3-27

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Preliminary

Product Description

Ordering Information

Typical Applications

Features

Functional Block Diagram

RF Micro Devices, Inc.

7625 Thorndike Road

Greensboro, NC 27409, USA

Tel (336) 664 1233

Fax (336) 664 0454

http://www.rfmd.com

Optimum Technology MatchingÆ Applied

Si BJT

GaAs MESFET

GaAs HBT

Si Bi-CMOS

¸

SiGe HBT

Si CMOS

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SHDNB

TX EN

NC

VIN

VINB

VCC

VCC

RAMP

GND

NC

NC

VOUT

VOUTB

SDA

CS

SCLK

Power

Control

Gain Control

and Serial Bus

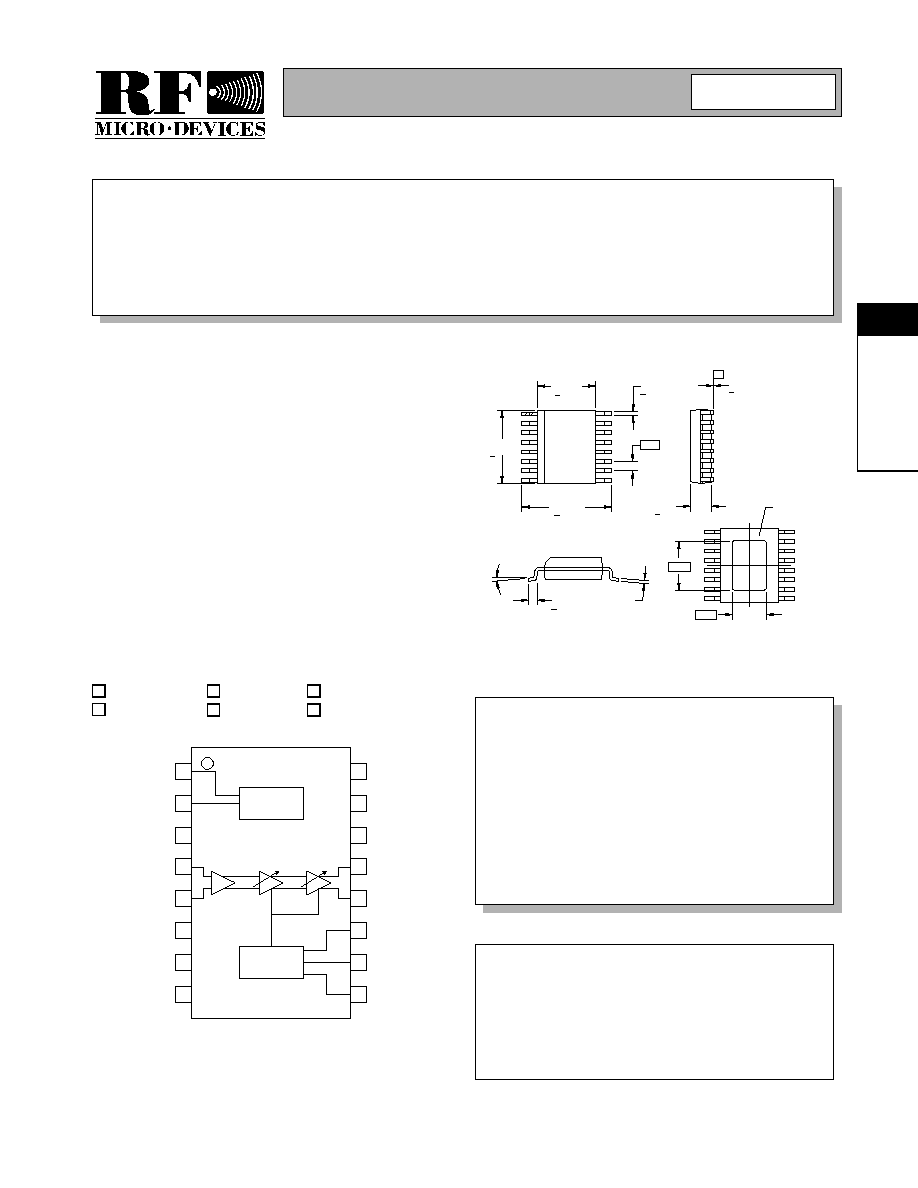

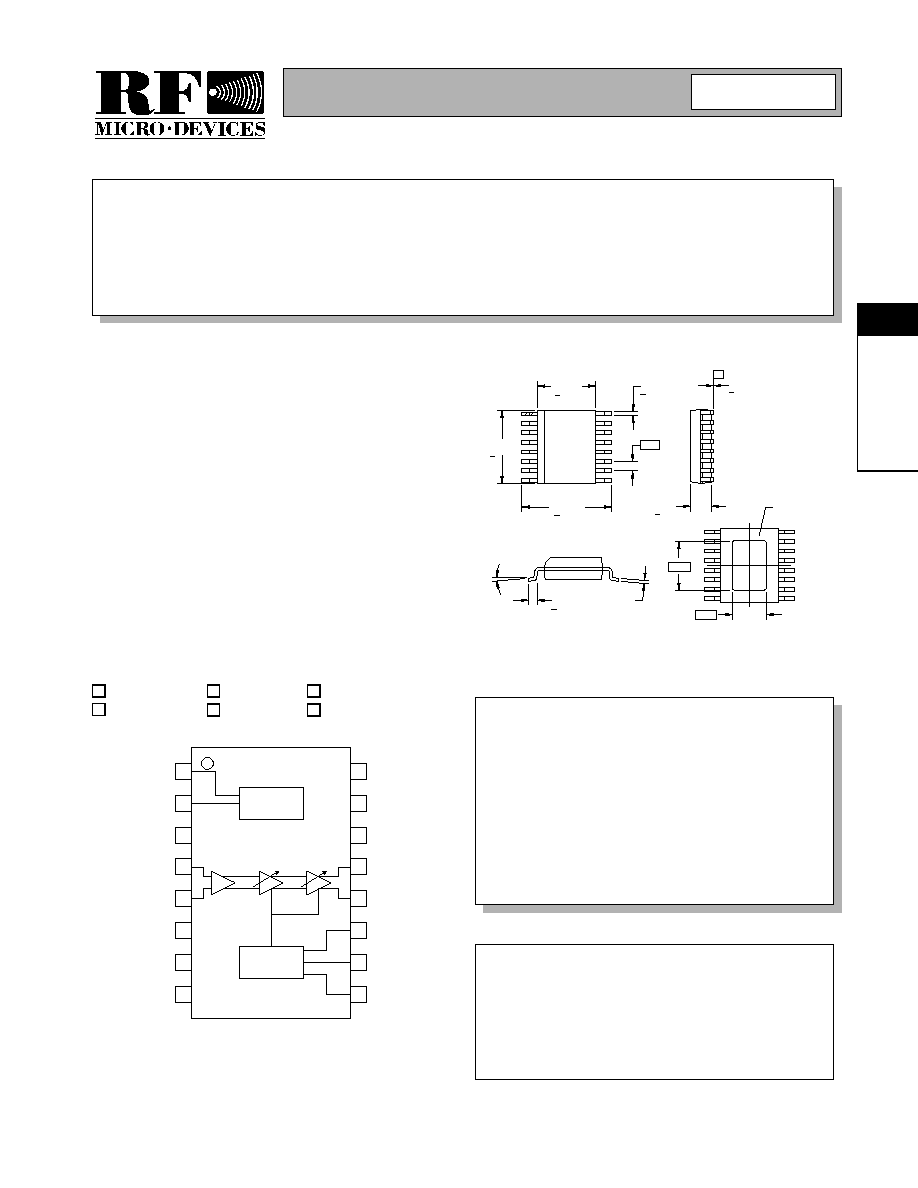

RF3320

CABLE REVERSE PATH

PROGRAMMABLE GAIN AMPLIFIER

∑ Euro-DOCSIS/DOCSIS Cable Modems

∑ CATV Set-Top Boxes

∑ Telephony Over Cable

∑ Home Networks

∑ Automotive/Mobile Multimedia

∑ Coaxial and Twisted Pair Line Driver

The RF3320 is a variable gain amplifier for use in CATV

reverse path (upstream) applications. It is DOCSIS-com-

pliant for use in cable modems. The gain control covers a

58dB range and is serially programmable via three-wire

digital bus for compatibility with standard baseband

chipsets. Amplifier shutdown and transmit disable modes

are software- and hardware-controlled. The device is

placed into software-shutdown mode via the serial control

bus. The device operates over the frequency band of

5 MHz to 65MHz for use in current U.S. and European

systems. The amplifier delivers up to 60dBmV at the out-

put of the balun. Gain is controllable in accurate 1 dB

steps. The device is provided in a thermally enhanced,

exposed die flag package.

∑ Single 5V Supply

∑ Differential Input and Output

∑ -30dB to +28dB Voltage Gain Range

∑ 5MHz to 65MHz Operation

∑ Sophisticated Power Management

∑ DOCSIS 1.1 RF Compliant

RF3320

Cable Reverse Path Programmable Gain Amplifier

RF3320 PCBA

Fully Assembled Evaluation Board

3

Rev A10 010514

NOTES:

1. Shaded lead is pin 1.

2. Lead coplanarity - 0.10 with

respect to datum "A".

3. Lead standoff is specified from

the lowest point on the package

underside.

8∞ MAX

0∞ MIN

0.60

+ 0.15

0.24

0.20

3.90

+ 0.10

0.25

+ 0.05

0.65

6.00

+ 0.20

4.90

+ 0.20

EXPOSED DIE

FLAG

3.302

2.286

1.40

+ 0.10

0.05

+ 0.05

Note 3

-A-

Package Style: SSOP-16 EDF Slug

Preliminary

3-28

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Absolute Maximum Ratings

Parameter

Rating

Unit

Supply Voltage

-0.5 to +6.0

V

DC

Input RF Level

12

dBm

Operating Ambient Temperature

-40 to +85

∞C

Storage Temperature

-40 to +150

∞C

Humidity

80

%

Maximum Power Dissipation

0.5

W

Maximum T

J

150

∞C

Parameter

Specification

Unit

Condition

Min.

Typ.

Max.

Overall

V

CC

= 4.75V to 5.25V, TXEN= SHDNB =1,

V

IN

=30dBmV (rms) differential, output

impedance= 75

through a 2:1 transformer.

Typical performance is at T

A

= +25∞C,

V

CC

=5V.

DC Specifications

Supply Voltage

4.75

5.0

5.25

V

Supply Current

Maximum Gain

130

160

mA

Gain Control Word= 58

Low Gain

65

105

mA

Gain Control Word<35

Transmit Disable

25

35

mA

TXEN= 0

Software-Shutdown

3

5

mA

Bit 7 of gain control word FALSE

Sleep

0.05

mA

SHDNB= 0

Logic High Voltage

2

V

Logic Low Voltage

0.8

V

Logic Leakage Current

-1

1

µ

A

AC Specifications

Voltage Gain

Maximum

27

28

dB

5MHz to 42MHz; Gain Control Word= 58

26

dB

42MHz to 65MHz; Gain Control Word= 58

Minimum

-30

-29

dB

5MHz to 42MHz; Gain Control Word= 0

-28

dB

42MHz to 65MHz; Gain Control Word=0

3dB Bandwidth

100

MHz

Intended operating range is 5MHz to

65MHz.

1dB Compression Point

66

dBmV

Maximum Input Level

34

dBmV(rms)

Modulated. To meet distortion specifications.

Maximum Output Level

60

dBmV(rms)

Modulated. Into 75

load at balun output, all

distortion tones < -50dBc.

ACPR

-59

-47

dBc

V

IN

=34dBmV (rms); QPSK modulation;

Symbol rate= 160ksps (2 bits per symbol);

20-bit PRBS (pseudo-random bit stream);

0.25 alpha root cosine filter

Output IM3

-58

-55

dBc

Tones at 40MHz and 40.2MHz,

V

OUT

= +54dBmV/tone, maximum gain, OIP3

is therefore +84dBmV, IIP3 is 58dBmV.

Output Third Harmonic

Distortion

F =20MHz, V

OUT

= 59dBmV

-60

-55

dBc

Maximum Gain, CW

F =65MHz, V

OUT

= 59dBmV

-55

-50

dBc

Maximum Gain, CW

Output Second Harmonic

Distortion

F =20MHz, V

OUT

=59dBmV

-70

-60

dBc

Maximum Gain

F =65MHz, V

OUT

=59dBmV

-70

-60

dBc

Maximum Gain

Caution! ESD sensitive device.

RF Micro Devices believes the furnished information is correct and accurate

at the time of this printing. However, RF Micro Devices reserves the right to

make changes to its products without notice. RF Micro Devices does not

assume responsibility for the use of the described product(s).

Preliminary

3-29

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Note 1: The enable time is determined by the value of the capacitor on pin 8 (RAMP). A higher capacitor value will

increase the enable time, but will reduce the transient voltage.

Parameter

Specification

Unit

Condition

Min.

Typ.

Max.

AC Specifications, cont'd

Output Step Size

0.8

1.0

1.1

dB

Isolation in Transmit Disable

Mode

-80

-95

dBc

Maximum Gain, 20MHz

Output Noise

Maximum Gain

-37

-30

dBmV/

160kHz

-96dBc for a 59dBmV carrier in a 160kHz

bandwidth.

Minimum Gain

-55

-50

dBmV/

160kHz

-64dBc for an 8dBmV carrier in a 160kHz

bandwidth.

Transmit Disabled

-75

-70

dBmV/

160kHz

TXEN =0

TX EN Enable Time

0.5

1.0

µ

S

Time for gain to reach 99% of final value.

See Note 1.

TX EN Transient Duration

2.4

3.0

µ

S

See Note 1.

Output Switching Transients

5

10

mV

P-P

Maximum Gain

3

5

mV

P-P

Minimum Gain

Output Impedance

255

300

345

Chip output impedance is nominally 300

.

Differential to single-ended output conver-

sion to 75

is performed in a balun with a

2:1 turns ratio, corresponding to a 4:1 imped-

ance ratio.

Input Impedance

75

Differential

Thermal

Theta

JC

28

∞C/W

Preliminary

3-30

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

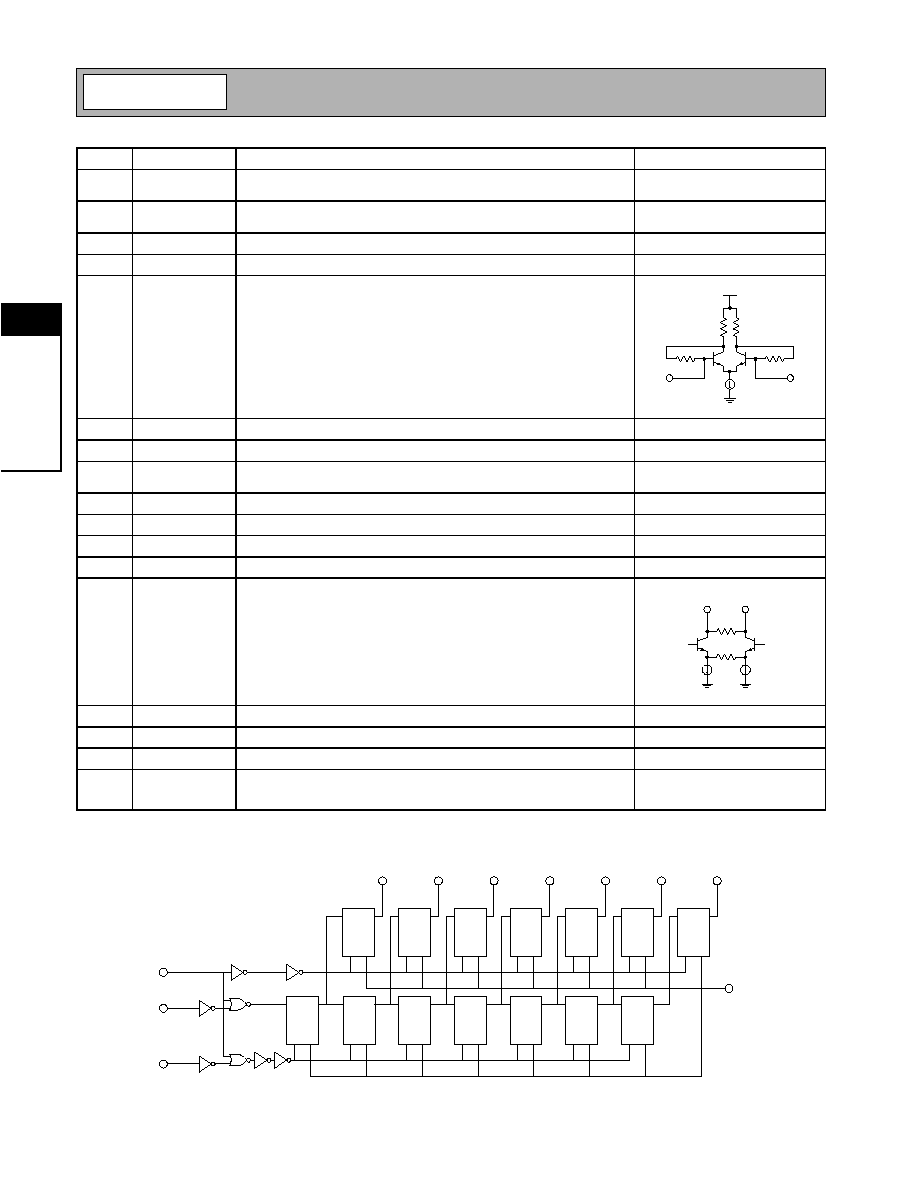

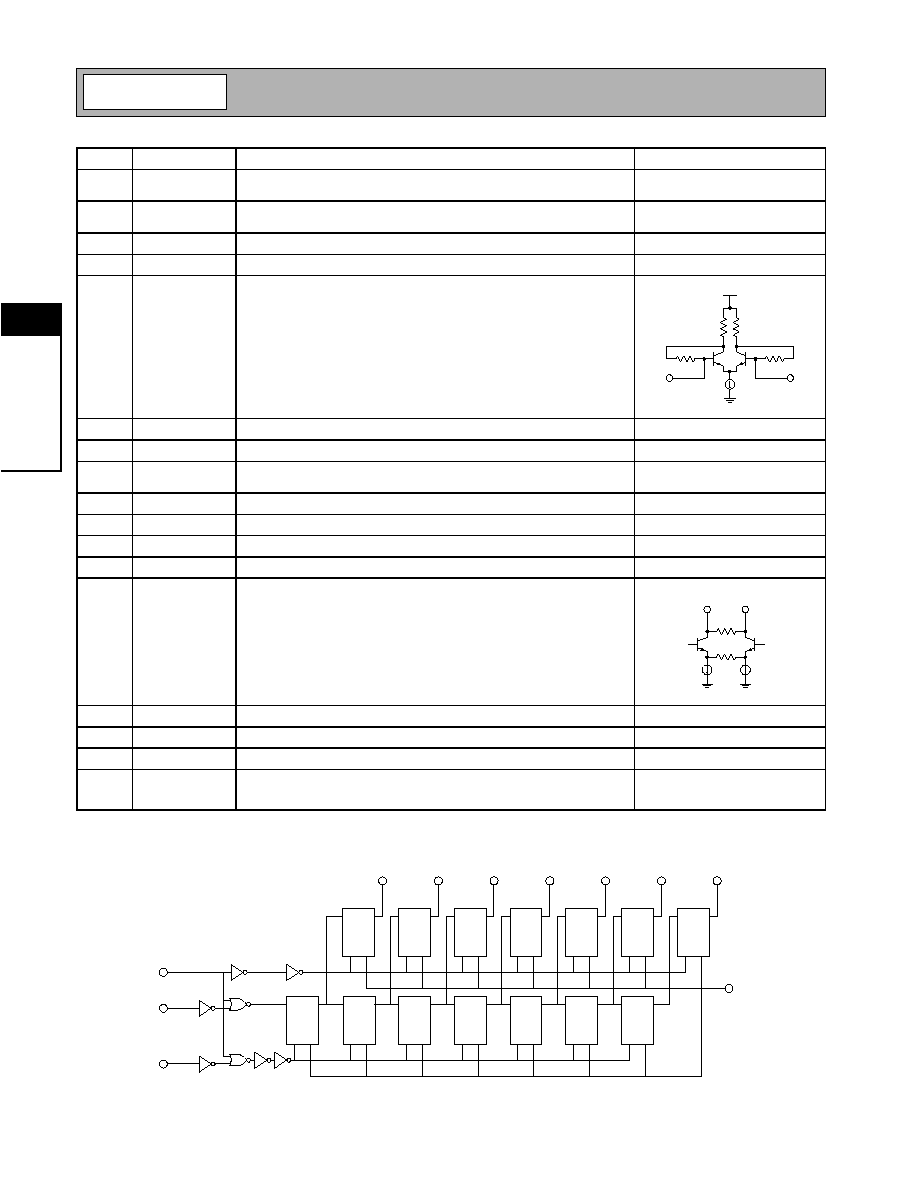

Serial Bus Block Diagram

Pin

Function

Description

Interface Schematic

1

SHDNB

Chip shutdown pin. Forcing a logic low causes all circuits to switch off

and gain settings to be lost.

2

TX EN

Signal path enable pin. Logic high turns on signal path. Logic low turns

off signal path, but leaves serial bus active.

3

NC

Not connected. This pin should be grounded.

4

VIN

Input pin. This should be externally AC-coupled to signal source.

See pin 5.

5

VINB

Complementary input pin. This should be externally coupled to signal

source. For single-ended use, this pin should be AC-coupled to ground.

6

VCC

This pin is connected to the supply voltage.

7

VCC

Same as pin 6.

8

RAMP

An external capacitor between this pin and ground controls turn-on

time.

9

SCLK

Serial bus clock input.

10

CS

Serial bus enable.

11

SDA

Serial bus data input.

12

VOUTB

Open collector output. Connect to VCC via balun primary.

See pin 13.

13

VOUT

Open collector output. Connect to VCC via balun primary.

14

NC

Same as pin 3.

15

NC

Same as pin 3.

16

GND

Connect to ground.

PKG

BASE

GND

Die is mounted on a heat sink slug that should be connected to ground.

Device grounds are internally bonded to the slug.

550

550

V

CC

500

500

V

INB

V

IN

300

V

OUT

V

OUTB

RE

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D

CK

Q

CLR

D0

D1

D2

D3

D4

D5

D6

POR

CS

SDA

SCLK

Preliminary

3-31

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Table 1. Serial Interface Control Word Format

Serial Bus Timing Diagram

Table 2. Timing Data

Table 3. Programming State

Bit

Mnemonic

Description

MSB 6

D6

Sleep Mode (Software Shutdown)

5

D5

Gain Control, Bit MSB

4

D4

Gain Control, Bit 4

3

D3

Gain Control, Bit 3

2

D2

Gain Control, Bit 2

1

D1

Gain Control, Bit 1

LSB 0

D0

Gain Control, Bit LSB

Parameter

Symbol

Min

Typ

Max

Units

SCLK Pulsewidth

T

WH

50

ns

SCLK Period

T

C

100

ns

Setup Time, SDA versus S CLK

T

DS

10

ns

Setup Time, CS versus S CLK

T

ES

10

ns

Hold Time, SDA versus S CLK

T

DH

20

ns

Hold Time, CS versus S CLK

T

EH

20

ns

SCLK Pulsewidth, High

T

DATAH

50

ns

SCLK Pulsewidth, Low

T

DATAL

50

ns

TX

SHDND

MSB6

Enter Sleep Mode

X

H

L

H= High Voltage Logic

Exit Sleep Mode

X

H

H*

L=Low Voltage Logic

Enter Shutdown

X

L

X

X =Don't Care

Exit Shutdown

X

H

H*

*Gain Control Data Must be Re-Sent

TX Enable

H

X

X

TX Disable

L

X

X

D0

D1

D2

D3

D4

D5

D6

T

ES

T

DS

T

DH

T

EH

T

WH

T

C

T

DATAH

,T

DATAL

CS

SCLK

SDA

(Data)

Preliminary

3-32

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Typical Application Schematic

10 nF

10 nF

VIN

VINB

SDA

CS

SCLK

SHDNB

4:1

100 pF

VOUT

V

CC1

V

CC2

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Power

Control

Gain Control

and Serial Bus

PACKAGE BASE

220 pF

TXEN

Preliminary

3-33

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

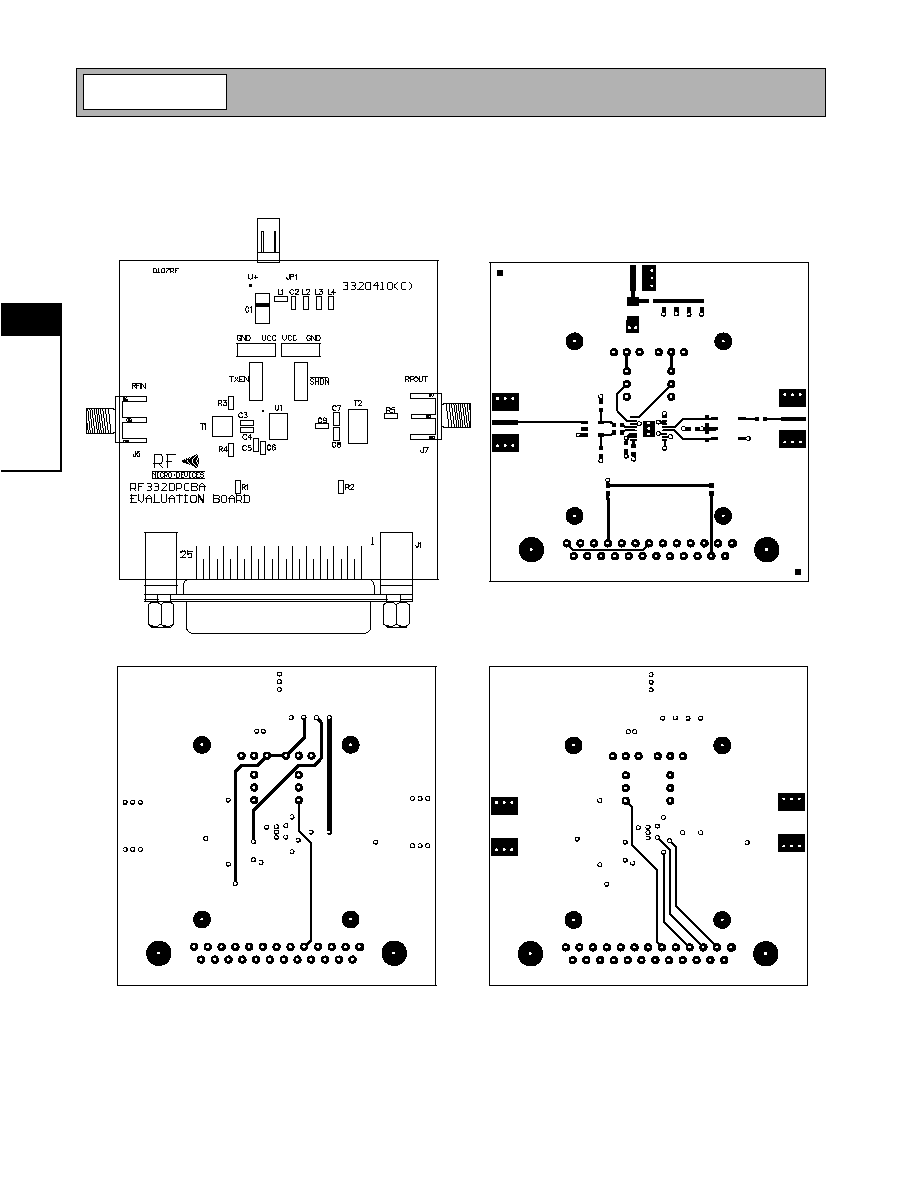

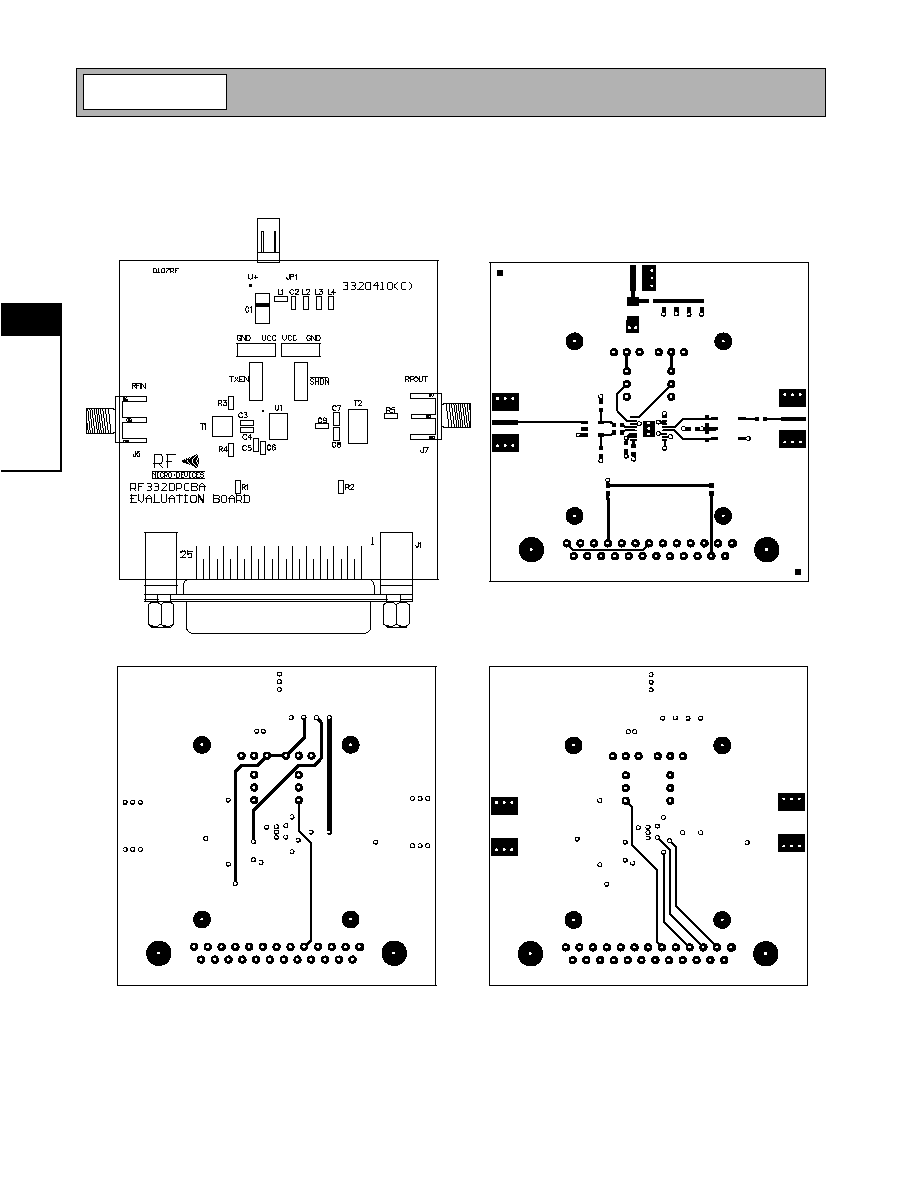

Evaluation Board Schematic

PCB Layout Considerations

The RF3320 Evaluation board can be used as a guide for the layout in your application. Care should be taken in laying

out the RF3320 in other applications. The RF3320 will have similar results if the following guidelines are taken into con-

sideration:

∑

Make sure underside of package is soldered to a good ground on the PCB.

∑

Keep input and output traces as short as possible.

∑

Ensure a good ground plane by using multiple vias to the ground plane.

∑

Use a low noise power supply along with decoupling capacitors.

C3

1 nF

C4

1 nF

T2

4:1

C9

100 pF

C8

15 pF

C7

15 pF

R5

24

J7

RF OUT

VCC2

T1

1:1

R4

75

R3

75

J6

RF IN

VCC1

C5

0.1

µ

F

SDA

CS

SCLK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

R1

100 k

R2

100 k

VCC

NC

CS

SDA

SCLK

SHDNB

TXEN

NC

NC

GND

GND

GND

GND

GND

GND

GND

GND

VCC

VCC

NC

NC

NC

NC

NC

NC

CS

SDA

J5-1

J3-1

SCLK

J1

J3

1

2

3

J1-6

TXEN

J2

1

2

3

VCC

GND

J5

1

2

3

J1-5

SHDNB

J4

1

2

3

VCC

GND

JP1

1

2

VCC

GND

+

C2

1 nF

L1 (Ferrite)

30

C1

10

µ

F

(10 V)

L3 (Ferrite)

30

L4 (Ferrite)

30

L2 (Ferrite)

30

VCC

VCC1

VCC2

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Power

Control

Gain Control

and Serial Bus

PACKAGE BASE

C6

220 pF

Notes:

1. 4-layer board.

2. Underside of package must solder to ground.

3. Place C5 and C6 as close to pin as possible.

4. C1 is tantalum, size code Y.

5. All other components are 0603 size.

6. Replace R5 with 0

resistor if 75

connector is used.

3320400B

Preliminary

3-34

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Evaluation Board Layout

Board Size 2.5" x 2.5"

Board Thickness 0.058", Board Material FR-4

Preliminary

3-35

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

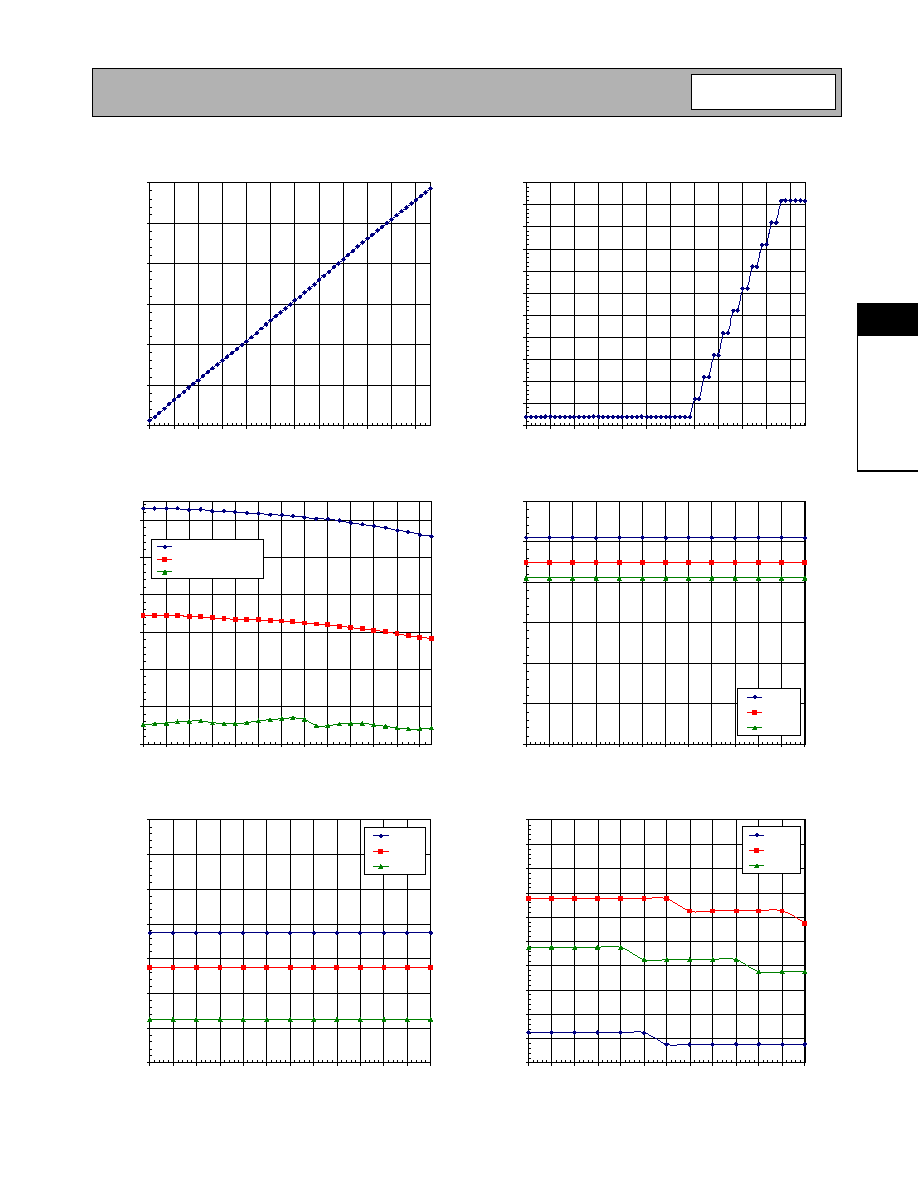

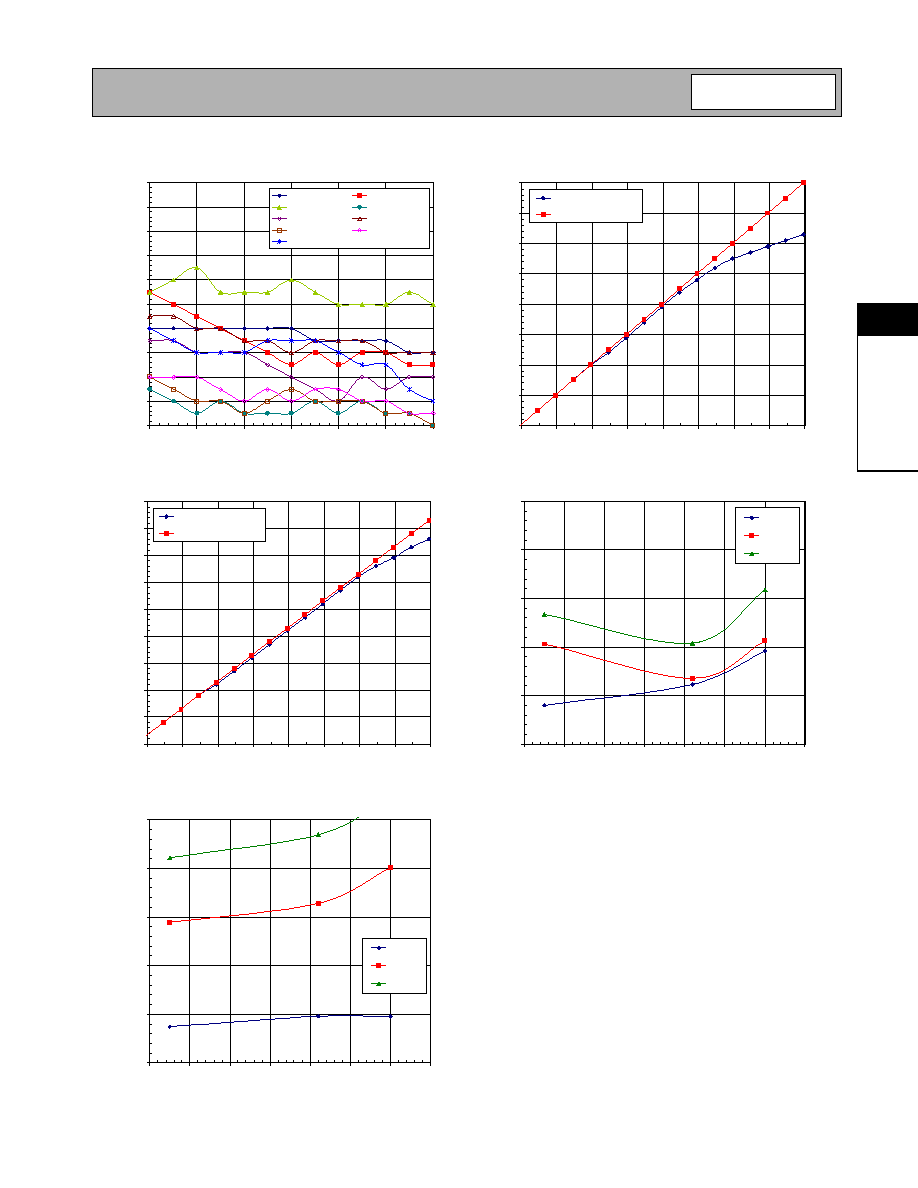

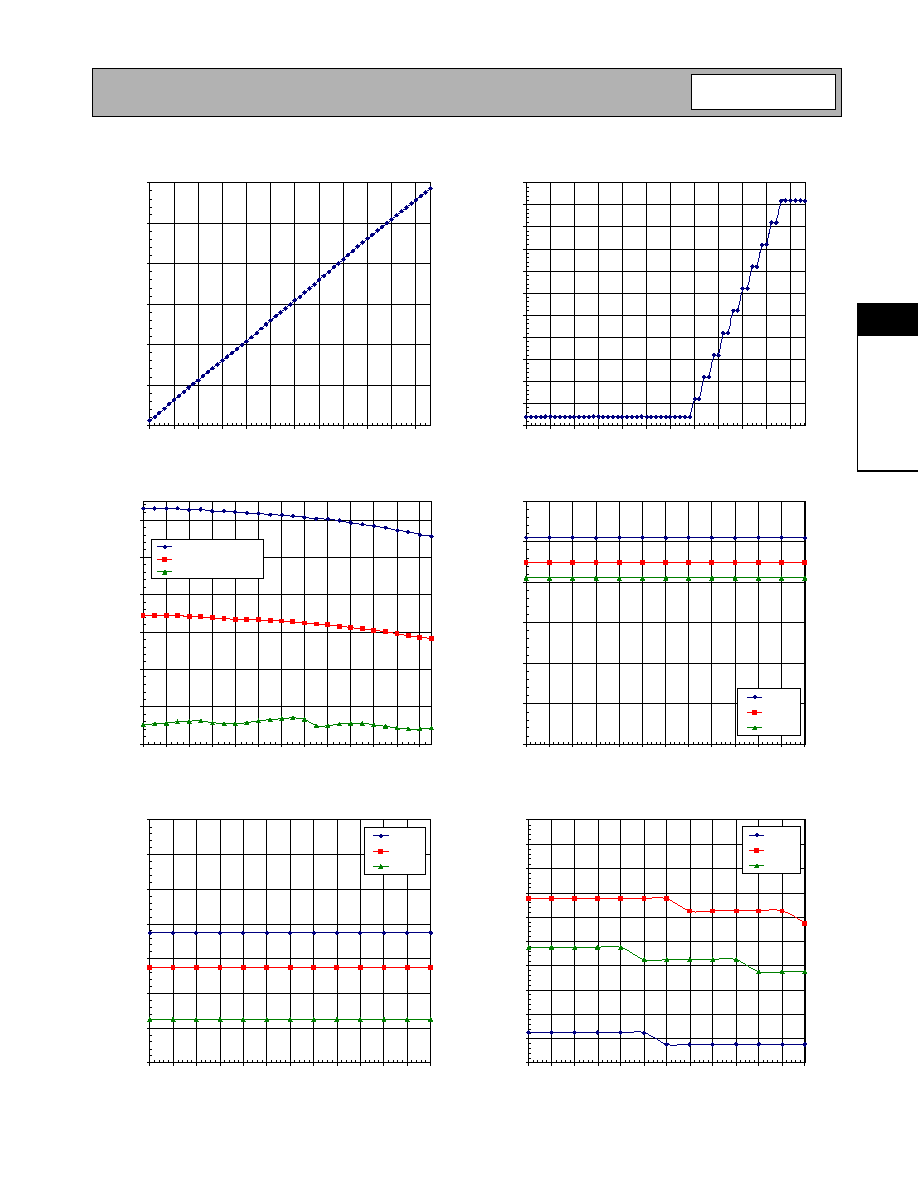

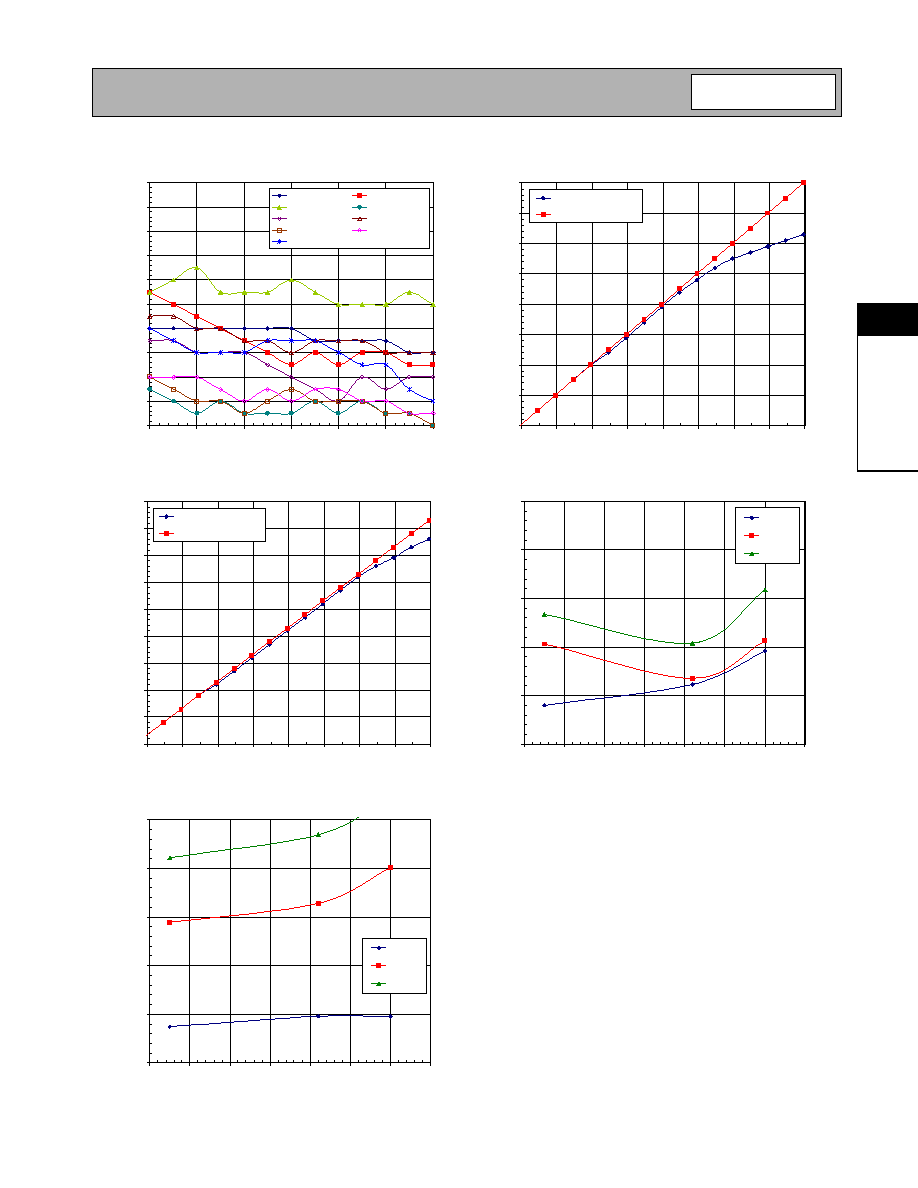

Gain versus Gain Control Word

at 5 MHz

-32.0

-22.0

-12.0

-2.0

8.0

18.0

28.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

Gain Control Word

Gain

(dB)

Current versus Gain Control Word

90.0

95.0

100.0

105.0

110.0

115.0

120.0

125.0

130.0

135.0

140.0

145.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

Gain Control Word

Current

(mA)

Gain versus Frequency

-35

-25

-15

-5

5

15

25

5

25

45

65

85

105

125

145

165

185

205

225

245

Frequency (MHz)

Voltage

Gain

(dB)

Gain Control Word = 58

Gain Control Word = 29

Gain Control Word = 0

Gain versus Supply Voltage

(GCW = 58)

25.40

25.90

26.40

26.90

27.40

27.90

28.40

4.70 4.75 4.80

4.85

4.90 4.95 5.00 5.05 5.10

5.15

5.20 5.25 5.30

Voltage (V)

Gain

(dB)

5 MHz

42 MHz

65 MHz

Gain versus Supply Voltage

(GCW = 0)

-30.00

-29.80

-29.60

-29.40

-29.20

-29.00

-28.80

-28.60

-28.40

-28.20

-28.00

4.70 4.75 4.80

4.85 4.90

4.95 5.00 5.05 5.10 5.15 5.20

5.25 5.30

Voltage (V)

Gain

(dB)

5 MHz

42 MHz

65 MHz

Gain versus Supply Voltage

(GCW = 29)

-1.40

-1.20

-1.00

-0.80

-0.60

-0.40

-0.20

0.00

4.70

4.75

4.80 4.85 4.90

4.95

5.00 5.05 5.10

5.15

5.20 5.25 5.30

Voltage (V)

Gain

(dB)

5 MHz

42 MHz

65 MHz

Preliminary

3-36

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Gain versus Frequency

at Gain Control Word = 58

24.0

24.5

25.0

25.5

26.0

26.5

27.0

27.5

28.0

28.5

5

55

105

155

205

255

Frequency (MHz)

Voltage

Gain

(dB)

Temp = 85∞C

Temp = 0∞C

Temp = -40∞C

Gain versus Frequency

at Gain Control Word = 25

-8.0

-7.0

-6.0

-5.0

-4.0

-3.0

-2.0

-1.0

0.0

5

55

105

155

205

255

Frequency (MHz)

Voltage

Gain

(dB)

Temp = 85∞C

Temp = 0∞C

Temp = -40∞C

Gain versus Frequency

at Gain Control Word = 0

-31.5

-31.0

-30.5

-30.0

-29.5

-29.0

-28.5

-28.0

-27.5

-27.0

-26.5

-26.0

5

55

105

155

205

255

Frequency (MHz)

Voltage

Gain

(dB)

Temp = 85∞C

Temp = 0∞C

Temp = -40∞C

Gain versus Gain Control Word

-30.0

-20.0

-10.0

0.0

10.0

20.0

30.0

0

10

20

30

40

50

Gain Control Word

Voltage

Gain

(dB)

85∞C

0∞C

-40∞C

Gain versus Supply Voltage

at Gain Control Word = 58

27.0

27.2

27.4

27.6

27.8

28.0

28.2

4.7

4.8

4.9

5.0

5.1

5.2

5.3

Supply Voltage (V)

Voltage

Gain

(dB)

5 MHz at 85∞C

42 MHz at 85∞C

65 MHz at 85∞C

5 MHz at 0∞C

42 MHz at 0∞C

65 MHz at 0∞C

5 MHz at -40∞C

42 MHz at -40∞C

65 MHz at -40∞C

Gain versus Supply Voltage

at Gain Control Word = 29

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

4.7

4.8

4.9

5.0

5.1

5.2

5.3

Supply Voltage (V)

Voltage

Gain

(dB)

5 MHz at 85∞C

42 MHz at 85∞C

65 MHz at 85∞C

5 MHz at 0∞C

42 MHz at 0∞C

65 MHz at 0∞C

5 MHz at -40∞C

42 MHz at -40∞C

65 MHz at -40∞C

Preliminary

3-37

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

-1 dB Compression Point

(GCW = 58)

60.0

61.0

62.0

63.0

64.0

65.0

66.0

67.0

68.0

33.8

34.8

35.8

36.8

37.8

38.8

39.8

40.8

41.8

Power In (dBmV)

Power

O

ut

(dBmV)

Gain Control Word = 58

Trend

-1 dB Compression Point

(GCW = 29)

31.0

32.0

33.0

34.0

35.0

36.0

37.0

38.0

39.0

40.0

33.8

34.8

35.8

36.8

37.8

38.8

39.8

40.8

41.8

Power In (dBmV)

Power

O

ut

(dBmV)

Gain Control Word = 29

Trend

Second Harmonic versus Frequency and Output Level

-75.0

-70.0

-65.0

-60.0

-55.0

-50.0

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

Frequency (MHz)

Second

Harmonic

(

dBc)

30dBmV

57dBmV

60dBmv

Third Harmonic versus Frequency and Output Level

-75.0

-70.0

-65.0

-60.0

-55.0

-50.0

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

Frequency (MHz)

Third

H

armonic

(

dBc)

30dBmV

57dBmV

60dBmV

Gain versus Supply Voltage

at Gain Control Word = 0

-30.0

-29.8

-29.6

-29.4

-29.2

-29.0

-28.8

-28.6

-28.4

-28.2

-28.0

4.7

4.8

4.9

5.0

5.1

5.2

5.3

Supply Voltage (V)

Voltage

Gain

(dB)

5 MHz at 85∞C

42 MHz at 85∞C

65 MHz at 85∞C

5 MHz at 0∞C

42 MHz at 0∞C

65 MHz at 0∞C

5 MHz at -40∞C

42 MHz at -40∞C

65 MHz at -40∞C

Preliminary

3-38

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

CH1

S

11 log MAG

10 dB/

REF 0 dB

START 1.000 000 MHz

STOP 100.000 000 MHz

Cor

PRm

1

2

3

1: -19.249 dB

4.960 000 MHz

2: -20.665 dB

42.085 MHz

3: -21.65 dB

64.855 MHz

S

11

Transmit Enable = 5V

CH1

S

22

log MAG

10 dB/

REF 0 dB

START 1.000 000

STOP 100.000 000 MHz

Cor

PRm

1

2

3

1: -25.52 dB

4.960 000

2: -25.226 dB

42.085 MHz

3: -22.568 dB

64.855 MHz

S

22

Transmit Enable = 5V

CH1

S

11

log MAG

10 dB/

START 1.000 000 MHz

STOP 100.000 000 MHz

Cor

PRm

1

2

3

1: -19.335 dB

4.960 000 MHz

2: -20.627 dB

42.085 MHz

3: -21.815 dB

64.855 MHz

S

11

Transmit Enable = 0V

CH1

S

22

log MAG

10 dB/

START 1.000 000 MHz

STOP 100.000 000 MHz

Cor

PRm

1

2

3

1: -25.612 dB

4.960 000 MHz

2: -25.871 dB

42.085 MHz

3: -22.989 dB

64.855 MHz

S

22

Transmit Enable = 0V

Preliminary

3-39

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

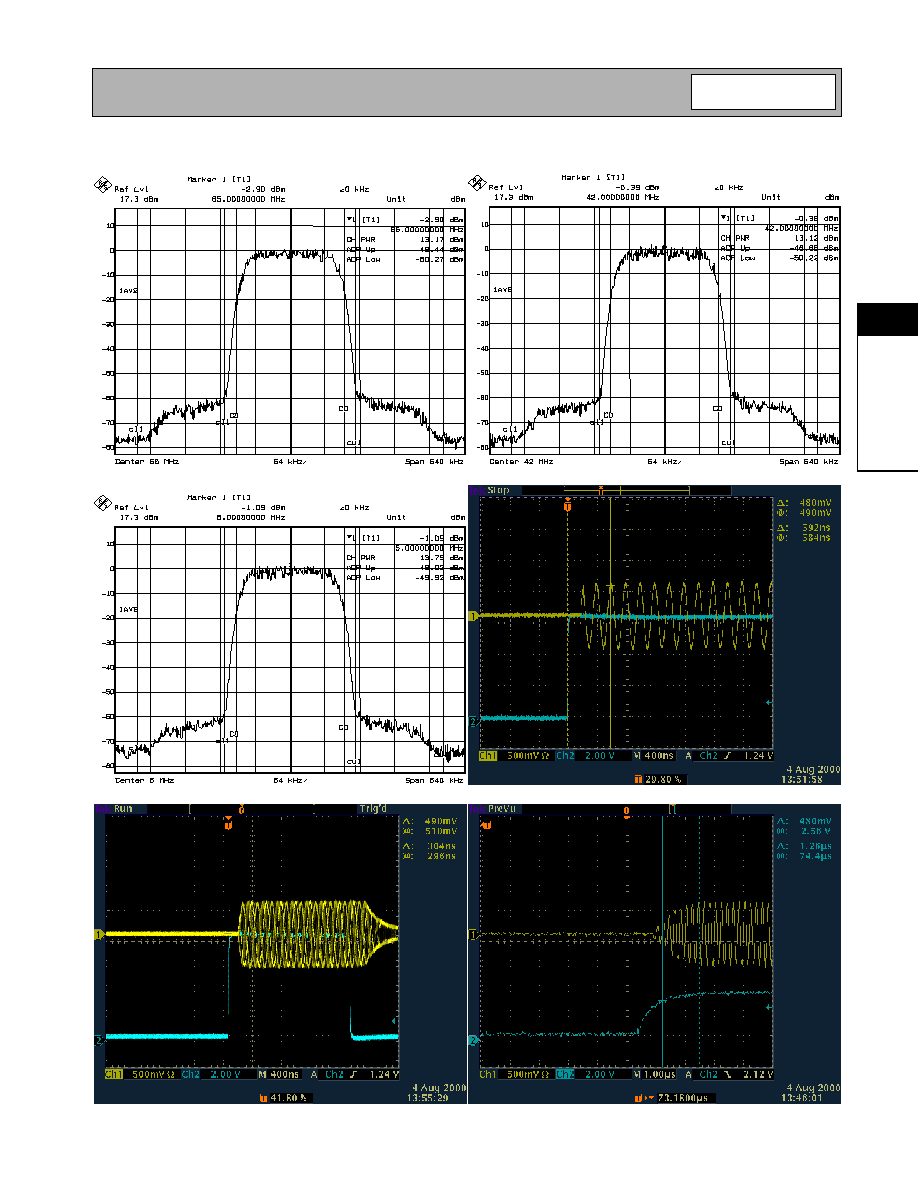

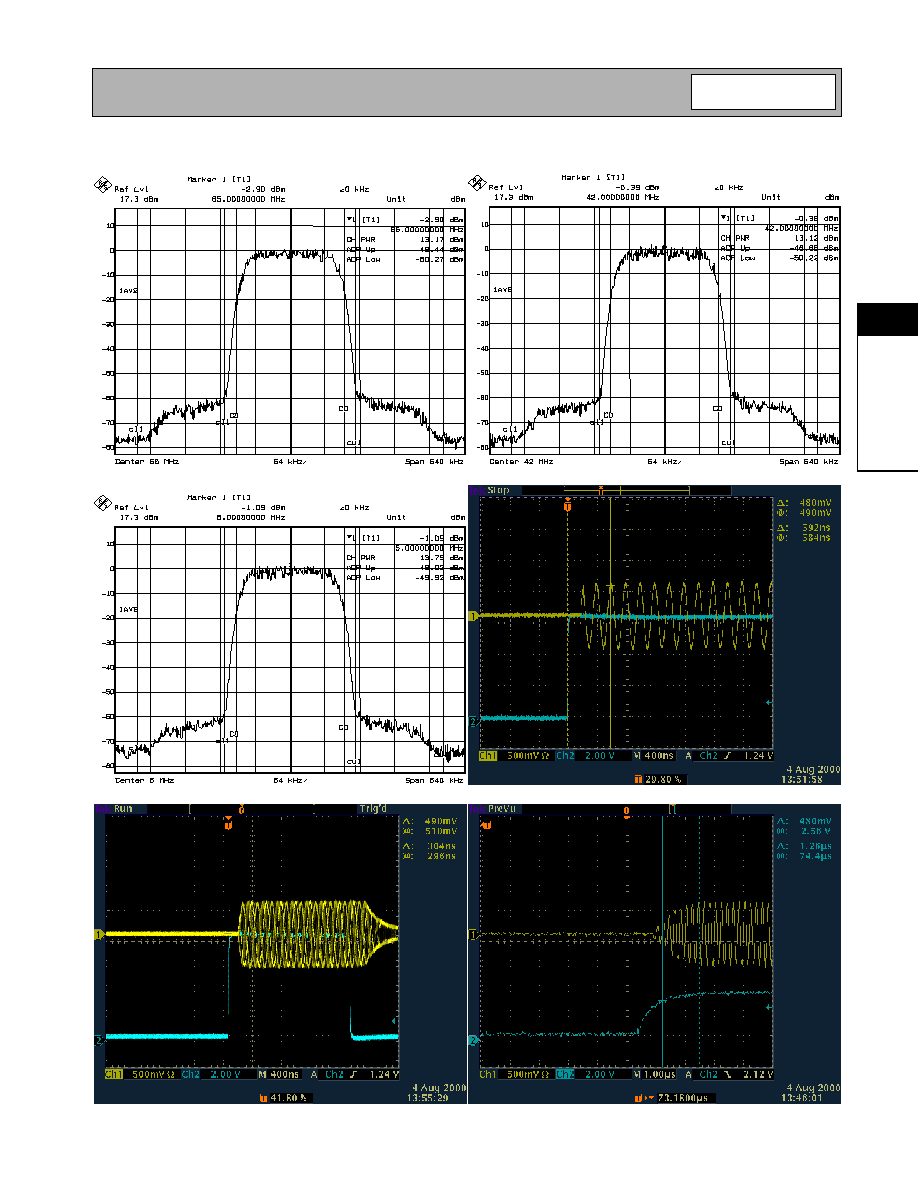

Power Up Settling Time Coming Out Of Shutdown Condition

Power Up Settling Time Coming Out Of Shutdown Condition (Entire Pulse)

Power Up Settling Time Coming Out Of Sleep Condition

ACPR at 65MHz

ACPR at 42MHz

ACPR at 5MHz

Preliminary

3-40

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

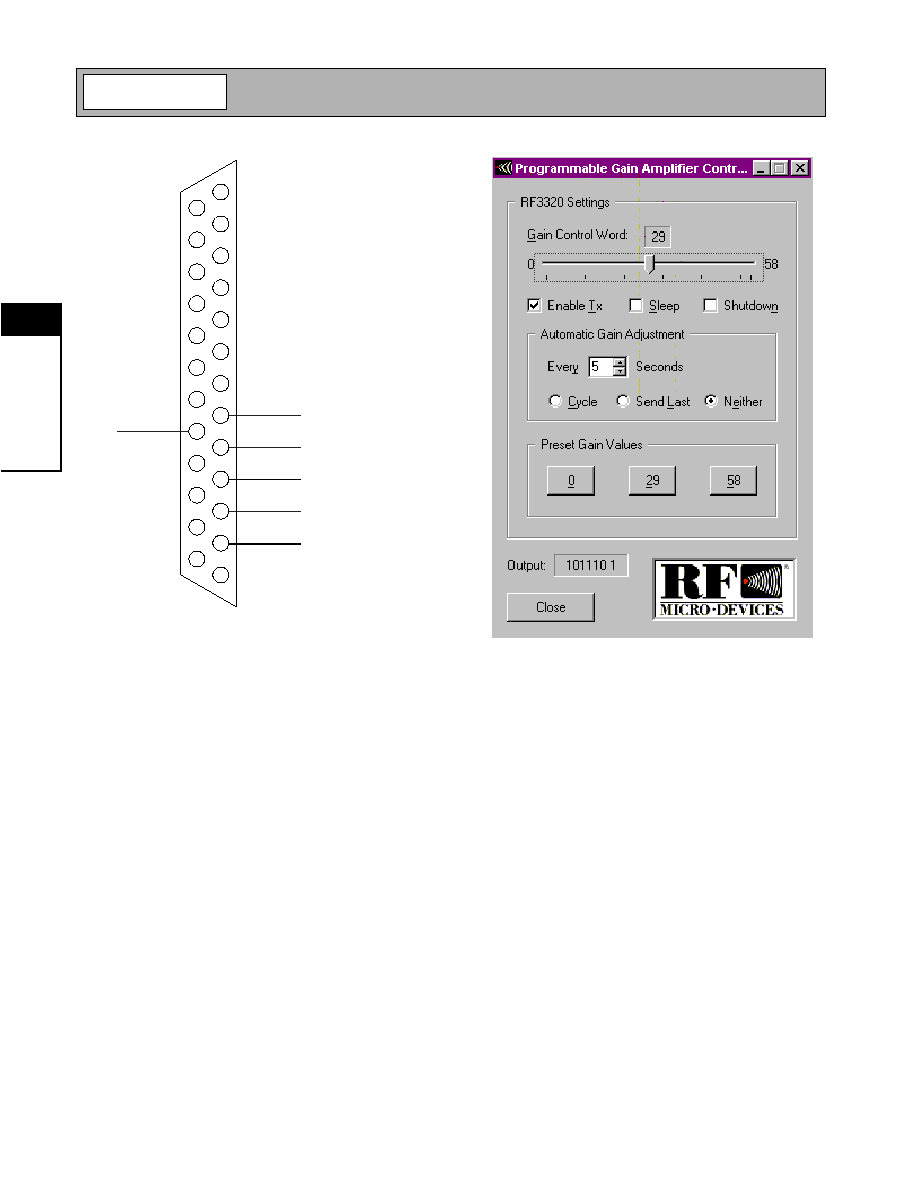

Evaluation Kit

General Description

The RF3320 PCBA is a fully assembled evaluation

board of the RF3320 reverse path high output power

programmable gain amplifier, useful for providing a

demonstration of the RF3320's functionality. The

RF3320 PCBA is a digitally controlled variable gain

amplifier capable of driving a 75

source. The RF3320

is designed to send cable modem data with QPSK or

QAM modulated format at frequencies between 5MHz

and 65MHz. The gain is controlled by an 7-bit serial

data word which adjusts the output gain from -30dB to

+28 dB.

The kit includes a fully functional evaluation board

along with a serial data cable and software. The cable

connects directly to the parallel port of a standard PC.

The software is used to control the serially programma-

ble gain through a simple, easy to understand user

interface.

Input and output to the evaluation board is provided

through 50

SMA connectors. The input and output of

the evaluation board is matched to 50

and connected

through a balun for single-ended operation. This allows

easy connection to test equipment, but the evaluation

board can easily be converted to a 75

input and out-

put, or for differential input and output. The output cir-

cuit is matched using a 24

series resistor which is

used to bring the load impedance up to 75

when

using standard 50

test equipment. This will introduce

a loss which must be accounted for in all measure-

ments (see measurement section and evaluation board

schematic for more detail).

PCBA Details

Input Circuit

The input to the RF3320 is differential and the imped-

ance is 75

; However, for ease of testing, the evalua-

tion board has been changed to single-ended and the

impedance has been matched to 50

. If a 75

input is

required, simply replace the 50

SMA connector with

a 75

F-style connector and remove R3 and R4.

Output Circuit

The output of the RF3320 is differential and the imped-

ance is 300

. In normal applications this is converted

into a single-ended 75

output using a 2:1 (voltage

ratio) transformer with a center-tap on the secondary

which supplies power to the output stage. The evalua-

tion board is configured for use with 50

test equip-

ment. This has been achieved with a 24

resistor in

series with the output to increase the load seen by the

device to 75

. This introduces a voltage loss of 3.5 dB

which must be accounted for in all measurements.

Some spectrum analyzers have a setting to account for

this method of 75

testing (e.g., on a Rhode &

Schwartz spectrum analyzer the input can be set to

'"75

RAZ" and the loss is accounted for automati-

cally). A more accurate way of making this measure-

ment is to use a 75

spectrum analyzer, or use a

matching transformer or minimum loss pad. This

ensures that the source impedance seen by the equip-

ment is also 75

. If a 75

output is required, simply

replace the 50

SMA connector (J7) with a 75

F-

style connector and replace R5 with a 0

jumper. The

evaluation board is tested with a Coilcraft balun; how-

ever, additional baluns may be used as long as care is

taken in modifying the decoupling capacitors around

the balun. These capacitors can greatly affect the har-

monic suppression. Other baluns may be used but

should be tested for second and third order harmonic

suppression.

Transmit Enable

The transmit enable can be set to "continuous on" by

placing the TXEN jumper in the up position (up position

when viewing the top of the evaluation board with the

25 pin connector closest to the viewer) and placing the

associated GND/V

CC

jumper in the "V

CC

" position. The

transmit enable can be set to "continuous off" by plac-

ing the GND/V

CC

jumper in the "GND" position. If a

computer controlled signal is used (J1), place the

TXEN jumper in the down position.

Software Controlled

C

TX EN

GND

VCC

Continuous OFF

B

GND

VCC

TX EN

Continuous ON

A

GND

VCC

TX EN

Figure 1. TX Enable Configuration

Preliminary

3-41

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Shutdown Enable

Shutdown enable can be set to be "continuous on"

(chip enabled) by placing the SHDN jumper in the up

position and placing the associated GND/V

CC

jumper

in the "V

CC

" position. Shutdown enable can be set to

"continuous off" (chip disabled) by placing the associ-

ated GND/V

CC

jumper in the "GND" position. If a com-

puter controlled signal is used (J1), place the SHDN

jumper in the down position.

V

CC

Settings

V

CC1

should be set to 5.0V

DC

.

Evaluation Board Setup

Equipment Needed

∑

Signal Generator

∑

Spectrum Analyzer

∑

Power Supply (5.0 V@300 mA)

∑

RF3320 PCBA

∑

Serial Cable (included with kit)

∑

Standard PC

∑

Three-Wire Bus Software

Optional Equipment

∑

Variable Low-Pass or Band-Pass Filters

∑

Power Meter

∑

Second Signal Generator with Modulation for ACPR

and IP2, IP3 Testing

∑

Arbitrary Wave Generator

∑

Two-Channel Oscilloscope

Software Setup

To install the software, you need a computer with the

following.

∑

133MHz Pentium processor

∑

16MB RAM

∑

Hard Drive with 5MB free space

∑

Free 25-pin LPT port

∑

VGA Monitor

The software may be downloaded from www.rfmd.com

by following these steps.

Select the "Product Support" tab;

Select "Evaluation Board Information";

Select "RF3320".

Unzip the file using WinZip 7.0 or higher (http://

www.winzip.com). Unzip to a temporary directory and

run RF3320.exe.

The 7-bit Gain Control Word (GCW) in the data latch

determines the gain setting in the RF3320. The gain

control data (SDA) load sequence is initiated by a fall-

ing edge on CS. The SDA is serially loaded (LSB first)

into the 7-bit shift register at each rising edge of the

clock. While CS is low, the data latch holds the previ-

ous data word allowing the gain level to remain

unchanged. After seven clock cycles the new data

word is fully loaded and CS is switched high. This

enables the data latch and the loaded register data is

passed to the gain control block with the updated gain

value. Also at this CS transition, the internal clock is

disabled, thus inhibiting new serial input data.

Software and Cable

Figure 3 shows the cable configuration. Connect the

cable into the LPT1 port of the computer running the

software. Connect the other end of the cable to the 25-

pin connector of the evaluation board. Executing the

software (RF3320.exe) will produce the screen shown

in Figure 4. The user may set the gain of the evaluation

board by sliding the gain control switch to the desired

gain setting. Pressing the Preset Gain Value buttons

automatically sets the gain of the unit to the value

shown on the button. The Automatic Gain Adjustment

when set to "Cycle" will automatically cycle through all

of the gain steps (0-58) in seconds (at the rate set by

the user). The user may place the unit in sleep, shut-

down and transmit enable/disable modes by checking

the corresponding box. The bit pattern being sent to

the PCBA is shown at the bottom of the screen. See

README_3320.txt file for proper pin/signal mapping

for the 25 pin interface.

Software Controlled

C

GND

VCC

SHDN

Continuous ON

B

SHDN

GND

VCC

Continuous OFF

A

GND

VCC

SHDN

Figure 2. SHDN Enable Configuration

Preliminary

3-42

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Hardware Setup

Gain and Harmonic Distortion Test Setup

To test the gain of the RF3320 PCBA, connect a low-

pass or band-pass filter to the output of the signal gen-

erator. Use a filter just above the frequency you want to

test. The filter is used to attenuate any harmonics out-

put by the signal generator. Connect the signal genera-

tor to the power meter and measure the power.

Compare with modulation enabled and disabled to

make sure the meter was measuring average rather

than peak power. No more than 0.2 dB difference in

power should be observed. An offset on the signal gen-

erator may be needed to match the level shown on the

power meter. The signal generator should then be con-

nected directly to a spectrum analyzer. Make sure the

output of the signal generator is the same as the input

read by the spectrum analyzer. Adjust the offset of the

spectrum analyzer until the signal out is the same as

the signal in on the spectrum analyzer. Turn off the RF

and modulation. Check positioning of the jumpers on

the board. Refer to the PCBA section of this applica-

tion note to verify proper positions. Connect the output

of the signal generator to J6: RFIN of the PCB. Con-

nect J7: RFOUT to the spectrum analyzer. Ensure that

you are accounting correctly for the losses in the 75

to 50

conversion at the output of the device; there is

an output voltage loss of 3.5 dB for the evaluation

board in its standard configuration (see output stage

circuit description). Connect one end of the serial cable

into the computer and the other end into J1 of the PCB.

Connect +5.0V

DC

into V+ and ground into GND(JP1).

Turn on the DC power and turn on RF from the signal

generator. Set the GCW to 58 and make sure

TXEnable is checked. The amplified signal should be

displayed on the spectrum analyzer. The harmonics

can also be viewed with this setup. As you change the

GCW from 58 to 0 (in steps of one), there will be a 1 dB

change in the output of the PCB.

ACPR Test Setup

To test the ACPR of the RF3320 PCBA set modulation

to:

∑

QPSK

∑

2Bits/Sym

∑

160 ksps

∑

= 0.25

∑

PRBS-20bit Data

4

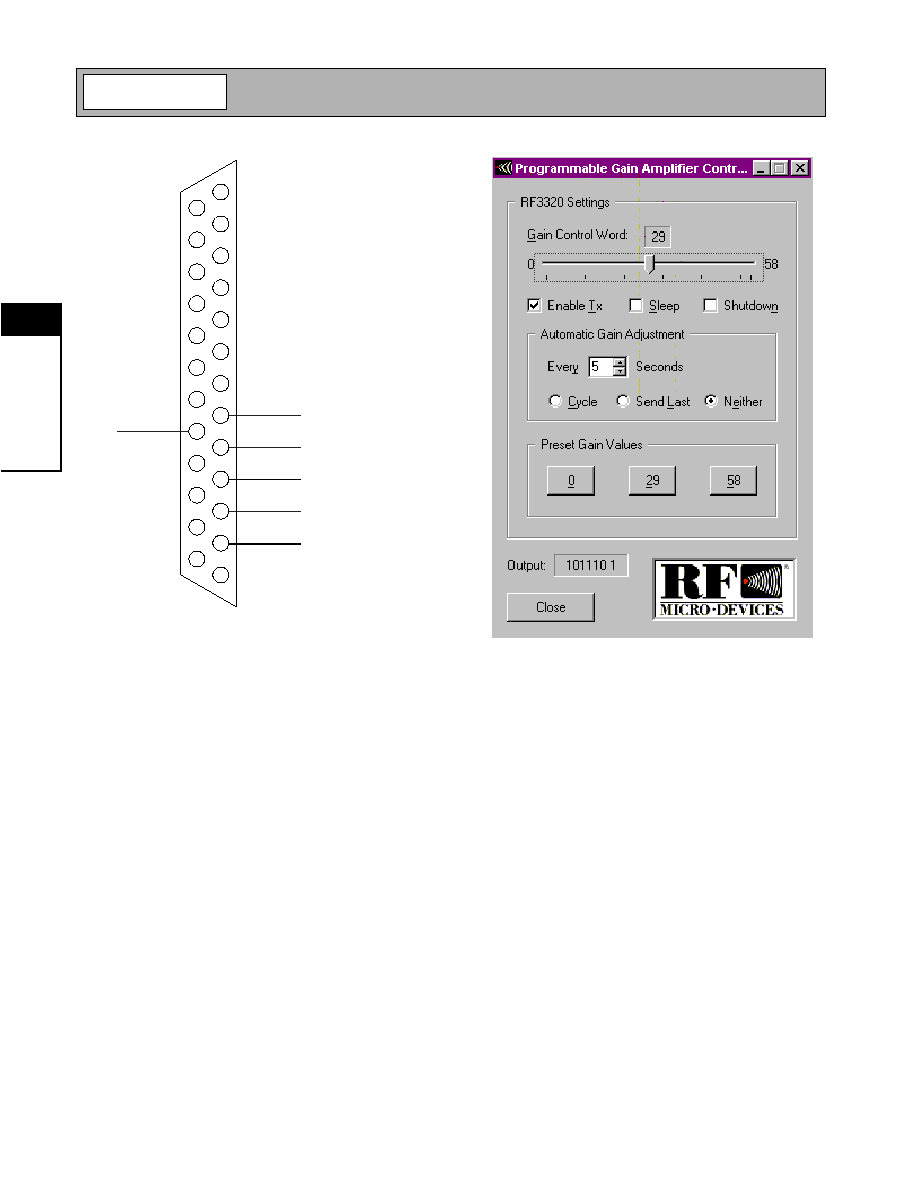

CLK Line

5

SHUTDOWN Line

3

Data Line

6

TX Enable Line

25 Pin D-Connector (Back View)

RF3320 PCBA Cable

2

CS Line

18

Ground

Figure 3. Cable Configuration

Figure 4. On-Screen Display

Preliminary

3-43

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Set signal generator to:

∑

45MHz,

∑

-13.0dBm output power,

∑

0dB offset.

Connect 50MHz coaxial filter to output, then to output

cable.

Zero and calibrate the power meter. Connect signal

generator to power meter and set offset on signal gen-

erator until power meter reads -13.0dBm. Make sure

power meter reads the same (±0.2 dBm) with modula-

tion enabled and disabled to verify power meter is

measuring average power rather than peak power.

Check positioning of the jumpers on the board. Refer

to the PCBA section of this application note to verify

proper positions. Connect the output of the signal gen-

erator to J6: RFIN of the PCB. Connect J7: RFOUT to

the power meter. Connect one end of the serial cable

to the computer and the other end into P1 of the PCB.

Connect +5.0 V

DC

to V

CC

and ground to GND. Turn on

the DC power and turn on RF and modulation from the

signal generator. Set the GCW to 58 and make sure

TX Enable is checked. Measure and record channel

power at RFOUT using the power meter (accounting

for 75/50 conversion losses). Connect RFOUT to spec-

trum analyzer and adjust offset of the spectrum ana-

lyzer until the channel power displayed by the

spectrum analyzer is equal to the channel power

recorded

in

the

previous

step

(channel

bandwidth= 200kHz). Now use the spectrum analyzer

to measure relative ACP (this way the uncertainties in

the spectrum analyzer power measurement are imma-

terial). The ACP is measured in 200 kHz channel band-

widths at a 220kHz offset (i.e., from 20kHz to 220kHz

outside the channel). As you increase the input power,

you will notice a degradation of the ACP upper and

lower bands. Datasheet performance is measured at

an input level of 34 dBmV.

Transmit Turn-On and Turn-Off Transients

Use an Arbitrary Waveform Generator set to a 3V

square wave, 5% duty cycle, 120 Hz as the input to the

transmit enable. Set a signal generator to 10MHz, -

13.0dbm output power, 0dB offset. Connect output of

the signal generator to J6, RFIN of the PCB. Remove

the TXEN jumper and connect the arbitrary wave gen-

erator square wave output to the center pin of the

TXEN 3-pin header. Connect the output of the evalua-

tion board to the oscilloscope (channel 1). Connect the

TXEN signal from the arbitrary wave generator to

channel 2 of the oscilloscope and trigger off of the ris-

ing edge. As the TXEN line is sent, the oscilloscope

will trigger and capture the pulsed RFOUT signal. This

will be displayed on the oscilloscope. Measure the

amount of time between 90 percent of the TXEN turn-

on to where the output signal reaches 90 percent of full

turn-on. This is defined as the transmit turn-on time.

To measure the transient pulse, replace the signal gen-

erator input with a 50

terminator and repeat the steps

above. Measure the size of the transient. This can be

affected by the C

RAMP

capacitor (C6), and the output

balun and capacitor values around the balun. Larger

values of C

RAMP

will decrease the transient voltage

and increase the TX enable time.

PCB Layout Considerations

The RF3320 Evaluation board can be used as a guide

for the layout in your application. Care should be taken

in laying out the RF3320 in other applications. The

RF3320 will have similar results if the following guide-

lines are taken into consideration:

∑

Make sure underside of package is soldered to a

good ground on the PCB.

∑

Move C2, C7, C8, and C9 as close to T1 as possi-

ble.

∑

Keep input and output traces as short as possible.

∑

Ensure a good ground plane by using multiple vias

to the ground plane.

∑

Use a low noise power supply along with decou-

pling capacitors.

Preliminary

3-44

RF3320

Rev A10 010514

3

LI

N

E

A

R

C

A

TV

A

M

P

L

IF

IE

R

S

Special Handling Information for Shrunk Small

Outline Package (SSOP1-EPP) Products

These packages are considered JEDEC Level 5 for

moisture sensitivity and require special handling to

assure reliable performance.

The exposed copper slug on the bottom of the package

improves both thermal and electrical performance.

Since the RFIC is mounted directly on the thermal

slug, and the slug is soldered directly on the PCB, the

thermal resistance to the PCB is minimized. Also, the

RF ground for the amplifier is established through this

copper slug as it is soldered to the ground plane on the

PCB. This offers the least inductance ground path

available.

Care must be taken when soldering these packages to

the PCB. They are currently considered JEDEC Level

5 for moisture sensitivity. Therefore the parts must be

handled in a dry environment prior to soldering, as is

specified in the JEDEC specification. Specifically,

RFMD recommends the following procedure prior to

assembly:

1. Dry-bake the parts at 125∞C for 24 hours minimum.

Note: the shipping tubes cannot withstand 125∞C

baking temperature.

2. Parts delivered on tape and reel are already dry-

baked and dry-packed. These may be stored for up

to one year, but must be assembled within 48 hours

after opening the bag.

3. Assemble the dry-baked parts within two days of

removal from the oven.

4. During this two-day period, the parts must be stored

in humidity less than 60 percent.

IMPORTANT!

If the two-day period is exceeded, then this procedure

must be repeated prior to assembly.