| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: S-8603AWI | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Rev.1.0

_20

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Seiko Instruments Inc.

1

The S-8603AWI is a suitable linear image sensor for a

multichip-type contact image sensor with a resolution of 8

dots per mm. This IC integrates a 64 dots photo-transistor

array and a CMOS scanning circuit. Picture signals are

output one after another in analog signals, synchronized with

a clock signal.

Features

∑ Adjustable scanning length for various sizes of paper : 8 mm.

Various sizes of paper can be read by simply changing the number of chips aligned in a line.

∑ 2-input signals : SI, CLK.

Only these two input signals, start and clock, make the scanning easily.

∑ High sensitivity : High sensitive photo transistor.

∑ Low current consumption : 5 V single power supply and CMOS scanning circuit.

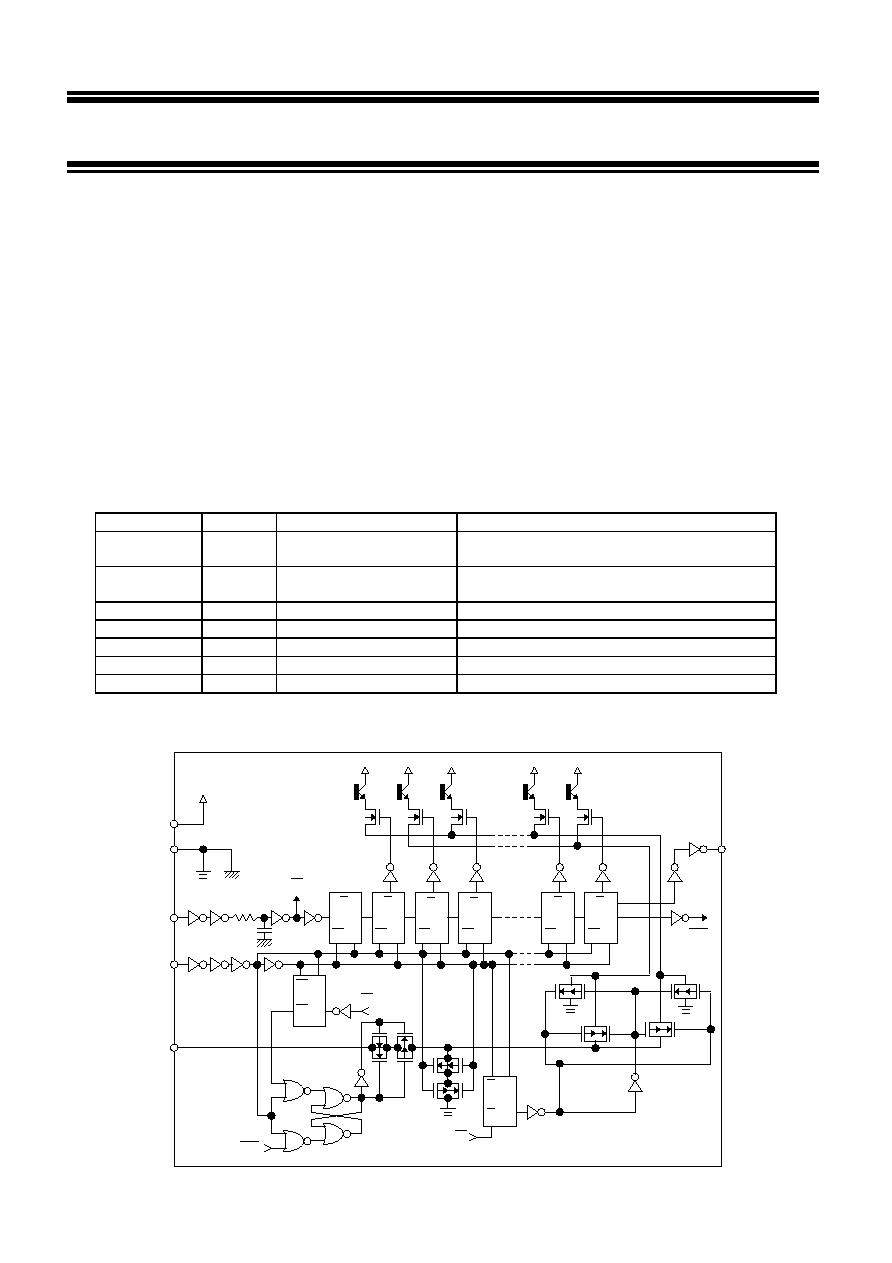

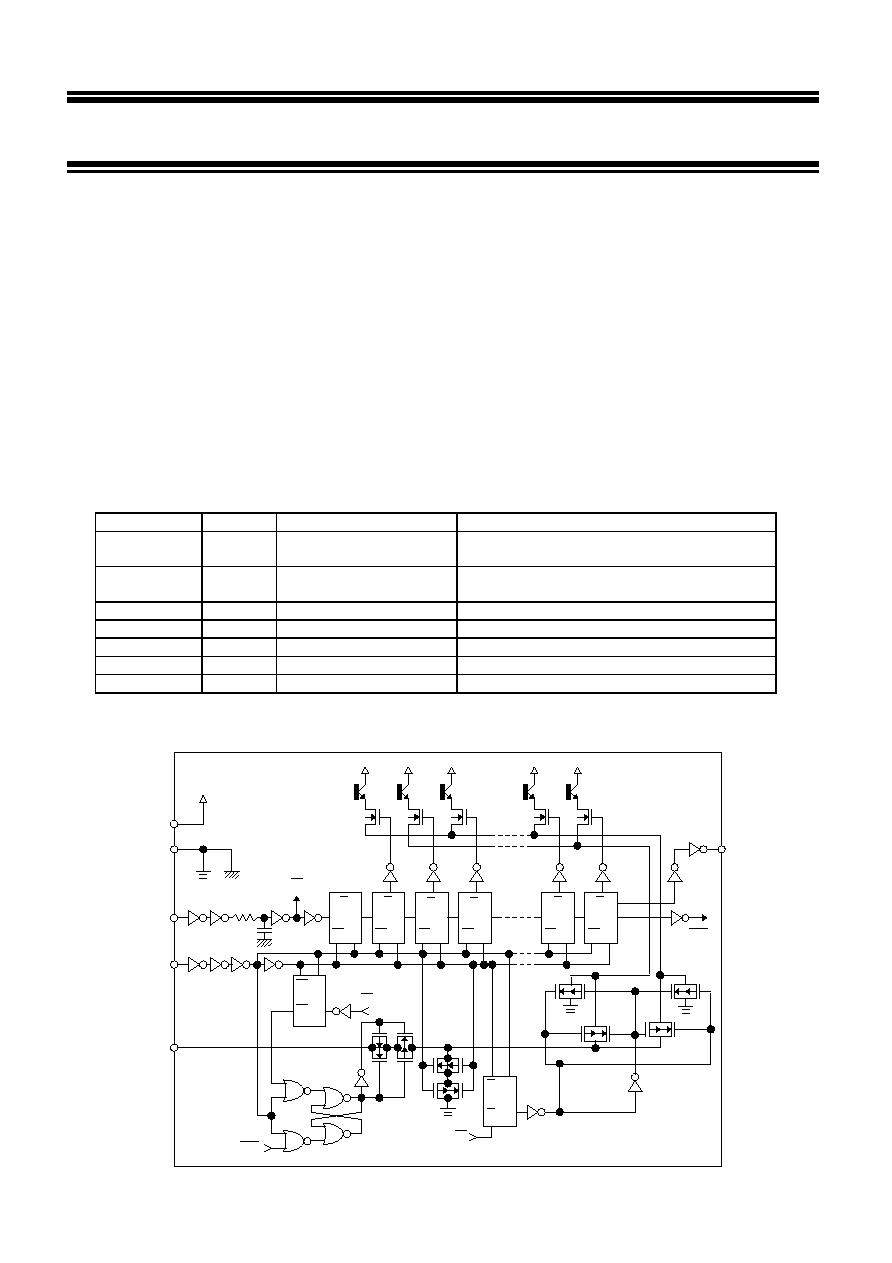

Terminal functions

Table-1

Terminal No.

Symbol

Name

Operation

1

SI

Start input pin

Shift register data input pin

CMOS input (Logic level is TTL- level)

2

CLK

Clock input pin

Shift register clock input pin

CMOS input (Logic level is TTL- level)

3

VDD

Power supply pin

Normally +5 V

4

GND

Ground pin

Normally 0 V

5

SIG

Video signal output pin

Picture image analog signal output pin

6

N.C.

7

SO

Start output pin

Shift register data output pin

Circuit diagram

Q

D Q

CK CK

CK CK

Q

D Q

CK CK

Q

D Q

CK CK

Q

D Q

CK CK

Q

M

D Q

CK CK

3

64

63

2

1

Q

D Q

CK CK

D

M

T T

R

Q

SO

Q64

VDD

GND

SI

64

63

3

2

1

0

D.G.

A.G.

SI

CLK

SIG

SI

Q64

SI

RGE

RGO

SCS

SCE

SCO

RGS

Figure-1

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Rev.1.0

_20

Seiko Instruments Inc.

2

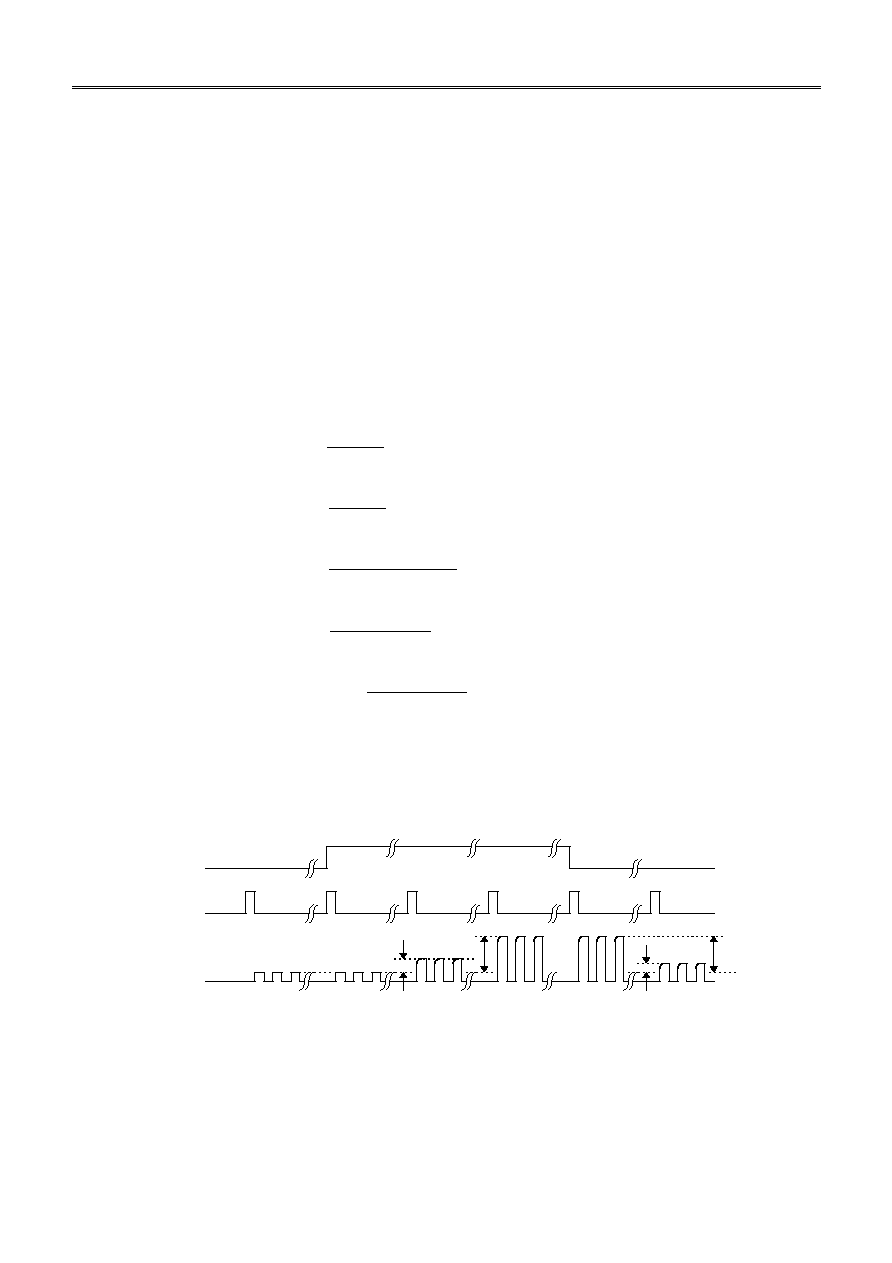

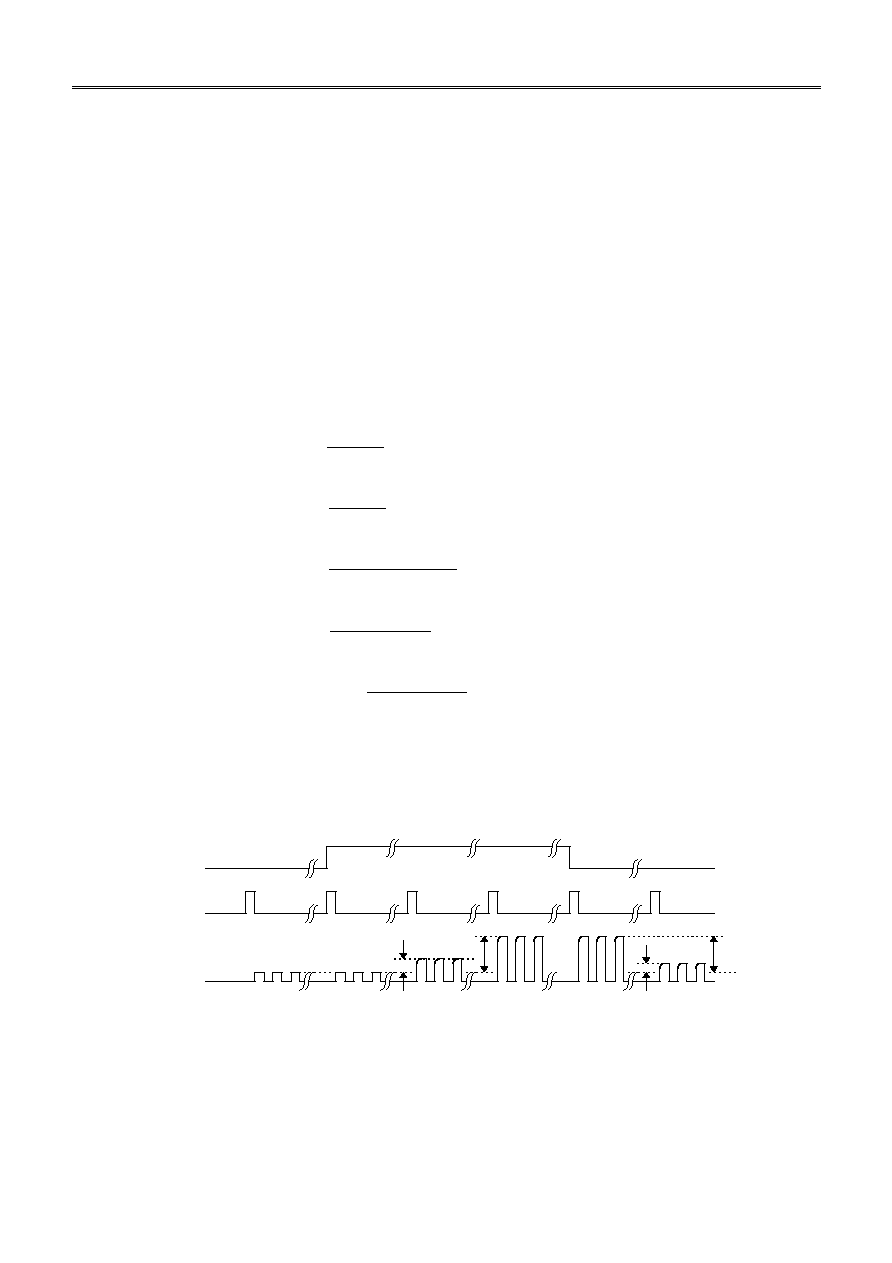

Timing chart

CLK

th

tsu

SI

R

SCO

(SI for 2nd IC)

(dash line : 2nd IC)

SI(SO)

Q0

Q1

Q2

Q63

Q64

SO

63

62

61

60

6

5

4

3

2

1

SIG

SCS

(RGS)

(RGE)

1

64

62

63

61

60

6

5

4

3

Tw

2

SCE

(RGO)

tphl

tplh

Figure-2

64

Absolute maximum ratings

Table-2

Parameter

Symbol

Condition

Rating

Unit

Power supply voltage

V

DD

VDD-GND

-0.4

+7.0

V

Input voltage

V

IN

SI, CLK

-0.4

V

DD

+0.4

V

Output voltage

V

OUT

SO, SIG

-0.4

V

DD

+0.4

V

Operating temperature

T

opr

-5

+85

∞C

Storage temperature

T

stg

-40

+125

∞C

Caution The absolute maximum ratings are rated values exceeding which the product could

suffer physical damage. These values must therefore not be exceeded under any

conditions.

Electric characteristics

1) DC characteristics

Table-3

V

DD

=5V

±

10%, T

OPR

=55

∞

C

Parameter

Symbol

Condition

Rating

Unit

min.

typ.

max.

Input voltage

VIH

SI, CLK

2.4

V

VIL

0.8

Input current

IIH

SI, CLK

0.5

µA

IIL

-0.5

Output voltage

VOH

IOH = -100

µA

3.8

V

VOL

IOL = 100

µA

0.4

Current consumption

IDD

fck = 1 MHz

0.2

3.0

mA

Leak current

IS

VDD-GND

0.2

µA

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

Rev.1.0

_20

S-8603 AWI

Seiko Instruments Inc.

3

2) Switching characteristics

Table-4

V

DD

=5V

±

10%, T

OPR

=55

∞

C

Parameter

Symbol

Condition

Rating

Unit

A

B

min.

typ.

max.

*1)

*2)

Clock pulse width

Tw

High period of CLK

100

(1/fck)

-100

ns

Data set up time

tsu

100

1/fck

ns

Data hold time

th

0

(1/fck)

-200

ns

Clock frequency

fck

Assurance of shift-

register operation

2.5

MHz

CLK-SO L-H

delay time

tplh

fck = 2.5 MHz

C

L

= 10 pF

150

ns

CLK-SO H-L

delay time

tphl

fck = 2.5 MHz

C

L

= 10 pF

150

ns

Output stable time1

*3)

tpd1

900

ns

Output stable time 2

*3)

tpd2

300

ns

*1) All products are tested.

*2) Extracted products are examined.

*3) At measuring light level of photoelectric conversion characteristics.

(Note)

SIG

CLK

50%

90%

100%

10%

tpd2

Figure-3

tpd1

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Rev.1.0

_20

Seiko Instruments Inc.

4

3) Photoelectric conversion characteristics

Condition :

V

DD

=5 V, T

OPR

=55

∞

C, fck=500 kHz(duty=50 %)

Read period RT=5 ms, load capacitor C

L

=100 pF

Light source LED

(

=570 nm, half width

30 nm, illuminance 12 lx)

Connecting a capacitor of 0.1

µ

F between VDD and GND.

Vp is measured using the measurement circuit of Figure-4.

+

+5V

Vp

-5V

(AD843)

SIG

CLK

100 pF

74HC4066

Figure-4 Measurement circuit

-

Av=2

1k

1k

Table-5

Parameter

Symbol

Condition

Rating

Unit

Note

A

B

min.

typ.

max.

*1)

*2)

Light level

Vpave

Exposure value

Ep = 0.06 lx s

0.570

1.268

V

3)-2

dV1

Read period

-6.0

+6.0

%

3)-1

Light level

dV2

RT = 5 ms

-6.0

+6.0

%

deviation

dV3

0.0

+7.5

%

dV4

, i = 2

62

-7.0

+7.0

%

, i = 1 , 64

-15.0

+15.0

%

dV1

+dV2

RT = 5 ms

-10.0

+10.0

%

Dark level 1

Vd1

RT = 5 ms

fck = 500 kHz

24

60

mV

Dark level 2

Vd2

RT = 32 ms

fck = 2 kHz

240

mV

Dark level

deviation

inside the

wafer *4)

dark

RT = 5 ms

fck = 500 kHz

0

9

mV

Linearity

0.95

1.1

1.2

3)-3

Image lag

RIL

measuring Vpave

40

%

3)-1

Light response

RIR

measuring Vpave

35

%

3)-1

*1) All products are tested.

*2) Extracted products are examined.

*4) The deviation of the average value of Vd1(1

64 bit) inside a wafer.

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

Rev.1.0

_20

S-8603 AWI

Seiko Instruments Inc.

5

3)-1 Parameter definition

Vp_ ave

: average of all bit output

Vp_ max

: maximum output

Vave1: average of 2

10bit

Vp_ min

: Fminimum output

Vave2

: average of 28

36bit

Vp(i)

: i bit output ( i =1

to

63)

Vave3

: average of 55

63bit

V1 = Vave2 - Vave1

V2 = Vave3 - Vave2

dV1

V1

Vp_ ave

=

◊

100

(%)

dV2

V2

Vp_ ave

=

◊

100

dV3

Vp_ max Vp_ min

Vp_ max Vp_ min

=

-

+

◊100

dV4

Vp(i) Vp(i 1)

Vp_ ave

100

=

-

+

◊

dV1 dV2

Vave3 Vave1

Vp_ ave

100

+

=

-

◊

RIL

: Image lag (cf. Figure-5)

RIR

: Light response (cf. Figure-5)

100%

Vp

Image lag : RIL

40%

Figure-5

Light response : RIR

35%

Vp

OFF

ON

OFF

Vd

8

7

6

2

1

LED

SIG

SI

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Rev.1.0

_20

Seiko Instruments Inc.

6

3)-2 Light level ranking

Table-6

Vpave(typ)

±

2.5 %

RANK

Vpave(V)

RANK

Vpave(V)

min.(

)

typ.

max.(<)

min.(

)

typ.

max.(<)

0

0.570

0.584

0.599

8

0.850

0.872

0.893

1

0.599

0.614

0.630

9

0.893

0.916

0.939

2

0.630

0.646

0.662

A

0.939

0.963

0.987

3

0.662

0.679

0.696

B

0.987

1.013

1.038

4

0.696

0.714

0.731

C

1.038

1.065

1.091

5

0.731

0.750

0.769

D

1.091

1.119

1.147

6

0.769

0.789

0.808

E

1.147

1.177

1.206

7

0.808

0.829

0.850

F

1.206

1.237

1.268

3)-3 Linearity

value is achieved using the non-linear regression based on the following equation,

measuring Vp every 0.01 Lx s from dark status to 0.06 Lx s.

Vp_ ave A B Ep

= + ∑

(A,B: constant , Ep: exposure value)

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

Rev.1.0

_20

S-8603 AWI

Seiko Instruments Inc.

7

Pad configuration

Photo detecting windous

Figure-6

AR

7

6

5

4

AC

3

2

1

AL

Chip size : 8000

µm◊350µm (before scribing)

Pad size : 100

µm◊80µm (Opening area)

(0,0) : The coordinate origin is the center of left bottom scribing area

The minimum distance between boundary of pad opening area and Al pattern

15µm

Table-7

Unit :

µ

m

PAD No.

Name

Coordinate

PAD No.

Name

Coordinate

X

Y

X

Y

1

SI

1431

102

5

SIG

4870

102

2

CK

1832

102

6

N.C.

6223

102

3

VDD

3182

102

7

SO

7021

102

4

GND

4245

102

Table-8 Unit:

µ

m

Alignment mark

Coordinate

name

X

Y

AL

240

102

AC

4000

102

AR

7790

102

Chip size and sensor arrangement diagram

Shaded area : photo detecting window (X=85,Y=60)

P

◊31

64

63

62

61

(Scribe center)

X

Y

145.5

32

34

33

31

80

4

3

2

1

P

P

(P=124.12)

Unit :

µm

P

P

P

P

79.5

P

◊31

8000

Chip size : 8000

µm ◊ 350 µm (before scribing)

79.5

Figure-7

Note : The coordinate origin is the center of

the scribe line of the lower left corner

of the IC, and the coordinate values

point the center of the pads and the

alignment marks .

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Rev.1.0

_20

Seiko Instruments Inc.

8

Wafer form

Note: The arrangement of IC is subject to change without notes.

Wafer thickness: 350

±

30

µ

m

Wafer diameter

:

6 inches

O

r

ient

a

t

io

n F

l

at

Wa

f

e

r N

o

.

Lot

N

o

.

(Pad side)

IC chip

(Sensor side)

Figure-8

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

Rev.1.0

_20

S-8603 AWI

Seiko Instruments Inc.

9

Scribe line

60

(Scribe line area)

60

50

51

290

54

(Unit :

µm)

(Photo detecting window)

(Passivasion boundary)

60

7940

Figure-9

Alignment mark

(Unit :

µm)

The minimum distance between boundary of pad opening

area and Al pattern area has to be 15

µm or more.

Figure-10

Al pattern

Passivasion

opening

35

35

30

4

25

27.5

27.5

4

LINEAR IMAGE SENCER IC FOR CONTACT IMAGE SENSOR

S-8603 AWI

Rev.1.0

_20

Seiko Instruments Inc.

10

Handling precautions

Products are shipped in wafer or bare chip form. Keep these precautions when handling a product.

1. Protect against static electricity damage when mounting on a sawing or dicing machine.

∑ Wear charge-proof clothing and discharge all static electricity from body.

∑ Work on a grounded conductive mat.

∑ Ground all soldering irons and machines.

∑ Maintain room humidity from 50 to 60 %RH.

2. Prevent malfunctions due to corrosion of electrode pads.

∑ Do not store products in a high-temperature, humid and dusty environment or one that includes

corrosive gas.

∑ Coat surface of IC with silicon resin to keep surface clean.

∑ Use clear and non-static packing material.

∑ Store products in a dry box filled with dry N2 gas having the dew point ≠30∞C or less when storing

products for 3 months or more.

3. Protect the internal Al lines and protective film of the IC when mounting products.

∑ Do not damage the surface of the IC when mounting a die or bonding wires.

∑ Do not touch the surface of the IC with tweezers.

4. Maintain the stability of the IC.

∑ Always supply VDD to the IC since the substrate is n-type semiconductor.

∑ Send the null data until the Vsig signal becomes stable at power on.

∑ Coat the IC with a transparent resin like silicon resin or enclose the IC with glass.

∑ Decrease the parasitic resistance of GND line and VDD line of the circuit board on which the IC is

mounted.

∑ Decrease the parasitic capacitance between CLK and SIG of the circuit board on which the IC is

mounted.

∑ Fix the cycle and duty of the input signal while operating.

∑ Mount a capacitor between VDD and GND to prevent influence of voltage fluctuation due to the

response current of the IC. Decide the mounting method and the capacitance of the capacitor based on

evaluation of the product in an actual application.

∑

The information described herein is subject to change without notice.

∑

Seiko Instruments Inc. is not responsible for any problems caused by circuits or diagrams described herein

whose related industrial properties, patents, or other rights belong to third parties. The application circuit

examples explain typical applications of the products, and do not guarantee the success of any specific

mass-production design.

∑

When the products described herein are regulated products subject to the Wassenaar Arrangement or other

agreements, they may not be exported without authorization from the appropriate governmental authority.

∑

Use of the information described herein for other purposes and/or reproduction or copying without the

express permission of Seiko Instruments Inc. is strictly prohibited.

∑

The products described herein cannot be used as part of any device or equipment affecting the human

body, such as exercise equipment, medical equipment, security systems, gas equipment, or any apparatus

installed in airplanes and other vehicles, without prior written permission of Seiko Instruments Inc.

∑

Although Seiko Instruments Inc. exerts the greatest possible effort to ensure high quality and reliability, the

failure or malfunction of semiconductor products may occur. The user of these products should therefore

give thorough consideration to safety design, including redundancy, fire-prevention measures, and

malfunction prevention, to prevent any accidents, fires, or community damage that may ensue.