| ÐлекÑÑоннÑй компоненÑ: SP7650 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

1

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

SP7650

FEATURES

2.5V to 28V Step Down Achieved Using Dual Input

Output Voltage down to 0.8V

3A Output Capability

Built in Low R

DSON

Power Switches (40 m typ)

Highly Integrated Design, Minimal Components

300 kHz Fixed Frequency Operation

UVLO Detects Both V

CC

and V

IN

Over Temperature Protection

Short Circuit Protection with Auto-Restart

Wide BW Amp Allows Type II or III Compensation

Programmable Soft Start

Fast Transient Response

High Efficiency: Greater than

95%

Possible

Asynchronous Start-Up into a Pre-Charged Output

Small 7mm x 4mm DFN Package

Wide Input Voltage Range 3A, 300kHz, Buck Regulator

The SP7650 is a synchronous step-down switching regulator optimized for high efficiency. The part is designed to be

especially attractive for dual supply, 12V or 24V distributed power systems step down with 5V used to power the

controller. This lower V

CC

voltage minimizes power dissipation in the part and is used to drive the top switch. The SP7650

is designed to provide a fully integrated buck regulator solution using a fixed 300kHz frequency, PWM voltage mode

architecture. Protection features include UVLO, thermal shutdown and output short circuit protection. The SP7650 is

available in the space saving DFN package

.

®

Advanced

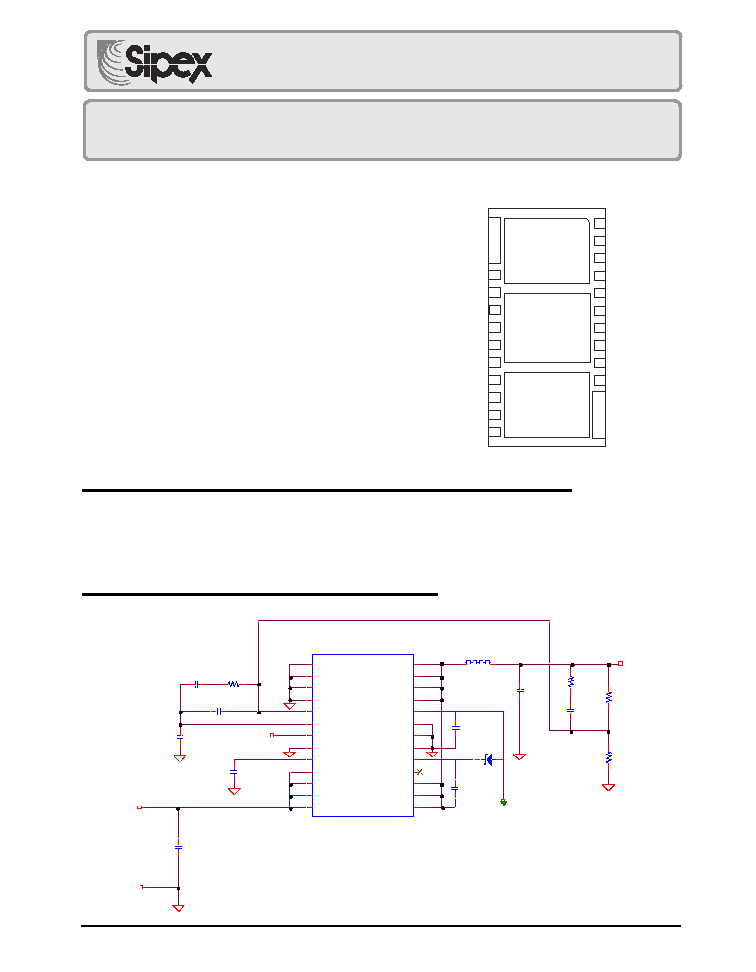

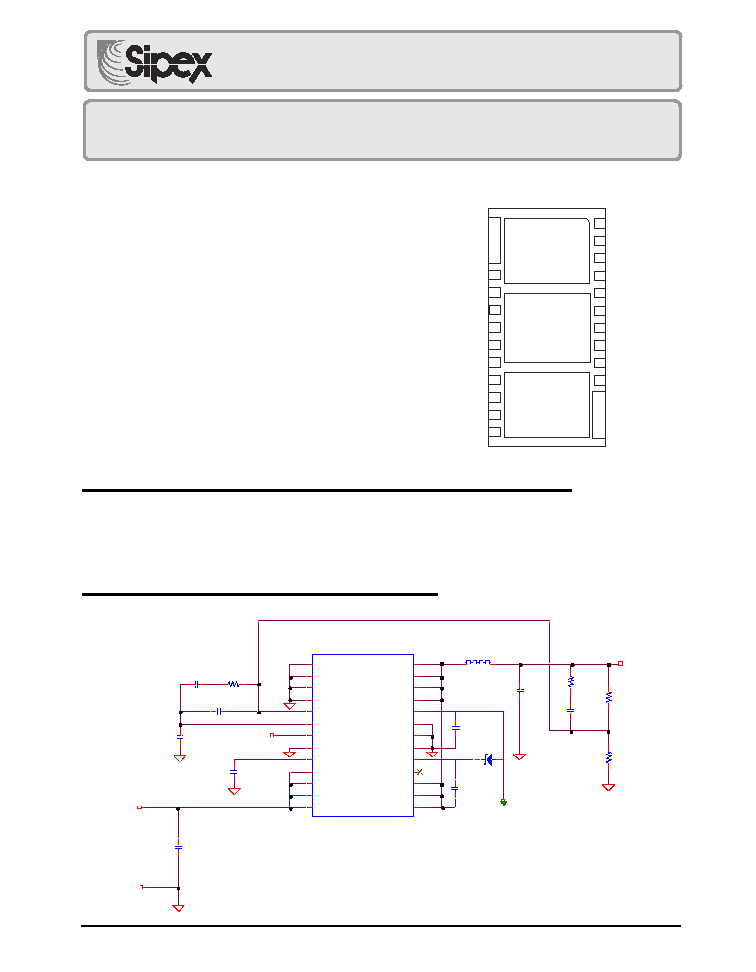

TYPICAL APPLICATION CIRCUIT

Now Available in Lead Free Packaging

DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

2 2

23

24

25

26

TOP VIEW

Heatsink Pad 1

Connect to Lx

Heatsink pad 2

Connect to GND

Heatsink pad 3

Connect to V

IN

P

GND

P

GND

GND

V

FB

COMP

UVIN

GND

SS

V

IN

LX

LX

LX

LX

V

CC

GND

GND

GND

BST

NC

LX

LX

LX

DFN PACKAGE

7mm x 4mm

SP7650

P

GND

V

IN

V

IN

V

IN

CBST

6800pF

L1

2.2uH, Irate=4.78A

C1

22uF

CVCC

2.2uF

U1

SP7650

PGND

1

PGND

2

PGND

3

GND

4

VFB

5

COMP

6

UVIN

7

GND

8

SS

9

VIN

10

VIN

11

VIN

12

VIN

13

LX

14

LX

15

LX

16

NC

17

BST

18

GND

19

GND

20

GND

21

VCC

22

LX

23

LX

24

LX

25

LX

26

DBST

CSS

47nF

CP1

22pF

3.3V

0-3A

RSET

21.5k,1%

GND

C3

47uF

N o t e s :

1 2 V

VIN

1. U1 Bottom-Side Layout should

has three contacts isolated from

one another Vin SWNODE and GND

SD101AWS

VOUT

RZ3

7.15k,1%

CZ3

150pF

CZ2

1,000pF

R1

68.1k,1%

RZ2

15k,1%

CF1

100pF

fs=300Khz

+5V VCC

ENABLE

2. RSET=54.48/(Vout-0.8V) (KOhm)

1 6 V

6.3V

(note 2)

2

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

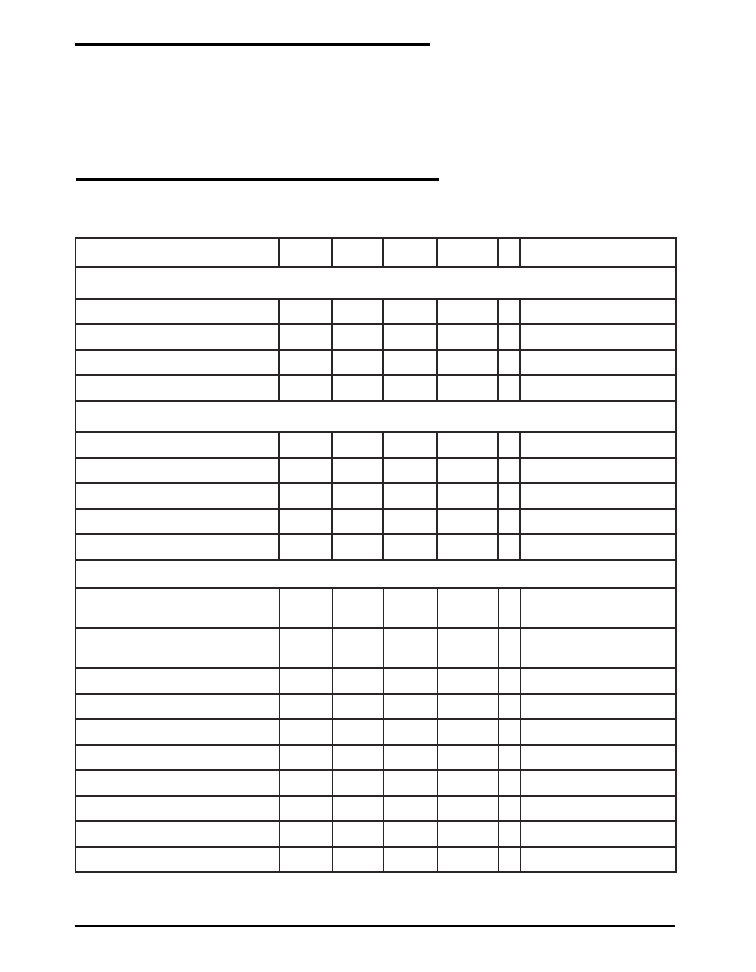

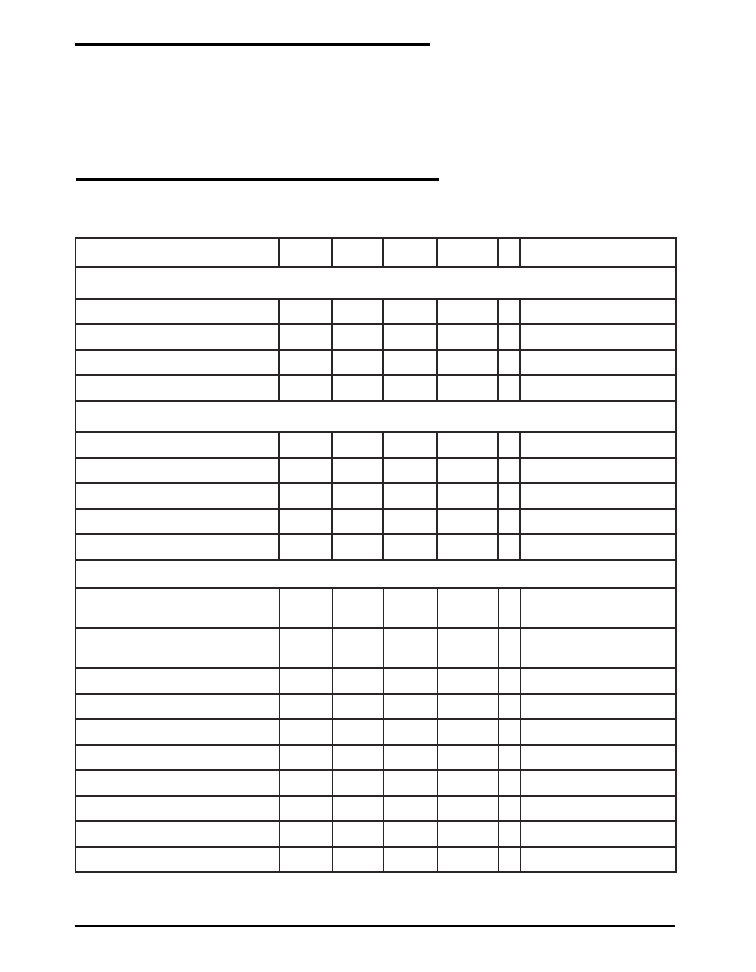

ELECTRICAL SPECIFICATIONS

Unless otherwise specified: -40°C < T

AMB

< 85°C, -40°C<Tj<125°C, 4.5V < V

CC

< 5.5V, 3V<Vin<28V, BST=LX

+ 5V, LX =

GND = 0V, UVIN = 3.0V, CV

CC

= 1µF, C

COMP

= 0.1µF, C

SS

= 50nF, Typical measured at V

CC

= 5V.

The denotes the specifications which apply over the full temperature range, unless otherwise specified.

These are stress ratings only and functional operation of the device at

these ratings or any other above those indicated in the operation sections

of the specifications below is not implied. Exposure to absolute maximum

rating conditions for extended periods of time may affect reliability.

V

CC

.................................................................................................. 7V

V

IN ...........................................................................................................................................

30V

I

LX ...............................................................................................................................................

5A

BST ............................................................................................... 35V

BST-SWN ......................................................................... -0.3V to 7V

SWN ................................................................................... -1V to 30V

GH ......................................................................... -0.3V to BST+0.3V

GH-SWN ......................................................................................... 7V

All other pins .......................................................... -0.3V to V

CC

+0.3V

Storage Temperature .................................................. -65°C to 150°C

Power Dissipation ...................................... Internally Limited via OTP

Lead Temperature (Soldering, 10 sec) ...................................... 300°C

ESD Rating .......................................................................... 2kV HBM

Thermal Resistance

JC ....................................................................................

5°C/W

ABSOLUTE MAXIMUM RATINGS

R

E

T

E

M

A

R

A

P

.

N

I

M

.

P

Y

T

.

X

A

M

S

T

I

N

U

S

N

O

I

T

I

D

N

O

C

T

N

E

R

R

U

C

T

N

E

C

S

E

I

U

Q

V

C

C

)

g

n

i

h

c

t

i

w

s

o

N

(

t

n

e

r

r

u

C

y

l

p

p

u

S

5

.

1

3

A

m

V

B

F

V

9

.

0

=

V

C

C

)

g

n

i

h

c

t

i

w

s

(

t

n

e

r

r

u

C

y

l

p

p

u

S

8

D

B

T

A

m

)

g

n

i

h

c

t

i

w

s

o

N

(

t

n

e

r

r

u

C

y

l

p

p

u

S

T

S

B

2

.

0

4

.

0

A

m

V

B

F

V

9

.

0

=

)

g

n

i

h

c

t

i

w

s

(

t

n

e

r

r

u

C

y

l

p

p

u

S

T

S

B

0

.

4

D

B

T

A

m

O

L

V

U

:

N

O

I

T

C

E

T

O

R

P

V

C

C

d

l

o

h

s

e

r

h

T

t

r

a

t

S

O

L

V

U

0

0

.

4

5

2

.

4

5

.

4

V

V

C

C

s

i

s

e

r

e

t

s

y

H

O

L

V

U

0

0

1

0

0

2

0

0

3

V

m

d

l

o

h

s

e

r

h

T

t

r

a

t

S

N

I

V

U

3

.

2

5

.

2

5

6

.

2

V

s

i

s

e

r

e

t

s

y

H

N

I

V

U

0

0

2

0

0

3

0

0

4

V

m

t

n

e

r

r

u

C

t

u

p

n

I

N

I

V

U

1

A

µ

V

0

.

3

=

N

I

V

U

E

C

N

E

R

E

F

E

R

R

E

I

F

I

L

P

M

A

R

O

R

R

E

e

c

n

e

r

e

f

e

R

r

e

i

f

il

p

m

A

r

o

r

r

E

2

9

7

.

0

0

0

8

.

0

8

0

8

.

0

V

e

r

u

s

a

e

M

,

.

g

i

f

n

o

C

n

i

a

G

X

2

V

B

F

V

;

C

C

C

º

5

2

=

T

,

V

5

=

e

c

n

e

r

e

f

e

R

r

e

i

f

il

p

m

A

r

o

r

r

E

e

r

u

t

a

r

e

p

m

e

T

d

n

a

e

n

i

L

r

e

v

O

8

8

7

.

0

0

0

8

.

0

2

1

8

.

0

V

e

c

n

a

t

c

u

d

n

o

c

s

n

a

r

T

r

e

i

f

il

p

m

A

r

o

r

r

E

6

V

/

A

m

n

i

a

G

r

e

i

f

il

p

m

A

r

o

r

r

E

0

6

B

d

d

a

o

L

o

N

t

n

e

r

r

u

C

k

n

i

S

P

M

O

C

0

5

1

A

µ

V

B

F

V

9

.

0

=

P

M

O

C

,

V

9

.

0

=

t

n

e

r

r

u

C

e

c

r

u

o

S

P

M

O

C

0

5

1

A

µ

V

B

F

V

2

.

2

=

P

M

O

C

,

V

7

.

0

=

V

B

F

t

n

e

r

r

u

C

s

a

i

B

t

u

p

n

I

0

5

0

0

2

A

n

V

B

F

V

8

.

0

=

e

l

o

P

l

a

n

r

e

t

n

I

4

z

H

M

p

m

a

l

C

P

M

O

C

5

.

2

V

V

B

F

C

º

5

2

=

A

T

,

V

7

.

0

=

t

n

e

i

c

i

f

f

e

o

C

.

p

m

e

T

p

m

a

l

C

P

M

O

C

2

-

C

º

/

V

m

3

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

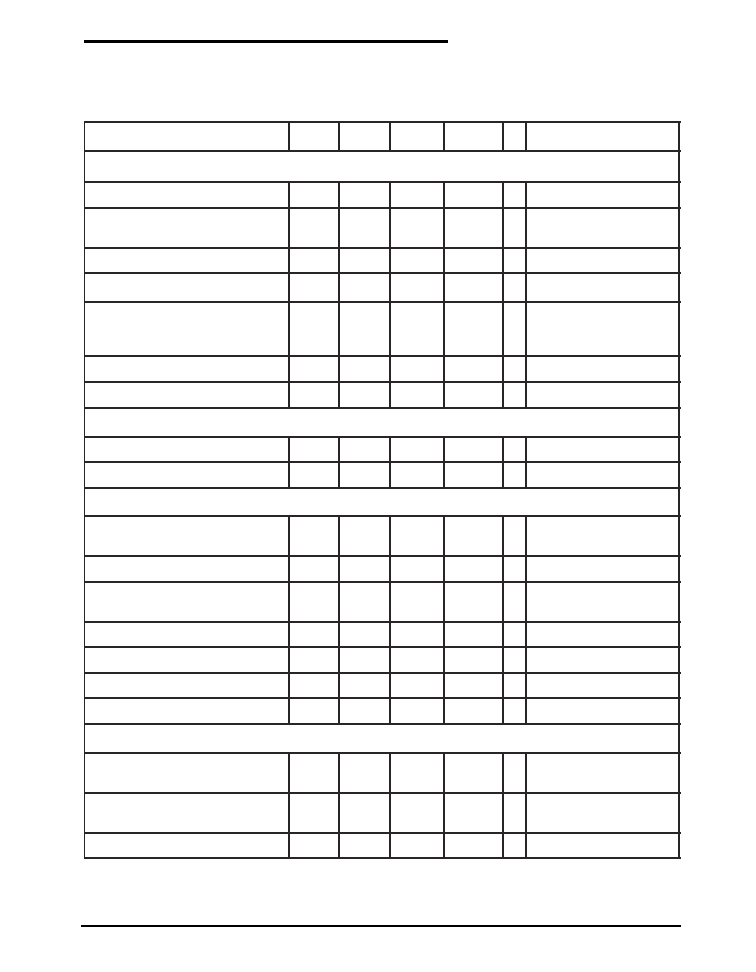

ELECTRICAL SPECIFICATIONS

Unless otherwise specified: -40°C < T

AMB

< 85°C, -40°C<Tj<125°C, 4.5V < V

CC

< 5.5V, 3V<Vin<28V, BST=LX

+ 5V, LX =

GND = 0V, UVIN = 3.0V, CV

CC

= 1µF, C

COMP

= 0.1µF, C

SS

= 50nF, Typical measured at V

CC

= 5V.

The denotes the specifications which apply over the full temperature range, unless otherwise specified.

R

E

T

E

M

A

R

A

P

.

N

I

M

.

P

Y

T

.

X

A

M

S

T

I

N

U

S

N

O

I

T

I

D

N

O

C

H

T

A

P

Y

A

L

E

D

P

O

O

L

&

P

M

A

R

,

R

O

T

A

R

A

P

M

O

C

M

W

P

:

P

O

O

L

L

O

R

T

N

O

C

e

d

u

t

il

p

m

A

p

m

a

R

2

9

.

0

1

.

1

8

2

.

1

V

t

e

s

f

f

O

P

M

A

R

1

.

1

V

T

A

P

M

O

C

P

M

A

R

,

C

º

5

2

=

g

n

i

h

c

t

i

w

S

s

t

r

a

t

s

H

G

li

t

n

u

t

n

e

i

c

i

f

f

e

o

C

.

p

m

e

T

t

e

s

f

f

o

P

M

A

R

2

-

C

º

/

V

m

h

t

d

i

W

e

s

l

u

P

m

u

m

i

n

i

M

H

G

0

9

0

8

1

s

n

o

i

t

a

R

y

t

u

D

e

l

b

a

ll

o

r

t

n

o

C

m

u

m

i

x

a

M

2

9

7

9

%

o

i

t

a

R

y

t

u

D

m

u

m

i

x

a

M

e

r

o

f

e

b

t

s

u

j

d

e

r

u

s

a

e

M

s

n

i

g

e

b

g

n

i

s

l

u

p

o

i

t

a

R

y

t

u

D

m

u

m

i

x

a

M

0

0

1

%

s

e

l

c

y

c

0

2

r

o

f

d

il

a

V

o

i

t

a

R

r

o

t

a

ll

i

c

s

O

l

a

n

r

e

t

n

I

0

4

2

0

0

3

0

6

3

z

H

k

T

R

A

T

S

T

F

O

S

:

S

R

E

M

I

T

:

t

n

e

r

r

u

C

e

g

r

a

h

C

S

S

0

1

A

µ

:

t

n

e

r

r

u

C

e

g

r

a

h

c

s

i

D

S

S

1

A

m

V

2

.

0

=

S

S

,

t

n

e

s

e

r

P

t

l

u

a

F

l

a

m

r

e

h

T

&

t

i

u

c

r

i

C

t

r

o

h

S

:

N

O

I

T

C

E

T

O

R

P

e

g

a

t

l

o

V

d

l

o

h

s

e

r

h

T

t

i

u

c

r

i

C

t

r

o

h

S

2

.

0

5

2

.

0

3

.

0

V

V

d

e

r

u

s

a

e

M

F

E

R

-

)

V

8

.

0

(

V

B

F

t

u

o

e

m

i

T

p

u

c

c

i

H

0

0

2

s

m

V

B

F

V

5

.

0

=

s

e

l

c

y

C

k

c

o

l

C

e

l

b

a

w

o

ll

A

f

o

r

e

b

m

u

N

e

l

c

y

C

y

t

u

D

%

0

0

1

t

a

0

2

s

e

l

c

y

C

s

e

l

c

y

C

0

2

r

e

t

f

A

e

s

l

u

P

L

G

m

u

m

i

n

i

M

5

.

0

s

e

l

c

y

C

V

B

F

V

7

.

0

=

e

r

u

t

a

r

e

p

m

e

T

n

w

o

d

t

u

h

S

l

a

m

r

e

h

T

5

4

1

C

º

V

B

F

V

7

.

0

=

e

r

u

t

a

r

e

p

m

e

T

y

r

e

v

o

c

e

R

l

a

m

r

e

h

T

5

3

1

C

º

s

i

s

e

r

e

t

s

y

H

l

a

m

r

e

h

T

0

1

C

º

E

G

A

T

S

R

E

W

O

P

:

T

U

P

T

U

O

R

h

c

t

i

w

S

e

d

i

S

h

g

i

H

N

O

S

D

0

4

m

V

C

C

I

;

V

5

=

T

U

O

A

3

=

T

B

M

A

C

º

5

2

=

R

h

c

t

i

w

S

e

d

i

s

w

o

L

s

u

o

r

h

c

n

y

S

N

O

S

D

0

4

m

V

C

C

I

;

V

5

=

T

U

O

A

3

=

T

B

M

A

C

º

5

2

=

t

n

e

r

r

u

C

t

u

p

t

u

O

m

u

m

i

x

a

M

3

A

4

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

General Overview

The SP7650 is a fixed frequency, voltage mode,

synchronous PWM regulator optimized for high

efficiency. The part has been designed to be

especially attractive for high voltage applica-

tions utilizing 5V to power the controller and

2.5V to 28V for step down conversion.

The heart of the SP7650 is a wide bandwidth

transconductance amplifier designed to accom-

modate Type II and Type III compensation

schemes. A precision 0.8V reference, present on

the positive terminal of the error amplifier per-

mits the programming of the output voltage

down to 0.8V via the V

FB

pin. The output of the

error amplifier, COMP, compared to a 1.1V

peak-to-peak ramp is responsible for trailing

edge PWM control. This voltage ramp, and

PWM control logic are governed by the internal

oscillator that accurately sets the PWM fre-

quency to 300kHz.

THEORY OF OPERATION

The SP7650 contains two unique control fea-

tures that are very powerful in distributed appli-

cations. First, asynchronous driver control is

enabled during start up, to prohibit the low side

switch from pulling down the output until the

high side switch has attempted to turn on. Sec-

ond, a 100% duty cycle timeout ensures that the

low side switch is periodically enhanced during

extended periods at 100% duty cycle. This guar-

antees the synchronized refreshing of the BST

capacitor during very large duty ratios.

The SP7650 also contains a number of valuable

protection features. Programmable V

IN

UVLO

allows the user to set the exact value at which the

conversion voltage can safely begin down con-

version, and an internal V

CC

UVLO which en-

sures that the controller itself has enough volt-

age to properly operate. Other protection fea-

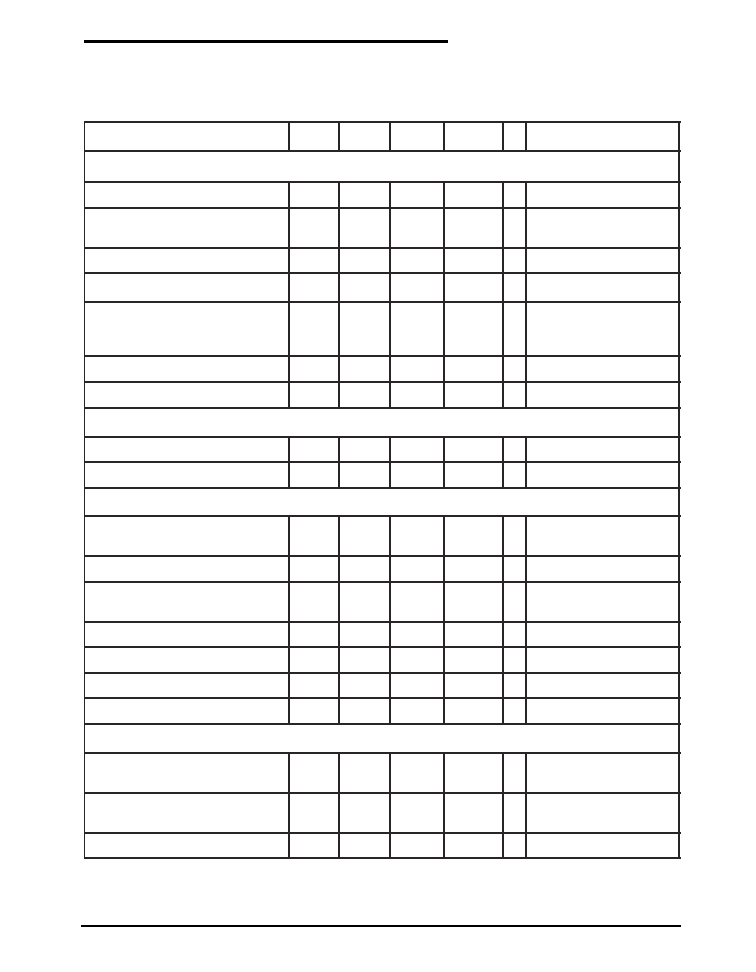

PIN DESCRIPTION

#

n

i

P

e

m

a

N

n

i

P

n

o

i

t

p

i

r

c

s

e

D

3

-

1

P

D

N

G

r

e

i

f

i

t

c

e

r

s

u

o

n

o

r

h

c

n

y

s

e

h

t

r

o

f

n

o

i

t

c

e

n

n

o

c

d

n

u

o

r

G

1

2

-

9

1

,

8

,

4

D

N

G

e

r

a

r

e

v

i

r

d

r

e

w

o

p

r

e

w

o

l

d

n

a

C

I

e

h

t

f

o

y

r

t

i

u

c

r

i

c

l

o

r

t

n

o

c

e

h

T

.

n

i

P

d

n

u

o

r

G

)

-

(

e

h

t

o

t

s

e

c

a

r

t

d

n

u

o

r

g

r

e

h

t

o

m

o

r

f

y

l

e

t

a

r

a

p

e

s

n

r

u

t

e

R

.

n

i

p

s

i

h

t

o

t

d

e

c

n

e

r

e

f

e

r

.

t

u

o

C

f

o

l

a

n

i

m

r

e

t

5

V

B

F

t

u

p

n

i

g

n

i

t

r

e

v

n

i

e

h

t

s

i

t

I

.

n

i

p

n

o

i

t

c

e

t

e

D

t

i

u

c

r

i

C

t

r

o

h

S

d

n

a

e

g

a

t

l

o

V

k

c

a

b

d

e

e

F

r

o

f

t

n

i

o

p

k

c

a

b

d

e

e

f

e

g

a

t

l

o

v

t

u

p

t

u

o

e

h

t

s

a

s

e

v

r

e

s

d

n

a

r

e

i

f

il

p

m

A

r

o

r

r

E

e

h

t

f

o

d

e

t

s

u

j

d

a

e

b

n

a

c

d

n

a

d

e

s

n

e

s

s

i

e

g

a

t

l

o

v

t

u

p

t

u

o

e

h

T

.

r

e

t

r

e

v

n

o

C

k

c

u

B

e

h

t

V

r

e

v

e

n

e

h

W

.

r

e

d

i

v

i

d

r

o

t

s

i

s

e

r

l

a

n

r

e

t

x

e

n

a

h

g

u

o

r

h

t

B

F

e

h

t

w

o

l

e

b

V

5

2

.

0

s

p

o

r

d

p

u

c

c

i

h

s

r

e

t

n

e

C

I

e

h

t

d

n

a

d

e

t

c

e

t

e

d

s

i

t

l

u

a

f

t

i

u

c

r

i

c

t

r

o

h

s

a

,

e

c

n

e

r

e

f

e

r

e

v

i

t

i

s

o

p

.

e

d

o

m

6

P

M

O

C

t

u

p

n

i

g

n

i

t

r

e

v

n

i

e

h

t

o

t

d

e

t

c

e

n

n

o

c

y

ll

a

n

r

e

t

n

i

s

i

t

I

.

r

e

i

f

il

p

m

A

r

o

r

r

E

e

h

t

f

o

t

u

p

t

u

O

d

n

a

n

e

s

o

h

c

s

i

n

o

i

t

a

n

i

b

m

o

c

r

e

t

li

f

l

a

m

i

t

p

o

n

A

.

r

o

t

a

r

a

p

m

o

c

M

W

P

e

h

t

f

o

V

r

o

d

n

u

o

r

g

r

e

h

t

i

e

d

n

a

n

i

p

s

i

h

t

o

t

d

e

t

c

e

n

n

o

c

B

F

e

g

a

t

l

o

v

e

h

t

e

z

il

i

b

a

t

s

o

t

.

p

o

o

l

e

d

o

m

7

N

I

V

U

V

n

e

e

w

t

e

b

r

e

d

i

v

i

d

r

o

t

s

i

s

e

r

a

t

c

e

n

n

o

C

.

e

g

a

t

l

o

v

n

i

V

r

o

f

t

u

p

n

i

O

L

V

U

N

I

d

n

a

V

U

N

I

e

g

a

t

l

o

v

g

n

i

t

a

r

e

p

o

m

u

m

i

n

i

m

t

e

s

o

t

9

S

S

e

h

t

t

e

s

o

t

D

N

G

d

n

a

S

S

n

e

e

w

t

e

b

r

o

t

i

c

a

p

a

c

l

a

n

r

e

t

x

e

n

a

t

c

e

n

n

o

C

.

t

r

a

t

S

t

f

o

S

w

o

l

d

l

e

h

s

i

n

i

p

S

S

e

h

T

.

t

n

e

r

r

u

c

e

c

r

u

o

s

A

µ

0

1

e

h

t

n

o

d

e

s

a

b

e

t

a

r

t

r

a

t

s

t

f

o

s

.

s

n

o

i

t

i

d

n

o

c

t

l

u

a

f

ll

a

g

n

i

r

u

d

t

n

e

r

r

u

c

)

n

i

m

(

A

m

1

a

a

i

v

3

1

-

0

1

V

N

I

g

n

il

p

u

o

c

e

d

a

e

c

a

l

P

.

T

E

F

S

O

M

l

e

n

n

a

h

c

-

N

e

d

i

s

h

g

i

h

e

h

t

o

t

n

o

i

t

c

e

n

n

o

c

t

u

p

n

I

.

D

N

G

P

d

n

a

n

i

p

s

i

h

t

n

e

e

w

t

e

b

r

o

t

i

c

a

p

a

c

6

2

-

3

2

,

6

1

-

4

1

X

L

V

d

n

a

n

i

p

s

i

h

t

n

e

e

w

t

e

b

r

o

t

c

u

d

n

i

n

a

t

c

e

n

n

o

C

T

U

O

2

2

V

C

C

y

l

p

p

u

s

s

a

i

b

V

5

l

a

n

r

e

t

x

e

r

o

f

t

u

p

n

I

7

1

C

N

t

c

e

n

n

o

C

o

N

5

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

tures include thermal shutdown and short-cir-

cuit detection. In the event that either a thermal,

short-circuit, or UVLO fault is detected, the

SP7650 is forced into an idle state where the

output drivers are held off for a finite period

before a restart is attempted.

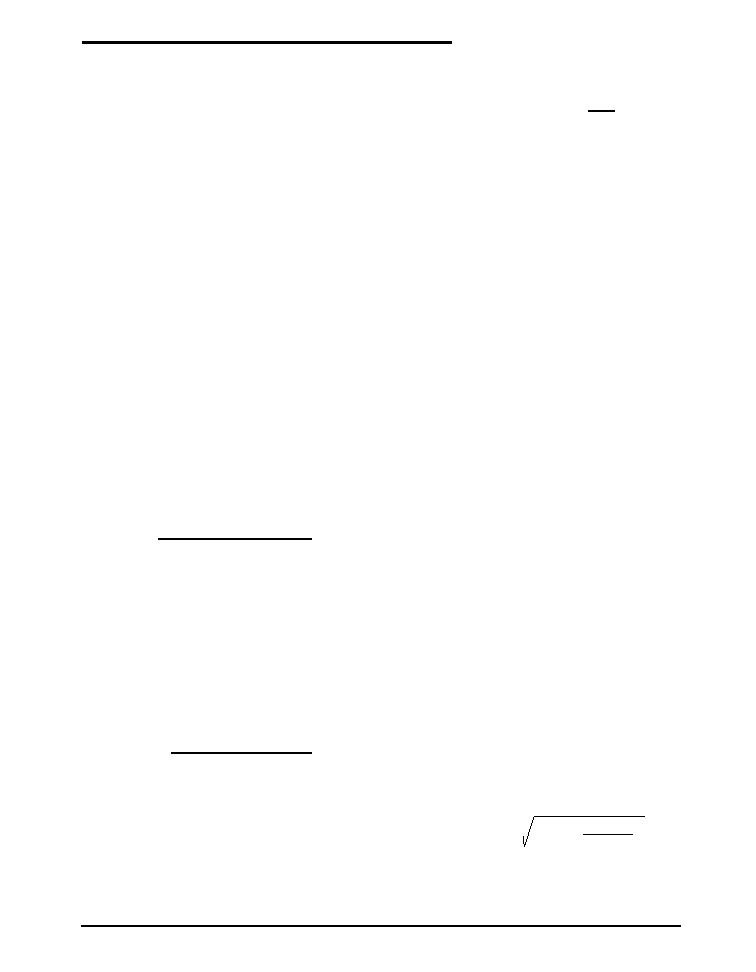

Soft Start

"Soft Start" is achieved when a power converter

ramps up the output voltage while controlling

the magnitude of the input supply source cur-

rent. In a modern step down converter, ramping

up the positive terminal of the error amplifier

controls soft start. As a result, excess source

current can be defined as the current required to

charge the output capacitor.

I

VIN

= C

OUT

* (DV

OUT

/ DT

SOFT-START

)

The SP7650 provides the user with the option to

program the soft start rate by tying a capacitor

from the SS pin to GND. The selection of this

capacitor is based on the 10uA pull up current

present at the SS pin and the 0.8V reference

voltage. Therefore, the excess source can be

redefined as:

IV

IN

= C

OUT

* (DV

OUT

*10

µA / (C

SS

* 0.8V)

Under Voltage Lock Out (UVLO)

The SP7650 contains two separate UVLO com-

parators to monitor the bias (V

CC

) and conver-

sion (V

IN

) voltages independently. The V

CC

UVLO threshold is internally set to 4.25V,

whereas the V

IN

UVLO threshold is program-

mable through the UVIN pin. When the UVIN

pin is greater than 2.5V, the SP7650 is permitted

to start up pending the removal of all other

faults. Both the V

CC

and V

IN

UVLO compara-

tors have been designed with hysteresis to pre-

vent noise from resetting a fault.

Thermal and Short-Circuit

Protection

Because the SP7650 is designed to drive large

output current, there is a chance that the power

converter will become too hot. Therefore, an

internal thermal shutdown (145

°C) has been

included to prevent the IC from malfunctioning

at extreme temperatures.

A short-circuit detection comparator has also

been included in the SP7650 to protect against

an accidental short at the output of the power

converter. This comparator constantly monitors

the positive and negative terminals of the error

amplifier, and if the V

FB

pin falls more than

250mV (typical) below the positive reference, a

short-circuit fault is set. Because the SS pin

overrides the internal 0.8V reference during soft

start, the SP7650 is capable of detecting short-

circuit faults throughout the duration of soft

start as well as in regular operation.

Handling of Faults:

Upon the detection of power (UVLO), thermal,

or short-circuit faults, the SP7650 is forced into

an idle state where the SS and COMP pins are

pulled low and both switches are held off. In the

event of UVLO fault, the SP7650 remains in this

idle state until the UVLO fault is removed.

Upon the detection of a thermal or short-circuit

fault, an internal 200ms timer is activated. In the

event of a short-circuit fault, a re-start is at-

tempted immediately after the 200ms timeout

expires. Whereas, when a thermal fault is de-

tected the 200ms delay continuously recycles

and a re-start cannot be attempted until the

thermal fault is removed and the timer expires.

Error Amplifier and Voltage Loop

Since the heart of the SP7650 voltage error loop

is a high performance, wide bandwidth

transconductance amplifier. Because of the

amplifier's current limited (+/-150

µA)

transconductance, there are many ways to com-

pensate the voltage loop or to control the COMP

pin externally. If a simple, single pole, single

THEORY OF OPERATION

6

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

THEORY OF OPERATION

zero response is desired, then compensation can

be as simple as an RC to ground. If a more

complex compensation is required, then the

amplifier has enough bandwidth (45

° at 4 MHz)

and enough gain (60dB) to run Type III compen-

sation schemes with adequate gain and phase

margins at cross over frequencies greater than

50kHz.

The common mode output of the error amplifier

is 0.9V to 2.2V. Therefore, the PWM voltage

ramp has been set between 1.1V and 2.2V to

ensure proper 0% to 100% duty cycle capability.

The voltage loop also includes two other very

important features. One is an asynchronous start

up mode. Basically, the synchronous rectifier

can not turn on unless the high side switch has

attempted to turn on or the SS pin has exceeded

1.7V. This feature prevents the controller from

"dragging down" the output voltage during

startup or in fault modes. The second feature is

a 100% duty cycle timeout that ensures synchro-

nized refreshing of the BST capacitor at very

high duty ratios. In the event that the high side

NFET is on for 20 continuous clock cycles, a

reset is given to the PWM flip flop half way

through the 21st cycle. This forces GL to rise for

the cycle, in turn refreshing the BST capacitor.

The boost capacitor is used to generate a high

voltage drive supply for the high side switch,

which is 5V above V

IN

.

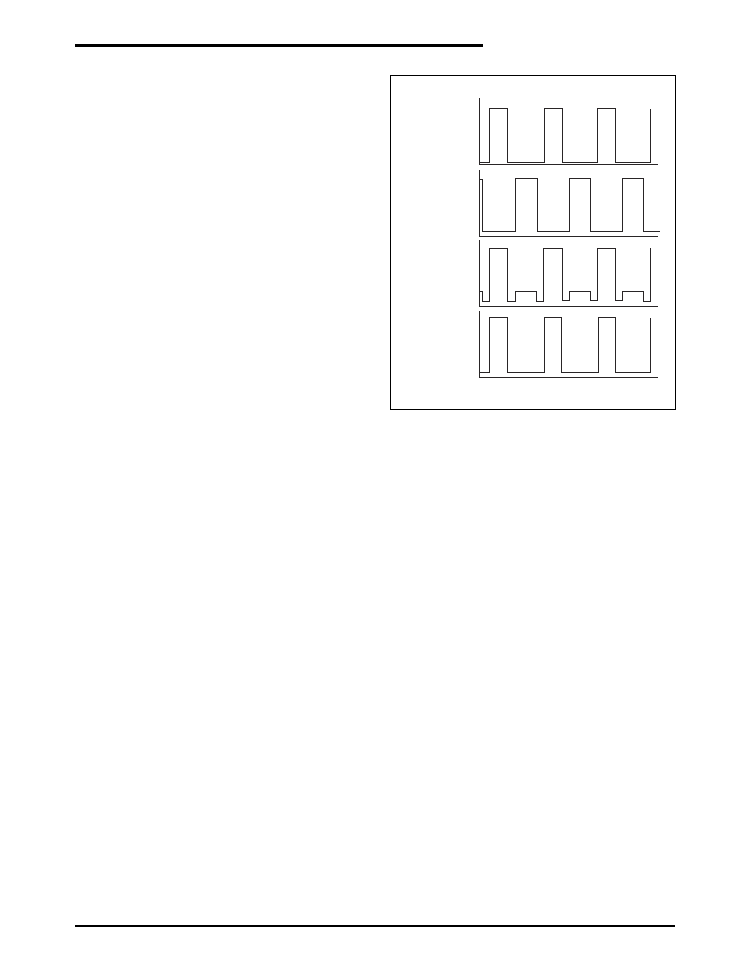

Power MOSFETs

The SP7650 contains a pair of integrated low

resistance N-channel switches designed to drive

up to 3A of output current. Care should be taken

to de-rate the output current based on the ther-

mal conditions in the system such as ambient

temperature, airflow and heat sinking. Maxi-

mum output current could be limited by thermal

limitations of a particular application by taking

advantage of the integrated over temperature

protective scheme employed in the SP7650.

The SP7650 incorporates a built-in over-tem-

perature protection to prevent internal overheat-

ing.

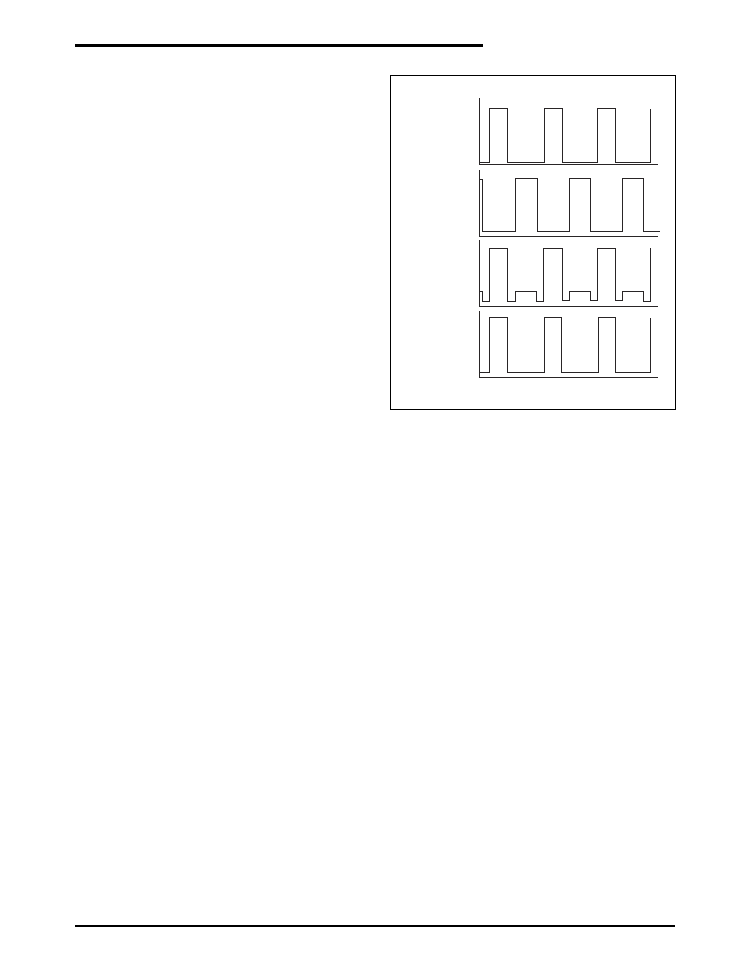

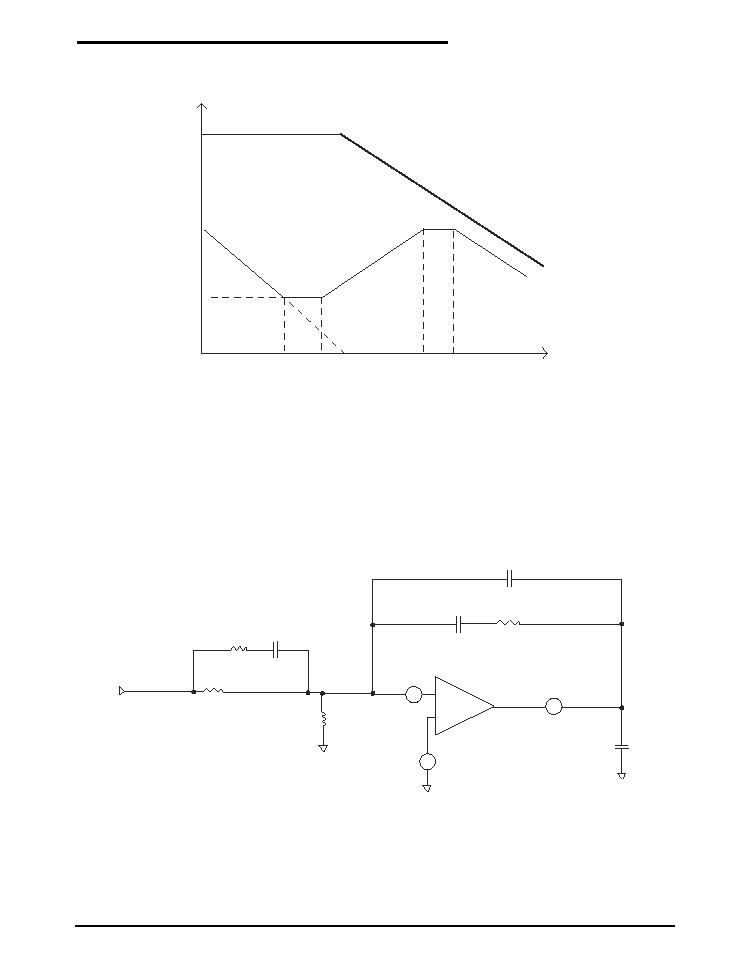

GH

Voltage

GL

Voltage

V(VIN)

0V

-0V

-V(Diode) V

V(VIN)+V(VCC)

BST

Voltage

V(VCC)

TIME

SWN

Voltage

VBST

VSWN

V(VCC)

The SP7650 can be set to different output

voltages. The relationship in the following

formula is based on a voltage divider from the

output to the feedback pin VFB, which is set

to an internal reference voltage of 0.80V.

Standard 1% metal film resistors of surface

mount size 0603 are recommended.

Vout = 0.80V ( R1 / R2 + 1 ) => R2 = R1 / [ (

Vout / 0.80V ) 1 ]

Where R1 = 68.1K

and for Vout = 0.80V

setting, simply remove R2 from the board.

Furthermore, one could select the value of R1

and R2 combination to meet the exact output

voltage setting by restricting R1 resistance

range such that 50K

< R1 < 100K for

overall system loop stability.

Setting Output Voltages

7

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

APPLICATIONS INFORMATION

Inductor Selection

There are many factors to consider in selecting

the inductor including core material, inductance

vs. frequency, current handling capability, effi-

ciency, size and EMI. In a typical SP7650 cir-

cuit, the inductor is chosen primarily for value,

saturation current and DC resistance. Increasing

the inductor value will decrease output voltage

ripple, but degrade transient response. Low in-

ductor values provide the smallest size, but

cause large ripple currents, poor efficiency and

more output capacitance to smooth out the larger

ripple current. The inductor must be able to

handle the peak current at the switching fre-

quency without saturating, and the copper resis-

tance in the winding should be kept as low as

possible to minimize resistive power loss. A

good compromise between size, loss and cost is

to set the inductor ripple current to be within

20% to 40% of the maximum output current.

The switching frequency and the inductor oper-

ating point determine the inductor value as fol-

lows:

( max)

(max )

(max)

)

(

OUT

r

S

IN

OUT

IN

OUT

I

K

F

V

V

V

V

L

-

=

where:

f

S

= switching frequency

Kr = ratio of the AC inductor ripple current to

the maximum output current

The peak to peak inductor ripple current is:

L

F

V

V

V

V

I

S

I N

OUT

IN

OUT

PP

(max)

(max)

)

(

-

=

Once the required inductor value is selected, the

proper selection of core material is based on

peak inductor current and efficiency require-

ments. The core must be large enough not to

saturate at the peak inductor current

2

(max)

P P

OUT

PEAK

I

I

I

+

=

and provide low core loss at the high switching

frequency. Low cost powdered iron cores have

a gradual saturation characteristic but can intro-

duce considerable AC core loss, especially when

the inductor value is relatively low and the

ripple current is high. Ferrite materials, although

more expensive, and have an abrupt saturation

characteristic with the inductance dropping

sharply when the peak design current is ex-

ceeded. Nevertheless, they are preferred at high

switching frequencies because they present very

low core loss while the designer is only required

to prevent saturation. In general, ferrite or

molypermalloy materials are a better choice for

all but the most cost sensitive applications.

Optimizing Efficiency

The power dissipated in the inductor is equal to

the sum of the core and copper losses. To mini-

mize copper losses, the winding resistance needs

to be minimized, but this usually comes at the

expense of a larger inductor. Core losses have a

more significant contribution at low output cur-

rent where the copper losses are at a minimum,

and can typically be neglected at higher output

currents where the copper losses dominate. Core

loss information is usually available from the

magnetic vendor. Proper inductor selection can

affect the resulting power supply efficiency by

more than 15%!

The copper loss in the inductor can be calculated

using the following equation:

WINDING

RMS

L

Cu

L

R

I

P

2

)

(

)

(

=

where I

L(RMS)

is the RMS inductor current that

can be calculated as follows:

I

L(RMS)

= I

OUT(max)

1 + 1

(

I

PP

)

2

3 I

OUT(max)

8

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

Output Capacitor Selection

The required ESR (Equivalent Series Resis-

tance) and capacitance drive the selection of the

type and quantity of the output capacitors. The

ESR must be small enough that both the resis-

tive voltage deviation due to a step change in the

load current and the output ripple voltage do not

exceed the tolerance limits expected on the

output voltage. During an output load transient,

the output capacitor must supply all the addi-

tional current demanded by the load until the

SP7650 adjusts the inductor current to the new

value.

In order to maintain V

OUT

,the capacitance must

be large enough so that the output voltage is

helped up while the inductor current ramps to

the value corresponding to the new load current.

Additionally, the ESR in the output capacitor

causes a step in the output voltage equal to the

current. Because of the fast transient response

and inherent 100%/0% duty cycle capability

provided by the SP7650 when exposed to output

load transient, the output capacitor is typically

chosen for ESR, not for capacitance value.

The output capacitor's ESR, combined with the

inductor ripple current, is typically the main

contributor to output voltage ripple. The maxi-

mum allowable ESR required to maintain a

specified output voltage ripple can be calculated

by:

R

ESR

V

OUT

I

PK-PK

where:

V

OUT

= Peak to Peak Output Voltage Ripple

I

PK-PK

= Peak to Peak Inductor Ripple Current

The total output ripple is a combination of the

ESR and the output capacitance value and can

be calculated as follows:

V

OUT

=

(

I

PP

(1 D)

)

2

+ (I

PP

R

ESR

)

2

C

OUT

F

S

F

S

= Switching Frequency

D = Duty Cycle

C

OUT

= Output Capacitance Value

Input Capacitor Selection

The input capacitor should be selected for ripple

current rating, capacitance and voltage rating.

The input capacitor must meet the ripple current

requirement imposed by the switching current.

In continuous conduction mode, the source cur-

rent of the high-side MOSFET is approximately

a square wave of duty cycle V

OUT

/V

IN

. More

accurately the current wave form is trapezoidal,

given a finite turn-on and turn-off, switch tran-

sition slope. Most of this current is supplied by

the input bypass capacitors. The RMS current

handling capability of the input capacitors is

determined at maximum output current and

under the assumption that the peak

to peak inductor ripple current is low, it is given

by:

I

CIN(RMS)

= I

OUT(max)

D(1 - D)

The worse case occurs when the duty cycle D is

50% and gives an RMS current value equal to

I

OUT

/2.

Select input capacitors with adequate ripple

current rating to ensure reliable operation.

The power dissipated in the input capacitor is:

)

(

2

)

(

CIN

ESR

rms

CIN

CIN

R

I

P

=

This can become a significant part of power

losses in a converter and hurt the overall energy

transfer efficiency. The input voltage ripple

primarily depends on the input capacitor ESR

and capacitance. Ignoring the inductor ripple

current, the input voltage ripple can be deter-

mined by:

APPLICATIONS INFORMATION

9

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

APPLICATIONS INFORMATION

2

)

(

)

(

(max)

)

(

IN

IN

S

OUT

I N

OUT

MAX

OUT

CIN

E SR

out

IN

V

C

F

V

V

V

I

R

I

V

-

+

=

The capacitor type suitable for the output capac-

itors can also be used for the input capacitors.

However, exercise extra caution when tantalum

capacitors are used. Tantalum capacitors are known

for catastrophic failure when exposed to surge

current, and input capacitors are prone to such

surge current when power supplies are connected

"live" to low impedance power sources. Although

tantalum capacitors have been successfully em-

ployed at the input, it is generally not recom-

mended.

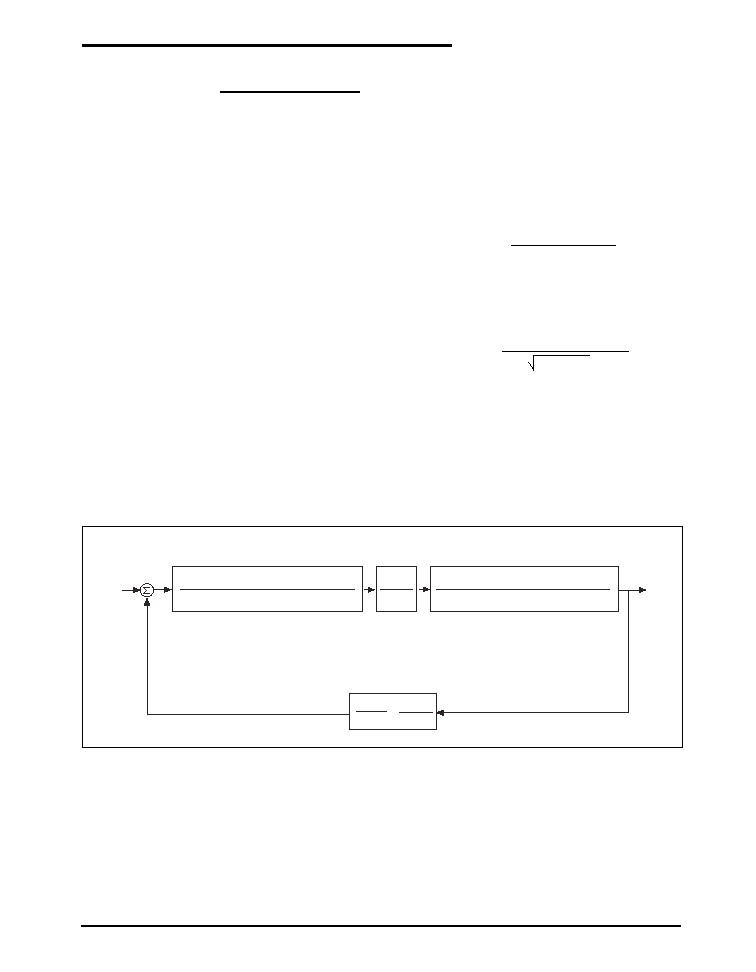

Loop Compensation Design

The open loop gain of the whole system can be

divided into the gain of the error amplifier,

PWM modulator, buck converter output stage,

and feedback resistor divider. In order to cross

over at the desired frequency cut-off (FCO), the

gain of the error amplifier has to compensate for

the attenuation caused by the rest of the loop at

this frequency. The goal of loop compensation

is to manipulate loop frequency response such

that its cross-over gain at 0db, results in a slope

of -20db/dec.

The first step of compensation design is to pick

the loop cross over frequency. High cross over

frequency is desirable for fast transient response,

but often jeopardizes the power supply stability.

Cross over frequency should be higher than the

ESR zero but less than 1/5 of the switching

frequency or 60kHz. The ESR zero is contrib-

uted by the ESR associated with the output

capacitors and can be determined by:

Z(ESR)

=

1

2

C

OUT

R

ESR

The next step is to calculate the complex conju-

gate poles contributed by the LC output filter,

P(LC)

=

1

2

L C

OUT

When the output capacitors are of a Ceramic

Type, the SP7650 Evaluation Board requires a

Type III compensation circuit to give a phase

boost of 180

° in order to counteract the effects of

an under damped resonance of the output filter

at the double pole frequency.

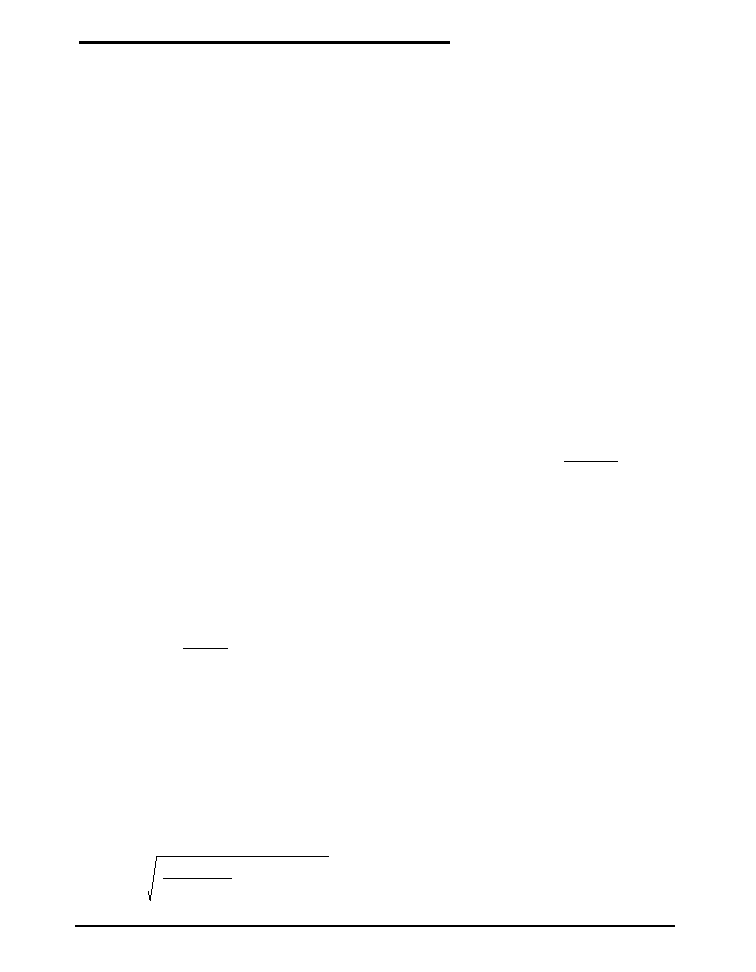

SP7650 Voltage Mode Control Loop with Loop Dynamic

(SRz2Cz2+1)(SR1Cz3+1)

(SR

ESR

C

OUT

+ 1)

[S^2LC

OUT

+S(R

ESR

+R

DC

) C

OUT

+1]

V

IN

SR1Cz2(SRz3Cz3+1)(SRz2Cp1+1)

V

RAMP_PP

V

OUT

(Volts)

+

_

V

REF

(Volts)

Notes: R

ESR

= Output Capacitor Equivalent Series Resistance.

R

DC

= Output Inductor DC Resistance.

V

RAMP_PP

= SP6132 Internal RAMP Amplitude Peak to Peak Voltage.

Condition: Cz2 >> Cp1 & R1 >> Rz3

Output Load Resistance >> R

ESR

& R

DC

R

2

V

REF

(R

1

+ R

2

)

or

V

OUT

V

FBK

(Volts)

Type III Voltage Loop

Compensation

G

AMP

(s) Gain Block

PWM Stage

G

PWM

Gain

Block

Output Stage

G

OUT

(s) Gain

Block

Voltage Feedback

G

FBK

Gain Block

Definitions:

R

ESR

= Output Capacitor Equivalent Series Resistance

R

DC

= Output Inductor DC Resistance

R

RAMP_PP

= SP7650 internal RAMP Amplitude Peak to Peak Voltage

Conditions:

C

Z

2 >> Cp1 and R1 >> Rz3

Output Load Resistance >>

R

ESR

and

R

DC

10

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

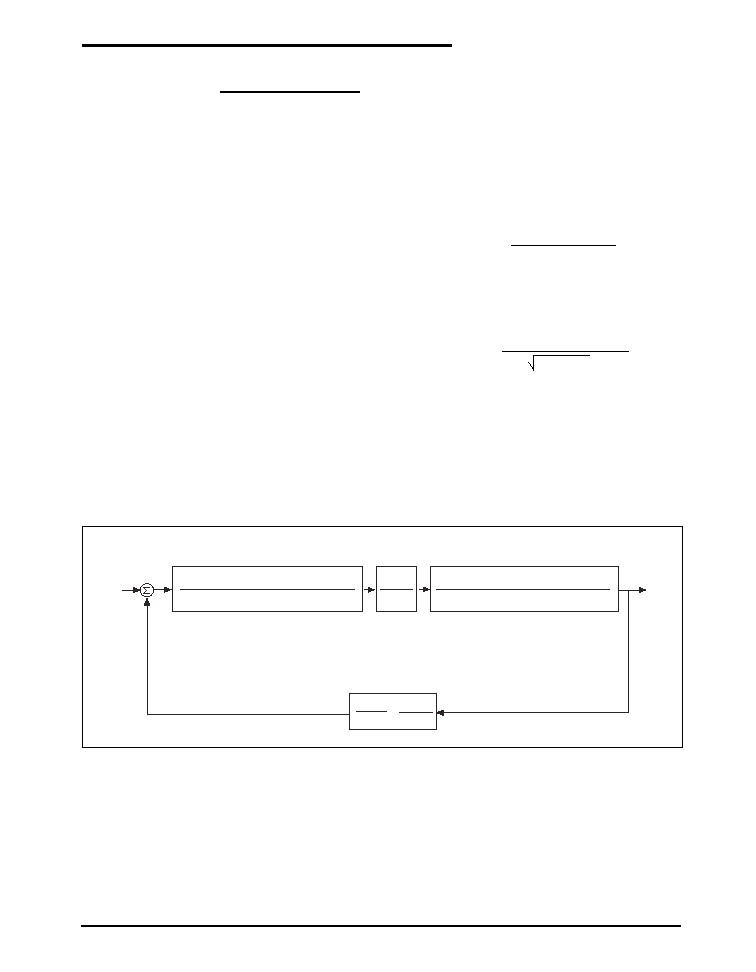

Bode Plot of Type III Error Amplifier Compensation.

CP1

RZ2

CZ2

-

+

6

5

VFB

COMP

+

- 0.8V

CF1

VOUT

R1

68.1k, 1%

R

SET

CZ3

RZ3

R

SET

=54.48/ (VOUT -0.8) (k)

Type III Error Amplifier Compensation Circuit

APPLICATIONS INFORMATION

Frequency

(Hz)

Error Amplifier Gain

Bandwidth Product

Condition:

C22 >> CP1, R1 >> RZ3

20 Log (RZ2/R1)

Gain

(dB)

1/6.28(R22) (CZ2)

1/6.28 (R1) (CZ3)

1/6.28 (R1) (CZ2)

1/6.28 (RZ2) (CP1)

1/6.28 (RZ3) (CZ3)

11

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

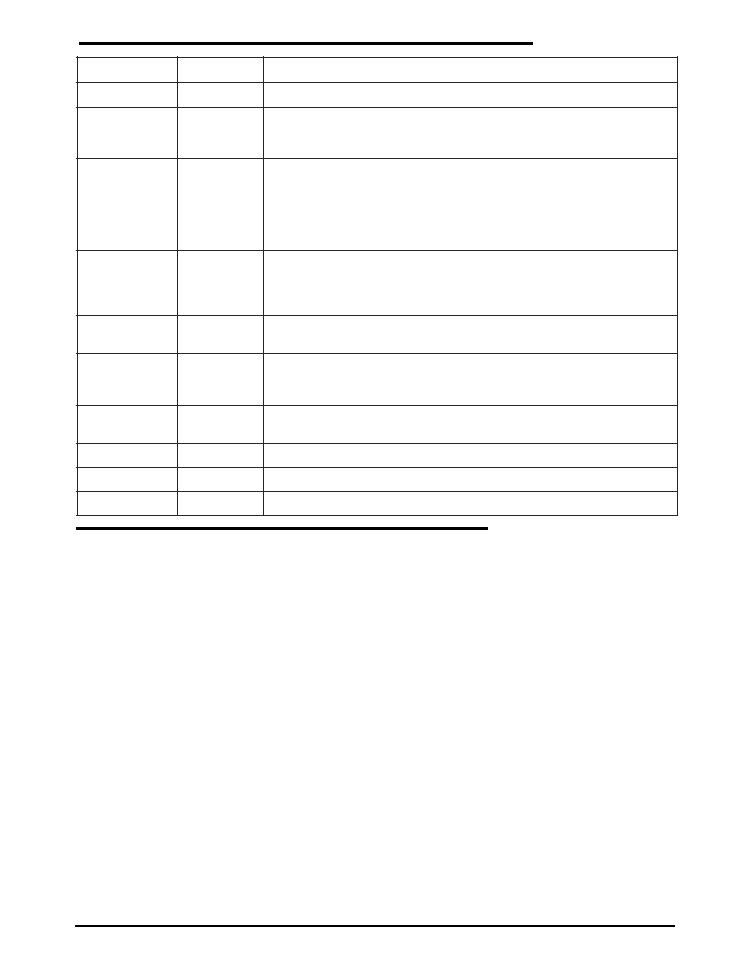

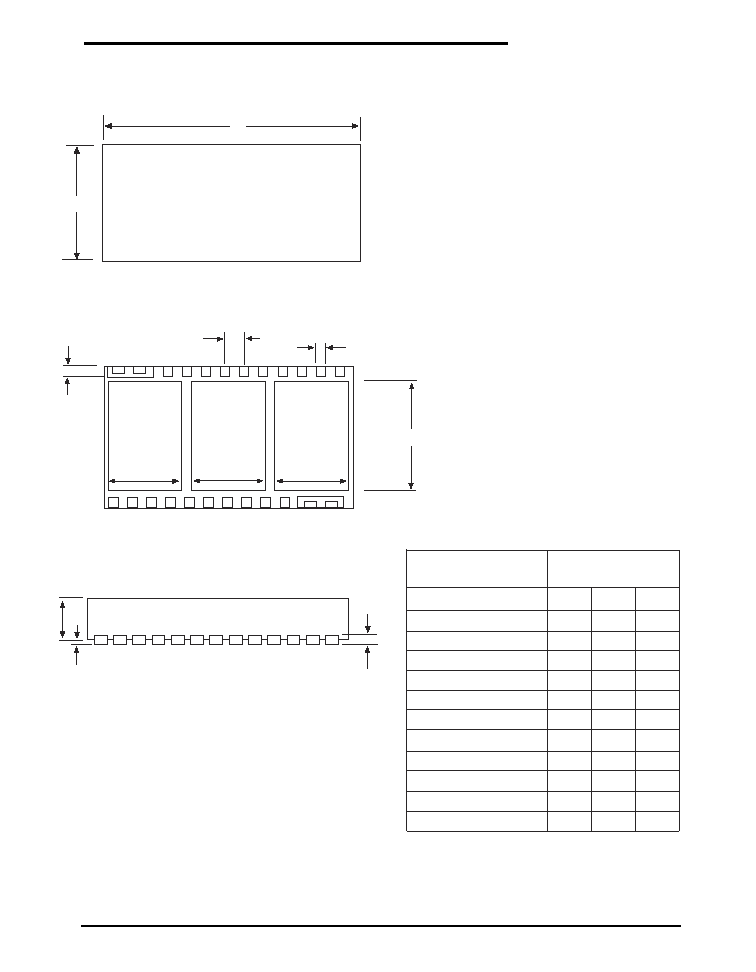

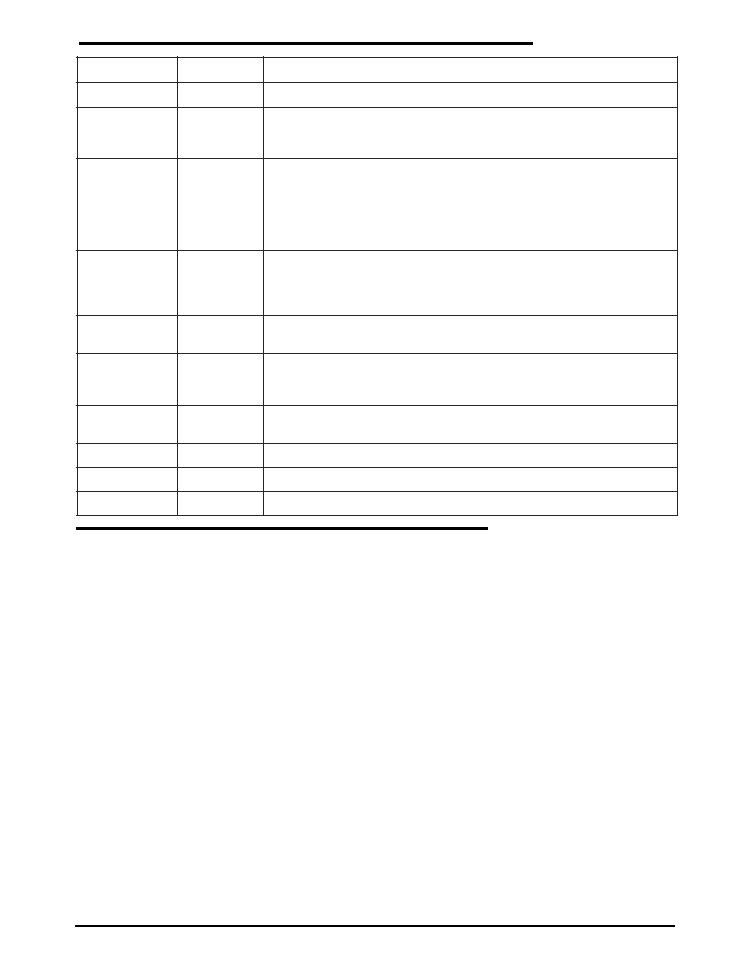

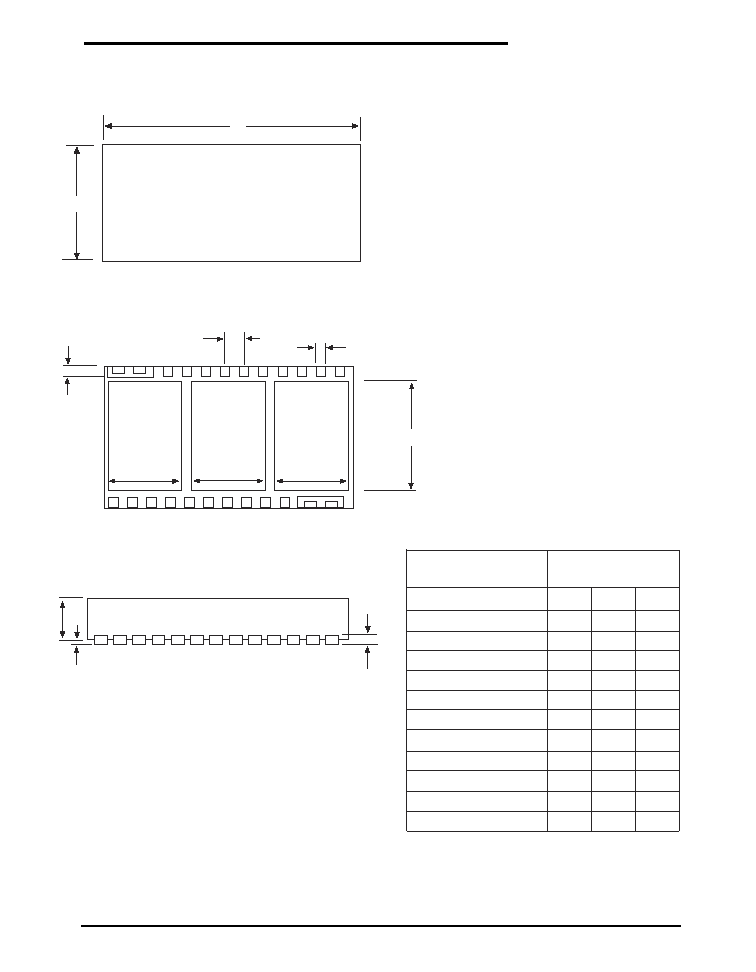

PACKAGE: 26 PIN DFN

26 Pin DFN

DIMENSIONS in

(mm)

26 Pin DFN

A

A1

A3

b

D

E2

E

e

D2

L

0.800 0.850 0.900

2.00

2.730 2.780 2.830

0.350

0.450

0.17

0.22

0.27

SYMBOL

MIN NOM MAX

0.050

3.95

4.05

6.95

7.05

7.00

2.05

2.10

0.178 0.203 0.228

0.400

1.78 1.83 1.88

D3

4.00

0.45 0.50 0.55

0.000

Side View

Top View

b

A3

A

A1

D

E

(7 x 4 mm)

e

L

E2

Bottom View

D2

D3

D2

-

12

Date: 08/24/04

SP7650 Wide Input Voltage Range 3A, 300kHz, Buck Regulator © Copyright 2004 Sipex Corporation

Corporation

ANALOG EXCELLENCE

Sipex Corporation reserves the right to make changes to any products described herein. Sipex does not assume any liability arising out of the

application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.

Sipex Corporation

Headquarters and

Sales Office

233 South Hillview Drive

Milpitas, CA 95035

TEL: (408) 934-7500

FAX: (408) 935-7600

ORDERING INFORMATION

Part Number

Temperature

Package

SP7650ER/TR ......................................... -40°C to +85°C ................................. 26 Pin 7 X 4 DFN

SP7650ER-L/TR ..................................... -40°C to +85°C ............. (Lead Free) 26 Pin 7 X 4 DFN

/TR = Tape and Reel

Pack quantity is 3000 DFN.