PROTECTION PRODUCTS

1

www.semtech.com

PROTECTION PRODUCTS

SLVU2.8

Low Voltage EPD TVS Diode

For ESD and Latch-Up Protection

Description

Features

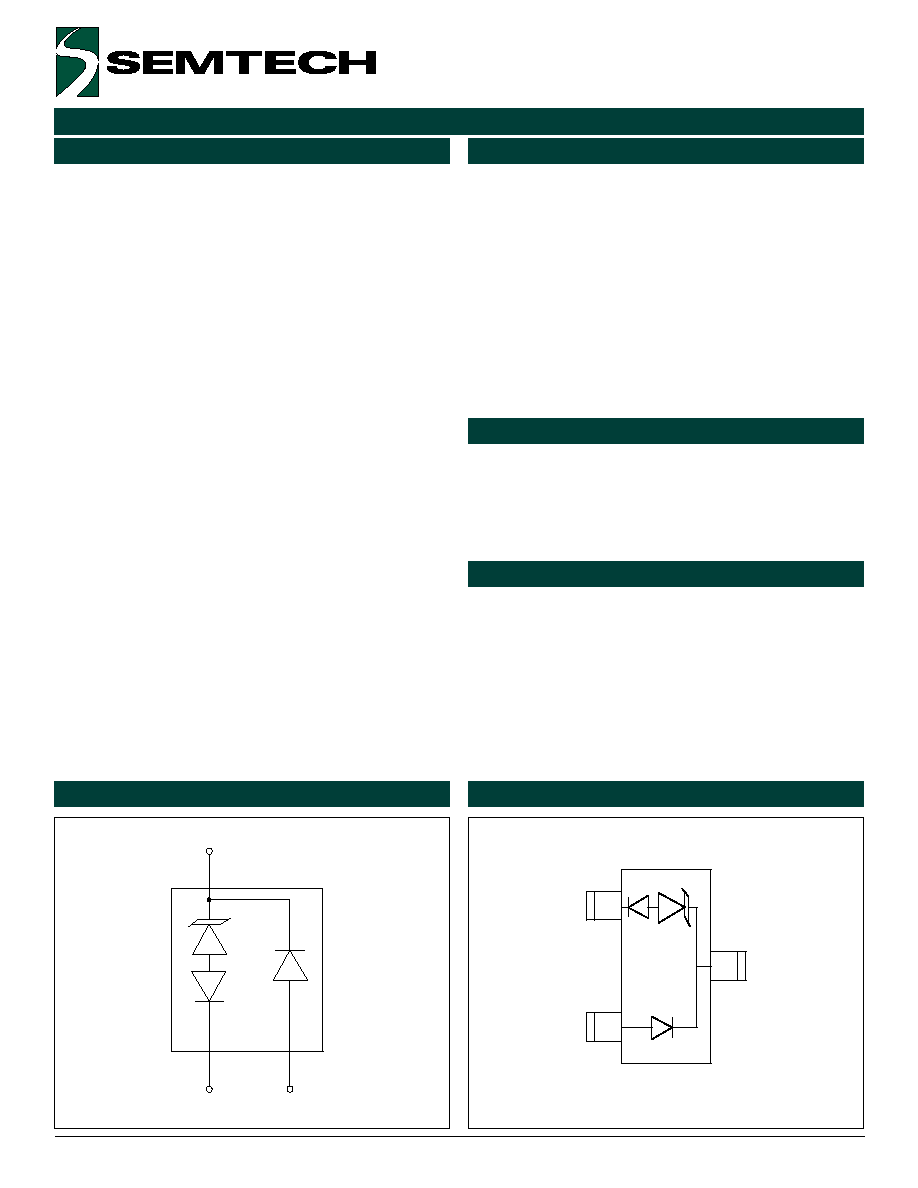

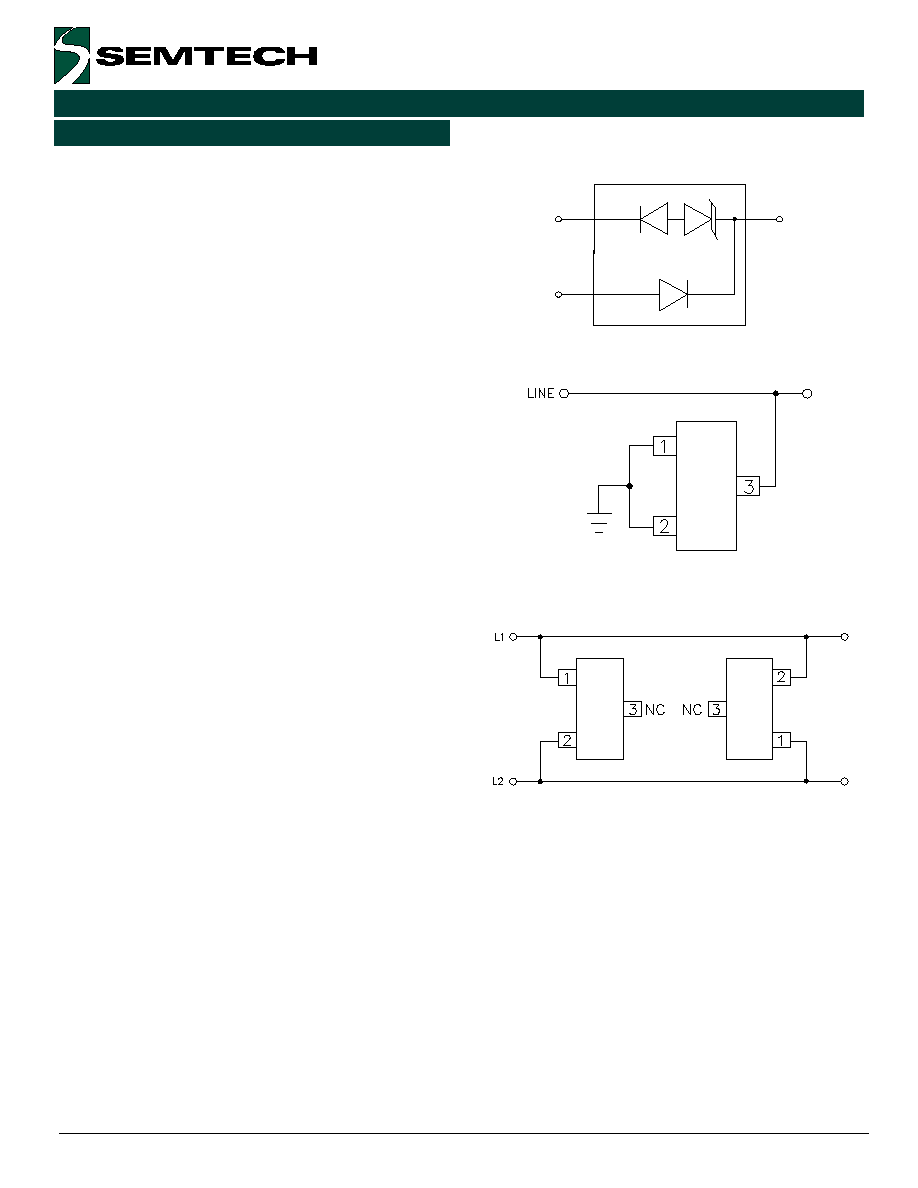

Circuit Diagram

Schematic & PIN Configuration

Revision 9/2000

The SLV series of transient voltage suppressors are

designed to protect low voltage, state-of-the-art CMOS

semiconductors from transients caused by electro-

static discharge (ESD), cable discharge events (CDE),

lightning and other induced voltage surges.

The devices are constructed using Semtechs propri-

etary EPD process technology. The EPD process pro-

vides low standoff voltages with significant reductions

in leakage currents and capacitance over silicon-

avalanche diode processes. The SLVU2.8 features an

integrated low capacitance compensation diode that

allows the device to be configured to protect one

unidirectional line or, when paired with a second

SLVU2.8, two high-speed line pairs. The low capaci-

tance design of the SLVU2.8 means signal integrity is

preserved in high-speed applications such as 10/100

Ethernet.

The SLVU2.8 is in an SOT23 package and has a low

2.8 volt working voltage. It is specifically designed to

protect low voltage components such as Ethernet

transceivers, laser diodes, ASICs, and high-speed RAM.

The low clamping voltage of the SLVU2.8 minimizes the

stress on the protected IC.

The SLV series TVS diodes will exceed the surge re-

quirements of IEC 61000-4-2, Level 4.

Applications

Mechanical Characteristics

u

10/100 Ethernet

u

WAN/LAN Equipment

u

Switching Systems

u

Desktops, Servers, Notebooks & Handhelds

u

Laser Diode Protection

u

Base Stations

u

400 Watts peak pulse power (tp = 8/20�s)

u

Transient protection for high speed data lines to

IEC 61000-4-2 (ESD) 15kV (air), 8kV (contact)

IEC 61000-4-4 (EFT) 40A (tp = 5/50ns)

IEC 61000-4-5 (Lightning) 24A (tp = 8/20�s)

u

One device protects one unidirectional line

u

Two devices protect two high-speed line pairs

u

Low capacitance

u

Low leakage current

u

Low operating and clamping voltages

u

Solid-state EPD TVS process technology

u

JEDEC SOT23 package

u

Molding compound flammability rating: UL 94V-0

u

Marking : U2.8

u

Packaging : Tape and Reel per EIA 481

SOT23 (Top View)

3

1

2

3

1

2

2

� 2000 Semtech Corp.

www.semtech.com

PROTECTION PRODUCTS

PROTECTION PRODUCTS

SLVU2.8

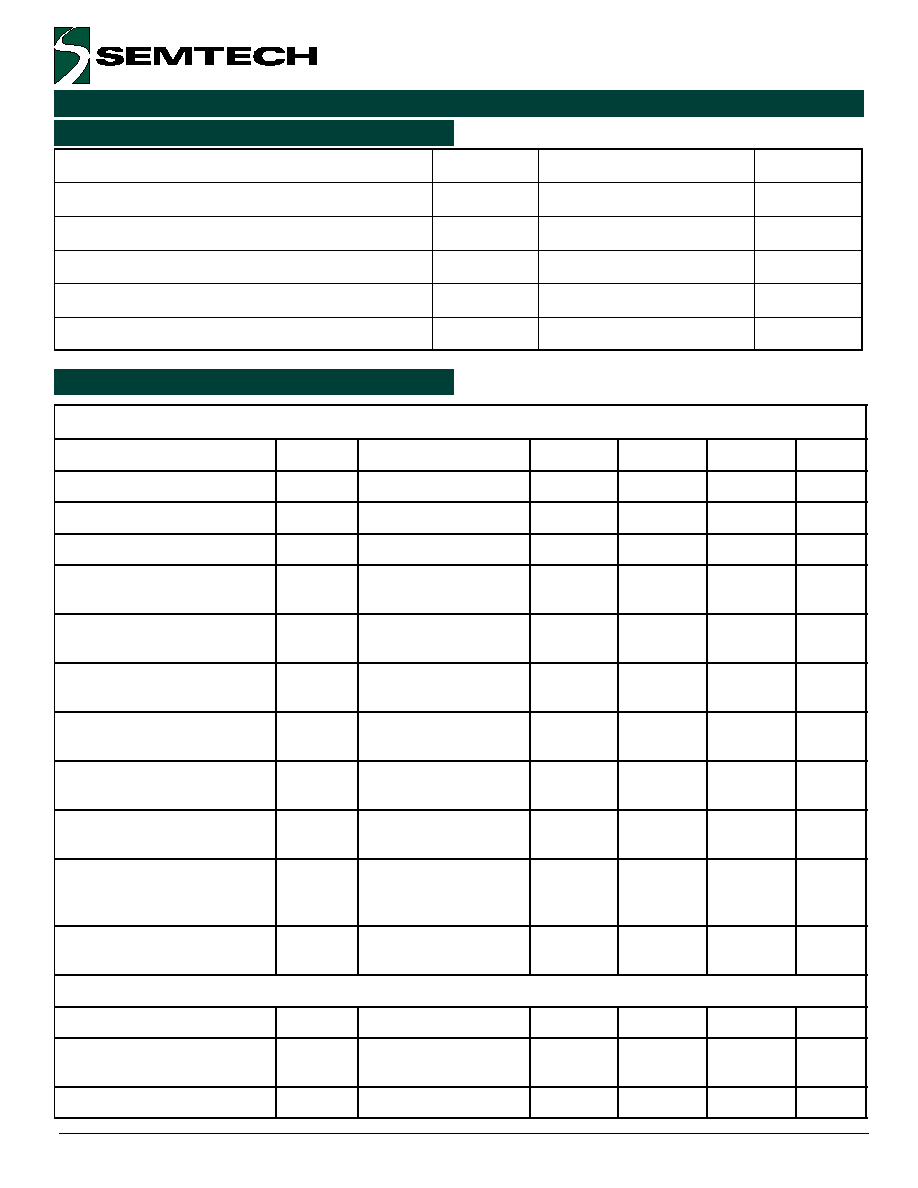

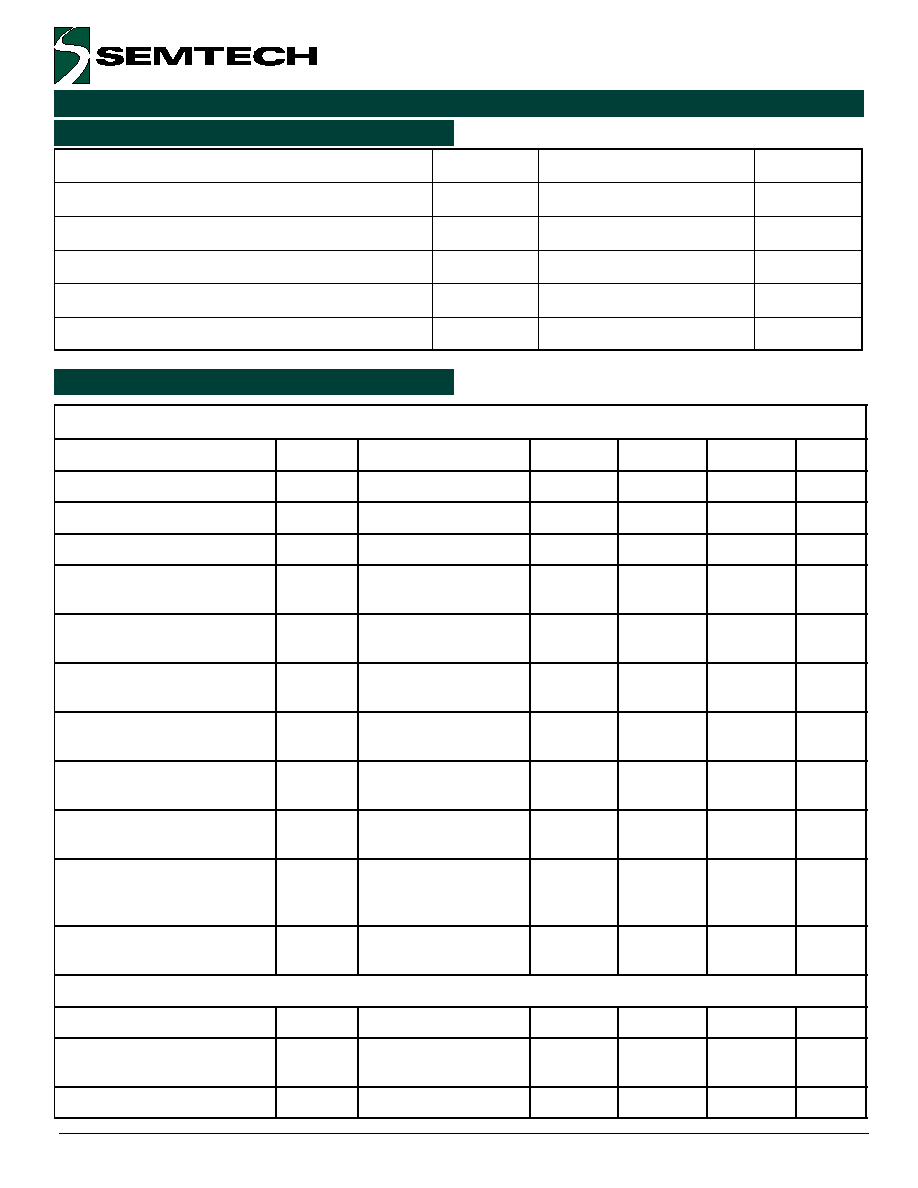

Absolute Maximum Rating

Electrical Characteristics

g

n

it

a

R

l

o

b

m

y

S

e

u

l

a

V

s

ti

n

U

0

2

/

8

=

p

t(

r

e

w

o

P

e

s

l

u

P

k

a

e

P

m )

s

P

k

p

0

0

4

s

tt

a

W

0

2

/

8

=

p

t(

t

n

e

rr

u

C

e

s

l

u

P

k

a

e

P

m )

s

I

P

P

4

2

A

e

r

u

t

a

r

e

p

m

e

T

g

n

ir

e

d

l

o

S

d

a

e

L

T

L

)

s

d

n

o

c

e

s

0

1

(

0

6

2

o

C

e

r

u

t

a

r

e

p

m

e

T

g

n

it

a

r

e

p

O

T

J

5

2

1

+

o

t

5

5

-

o

C

e

r

u

t

a

r

e

p

m

e

T

e

g

a

r

o

t

S

T

G

T

S

0

5

1

+

o

t

5

5

-

o

C

8

.

2

U

V

L

S

r

e

t

e

m

a

r

a

P

l

o

b

m

y

S

s

n

o

it

i

d

n

o

C

m

u

m

i

n

i

M

l

a

c

i

p

y

T

m

u

m

i

x

a

M

s

ti

n

U

e

g

a

tl

o

V

ff

O

-

d

n

a

t

S

e

s

r

e

v

e

R

V

M

W

R

1

o

t

2

n

i

P

r

o

1

o

t

3

n

i

P

8

.

2

V

e

g

a

tl

o

V

h

g

u

o

r

h

T

-

h

c

n

u

P

V

T

P

I

T

P

1

o

t

3

n

i

P

,

A

�

2

=

0

.

3

V

e

g

a

tl

o

V

k

c

a

B

-

p

a

n

S

V

B

S

I

B

S

1

o

t

3

n

i

P

,

A

m

0

5

=

8

.

2

V

t

n

e

rr

u

C

e

g

a

k

a

e

L

e

s

r

e

v

e

R

I

R

V

M

W

R

C

�

5

2

=

T

,

V

8

.

2

=

1

o

t

2

n

i

P

r

o

1

o

t

3

n

i

P

1

A

�

e

g

a

tl

o

V

g

n

i

p

m

a

l

C

V

C

I

P

P

s

�

0

2

/

8

=

p

t

,

A

2

=

1

o

t

3

n

i

P

9

.

3

V

e

g

a

tl

o

V

g

n

i

p

m

a

l

C

V

C

I

P

P

s

�

0

2

/

8

=

p

t

,

A

5

=

1

o

t

3

n

i

P

7

V

e

g

a

tl

o

V

g

n

i

p

m

a

l

C

V

C

I

P

P

s

�

0

2

/

8

=

p

t

,

A

4

2

=

1

o

t

3

n

i

P

5

.

2

1

V

e

g

a

tl

o

V

g

n

i

p

m

a

l

C

V

C

I

P

P

s

�

0

2

/

8

=

p

t

,

A

5

=

1

o

t

2

n

i

P

5

.

8

V

e

g

a

tl

o

V

g

n

i

p

m

a

l

C

V

C

I

P

P

s

�

0

2

/

8

=

p

t

,

A

4

2

=

1

o

t

2

n

i

P

5

1

V

e

c

n

a

ti

c

a

p

a

C

n

o

it

c

n

u

J

C

j

2

&

1

o

t

3

n

i

P

)r

e

h

t

e

g

o

t

d

e

it

2

&

1

n

i

P

(

V

R

z

H

M

1

=

f

,

V

0

=

0

7

0

0

1

F

p

e

c

n

a

ti

c

a

p

a

C

n

o

it

c

n

u

J

C

j

).

C

.

N

3

n

i

p

(

1

o

t

2

n

i

P

V

R

z

H

M

1

=

f

,

V

0

=

5

0

1

F

p

s

c

it

s

ir

e

t

c

a

r

a

h

C

e

d

o

i

D

g

n

ir

e

e

t

S

e

g

a

tl

o

V

n

w

o

d

k

a

e

r

B

e

s

r

e

v

e

R

V

R

B

I

T

2

o

t

3

n

i

P

,

A

�

0

1

=

0

4

V

t

n

e

rr

u

C

e

g

a

k

a

e

L

e

s

r

e

v

e

R

I

D

R

V

M

W

R

C

�

5

2

=

T

,

V

8

.

2

=

2

o

t

3

n

i

P

1

A

�

e

g

a

tl

o

V

d

r

a

w

r

o

F

V

F

I

F

3

o

t

2

n

i

P

,

A

1

=

2

V

3

� 2000 Semtech Corp.

www.semtech.com

PROTECTION PRODUCTS

PROTECTION PRODUCTS

SLVU2.8

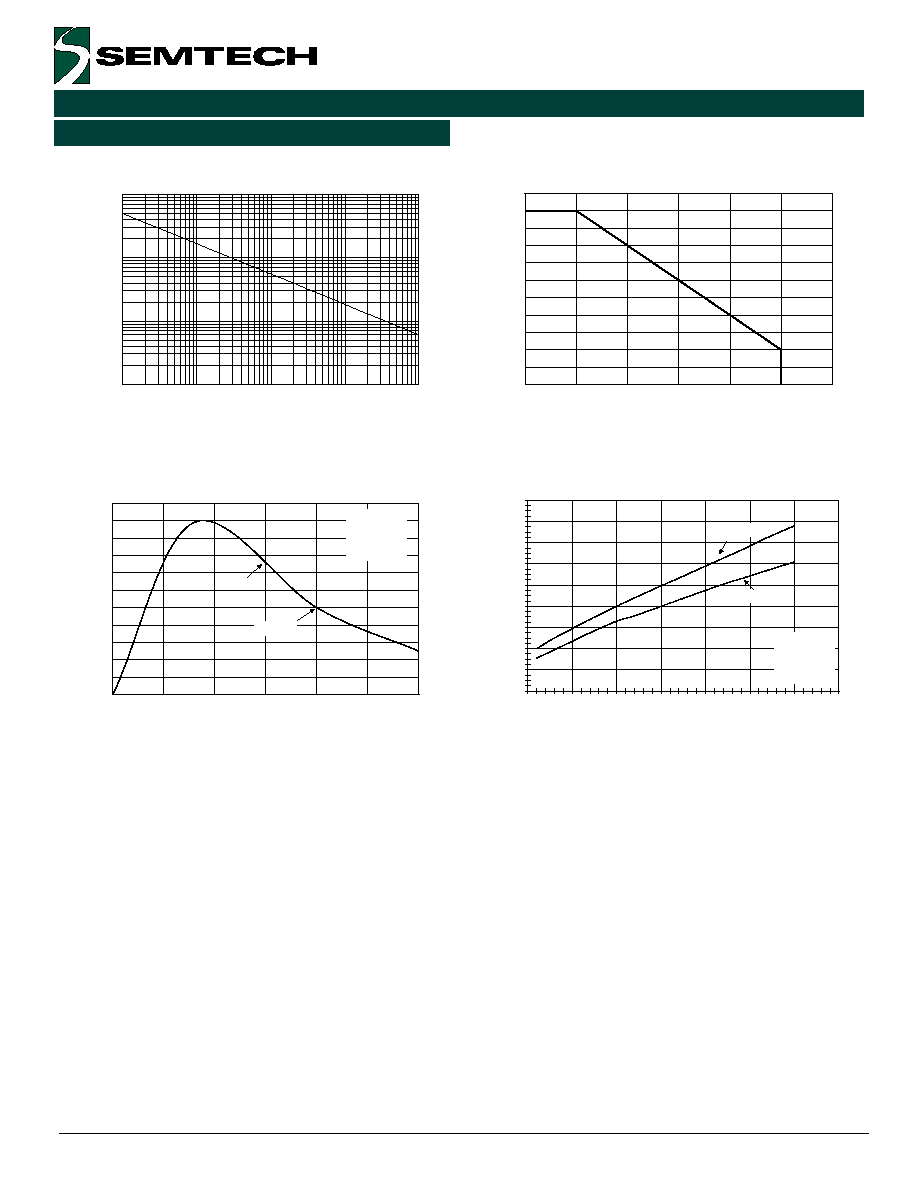

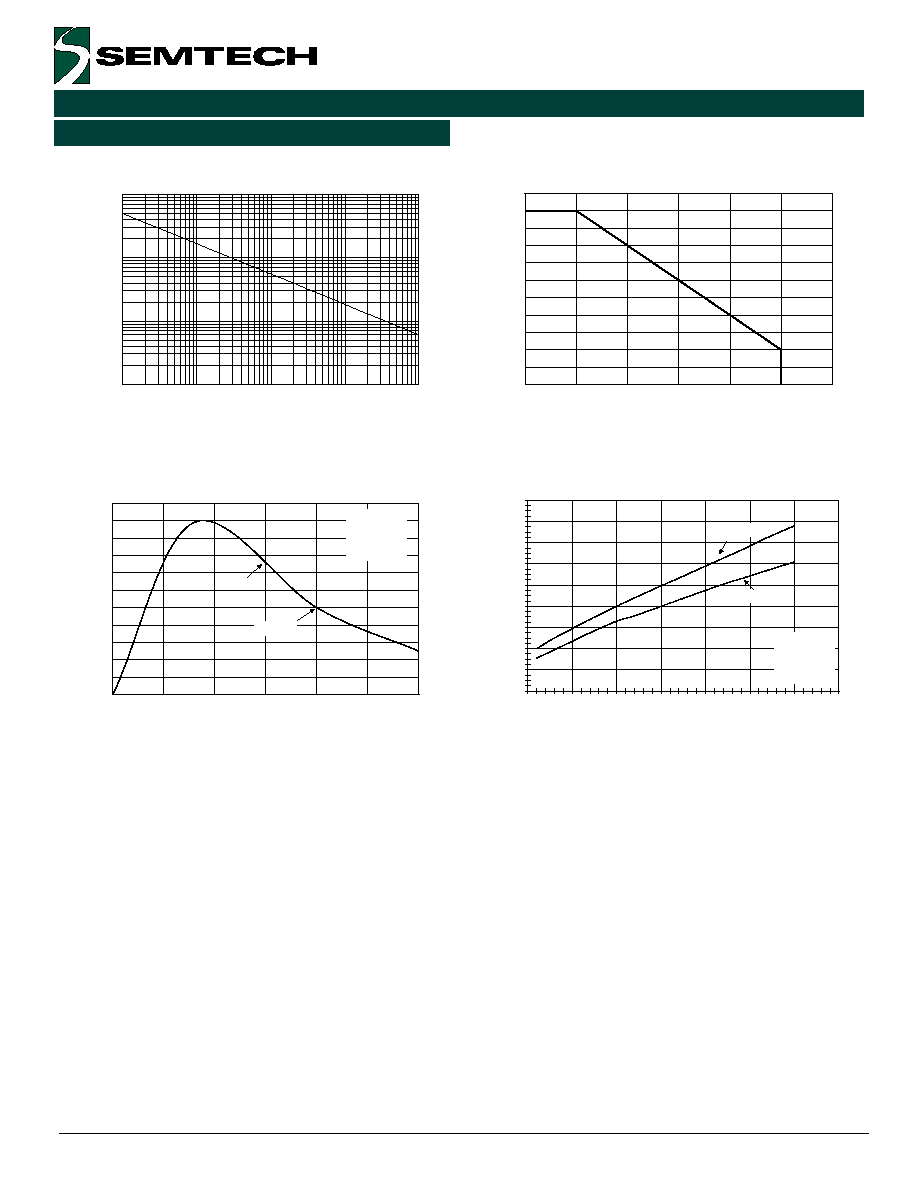

Typical Characteristics

Non-Repetitive Peak Pulse Power vs. Pulse Time

0

10

20

30

40

50

60

70

80

90

100

110

0

25

50

75

100

125

150

Ambient Temperature - T

A

(

o

C)

%

of Rated Power or I

PP

Power Derating Curve

Pulse Waveform

Clamping Voltage vs. Peak Pulse Current

0

10

20

30

40

50

60

70

80

90

100

110

0

5

10

15

20

25

30

Time (

�

s)

Percent of I

PP

e

-t

td = I

PP

/2

Waveform

Parameters:

tr = 8

�

s

td = 20

�

s

0.01

0.1

1

10

0.1

1

10

100

1000

Pulse Duration - tp (

�

s)

Peak Pulse Power - P

PP

(kW)

0

2

4

6

8

10

12

14

16

18

0

5

10

15

20

25

30

35

Peak Pulse Current - I

PP

(A)

Clamping Voltage - V

C

(V)

Pin 2 to 1

Pin 3 to 1

Waveform

Parameters:

tr = 8

�

s

td = 20

�

s

4

� 2000 Semtech Corp.

www.semtech.com

PROTECTION PRODUCTS

PROTECTION PRODUCTS

SLVU2.8

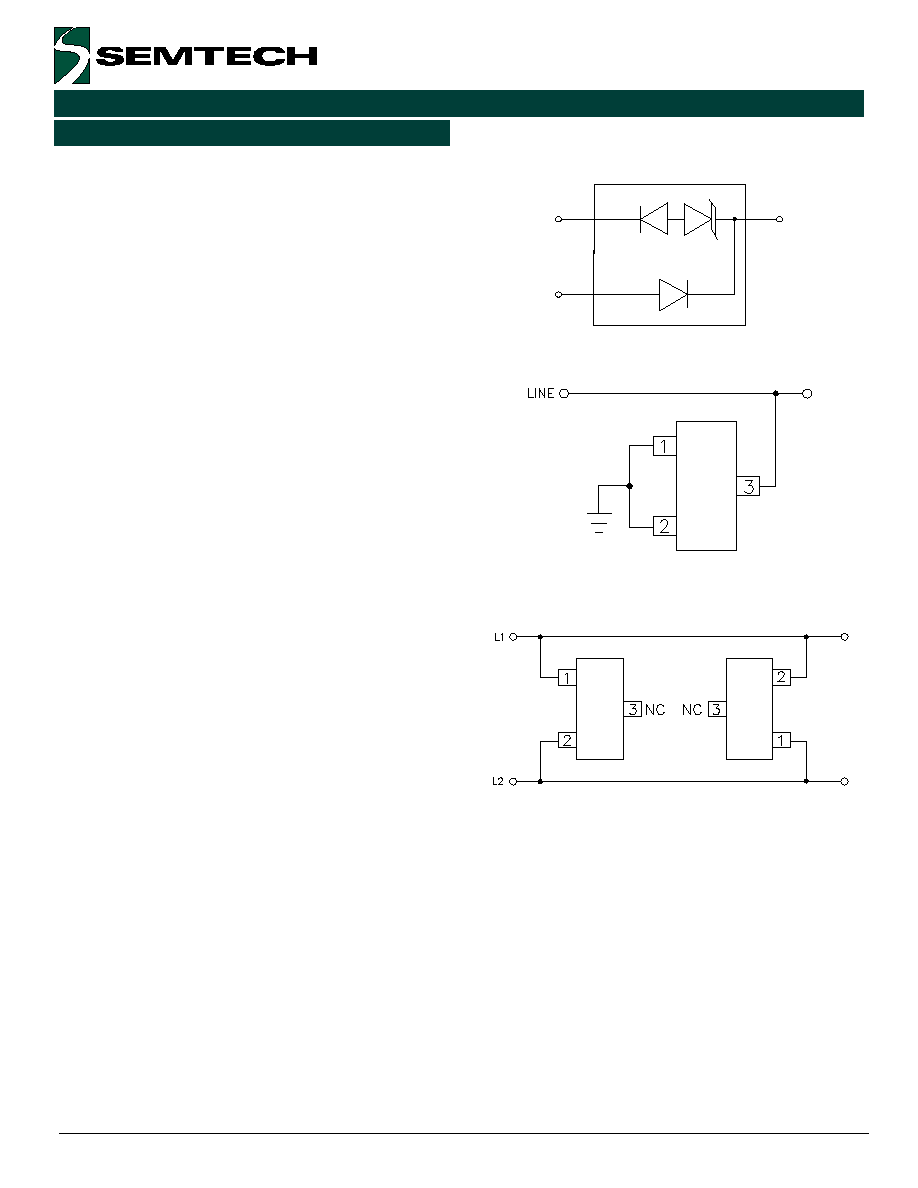

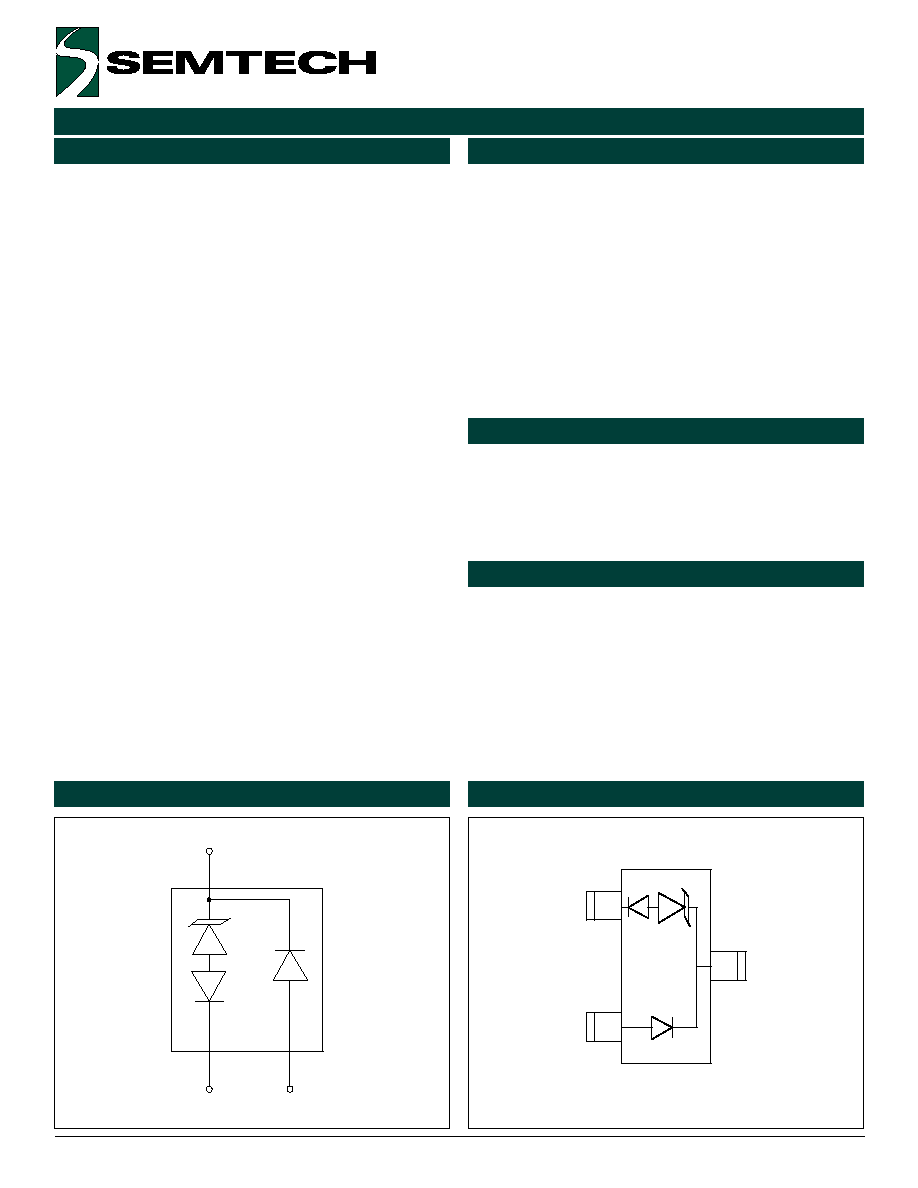

SLVU2.8 Circuit Diagram

Protection of one unidirectional line

Device Connection Options

Electronic equipment is susceptible to transient distur-

bances from a variety of sources including: ESD to an

open connector or interface, direct or nearby lightning

strikes to cables and wires, and charged cables hot

plugged into I/O ports. The SLVU2.8 is designed to

protect sensitive components from damage and latch-

up which may result from such transient events. The

SLVU2.8 can be configured to protect either one

unidirectional line or two (one line pair) high-speed data

lines. The options for connecting the devices are as

follows:

1. Protection of one unidirectional I/O line: Protec-

tion of one data line is achieved by connecting pin

3 to the protected line, and pins 1 and 2 to ground.

This connection option will allow the device to

operate on lines with positive polarity signal transi-

tions (during normal operation). In this configura-

tion, the device adds a maximum loading capaci-

tance of 100pF. During positive duration tran-

sients, the internal TVS diode will be reversed

biased and will act in the avalanche mode, con-

ducting the transient current from pin 3 to 1. The

transient will be clamped at or below the rated

clamping voltage of the device. For negative

duration transients, the internal steering diode is

forward biased, conducting the transient current

from pin 2 to 3. The transient is clamped below

the rated forward voltage drop of the diode.

2. Low capacitance protection of one differential

line pair: Protection of a high-speed differential line

pair is achieved by connecting two devices in anti-

parallel. Pin 1 of the first device is connected to

line 1 and pin 2 is connected to line 2. Pin 2 of the

second device is connected to line 1 and pin 1 is

connected to line 2 as shown. Pin 3 must be left

open on both devices. During negative duration

transients, the first device will conduct from pin 2

to 1. The steering diode conducts in the forward

direction while the TVS will avalanche and conduct

in the reverse direction. During positive transients,

the second device will conduct in the same man-

ner. In this configuration, the total loading capaci-

tance is the sum of the capacitance (between pins

1 and 2) of each device (typically <10pF) making

this configuration suitable for high-speed interfaces

such as 10/100 Ethernet (See application note

SI98-02).

1

2

3

Low capacitance protection of one high-speed line

pair

Circuit Board Layout Recommendations for Suppres-

sion of ESD.

Good circuit board layout is critical for the suppression

of ESD induced transients. The following guidelines are

recommended:

l

Place the SLVU2.8 near the input terminals or

connectors to restrict transient coupling.

l

Minimize the path length between the TVS and the

protected line.

l

Minimize all conductive loops including power and

ground loops.

l

The ESD transient return path to ground should be

kept as short as possible.

l

Never run critical signals near board edges.

l

Use ground planes whenever possible.

Applications Information

5

� 2000 Semtech Corp.

www.semtech.com

PROTECTION PRODUCTS

PROTECTION PRODUCTS

SLVU2.8

Applications Information (continued)

,

PP

,

6%

,

37

,

5

9

5:0

9

9

37

9

&

9

%55

,

%55

6%

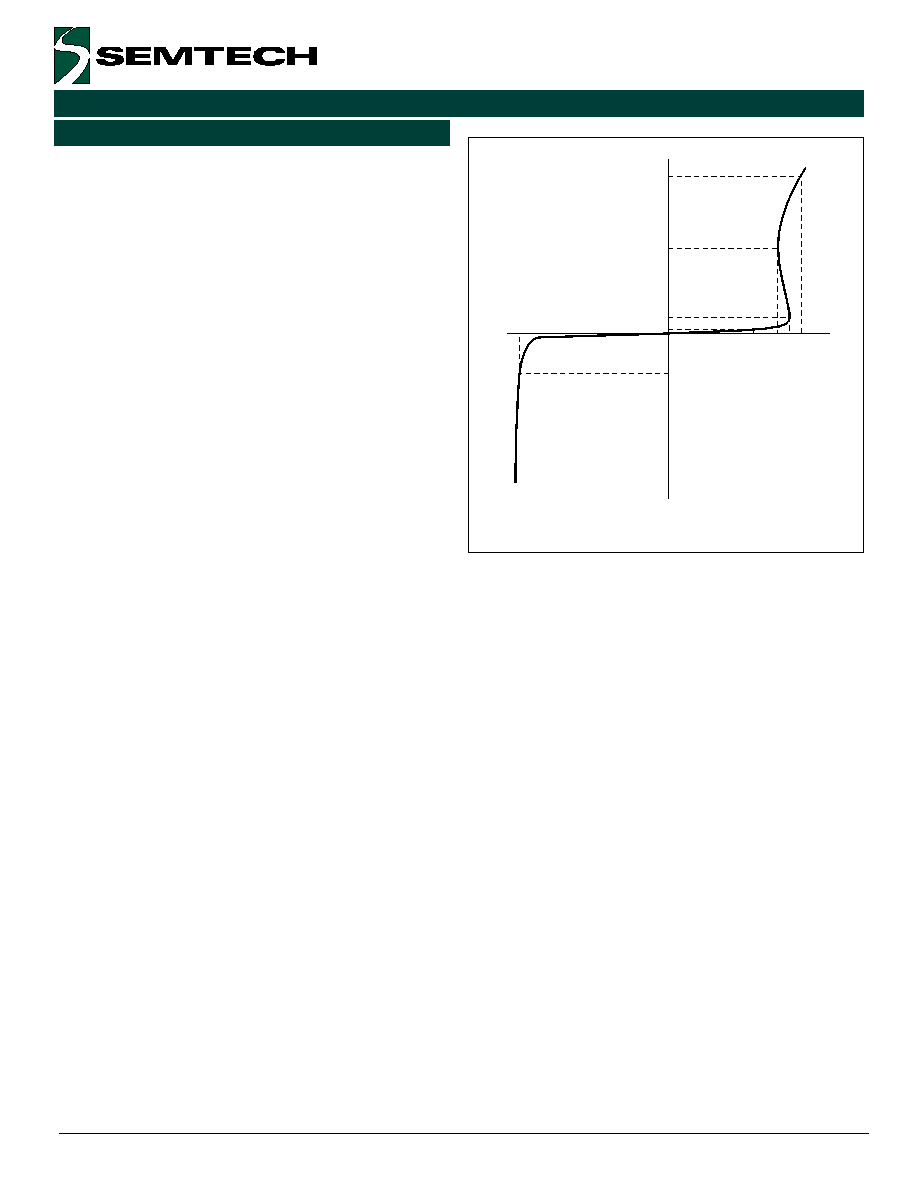

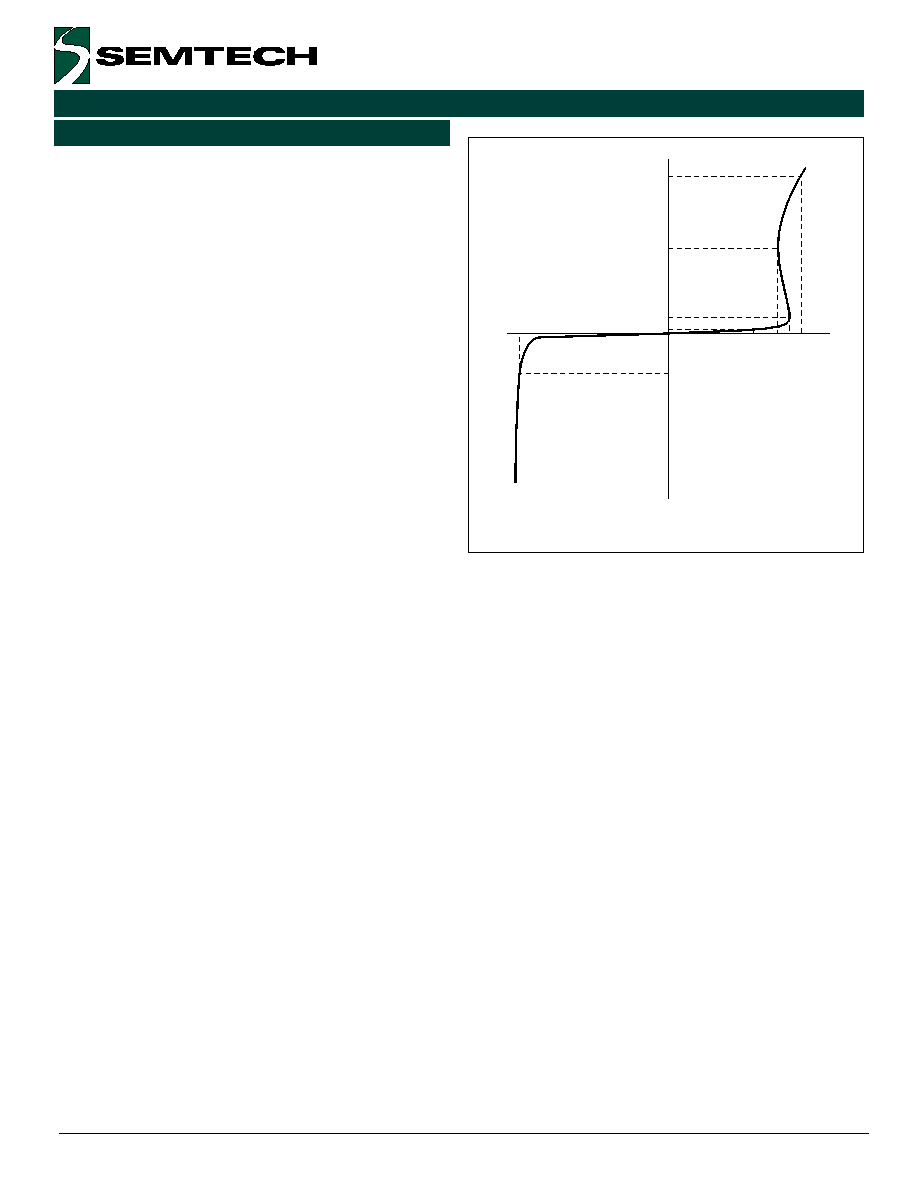

EPD TVS VI Characteristic Curve

EPD TVS

Characteristics

The SLVU2.8 is constructed using Semtechs propri-

etary EPD technology. The structure of the EPD TVS is

vastly different from the traditional pn-junction devices.

At voltages below 5V, high leakage current and junction

capacitance render conventional avalanche technology

impractical for most applications. However, by utilizing

the EPD technology, the SLVU2.8 can effectively

operate at 2.8V while maintaining excellent electrical

characteristics.

The EPD TVS employs a complex nppn structure in

contrast to the pn structure normally found in tradi-

tional silicon-avalanche TVS diodes. The EPD mecha-

nism is achieved by engineering the center region of

the device such that the reverse biased junction does

not avalanche, but will punch-through to a conduct-

ing state. This structure results in a device with supe-

rior dc electrical parameters at low voltages while

maintaining the capability to absorb high transient

currents.

The IV characteristic curve of the EPD device is shown

in Figure 1. The device represents a high impedance

to the circuit up to the working voltage (V

RWM

). During a

transient event, the device will begin to conduct as it is

biased in the reverse direction. When the punch-

through voltage (V

PT

) is exceeded, the device enters a

low impedance state, diverting the transient current

away from the protected circuit. When the device is

conducting current, it will exhibit a slight snap-back or

negative resistance characteristic due to its structure.

This must be considered when connecting the device

to a power supply rail. To return to a non-conducting

state, the current through the device must fall below

the snap-back current (approximately < 50mA).