Skyworks Solutions, Inc. ∑ Phone [781] 376-3000 ∑ Fax [781] 376-3100 ∑ sales@skyworksinc.com ∑ www.skyworksinc.com

200137 Rev. A ∑ Skyworks Proprietary Information ∑ Products and Product Information are Subject to Change Without Notice. ∑ February 7, 2005

1

Characteristic

Value

Operating temperature

-65 ∞C to +150 ∞C

Storage temperature

-65 ∞C to +200 ∞C

Power dissipation (derate

250 mW

linearly to zero @ 175 ∞C)

Typical lead strength

8 grams pull

Absolute Maximum Ratings

Features

Low capacitance

Low resistance

Fast switching

Oxide-nitride passivated

Durable construction

High voltage

Description

The DSG9500-000 is designed for low resistance, low capaci-

tance and fast switching time. The oxide-nitride passivation

layers provide reliable operation and stable junction parameters

that provide complete sealing of the junction permitting use in

assemblies with some degree of moisture sealing.

The DSG9500-000 is ideal for microstrip or stripline circuits and

for circuits requiring high isolation from a series mounted diode

such as broad band multi-throw switches, phase shifters, lim-

iters, attenuators and modulators.

DSG9500-000: Planar Beam Lead PIN Diode

DATA SHEET

Applications

Designed for switching applications

Performance is guaranteed only under the conditions listed in the specifications table and is

not guaranteed under the full range(s) described by the Absolute Maximum specifications.

Exceeding any of the absolute maximum/minimum specifications may result in permanent

damage to the device and will void the warranty.

CAUTION: Although this device is designed to be as robust as

possible, Electrostatic Discharge (ESD) can damage

this device. This device must be protected at all times

from ESD. Static charges may easily produce poten-

tials of several kilovolts on the human body or

equipment, which can discharge without detection.

Industry-standard ESD precautions must be employed

at all times.

Breakdown

Capacitance

Series Resistance

Minority Carrier

Voltage

Total @ 50 V,

(From Ins. Loss

Lifetime

RF Switching

Outline

Part

@ 10

µ

µA

1 MHz

@ 3 GHz, 50 mA)

(1)

I

F

= 10 mA,

Time

Drawing

Number

(V)

(pF)

(

)

I

R

= 6 mA (ns)

T

S

(ns)

(2)

Number

Min.

Max.

Max.

Typ.

DSG9500≠000

200

0.02

4.0

250

25

169-001

Low Capacitance Planar Beam Lead Diode

1. Total capacitance calculated from isolation at 9 GHz zero bias. Series resistance and capacitance are measured at microwave frequencies on a sample basis from each lot.

All diodes are characterized for capacitance at ≠50 V, 1 MHz, and series resistance at 1 KHz, 50 mA, measurements which correlate well with microwave measurements.

2. T

S

measured from RF transition, 90% to 10%, in series configuration.

DATA SHEET ∑ DSG9500-000

Skyworks Solutions, Inc. ∑ Phone [781] 376-3000 ∑ Fax [781] 376-3100 ∑ sales@skyworksinc.com ∑ www.skyworksinc.com

February 7, 2005 ∑ Skyworks Proprietary Information ∑ Products and Product Information are Subject to Change Without Notice. ∑ 200137 Rev. A

2

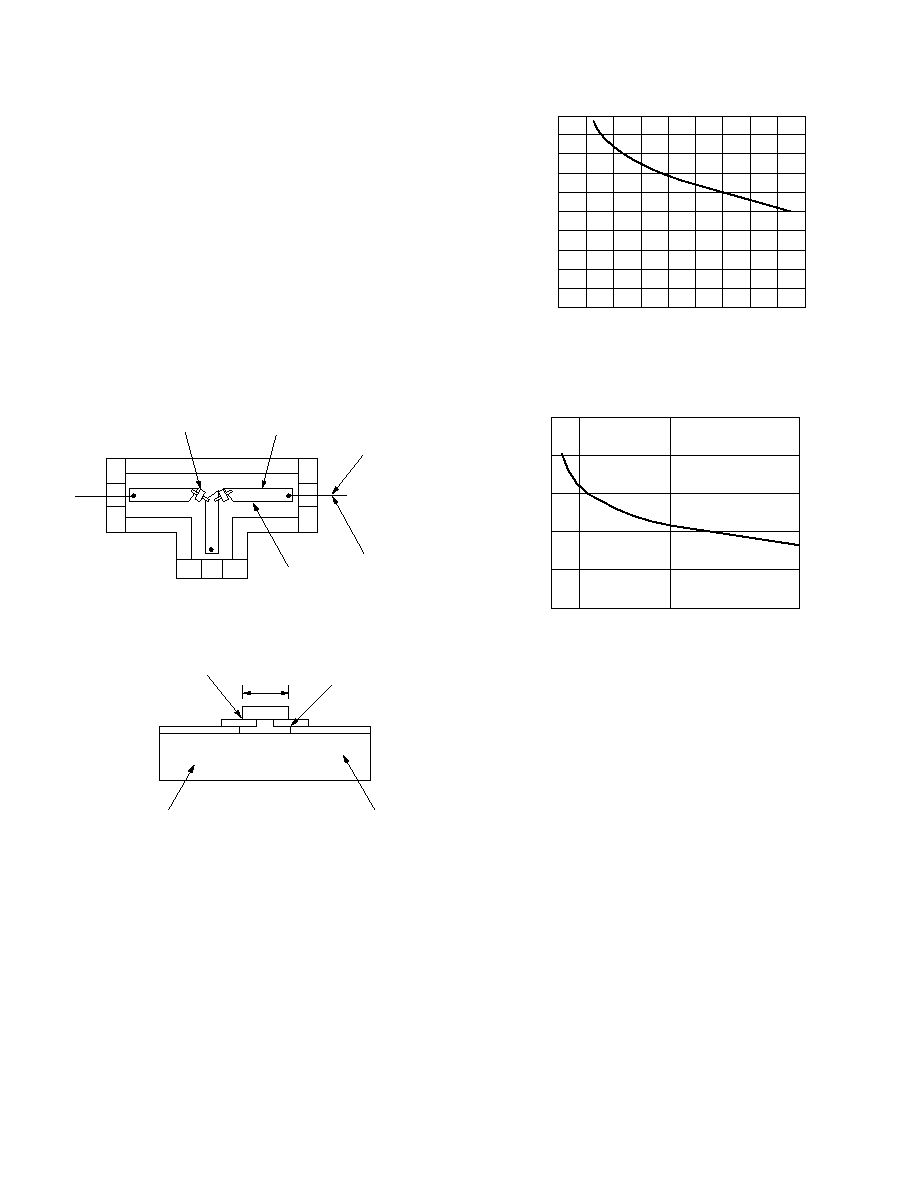

Duroid

Metal Conductor

Preferred Beam

Lead Orientation

Beam Lead Pin

0.005"

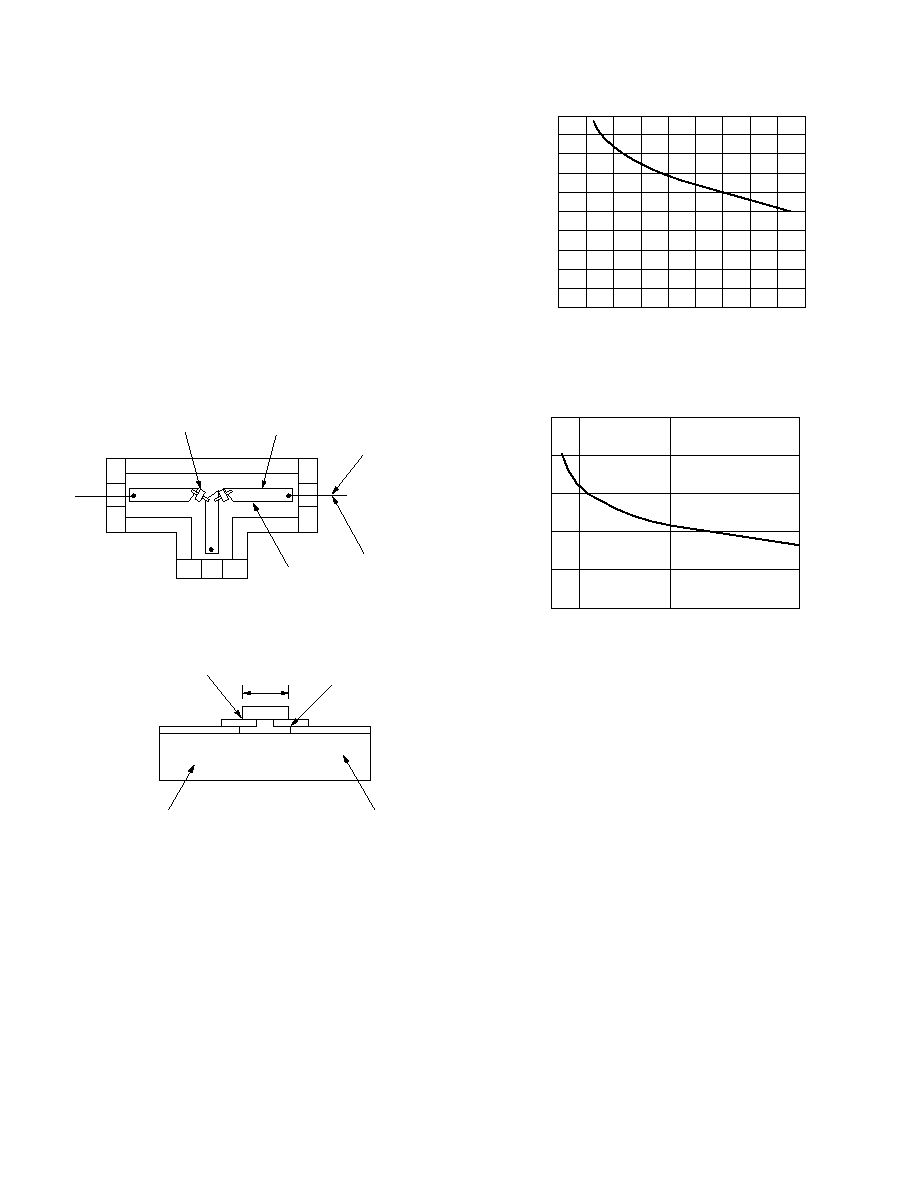

Figure 1. Typical SPDT Circuit Arrangement

Figure 2. Typical Beam Lead Mounting

Beam Lead Pin

Duroid Substrate

50

Glass Bead

Connecting

Lead

50

Transmission LIne

Isolation Loss (dB)

Frequency (GHz)

Figure 3. Isolation vs. Frequency, SPDT

0

2

4

6

8

10

12

14

16

18

0

8

4

12

16

20

24

28

32

36

38

Insertion Loss (dB)

Bias Current (mA)

Figure 4. Diode Insertion Loss vs. Bias,

SPST 18 GHz

0

10

50

100

0.5

1.0

1.5

2.0

2.5

0

Performance Data for DSG9500≠000

Figures 1 and 2 show a single pole double-throw 1≠18 GHz

switch these diodes are mounted an Alumina, Duroid, or Teflon

fiberglass 50

microstrip circuits. Typical bonding methods

include thermal compression bonding, parallel gap welding, and

soldering.

SPDT isolation curves are shown in Figure 3 and insertion loss in

Figures 4 and 5. With proper transitions and bias circuits, VSWR

is better than 2.0 to 1 through 18 GHz.

Switching Considerations

The typical minority carrier lifetime of the DSG9500 diodes is

100 ns. With suitable drivers, the individual diodes can be

switched from high impedance (off) to low R

S

(on) in about 10 ns.

DATA SHEET ∑ DSG9500-000

Skyworks Solutions, Inc. ∑ Phone [781] 376-3000 ∑ Fax [781] 376-3100 ∑ sales@skyworksinc.com ∑ www.skyworksinc.com

200137 Rev. A ∑ Skyworks Proprietary Information ∑ Products and Product Information are Subject to Change Without Notice. ∑ February 7, 2005

3

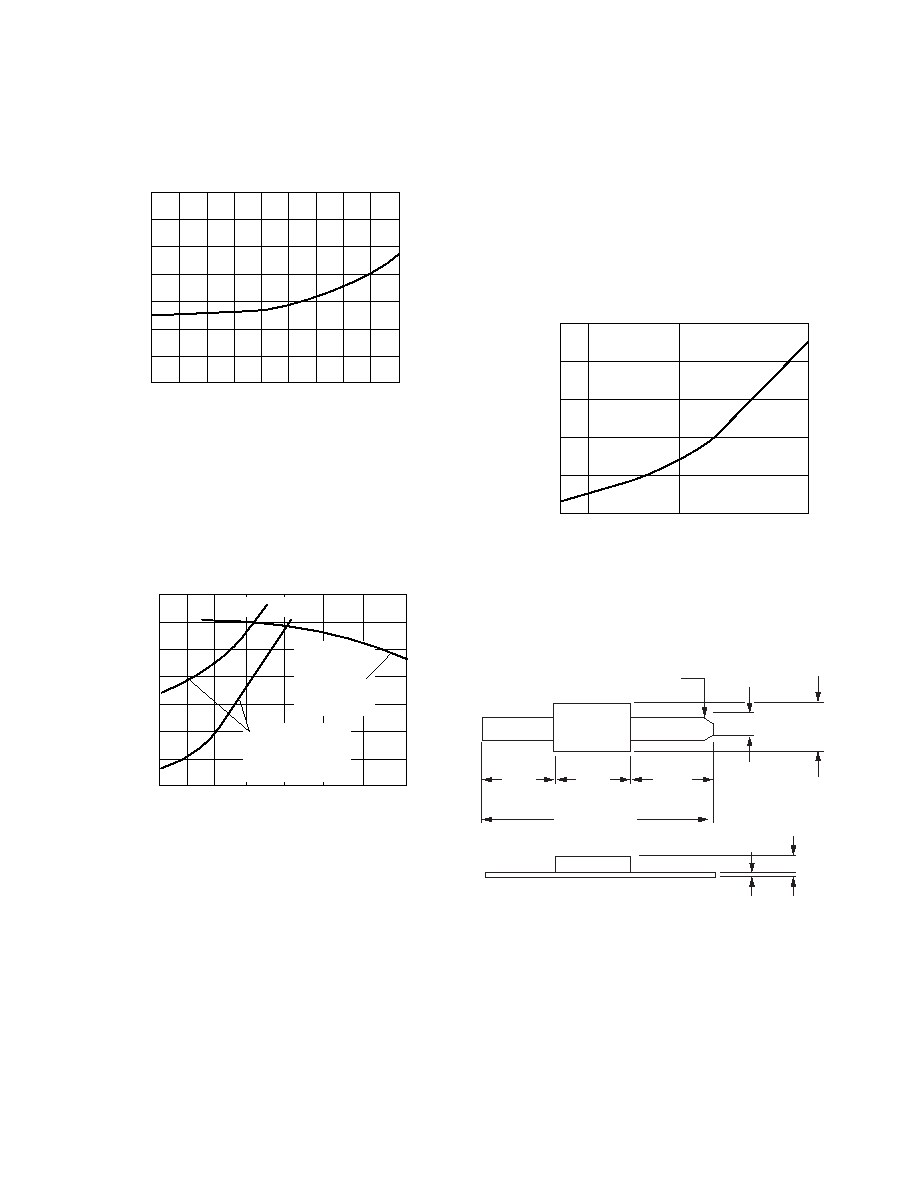

Isolation Loss (dB)

Frequency (GHz)

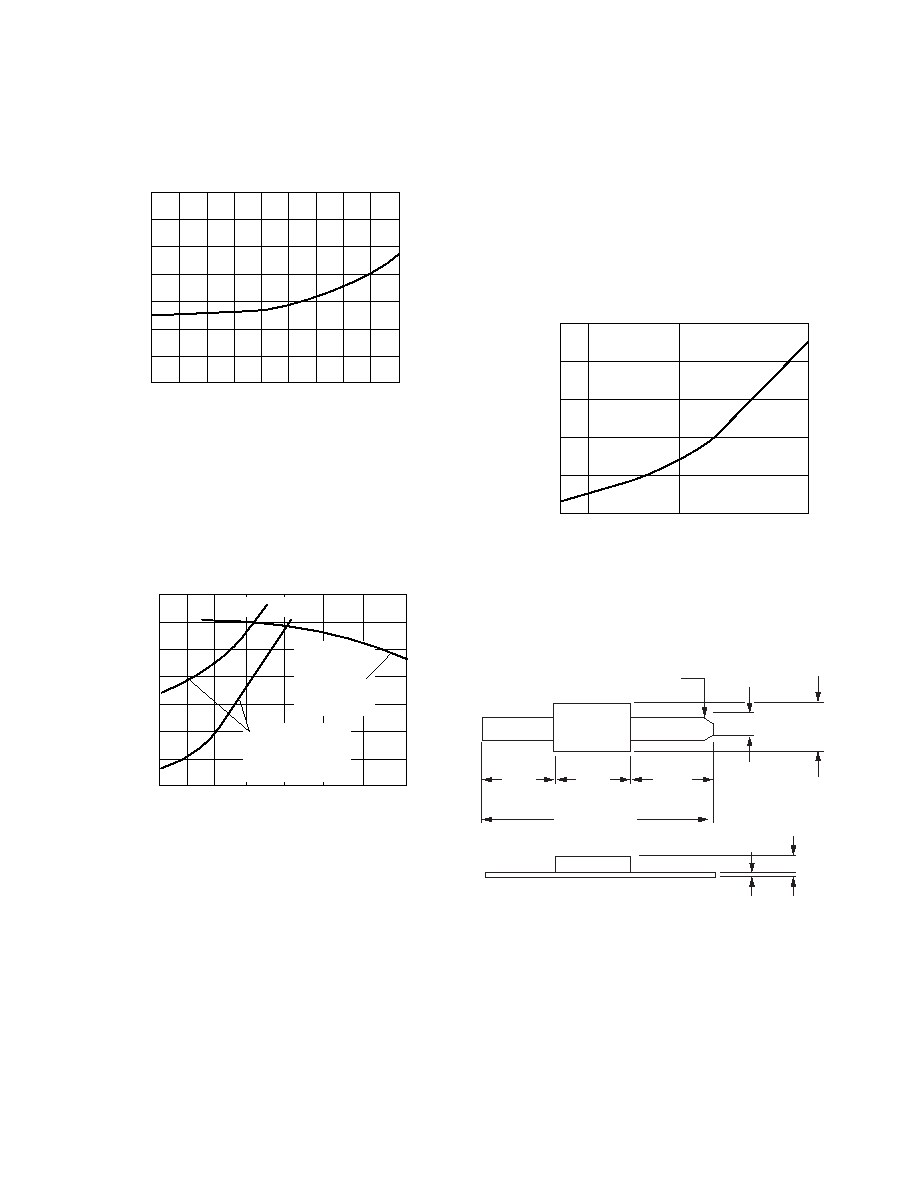

Figure 5. Diode Insertion Loss vs. Frequency,

SPST 50 mA Bias00

0.2

0.4

0.6

0.8

1.0

0

1.2

0

2

4

6

8

10

12

14

16

18

1.4

CW Power (Milliwatts)

Frequency (GHz)

Figure 6. Typical Series Switch Behavior

at Room Temperature and Biased at

50 mA/1 V/4 V

50

100

200

500

1000

20

2000

0.1

0.2

0.5

1.0

2.0

5.0

10

20

5000

10% increase

in small signal

insertion loss

when biased at

50 mA

10% decrease in

small signal insertion

loss when biased at

≠1 V/≠4 V

0.4 V

0.1 V

Peak Power (W)

Reverse Bias (V)

Figure 7. Peak Power Handling,

SPST 1 GHz

0

10

50

100

20

40

60

80

100

0

Power Handling for DSG9500≠000

Beam lead diodes are not suitable for high power operation

because of high internal thermal impedance of about 600 ∞C/W.

For pulsed operation, the total RF plus bias voltage must not

exceed the rated breakdown. Skyworks has made high power

tests at 1 GHz with 1

µs pulses, 0.001 duty, with 200 V diodes.

With 50 mA forward bias, there is no increase in insertion loss

over the 0 dBm level with a peak power input of 50 W. In the

open state, reverse bias voltage is required to keep the diode

from "rectifying," with resultant decrease in isolation and pos-

sible failure. Figure 7 shows allowed peak power versus reverse

bias at 1 GHz. At this frequency, the required reverse voltage is

almost equal to the peak RF voltage; at high frequency, the bias

can be reduced somewhat. Experimentation is necessary.

With maximum CW power dissipation of 250 mW, the

DSG9500≠000 diodes are normally rated at 2 W CW with linear

derating between 25 ∞C and 150 ∞C. Figure 6 presents data on

CW power handling as a function of bias and frequency.

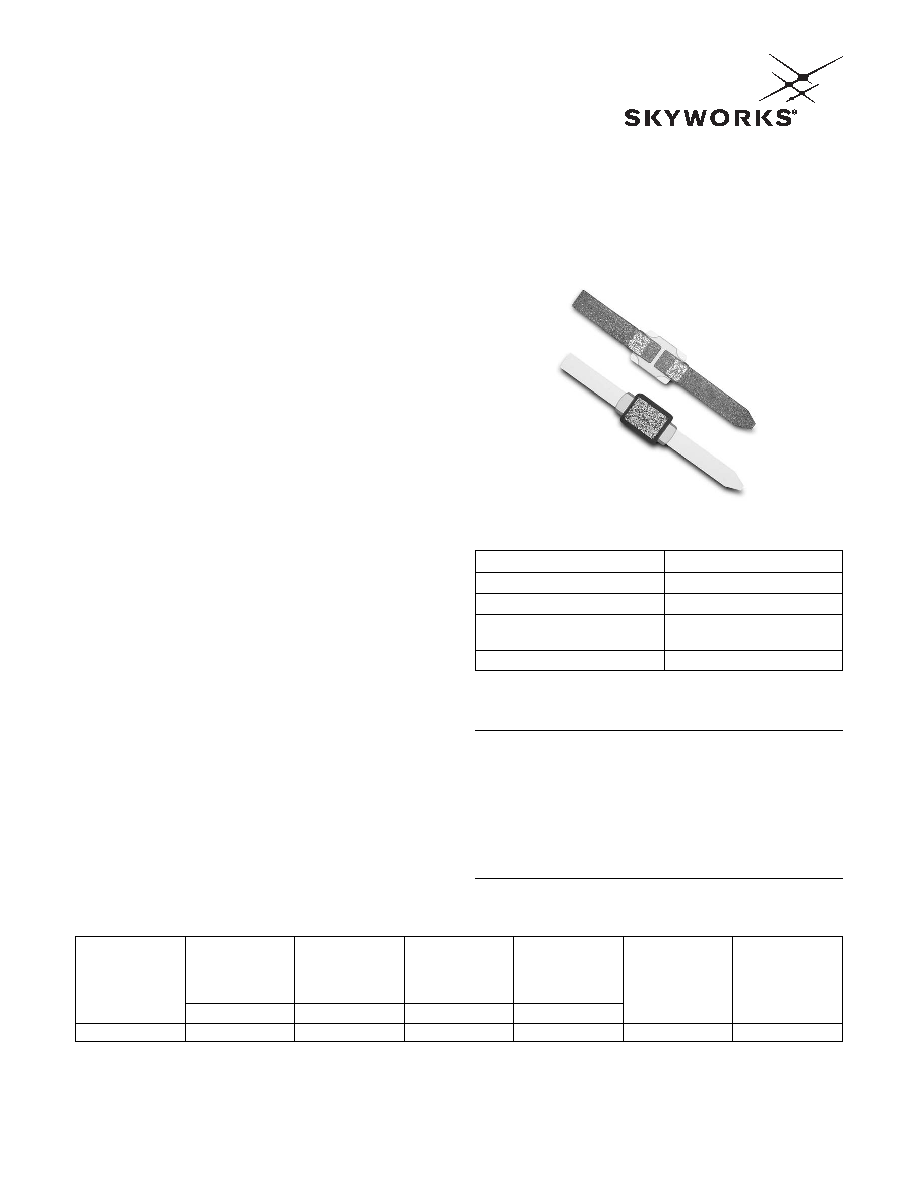

0.004 (0.10 mm)

0.002 (0.05 mm)

0.004 (0.10 mm)

0.002 (0.05 mm)

0.035 (0.89 mm)

0.033 (0.84 mm)

0.007

(0.18 mm)

Max.

0.0005

(0.013 mm)

Max.

0.010

(0.25 mm)

Min.

0.010

(0.25 mm)

Min.

0.011

(0.28 mm)

Max.

Cathode End Has

Blunted Point

169-001

DATA SHEET ∑ DSG9500-000

Skyworks Solutions, Inc. ∑ Phone [781] 376-3000 ∑ Fax [781] 376-3100 ∑ sales@skyworksinc.com ∑ www.skyworksinc.com

February 7, 2005 ∑ Skyworks Proprietary Information ∑ Products and Product Information are Subject to Change Without Notice. ∑ 200137 Rev. A

4

Beam-Lead Diodes

Handling

Due to their small size, beam-lead devices are fragile and should

be handled with extreme care. The individual plastic packages

should be handled and opened carefully, so that no undue

mechanical strain is applied to the packaged device. It is recom-

mended that the beam-lead devices be handled through use of a

vacuum pencil using an appropriate size vacuum needle or a

pointed wooden stick such as a sharpened Q-tip or match stick.

The device will adhere to the point and can easily be removed

from the container and positioned accurately for bonding without

damage. Such handling should be done under a binocular micro-

scope with magnification in the range of 20X to 30X.

Special handling precautions are also required to avoid electrical

damage, such as static discharge.

Bonding

The DSG9500-000 can best be bonded to substrates by means of

thermocompression bonding. Essentially this type of bonding

involves pressing the gold beam of the device against the gold

plated metalized substrate under proper conditions of heat and

pressure so that a metallurgical bond joint between the two

occurs.

Procedure

The beam-lead devices to be bonded should be placed on a

clean, hard surface such as a microscope slide. It is recom-

mended that the beam side of the device be down so that this

side will be toward the substrate when bonded. The device can

be picked up by pressing lightly against one beam with the

heated tip. The substrate can then be appropriately positioned

under the tip and the device brought down against the substrate,

with proper pressure applied by means of the weld head.

A bonding tip temperature in the 350 ∞C to 450 ∞C range is rec-

ommended along with a bonding force of 50 to 70 grams. The

bonding time is in the range of 2 to 3 seconds. Optimum bonding

conditions should be determined by trial and error to compensate

for slight variations in the condition of the substrate, bonding tip,

and the type of device being bonded.

Equipment

The heat and pressure are obtained through use of a silicon car-

bide bonding tip with a radius of two to three mils. Such an item

is available from several commercial sources. In order to supply

the required tip-travel and apply proper pressure, a standard

miniature weld head can be used. Also available is a heated

wedge shank which is held by the weld head and in turn holds

the tip and supplies heat to it. The wedge shank is heated by

means of a simple AC power supply or a pulse type heated tool.

Substrate

For optimum bonding a gold plated surface at least 100

microinches thick is necessary. Although it is possible to bond to

relatively soft metalized substrate material such as epoxy-fiber-

glass, etc., optimum bonding occurs when a hard material such

as ceramic can be used.

Quality

If a good bond has been obtained, it is impossible to separate the

beam-lead device from the metalized substrate without damage.

If the device is destructively removed, the beam will tear away,

leaving the bonded portion attached to the substrate.

Beam≠Lead Packaging

The DSG-9500-000 is shipped in 2" x 2" black gel packs. The

beam-leads are mounted on the gel, the devices are covered

with a piece of lint-free release paper, on top of which is placed

a piece of conductive foam.

DATA SHEET ∑ DSG9500-000

Skyworks Solutions, Inc. ∑ Phone [781] 376-3000 ∑ Fax [781] 376-3100 ∑ sales@skyworksinc.com ∑ www.skyworksinc.com

200137 Rev. A ∑ Skyworks Proprietary Information ∑ Products and Product Information are Subject to Change Without Notice. ∑ February 7, 2005

5

Copyright © 2002, 2003, 2004, 2005, Skyworks Solutions, Inc. All Rights Reserved.

Information in this document is provided in connection with Skyworks Solutions, Inc. ("Skyworks") products. These materials are provided by Skyworks as a service to its customers and may be

used for informational purposes only by the customer. Skyworks assumes no responsibility for errors or omissions in these materials. Skyworks may make changes to its documentation, products,

specifications and product descriptions at any time, without notice. Skyworks makes no commitment to update the information and shall have no responsibility whatsoever for conflicts,

incompatibilities, or other difficulties arising from future changes to its documentation, products, specifications and product descriptions.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by or under this document. Except as may be provided in Skyworks Terms and Conditions of

Sale for such products, Skyworks assumes no liability whatsoever in association with its documentation, products, specifications and product descriptions.

THESE MATERIALS ARE PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED OR OTHERWISE, RELATING TO SALE AND/OR USE OF SKYWORKS PRODUCTS INCLUDING

WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, PERFORMANCE, QUALITY OR NON-INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL

PROPERTY RIGHT. SKYWORKS FURTHER DOES NOT WARRANT THE ACCURACY OR COMPLETENESS OF THE INFORMATION, TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS.

SKYWORKS SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOST REVENUES OR LOST

PROFITS THAT MAY RESULT FROM THE USE OF THESE MATERIALS WHETHER OR NOT THE RECIPIENT OF MATERIALS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Skyworks products are not intended for use in medical, lifesaving or life-sustaining applications. Skyworks customers using or selling Skyworks products for use in such applications do so at their

own risk and agree to fully indemnify Skyworks for any damages resulting from such improper use or sale.

The following are trademarks of Skyworks Solutions, Inc.: Skyworks

Æ

, the Skyworks logo, and Breakthrough Simplicity

Æ

. Product names or services listed in this publication are for identification

purposes only, and may be trademarks of Skyworks or other third parties. Third-party brands and names are the property of their respective owners. Additional information, posted at

www.skyworksinc.com, is incorporated by reference.