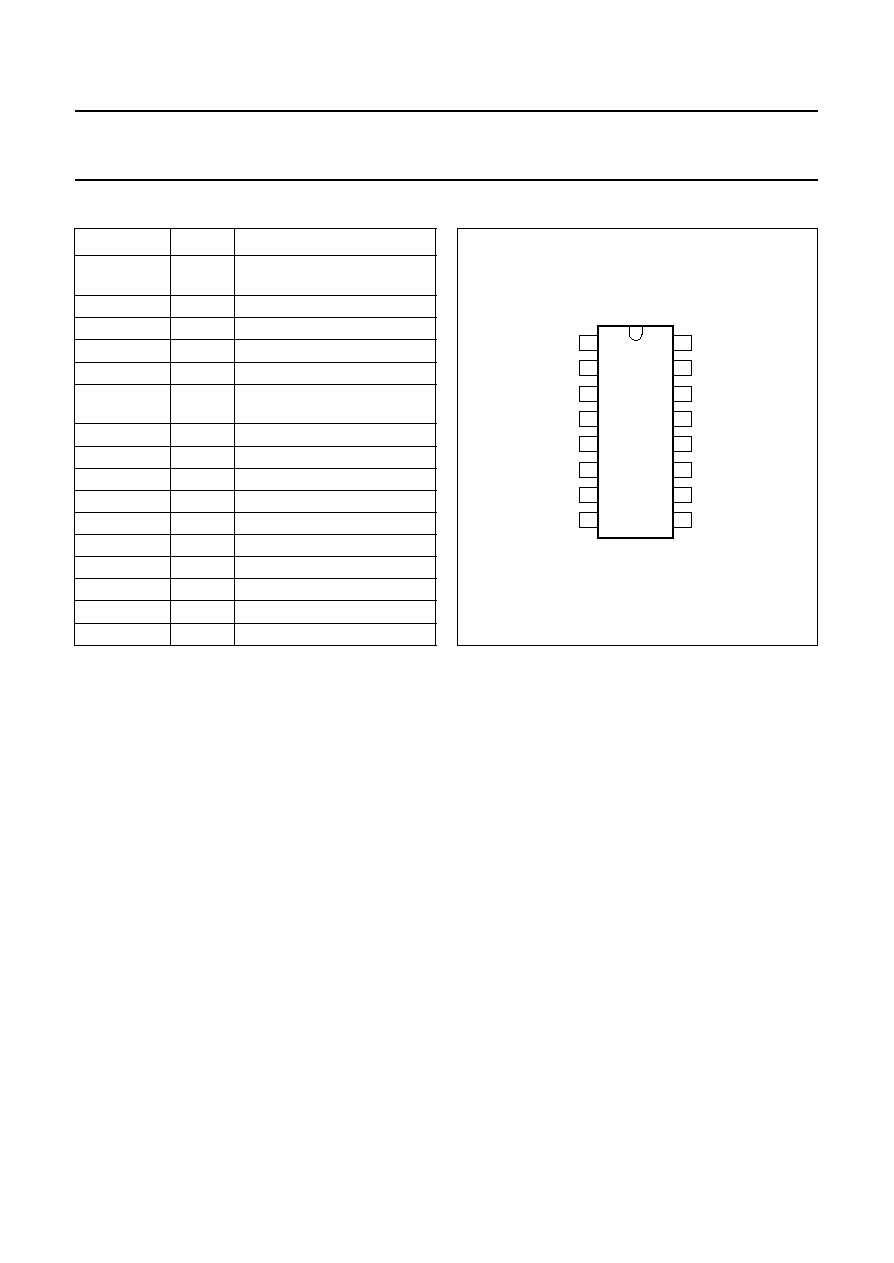

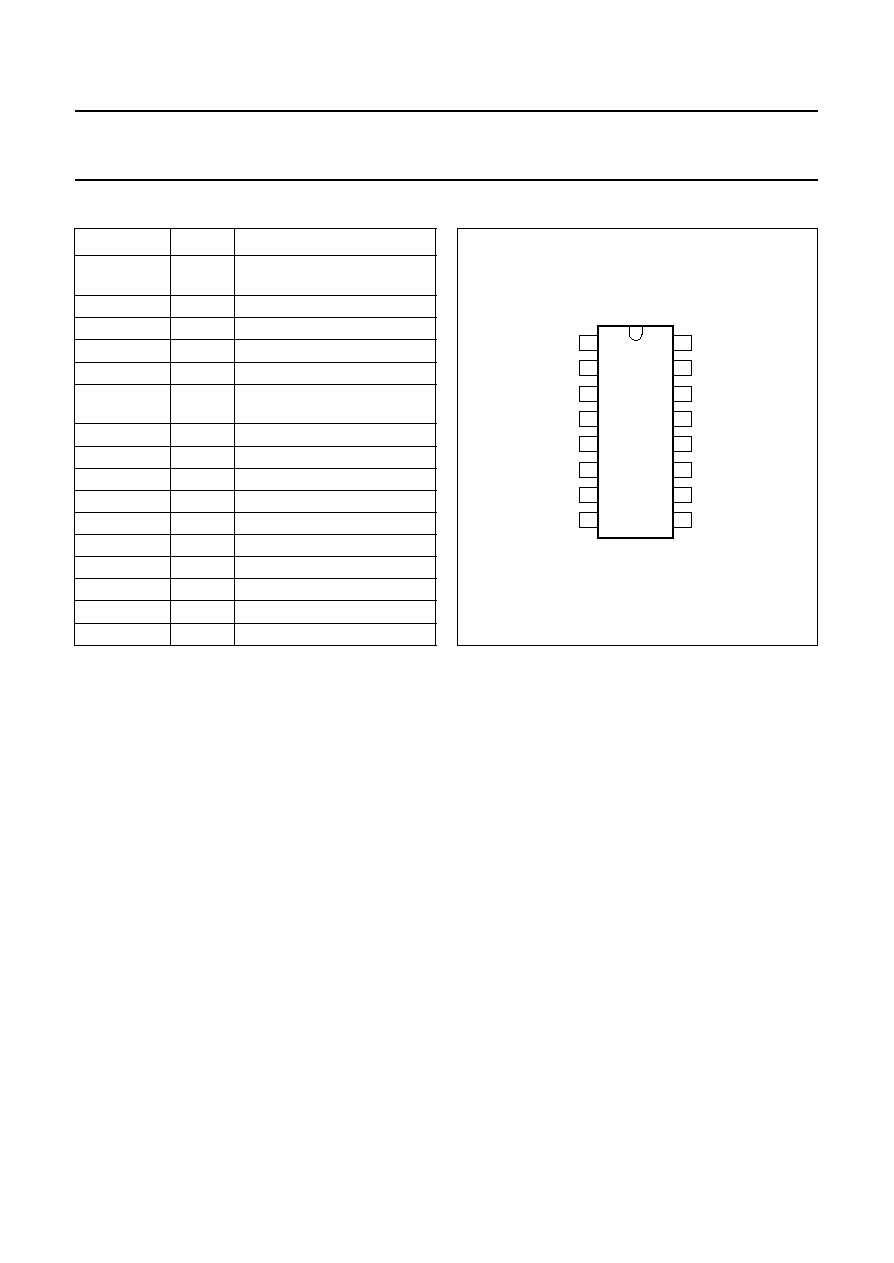

PINNING

SYMBOL

PIN

DESCRIPTION

LRSEL/RSI

1

left/right select; right serial

input

SI/LSI

2

serial input; left serial input

4/8FSSEL

3

4/8 oversampling select

V

REF

4

reference voltage output

V

SSO

5

operational amplifier ground

V

DDO

6

operational amplifier supply

voltage

RIN

7

right analog input

ROUT

8

right analog output

LOUT

9

left analog output

LIN

10

left analog input

V

DDA

11

analog supply voltage

V

SSA

12

analog ground

V

SSD

13

digital ground

V

DDD

14

digital supply voltage

WS

15

word select

BCK

16

bit clock input

Fig.2 Pin configuration.

handbook, halfpage

TDA1313

TDA1313T

MGE229

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

LRSEL/RSI

SI/LSI

4/8FSSEL

VREF

VSSO

VDDO

RIN

ROUT

LOUT

LIN

VDDA

VSSA

VSSD

VDDD

WS

BCK

FUNCTIONAL DESCRIPTION

The basic operation of the continuous calibration DAC is

illustrated in Fig.3. The figure shows the calibration and

operation cycle. During calibration of the MOS current

source (Fig.3a) transistor M1 is connected as a diode by

applying a reference current. The voltage V

gs

on the

intrinsic gate-source capacitance C

gs

of M1 is then

determined by the transistor characteristics. After

calibration of the drain current to the reference value I

REF

,

the switch S1 is opened and S2 is switched to the other

position (Fig.3b). The gate-to-source voltage V

gs

of M1 is

not changed because the charge on C

gs

is preserved.

Therefore, the drain current of M1 will still be equal to I

REF

and this exact duplicate of I

REF

is now available at the I

O

terminal.

In the TDA1313; 1313T, 32 current sources and one spare

current source are continuously calibrated (see Fig.1).

The spare current source is included to allow continuous

converter operation. The output of one calibrated source is

connected to an 11-bit binary current devider which

consists of 2048 transistors. A symmetrical offset

decoding principle is incorporated and arranges the bit

switching in such a way that the zero-crossing is

performed by switching only the LSB currents.

The TDA1313; T (CC-DAC) accepts serial input data

format of 16 bit word length. The most significant bit (bit 1)

must always be first. The timing is illustrated in Fig.4 and

the input data formats are illustrated in Figs 5 and 6.

Data is placed in the right and left input registers (Fig.1).

The data in the input registers is simultaneously latched to

the output registers which control the bit switches.

V

REF

and V

FS

are proportional to V

DD

.

Where: V

DD1

/V

DD2

= V

FS1

/V = V

REF1

/V

REF2

July 1993

6

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

Table 1

Mode application

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

Notes

1. Human body model: C = 100 pF; R = 1500

; 3 zaps positive and negative.

2. Machine model: C = 200 pF; L = 0.5

µ

H; R = 10

; 3 zaps positive and negative.

THERMAL RESISTANCE

4/8FSSEL

LRSEL/RSI

MODE

FIGURE

0

1

4FS/left = HIGH

6

0

0

4FS/left = LOW

6

1

data right

8FS

5

SYMBOL

PARAMETER

CONDITIONS

MIN.

MAX.

UNIT

V

DD

supply voltage

-

6.0

V

T

XTAL

maximum crystal temperature

-

+150

∞

C

T

stg

storage temperature

-

55

+150

∞

C

T

amb

operating ambient temperature

-

40

+85

∞

C

V

ES

electrostatic handling

note 1

-

2000

+2000

V

note 2

-

200

+200

V

SYMBOL

PARAMETER

THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air

DIL16

75 K/W

SO16

120 K/W

Fig.3 Calibration principle; (a) calibration (b) operation.

handbook, halfpage

MGE231

Cgs

S1

M1

(a)

(b)

Vgs

S2

IREF

IO

+

Cgs

S1

M1

Vgs

S2

IREF

IREF

IO

+

July 1993

7

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

CHARACTERISTICS

V

DDD

= V

DDA

= V

DDO

= 5 V; T

amb

= 25

∞

C; measured in Fig.7; unless otherwise specified.

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

Supply

V

DD

supply voltage

3.0

5.0

5.5

V

I

DD

total supply current

at code 0000H

-

8.0

9.5

mA

I

DDD

digital supply current

at code 0000H; no clock

running

-

0.2

-

mA

I

DDA

analog supply current

-

4.6

5.5

mA

I

DDO

operational amplifier supply

-

3.4

4

mA

current

PSRR

power supply ripple rejection

at code 0000H; note 1

-

30

-

dB

Digital inputs; pins WS, BCK, 4/8FSSEL, LRSEL/RSI and SI/LSI

I

IL

input leakage current LOW

V

I

= 0.V

-

-

10

µ

A

I

IH

input leakage current HIGH

V

I

= 5.5 V

-

-

10

µ

A

f

BCK

clock frequency

-

-

18.4

MHz

BR

bit rate data input

-

-

18.4

Mbits/s

f

WS

word select input frequency

-

-

384

kHz

Timing (see Fig.4)

t

r

rise time

-

-

12

ns

t

f

fall time

-

-

12

ns

t

CY

bit clock cycle time

54

-

-

ns

t

BCKH

bit clock pulse width HIGH

15

-

-

ns

t

BCKL

bit clock pulse width LOW

15

-

-

ns

t

SU;DAT

data set-up time

12

-

-

ns

t

HD:DAT

data hold time to bit clock

10

-

-

ns

t

HD:WS

word select hold time

10

-

-

ns

t

SU;WS

word select set-up time

12

-

-

ns

July 1993

8

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

Notes

1. V

ripple

= 1% of the supply voltage; f

ripple

= 100 Hz.

2. Measured with 1 kHz sinewave generated at a sampling rate of 384 kHz.

QUALITY SPECIFICATION

In accordance with UZW-BO/FQ-0601.

Analog outputs; pins V

OL

and V

OR

V

FS

full-scale voltage

3.8

4.2

4.6

V

TC

FS

full-scale temperature

coefficient

-

±

400

-

ppm

R

L

load resistance

3

-

-

k

C

L

load capacitance

-

-

200

pF

V

REF

reference output voltage

3.16

3.33

3.5

V

V

DC

output DC voltage

2.25

2.5

2.75

V

(THD+N)/S

total harmonic distortion plus

noise

at 0 dB signal level; note 2

-

-

88

-

81

dB

-

0.004

0.009

%

at 0 dB signal level; see

-

-

70

-

dB

Fig.8

-

0.03

-

%

at

-

60 dB signal level;

note 2

-

-

36

-

28

dB

-

1.6

4.0

%

at

-

60 dB signal level;

A-weighted; note 2

-

-

38

-

dB

-

1.3

-

%

at 0 dB signal level;

f = 20 Hz to 20 kHz

-

-

84

-

70

dB

-

0.006

0.03

%

t

cs

current settling time to

±

1

LSB

-

0.2

-

µ

s

channel separation

86

95

-

dB

see Fig.8

-

70

-

dB

I

O

unbalance between outputs

note 2

-

0.2

0.3

dB

t

d

time delay between outputs

-

±

0.2

-

µ

s

S/N

signal-to-noise ratio at

bipolar zero

A-weighted; at code 0000H

93

98

-

dB

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX.

UNIT

July 1993

9

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

TEST AND APPLICATION INFORMATION

Fig.4 Timing of input signals.

handbook, full pagewidth

MGE234

tCY

>

54

SAMPLE OUT

MSB

LSB

DATAR

DATAL

BCK

WS

tf

<

12

tr

<

12

tLB

>

15

tHB

>

15

tHD; WS

>

10

tSU; DAT

>

12

tHD; DAT

>

10

tSU; WS

>

12

July 1993

10

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

MGE235

RSI

LSI

BCK

WS

MSB

LSB

SAMPLE OUT

Fig.5 Format of input signals at 8FS.

MGE236

WS if

LRSEL

=

0

WS if

LRSEL

=

1

BCK

SI

MSB

LSB

MSB

LSB

LEFT

LEFT

RIGHT

RIGHT

SAMPLE OUT

Fig.6 Format of input signals at 4FS.

July 1993

11

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

APPLICATION INFORMATION

Fig.7 TDA1313T as line driver with 3 k

/200 pF load.

handbook, full pagewidth

MGE232

3

k

3

16

1

2

15

4

12

11

100 nF

VDDA

5

6

100 nF

VDDO

13

14

100 nF

VDDD

22

µ

F

8

7

9

10

1 nF

VOUTR

TDA1313T

200

pF

3

k

1 nF

VOUTL

200

pF

Fig.8 TDA1313T as headphone driver with 32

load.

handbook, full pagewidth

MGE233

8.2

k

8.2

k

32

32

3

16

1

2

15

4

12

11

100 nF

VDDA

5

6

100 nF

VDDO

13

14

100 nF

VDDD

100

µ

F

100

µ

F

22

µ

F

8

7

9

10

2

nF

2

nF

VOUTL

VOUTR

TDA1313T

July 1993

12

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

PACKAGE OUTLINES

UNIT

A

max.

1

2

b

1

c

E

e

M

H

L

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC

JEDEC

EIAJ

mm

inches

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

SOT38-1

92-10-02

95-01-19

A

min.

A

max.

b

max.

w

M

E

e

1

1.40

1.14

0.055

0.045

0.53

0.38

0.32

0.23

21.8

21.4

0.86

0.84

6.48

6.20

0.26

0.24

3.9

3.4

0.15

0.13

0.254

2.54

7.62

0.30

8.25

7.80

0.32

0.31

9.5

8.3

0.37

0.33

2.2

0.087

4.7

0.51

3.7

0.15

0.021

0.015

0.013

0.009

0.01

0.10

0.020

0.19

050G09

MO-001AE

M

H

c

(e )

1

M

E

A

L

seating plane

A

1

w

M

b

1

e

D

A

2

Z

16

1

9

8

b

E

pin 1 index

0

5

10 mm

scale

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

(1)

(1)

D

(1)

Z

DIP16: plastic dual in-line package; 16 leads (300 mil); long body

SOT38-1

July 1993

13

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

X

w

M

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

e

c

L

v

M

A

(A )

3

A

8

9

1

16

y

pin 1 index

UNIT

A

max.

A

1

A

2

A

3

b

p

c

D

(1)

E

(1)

(1)

e

H

E

L

L

p

Q

Z

y

w

v

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC

JEDEC

EIAJ

mm

inches

1.75

0.25

0.10

1.45

1.25

0.25

0.49

0.36

0.25

0.19

10.0

9.8

4.0

3.8

1.27

6.2

5.8

0.7

0.6

0.7

0.3

8

0

o

o

0.25

0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1.0

0.4

SOT109-1

91-08-13

95-01-23

076E07S

MS-012AC

0.069

0.0098

0.0039

0.057

0.049

0.01

0.019

0.014

0.0098

0.0075

0.39

0.38

0.16

0.15

0.050

1.05

0.041

0.24

0.23

0.028

0.020

0.028

0.012

0.01

0.25

0.01

0.004

0.039

0.016

0

2.5

5 mm

scale

SO16: plastic small outline package; 16 leads; body width 3.9 mm

SOT109-1

July 1993

14

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

"IC Package Databook" (order code 9398 652 90011).

DIP

S

OLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260

∞

C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300

∞

C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400

∞

C, contact may be up to 5 seconds.

SO

R

EFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250

∞

C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45

∞

C.

W

AVE SOLDERING

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

∑

A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

∑

The longitudinal axis of the package footprint must be

parallel to the solder flow.

∑

The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260

∞

C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150

∞

C within

6 seconds. Typical dwell time is 4 seconds at 250

∞

C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

R

EPAIRING SOLDERED JOINTS

Fix the component by first soldering two diagonally-

opposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300

∞

C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320

∞

C.

July 1993

15

Philips Semiconductors

Objective specification

Stereo continuous calibration DAC

(CC-DAC)

TDA1313; TDA1313T

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification

This data sheet contains target or goal specifications for product development.

Preliminary specification

This data sheet contains preliminary data; supplementary data may be published later.

Product specification

This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.