| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SSD1770Z | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

v

TABLE OF CONTENTS

1

GENERAL DESCRIPTION .........................................................................................................................................1

2

FEATURES ....................................................................................................................................................................2

3

ORDERING INFORMATION.....................................................................................................................................2

4

BLOCK DIAGRAM ......................................................................................................................................................3

5

DIE PAD FLOOR PLAN ..............................................................................................................................................4

6

PIN DESCRIPTION....................................................................................................................................................12

7

FUNCTIONAL BLOCK DESCRIPTIONS ..............................................................................................................15

8

COMMAND TABLE...................................................................................................................................................22

9

COMMAND DESCRIPTIONS ..................................................................................................................................30

10

MAXIMUM RATINGS...............................................................................................................................................51

11

DC CHARACTERISTICS..........................................................................................................................................52

12

AC CHARACTERISTICS..........................................................................................................................................53

13

APPLICATION EXAMPLES ....................................................................................................................................57

14

SSD1770Z DIE TRAY DIMENSIONS ......................................................................................................................60

vi

TABLE OF TABLES

Table 1 ≠ Ordering Information...................................................................................................................................2

Table 2 ≠ SSD1770 Series Bump Die Pad Coordinates (Bump center) ....................................................................5

Table 3 ≠ V

OUT

> V

L5

> V

L4

> V

L3

> V

L2

> V

SS

Relationship........................................................................................14

Table 4 ≠ Data bus selection modes ........................................................................................................................16

Table 5 ≠ COMMAND TABLE (D/ C = 0, R/

W

( WR ) = 0, E=1( RD = 1) unless specific setting is stated) .............22

Table 6 - Read Command Table ..............................................................................................................................28

Table 7 - RAM arrangements of 8-levels gray scale mode ......................................................................................30

Table 8 - RAM arrangements of 16-levels gray scale mode ....................................................................................31

Table 9 - RGB Arrangement modes .........................................................................................................................34

Table 10 - Gray scale selection mode ......................................................................................................................34

Table 11 - Area scrolling selection modes................................................................................................................36

Table 12 - Maximum Ratings (Voltage Referenced to V

SS

)......................................................................................51

Table 13 - DC Characteristics (Unless otherwise specified, Voltage Referenced to V

SS

, V

DD

= 2.4 to 3.6V, T

A

= -40

to 85

∞

∞

∞

∞C) .............................................................................................................................................................52

Table 14 - AC Characteristics (Unless otherwise specified, Voltage Referenced to V

SS

, V

DD

= 2.7V, T

A

= 25

o

C) ..53

Table 15 ≠ Parallel Timing Characteristics (T

A

= -40 to 85

∞

∞

∞

∞C, V

DD

= 2.4V to 3.6V) .................................................54

Table 16 ≠ Parallel Timing Characteristics (T

A

= -40 to 85

∞

∞

∞

∞C, V

DD

= 2.4V to 3.6V) .................................................55

Table 17 - Serial Timing Characteristics (T

A

= -40 to 85

∞

∞

∞

∞C, V

DD

= 2.4V to 3.6V) .....................................................56

TABLE OF FIGURES

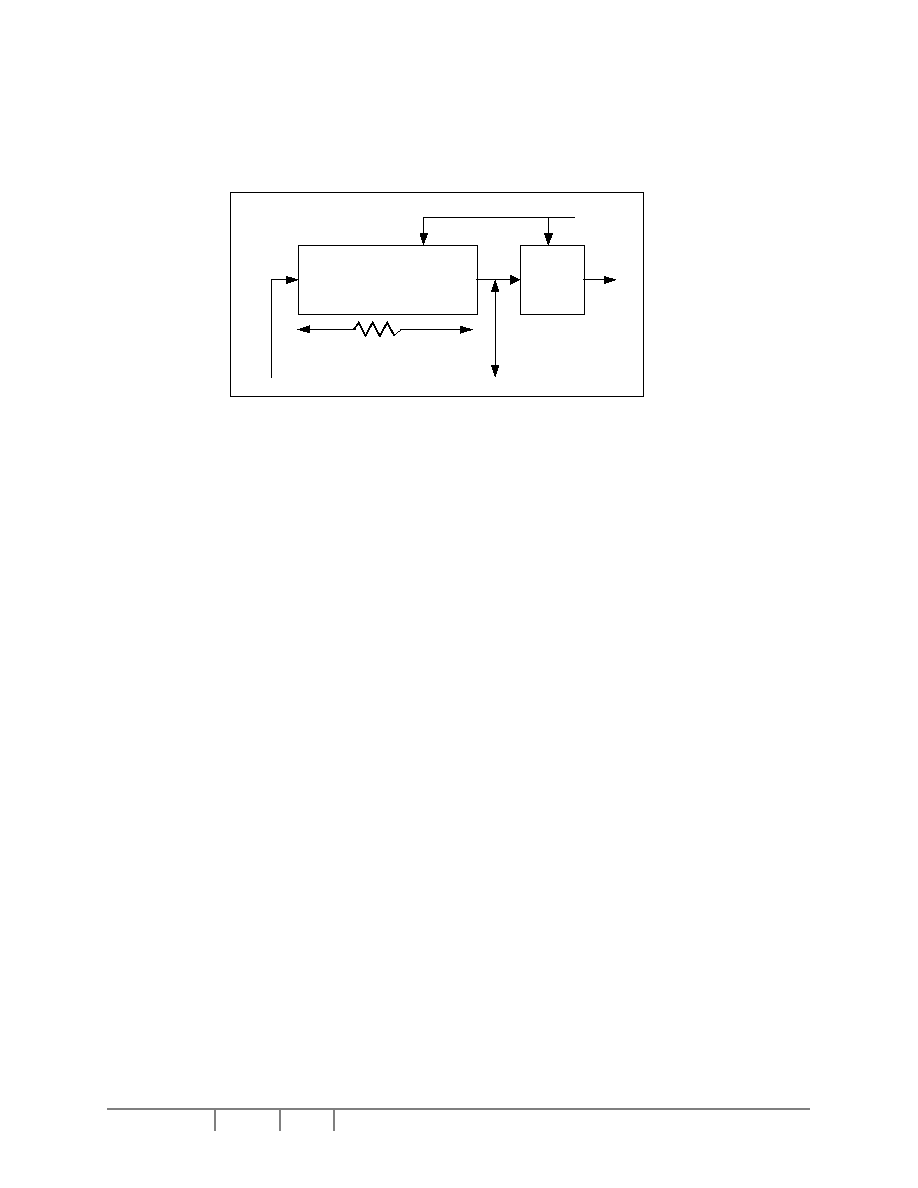

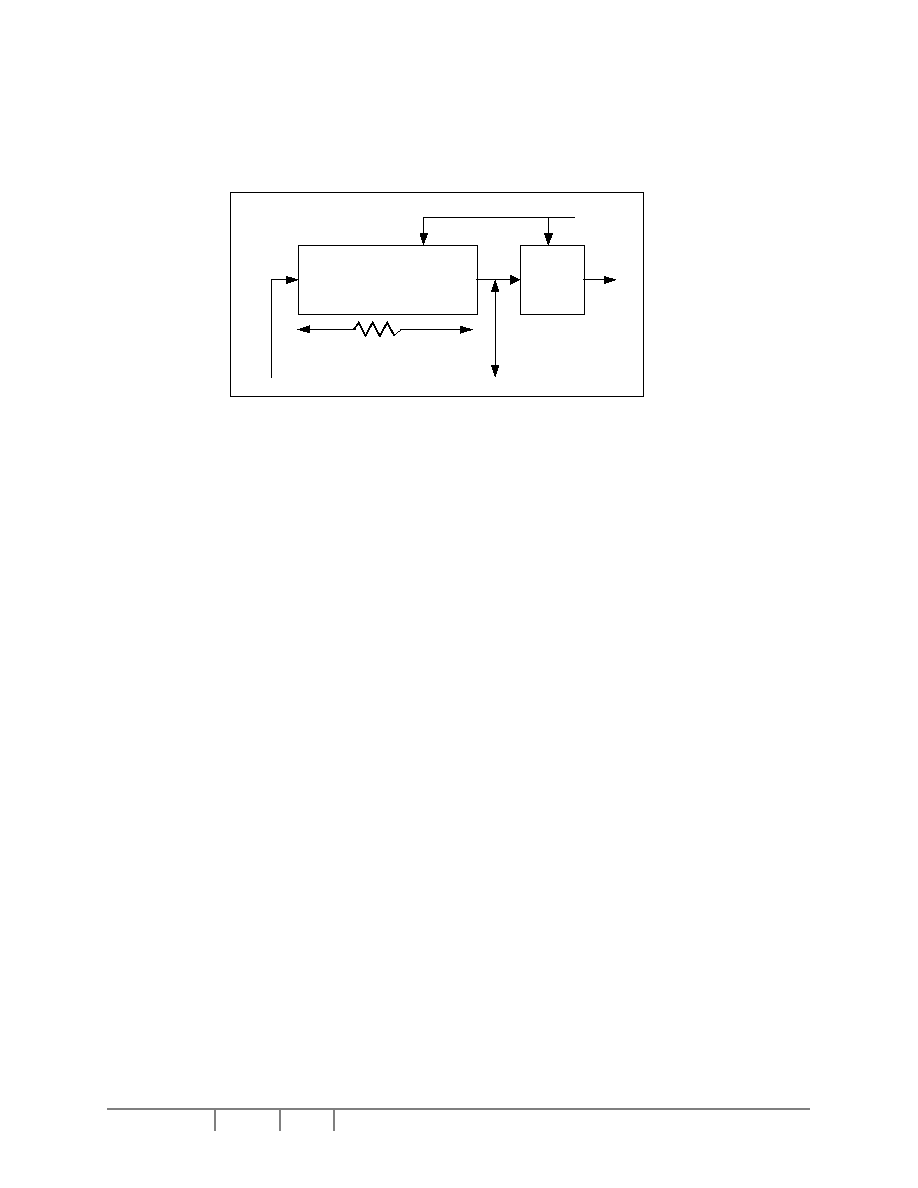

Figure 1 ≠ SSD1770 Block Diagram...........................................................................................................................3

Figure 2 ≠ SSD1770 Die Pad Floor Plan....................................................................................................................4

Figure 3 ≠ Display Data ............................................................................................................................................15

Figure 4 ≠ Display Data RAM Map ...........................................................................................................................19

Figure 5 ≠ SSD1770 Hardware Configurations ........................................................................................................20

Figure 6 ≠ Oscillator structural block diagram ..........................................................................................................21

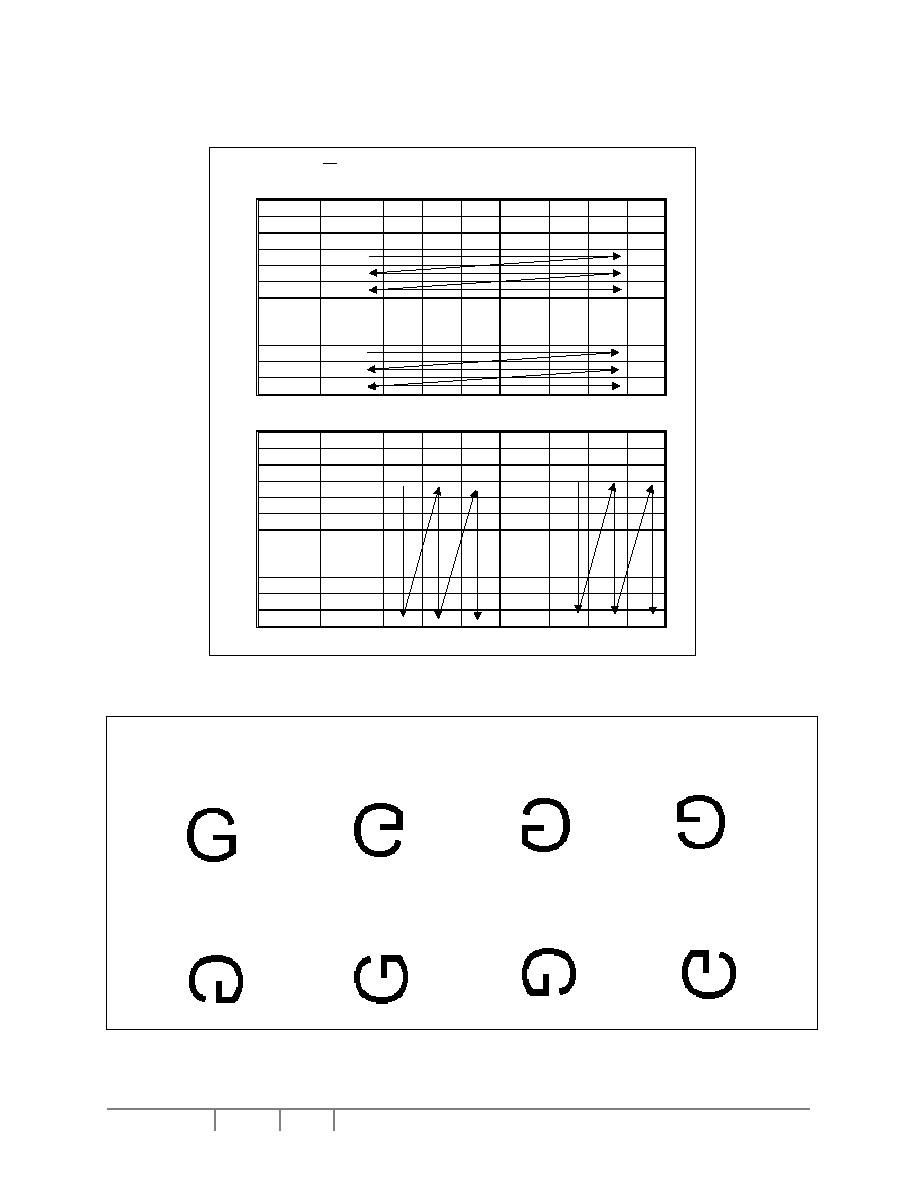

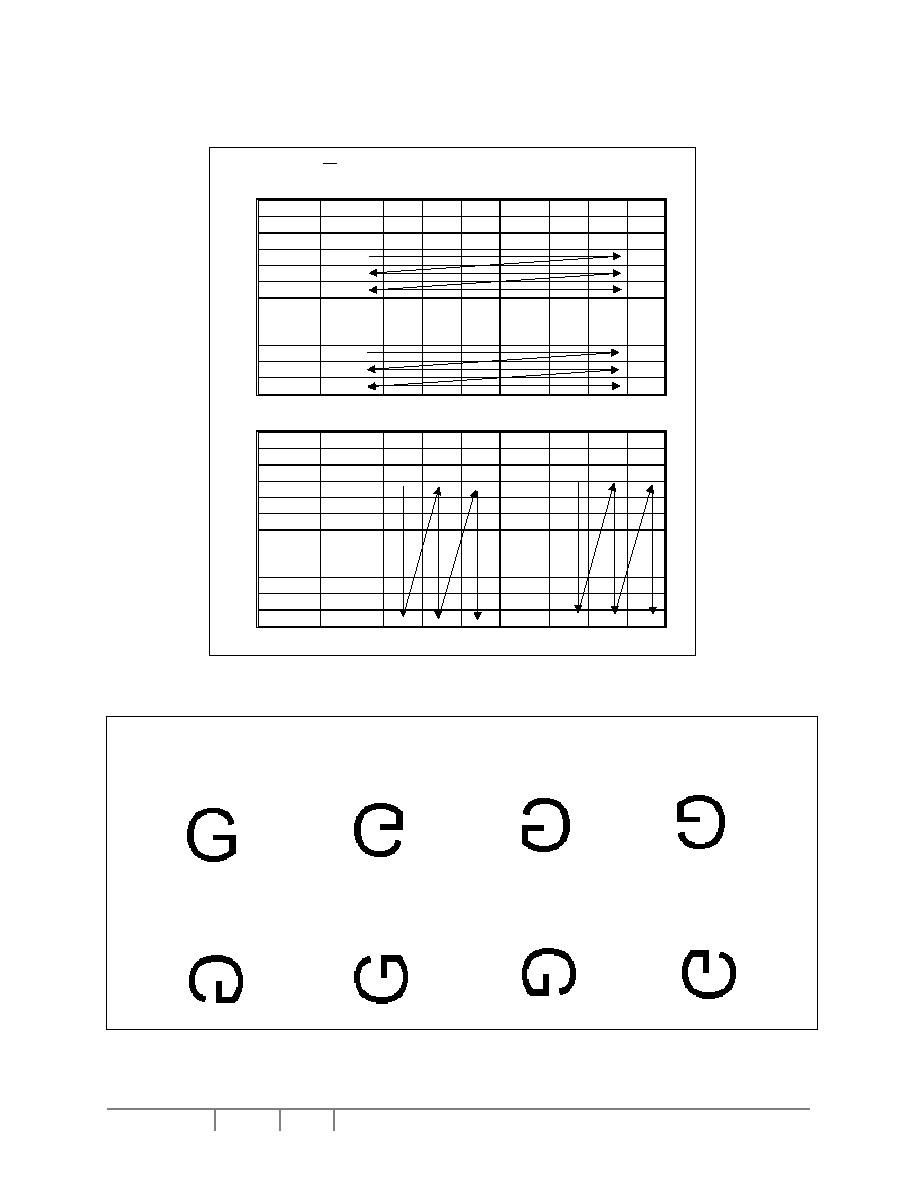

Figure 7 - column and page scan direction of 8-level gray scale mode ...................................................................32

Figure 8 - column and page scan direction of 16-level gray scale mode .................................................................33

Figure 9 ≠ Example of Normal or Reverse page/column/ scan directions ...............................................................33

Figure 10 - Examples: 8 gray-scale display arrangement ........................................................................................34

Figure 11 - Area scrolling selection modes ..............................................................................................................36

Figure 12 - GDDRAM updates for area scrolling......................................................................................................37

Figure 13 ≠ Example of Specified Center Scroll Mode.............................................................................................38

Figure 14 - Contrast Control Flow Set Segment Re-map.........................................................................................39

Figure 15 - Contrast Control Voltage Range Curve (V

DD

=2.7V; V

CI

=3V; Booster level = 6X; TC = -0.25%/

o

C) ....40

Figure 16 - Partial display mode...............................................................................................................................41

Figure 17 ≠ OTP programming circuitry ...................................................................................................................47

Figure 18 ≠ Flow chart of OTP programming Procedure .........................................................................................48

Figure 19 ≠ Parallel 6800-series Interface Timing Characteristics (PS0 = H, PS1 = H) ..........................................54

Figure 20 ≠ Parallel 8080-series Interface Timing Characteristics (PS0 = H, PS1 = L)...........................................55

Figure 21 - Serial Timing Characteristics (PS0 = L, PS1 =L) ...................................................................................56

Figure 22 - Application Example I (4-wires SPI mode).............................................................................................57

Figure 23 - Application Example II (6800 PPI mode) ...............................................................................................58

Figure 24 ≠ Applications notes for V

DD

/V

DDIO

connection .........................................................................................59

SOLOMON SYSTECH

SEMICONDUCTOR TECHNICAL DATA

This document contains information on a new product under definition stage. Solomon Systech Limited reserves

the right to change or discontinue this product without notice.

http://www.solomon-systech.com

SSD1770

Rev 1.00 P 1/61

Sep 2003

Copyright

2003 Solomon Systech Limited

SSD1770

Advance Information

LCD Segment / Common COLOR Driver with Controller

CMOS

1 General

Description

SSD1770 is a single-chip CMOS color STN LCD driver with controller for dot-matrix graphic liquid

crystal display system. SSD1770 consists of 393 high voltage driving output pins for driving maximum 104

RGB Segments, 80 Commons and 1 icon-driving Common.

SSD1770 consists of 312 (104 RGB) x 81 x 4 bits Graphic Display Data RAM (GDDRAM).

Data/Commands are sent from common MCU through 8-bit 6800-series / 8080-series compatible Parallel

Interface or 3-wires / 4-wires Serial Peripheral Interface by pins selection.

SSD1770 embeds DC-DC Converter, On-Chip Oscillator and Bias Divider so as to reduce the number of

external components. With the advanced design, low power consumption, stable LCD operating voltage

and flexible die package layout, SSD1770 is suitable for any portable battery-driven applications requiring

long operation period with compact size.

Solomon Systech

Sep 2003

P 2/61

Rev 1.00

SSD1770

2 FEATURES

∑ Power Supply: V

DD

= 2.4 V ≠ 3.6V

V

DDIO

= 2.4 V ≠ 3.6V

V

CI

= 2.4 V ≠ 3.6V

∑ LCD Driving Output Voltage: 12.5V

∑ Low Current Sleep Mode

∑ Maximum display size: 104 RGB columns by 80 rows with one Icon line

∑ Color display support: 256 colors or 4096 colors graphical display

∑ 256-colors Position Control and simultaneous RGB display control

∑ 8-bit 6800-series / 8080-series Parallel Interface, 3-wires / 4-wires Serial Peripheral Interface

∑ On-Chip 312 (104 RGB) X (81) x 4 = 101088 bits Graphic Display Data RAM

∑ Programmable partial display function

∑ Column Re-mapping and RAM Page scan direction control

∑ Software selection on Center Screen Scrolling, Top Screen Scrolling, Bottom Screen Scrolling

and Whole Screen Scrolling

∑ On-Chip Voltage Generator or External LCD Driving Power Supply Selectable

∑ 3X/ 4X / 5X / 6X On-Chip DC-DC Converter with internal flying capacitor

∑ 64 Levels Internal Contrast Control

∑ Programmable LCD Driving Voltage Temperature Compensation Coefficients

∑ On-Chip Bias Divider with internal flying capacitor (expect V

OUT

)

∑ Programmable drive duty ratio: 1 /8 to 1 /81

∑ On-Chip Oscillator

∑ 2-D Graphic Acceleration Engine

∑ Non-Volatile Memory (OTP) for calibration

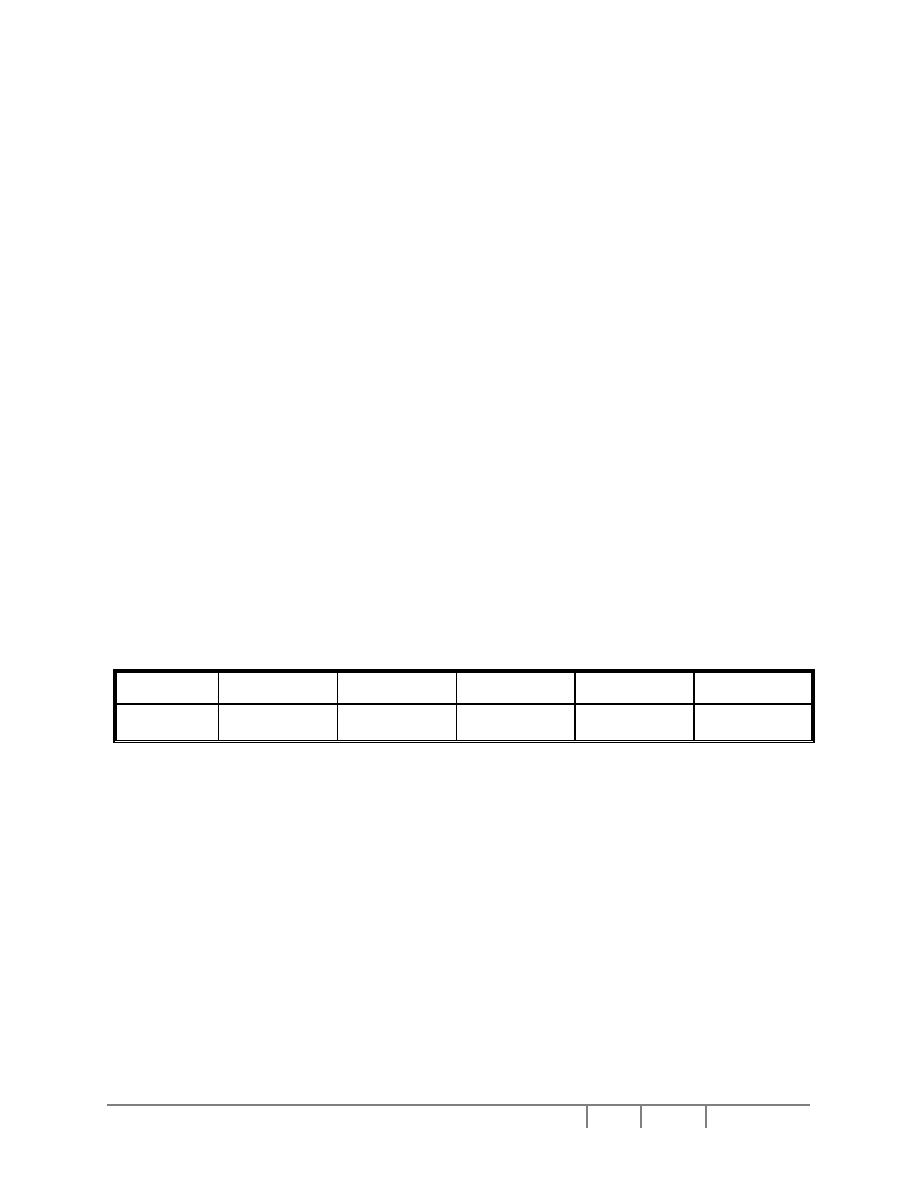

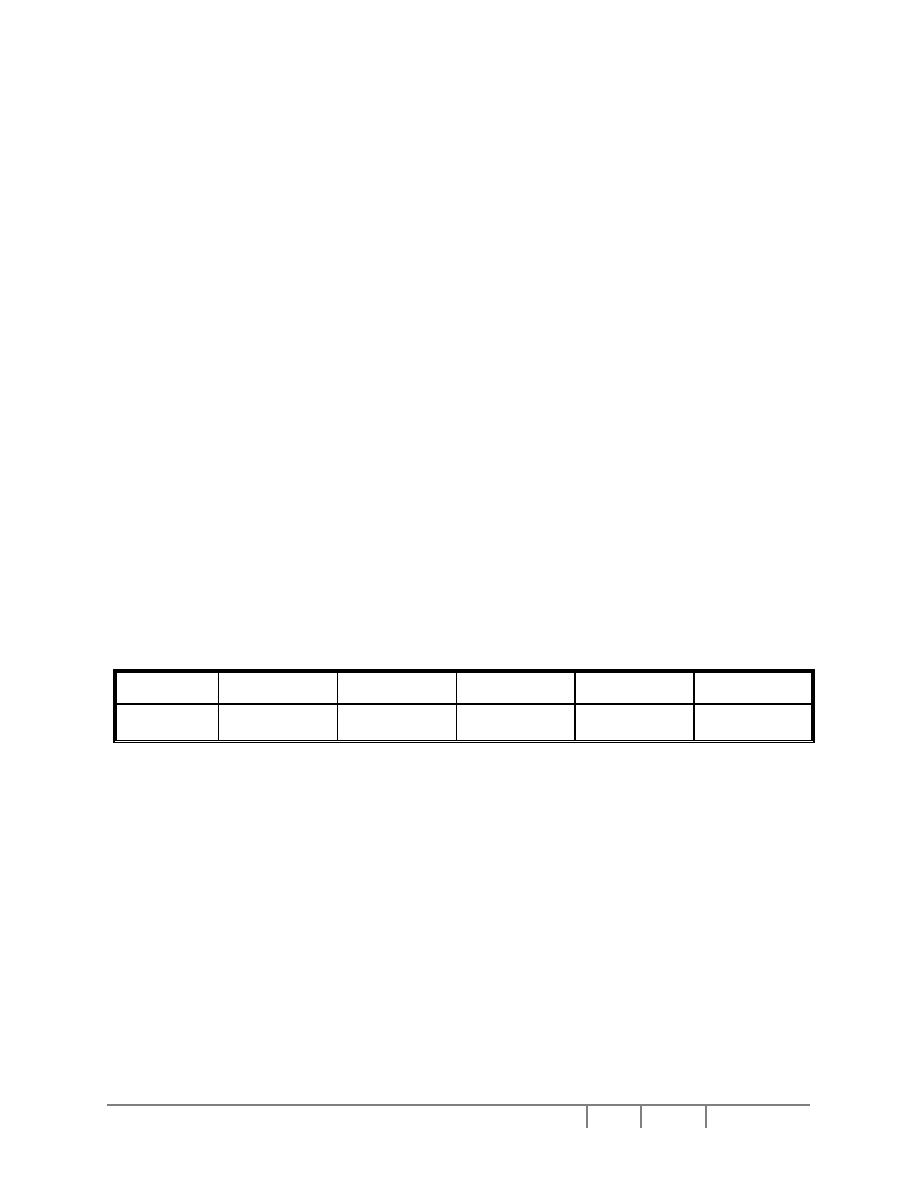

3 ORDERING INFORMATION

Ordering Part

Number

SEG

COM

Display Colors

Package Form

Reference

SSD1770Z 104

81

4096 or

256 colors

Gold Bump Die

Figure 2 on

page 4

Table 1 ≠ Ordering Information

SSD1770

Rev 1.00 P 3/61

Sep 2003

Solomon Systech

4 BLOCK

DIAGRAM

Figure 1 ≠ SSD1770 Block Diagram

COL0 ~ COL311

ROW0 ~ ROW79 ICON

Display Data L

GDDRAM 312 (104RGB)

X 81 X 4 bits

Display

Timing

Generator

Oscillator

Command Decoder

Microprocessor Interface Logic

M

CL

V

CI

104 RGB

Segment

Driver Circuits

81 Common

Driver

Circuits

Page

Address

Control

Circuit

MPU System

Control Circuit

LCD Driving

Voltage

Generator

3X/4X/5X/6X

DC/DC

Converter,

Voltage

Regulator,

Contrast

Control, Bias

Divider,

Temperature

Compensation

Status

Register

V

SS

D0 - D7

E (RD )

R/W

(

WR

)

PS0 PS1

D/C

CS

RES

CV

SS

RV

SS

SYN

BUSY

V

L5

V

OUT

V

L4

V

SS

V

L2

V

L3

2-D Graphic

Acceleration

Engine

V

DD

Column

Address

Control

Circuit

TEST17

TEST0

80

/

68

MUX

V

CIX2

VH

REF

V

L

REF

V

DDIO

Solomon Systech

Sep 2003

P 4/61

Rev 1.00

SSD1770

25 25

25

25

25

25

100

100

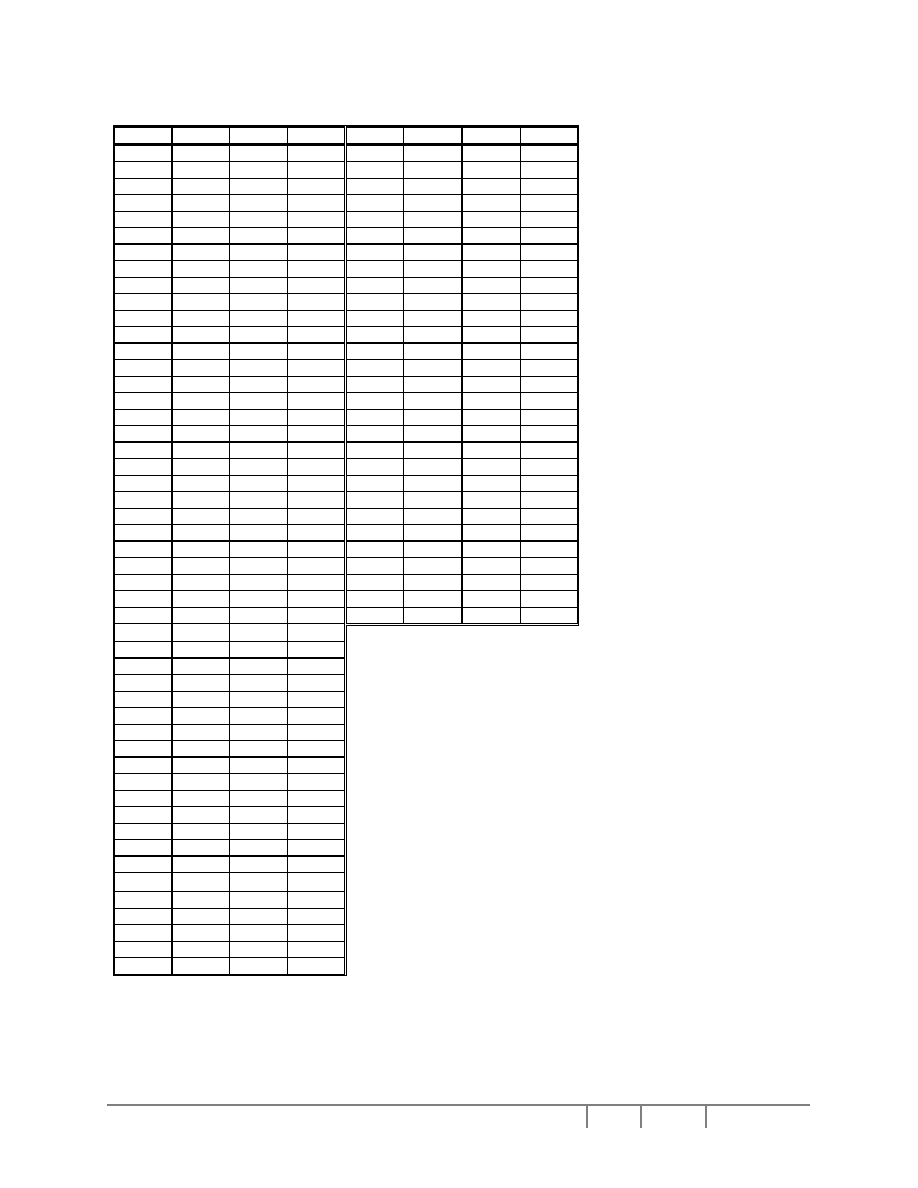

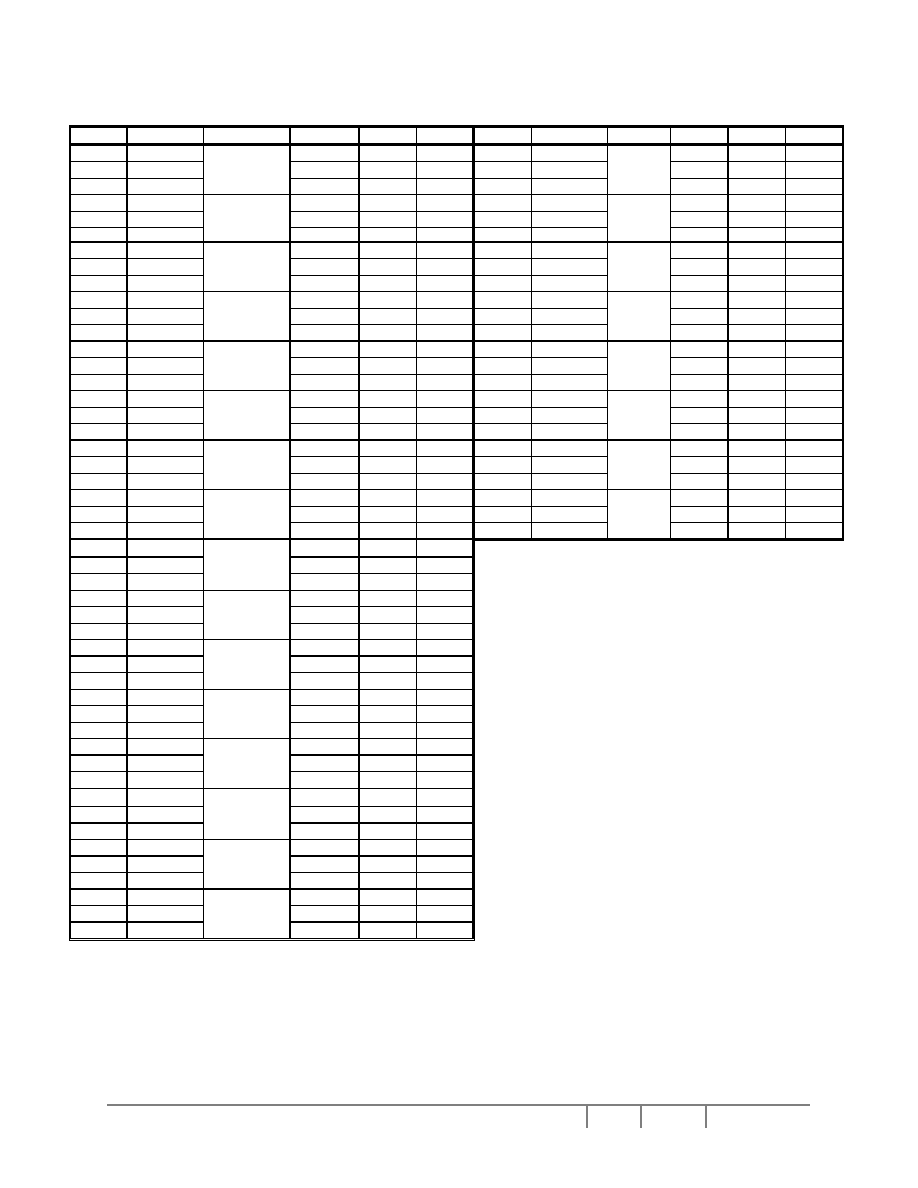

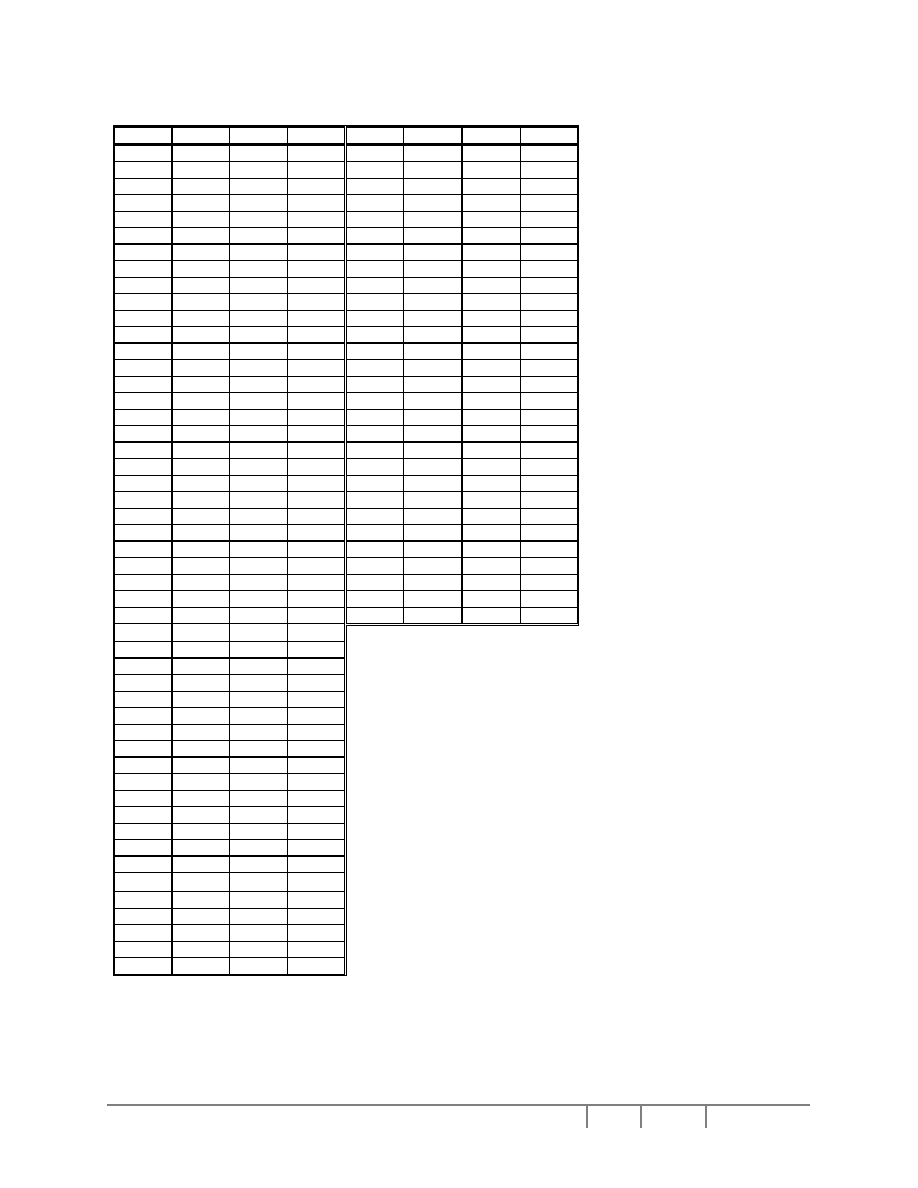

5 DIE PAD FLOOR PLAN

Figure 2 ≠ SSD1770 Die Pad Floor Plan

PIN 1

PIN 229

PIN 230

0

,

0

Y

X

Die size: 17.74 mm x 1.88 mm

Die Thickness: 457 ± 25µm

Bump Height: typical 15µm

Bump co-planarity <3µm (within die)

Note:

1. Diagram showing the die face up.

2. Coordinates are reference to center of the chip.

3. Unit of coordinates and Size of all alignment

marks are in um.

4. All alignment keys do not contain gold bump.

18

100

75

100

25 25

25

25

50

100

100

Ce

nt

re

:

-8393.

7,

-602.

825

Ce

nt

re

:

8393.

7,

358.

375

Ce

nt

re

:

8393.

7,

-602.

825

Ce

nt

re

:

-8393.

7,

358.

375

PIN 126

PIN 127

PIN 272

PIN 585

PIN 627

SSD1770

Rev 1.00 P 5/61

Sep 2003

Solomon Systech

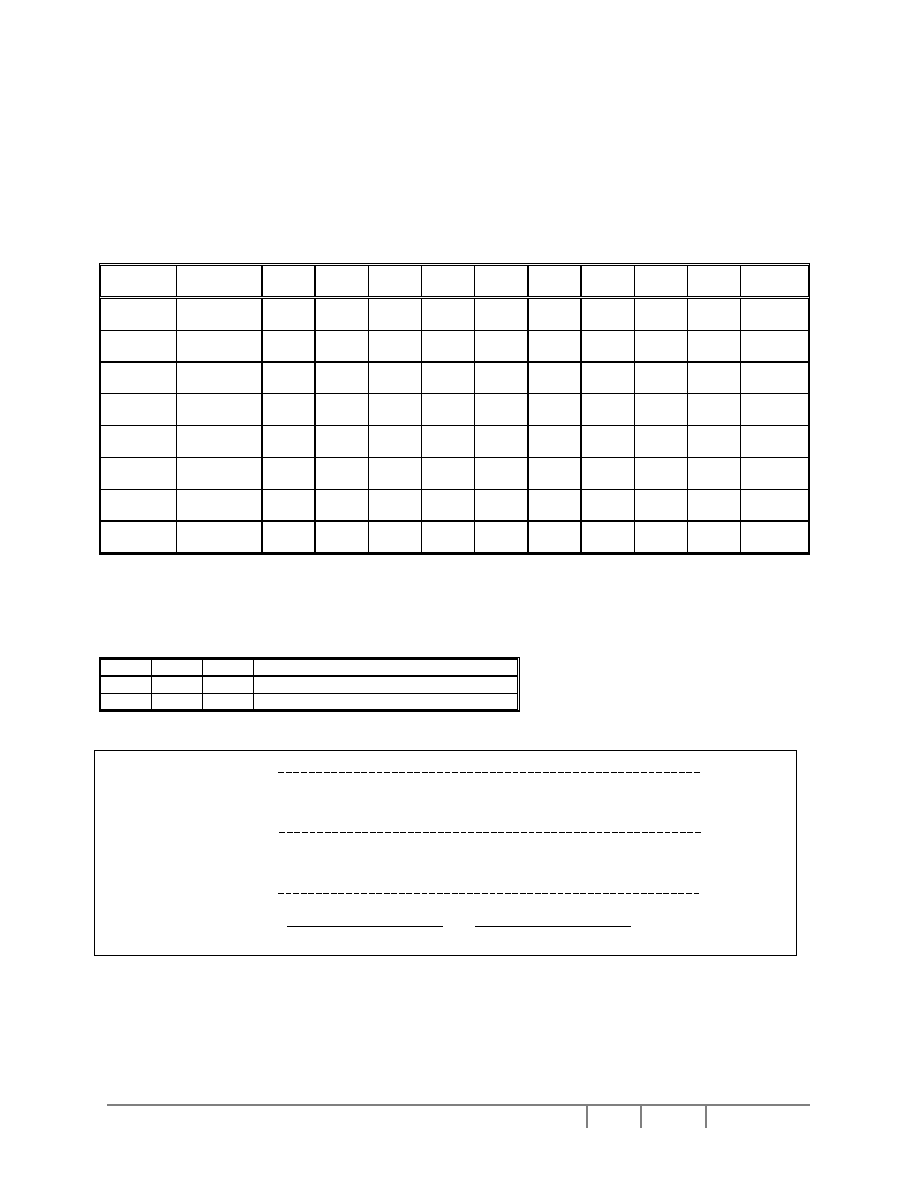

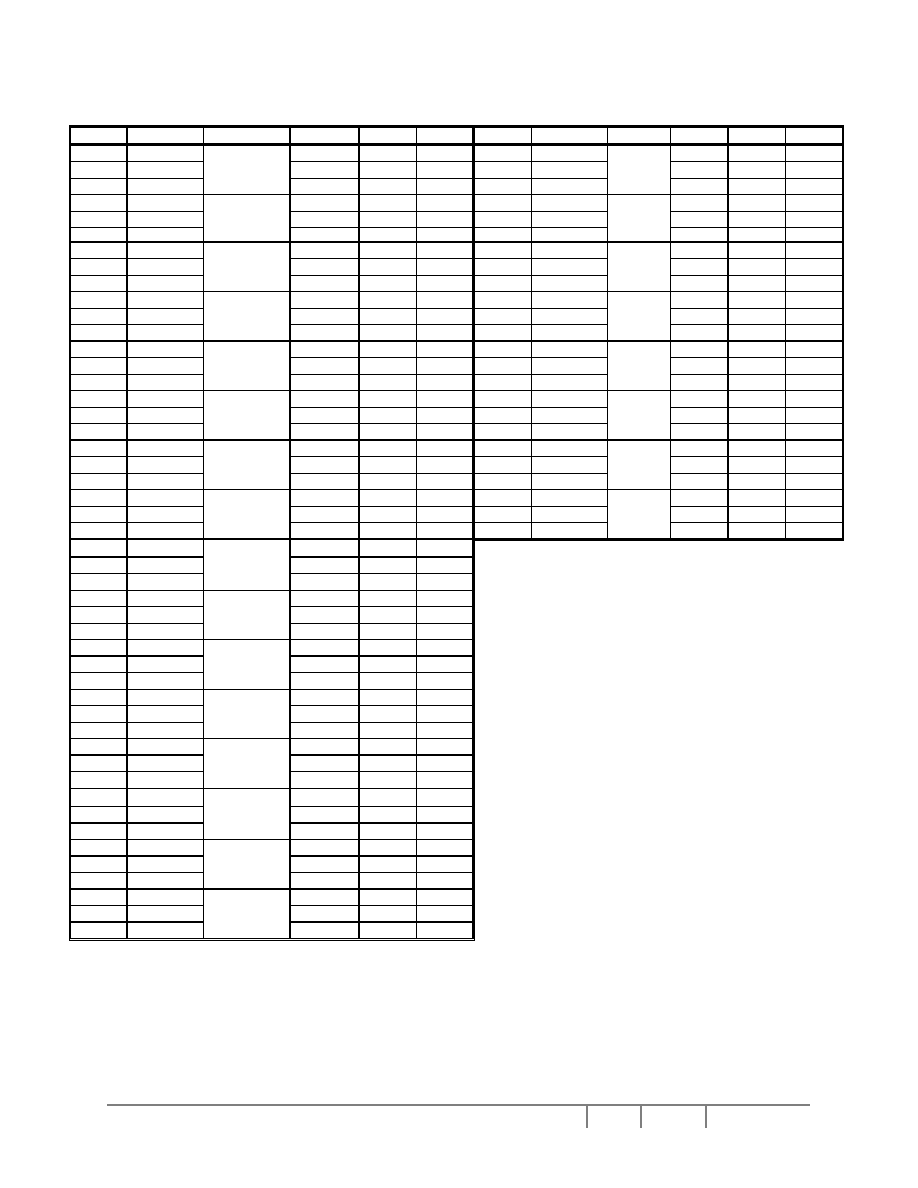

Table 2 ≠ SSD1770 Series Bump Die Pad Coordinates (Bump center)

Pad #

Signal

X-pos

Y-pos

Pad #

Signal

X-pos

Y-pos

Pad #

Signal X-pos

Y-pos

1 DUMMY

-8706.0 -769.7

51

C

/

D

-4896.0

-769.7

101 V

CI

-1066.6

-769.7

2 DUMMY

-8629.8 -769.7

52 BUSY

-4819.8

-769.7

102 V

CI

-990.4

-769.7

3 DUMMY

-8553.6 -769.7

53 BUSY

-4743.6

-769.7

103 V

CI

-914.2

-769.7

4 DUMMY

-8477.4 -769.7

54 V

SS

-4667.4

-769.7

104

V

CI

-838.0

-769.7

5 DUMMY

-8401.2 -769.7

55

80

/

68

MUX

-4591.2

-769.7

105 V

CI

-761.8

-769.7

6 DUMMY

-8325.0 -769.7

56 V

DD

-4515.0

-769.7

106

V

CI

-685.6

-769.7

7 TEST0

-8248.8 -769.7

57 TEST1

-4438.8

-769.7

107 V

CI

-609.4

-769.7

8 CL

-8172.6 -769.7

58 TEST2

-4362.6

-769.7

108 V

CI

-533.2

-769.7

9 M

-8096.4 -769.7

59 TEST3

-4286.4

-769.7

109 V

CI

-457.0

-769.7

10 SYN

-8020.2 -769.7

60 TEST4

-4210.2

-769.7

110 V

CI

-380.8

-769.7

11 V

DD

-7944.0

-769.7

61 TEST5

-4134.0

-769.7

111

V

CI

-304.6

-769.7

12 PS0

-7867.8 -769.7

62 TEST6

-4057.8

-769.7

112 V

CI

-228.4

-769.7

13 V

SS

-7791.6

-769.7

63 TEST7

-3981.6

-769.7

113

V

CI

-152.2

-769.7

14 PS1

-7715.4 -769.7

64 TEST8

-3905.4

-769.7

114 V

CI

-76.0

-769.7

15 V

SS

-7639.2

-769.7

65 V

DD

-3829.2

-769.7

115

V

CI

0.2

-769.7

16

CS

-7563.0 -769.7

66 V

DD

-3753.0

-769.7

116 V

CI

76.4

-769.7

17

CS

-7486.8 -769.7

67 V

DD

-3676.8

-769.7

117 V

CI

152.6

-769.7

18 V

DD

-7410.6

-769.7

68 V

DD

-3600.6

-769.7

118 V

CI

228.8

-769.7

19

RES

-7334.4 -769.7

69 V

DD

-3524.4

-769.7

119 V

CI

305.0

-769.7

20

C

/

D

-7258.2 -769.7

70 V

DD

-3448.2

-769.7

120 V

CI

381.2

-769.7

21

C

/

D

-7182.0 -769.7

71 V

DD

-3372.0

-769.7

121 V

CI

457.4

-769.7

22

C

/

D

-7105.8 -769.7

72 V

DD

-3295.8

-769.7

122 V

CI

533.6

-769.7

23 V

SS

-7029.6

-769.7

73 V

DD

-3219.6

-769.7

123 V

CI

609.8

-769.7

24

W

/

R

(

WR

) -6953.4 -769.7

74 V

DD

-3143.4

-769.7

124 V

CI

686.0

-769.7

25

W

/

R

(

WR

) -6877.2 -769.7

75 V

DD

-3067.2

-769.7

125 V

CI

762.2

-769.7

26 E(

RD

) -6801.0

-769.7 76 V

DD

-2991.0

-769.7

126 V

CI

838.4

-769.7

27 E(

RD

) -6724.8

-769.7 77 V

DD

-2914.8

-769.7

127 RV

SS

914.6

-769.7

28 V

DD

-6648.6

-769.7

78 V

DD

-2838.6

-769.7

128 RV

SS

990.8

-769.7

29 D7 (SDA) -6572.4 -769.7

79 V

DD

-2762.4

-769.7

129 RV

SS

1067.0

-769.7

30 D7 (SDA) -6496.2 -769.7

80 V

DD

-2686.2

-769.7

130 CV

SS

1143.2

-769.7

31 D0

-6420.0 -769.7

81 V

DD

-2610.0

-769.7

131 CV

SS

1219.4

-769.7

32 D1

-6343.8 -769.7

82 V

DDIO

-2533.8

-769.7

132 CV

SS

1295.6

-769.7

33 D2

-6267.6 -769.7

83 V

DDIO

-2457.6

-769.7

133 CV

SS

1371.8

-769.7

34 D3

-6191.4 -769.7

84 V

CIX2

-2371.7

-769.7

134

CV

SS

1448.0

-769.7

35 D4

-6115.2 -769.7

85 V

CIX2

-2295.5

-769.7

135 CV

SS

1524.2

-769.7

36 D5

-6039.0 -769.7

86 V

CIX2

-2219.3

-769.7

136 CV

SS

1600.4

-769.7

37 D6 (SCK) -5962.8 -769.7

87 V

CIX2

-2143.1

-769.7

137 CV

SS

1676.6

-769.7

38 D6 (SCK) -5886.6 -769.7

88 V

CIX2

-2066.9

-769.7

138 CV

SS

1752.8

-769.7

39 D6 (SCK) -5810.4 -769.7

89 V

CIX2

-1990.7

-769.7

139 CV

SS

1829.0

-769.7

40 D7 (SDA) -5734.2 -769.7

90 V

CIX2

-1914.5

-769.7

140 CV

SS

1905.2

-769.7

41 D7 (SDA) -5658.0 -769.7

91 V

CIX2

-1838.3

-769.7

141 CV

SS

1981.4

-769.7

42 D7 (SDA) -5581.8 -769.7

92 V

CIX2

-1762.1

-769.7

142 CV

SS

2057.6

-769.7

43 D0

-5505.6 -769.7

93 VH

REF

-1685.9

-769.7

143 CV

SS

2133.8

-769.7

44 V

DD

-5429.4

-769.7

94 VL

REF

-1609.7

-769.7

144 CV

SS

2210.0

-769.7

45

CS

-5353.2 -769.7

95 V

CIX2

-1523.8

-769.7

145 CV

SS

2286.2

-769.7

46

CS

-5277.0 -769.7

96 VL

REF

-1447.6

-769.7

146 CV

SS

2362.4

-769.7

47 V

SS

-5200.8

-769.7

97 V

CI

-1371.4

-769.7

147 CV

SS

2438.6

-769.7

48

RES

-5124.6 -769.7

98 V

CI

-1295.2

-769.7

148 CV

SS

2514.8

-769.7

49

C

/

D

-5048.4 -769.7

99 V

CI

-1219.0

-769.7

149 CV

SS

2591.0

-769.7

50

C

/

D

-4972.2 -769.7

100 V

CI

-1142.8

-769.7

150 CV

SS

2667.2

-769.7

Solomon Systech

Sep 2003

P 6/61

Rev 1.00

SSD1770

Pad #

Signal X-pos

Y-pos

Pad #

Signal X-pos

Y-pos

151 CV

SS

2743.4

-769.7 201 V

L5

6563.1

-769.7

152 CV

SS

2819.6

-769.7 202 TEST17

6639.3

-769.7

153 CV

SS

2895.8

-769.7 203 V

CIX2

6715.5

-769.7

154 CV

SS

2972.0

-769.7 204 VH

REF

6791.7

-769.7

155 TEST9

3048.2 -769.7

205 VH

REF

6867.9

-769.7

156 TEST10

3124.4 -769.7

206 V

OUT

6944.1

-769.7

157 TEST11

3200.6 -769.7

207 V

OUT

7020.3

-769.7

158 TEST12

3276.8 -769.7

208 V

OUT

7096.5

-769.7

159 TEST13

3353.0 -769.7

209 V

OUT

7172.7

-769.7

160 TEST14

3429.2 -769.7

210 V

OUT

7248.9

-769.7

161 TEST15

3505.4 -769.7

211 V

OUT

7325.1

-769.7

162 TEST16

3581.6 -769.7

212 V

OUT

7401.3

-769.7

163 V

SS

3657.8

-769.7

213 V

OUT

7477.5

-769.7

164 V

SS

3734.0 -769.7

214 V

OUT

7553.7

-769.7

165 V

SS

3810.2 -769.7

215 V

OUT

7629.9

-769.7

166 V

SS

3886.4 -769.7

216 V

OUT

7706.1

-769.7

167 V

SS

3962.6 -769.7

217 V

OUT

7782.3

-769.7

168 V

SS

4038.8 -769.7

218 V

OUT

7858.5

-769.7

169 V

SS

4115.0 -769.7

219 SYN

7944.4

-769.7

170 V

SS

4191.2 -769.7

220 CL

8020.6

-769.7

171 V

SS

4267.4 -769.7

221 M

8096.8

-769.7

172 V

SS

4343.6 -769.7

222 CL

8173.0

-769.7

173 V

SS

4419.8 -769.7

223 DUMMY

8249.2

-769.7

174 V

SS

4496.0 -769.7

224 DUMMY

8325.4

-769.7

175 V

SS

4572.2 -769.7

225 DUMMY

8401.6

-769.7

176 V

SS

4648.4 -769.7

226 DUMMY

8477.8

-769.7

177 V

SS

4724.6 -769.7

227 DUMMY

8554.0

-769.7

178 V

SS

4800.8 -769.7

228 DUMMY

8630.2

-769.7

179 V

SS

4877.0 -769.7

229 DUMMY

8706.4

-769.7

180 V

SS

4953.2

-769.7

181 V

SS

5029.4 -769.7

182 V

SS

5105.6 -769.7

183 V

SS

5181.8 -769.7

184 V

SS

5258.0 -769.7

185 V

SS

5334.2 -769.7

186 V

SS

5410.4 -769.7

187 V

SS

5486.6 -769.7

188 V

CIX2

5572.5

-769.7

189 V

CIX2

5648.7

-769.7

190 V

L3

5724.9 -769.7

191 V

L3

5801.1 -769.7

192 V

L3

5877.3 -769.7

193 V

L3

5953.5 -769.7

194 V

L2

6029.7

-769.7

195 V

L2

6105.9

-769.7

196 V

L3

6182.1

-769.7

197 V

L3

6258.3

-769.7

198 V

L4

6334.5

-769.7

199 V

L4

6410.7

-769.7

200 V

L5

6486.9

-769.7

SSD1770

Rev 1.00 P 7/61

Sep 2003

Solomon Systech

Pad # Pad Name

Signal

(

80

MUX68/

=V

DD

) ≠ 68mux

Signal

(

80

MUX68/

=

V

SS

)≠

80 mux

X-pos Y-pos

Pad # Pad Name

Signal

Color

X-pos

Y-pos

230 DUMMY

DUMMY

DUMMY

8745.1

754.3

273 COL311

B

6748.7

754.3

231 DUMMY

DUMMY

DUMMY

8701.7

754.3

274 COL310

G

6705.3

754.3

232 ICONS

ICONS

ICONS

8658.3

754.3

275 COL309

SEG103

R

6661.9

754.3

233 ROW0

COM0

COM0

8614.9

754.3

276 COL308

B

6618.5

754.3

234 ROW1

COM1

COM1

8571.5

754.3

277 COL307

G

6575.1

754.3

235 ROW2

COM2

COM2

8528.1

754.3

278 COL306

SEG102

R

6531.7

754.3

236 ROW3

COM3

COM3

8484.7

754.3

279 COL305

B

6488.3

754.3

237 ROW4

COM4

COM4

8441.3

754.3

280 COL304

G

6444.9

754.3

238 ROW5

COM5

COM5

8397.9

754.3

281 COL303

SEG101

R

6401.5

754.3

239 ROW6

COM6

COM6

8354.5

754.3

282 COL302

B

6358.1

754.3

240 ROW7

COM7

COM7

8311.1

754.3

283 COL301

G

6314.7

754.3

241 ROW8

COM8

COM8

8267.7

754.3

284 COL300

SEG100

R

6271.3

754.3

242 ROW9

COM9

COM9

8224.3

754.3

285 COL299

B

6227.9

754.3

243 ROW10

COM10

COM10

8180.9

754.3

286 COL298

G

6184.5

754.3

244 ROW11

COM11

COM11

8137.5

754.3

287 COL297

SEG99

R

6141.1

754.3

245 ROW12

COM12

COM12

8094.1

754.3

288 COL296

B

6097.7

754.3

246 ROW13

COM13

COM13

8050.7

754.3

289 COL295

G

6054.3

754.3

247 ROW14

COM14

COM14

8007.3

754.3

290 COL294

SEG98

R

6010.9

754.3

248 ROW15

COM15

COM15

7963.9

754.3

291 COL293

B

5967.5

754.3

249 ROW16

COM16

COM16

7920.5

754.3

292 COL292

G

5924.1

754.3

250 ROW17

COM17

COM17

7877.1

754.3

293 COL291

SEG97

R

5880.7

754.3

251 ROW18

COM18

COM18

7833.7

754.3

294 COL290

B

5837.3

754.3

252 ROW19

COM19

COM19

7790.3

754.3

295 COL289

G

5793.9

754.3

253 ROW20

COM20

COM20

7746.9

754.3

296 COL288

SEG96

R

5750.5

754.3

254 ROW21

COM21

COM21

7703.5

754.3

297 COL287

B

5707.1

754.3

255 ROW22

COM22

COM22

7660.1

754.3

298 COL286

G

5663.7

754.3

256 ROW23

COM23

COM23

7616.7

754.3

299 COL285

SEG95

R

5620.3

754.3

257 ROW24

COM24

COM24

7573.3

754.3

300 COL284

B

5576.9

754.3

258 ROW25

COM25

COM25

7529.9

754.3

301 COL283

G

5533.5

754.3

259 ROW26

COM26

COM26

7486.5

754.3

302 COL282

SEG94

R

5490.1

754.3

260 ROW27

COM27

COM27

7443.1

754.3

303 COL281

B

5446.7

754.3

261 ROW28

COM28

COM28

7399.7

754.3

304 COL280

G

5403.3

754.3

262 ROW29

COM29

COM29

7356.3

754.3

305 COL279

SEG93

R

5359.9

754.3

263 ROW30

COM30

COM30

7312.9

754.3

306 COL278

B

5316.5

754.3

264 ROW31

COM31

COM31

7269.5

754.3

307 COL277

G

5273.1

754.3

265 ROW32

COM32

COM32

7226.1

754.3

308 COL276

SEG92

R

5229.7

754.3

266 ROW33

COM33

COM33

7182.7

754.3

309 COL275

B

5186.3

754.3

267 ROW34

Non select signal

COM34 7139.3

754.3

310 COL274

G

5142.9

754.3

268 ROW35

Non select signal

COM35 7095.9

754.3

311 COL273

SEG91

R

5099.5

754.3

269 ROW36

Non select signal

COM36 7052.5

754.3

312 COL272

B

5056.1

754.3

270 ROW37

Non select signal

COM37 7009.1

754.3

313 COL271

G

5012.7

754.3

271 ROW38

Non select signal

COM38 6965.7

754.3

314 COL270

SEG90

R

4969.3

754.3

272 ROW39

Non select signal

COM39 6922.3

754.3

315 COL269

B

4925.9

754.3

316 COL268

G

4882.5

754.3

317 COL267

SEG89

R

4839.1

754.3

318 COL266

B

4795.7

754.3

319 COL265

G

4752.3

754.3

320 COL264

SEG88

R

4708.9

754.3

Solomon Systech

Sep 2003

P 8/61

Rev 1.00

SSD1770

Pad #

Pad Name

Signal

Color

X-pos

Y-pos

Pad #

Pad Name

Signal Color

X-pos

Y-pos

321 COL263

B

4665.5

754.3

369 COL215

B

2582.3

754.3

322 COL262

G

4622.1

754.3

370 COL214

G

2538.9

754.3

323 COL261

SEG87

R

4578.7

754.3

371 COL213

SEG71

R

2495.5

754.3

324 COL260

B

4535.3

754.3

372 COL212

B

2452.1

754.3

325 COL259

G

4491.9

754.3

373 COL211

G

2408.7

754.3

326 COL258

SEG86

R 4448.5

754.3

374 COL210

SEG70

R 2365.3

754.3

327 COL257

B

4405.1

754.3

375 COL209

B

2321.9

754.3

328 COL256

G

4361.7

754.3

376 COL208

G

2278.5

754.3

329 COL255

SEG85

R

4318.3

754.3

377 COL207

SEG69

R

2235.1

754.3

330 COL254

B

4274.9

754.3

378 COL206

B

2191.7

754.3

331 COL253

G

4231.5

754.3

379 COL205

G

2148.3

754.3

332 COL252

SEG84

R

4188.1

754.3

380 COL204

SEG68

R

2104.9

754.3

333 COL251

B

4144.7

754.3

381 COL203

B

2061.5

754.3

334 COL250

G

4101.3

754.3

382 COL202

G

2018.1

754.3

335 COL249

SEG83

R

4057.9

754.3

383 COL201

SEG67

R

1974.7

754.3

336 COL248

B

4014.5

754.3

384 COL200

B

1931.3

754.3

337 COL247

G

3971.1

754.3

385 COL199

G

1887.9

754.3

338 COL246

SEG82

R

3927.7

754.3

386 COL198

SEG66

R

1844.5

754.3

339 COL245

B

3884.3

754.3

387 COL197

B

1801.1

754.3

340 COL244

G

3840.9

754.3

388 COL196

G

1757.7

754.3

341 COL243

SEG81

R

3797.5

754.3

389 COL195

SEG65

R

1714.3

754.3

342 COL242

B

3754.1

754.3

390 COL194

B

1670.9

754.3

343 COL241

G

3710.7

754.3

391 COL193

G

1627.5

754.3

344 COL240

SEG80

R

3667.3

754.3

392 COL192

SEG64

R

1584.1

754.3

345 COL239

B

3623.9

754.3

393 COL191

B

1540.7

754.3

346 COL238

G

3580.5

754.3

394 COL190

G

1497.3

754.3

347 COL237

SEG79

R

3537.1

754.3

395 COL189

SEG63

R

1453.9

754.3

348 COL236

B

3493.7

754.3

396 COL188

B

1410.5

754.3

349 COL235

G

3450.3

754.3

397 COL187

G

1367.1

754.3

350 COL234

SEG78

R

3406.9

754.3

398 COL186

SEG62

R

1323.7

754.3

351 COL233

B

3363.5

754.3

399 COL185

B

1280.3

754.3

352 COL232

G

3320.1

754.3

400 COL184

G

1236.9

754.3

353 COL231

SEG77

R

3276.7

754.3

401 COL183

SEG61

R

1193.5

754.3

354 COL230

B

3233.3

754.3

402 COL182

B

1150.1

754.3

355 COL229

G

3189.9

754.3

403 COL181

G

1106.7

754.3

356 COL228

SEG76

R

3146.5

754.3

404 COL180

SEG60

R

1063.3

754.3

357 COL227

B

3103.1

754.3

405 COL179

B

1019.9

754.3

358 COL226

G

3059.7

754.3

406 COL178

G

976.5

754.3

359 COL225

SEG75

R

3016.3

754.3

407 COL177

SEG59

R

933.1

754.3

360 COL224

B

2972.9

754.3

408 COL176

B

889.7

754.3

361 COL223

G

2929.5

754.3

409 COL175

G

846.3

754.3

362 COL222

SEG74

R

2886.1

754.3

410 COL174

SEG58

R

802.9

754.3

363 COL221

B

2842.7

754.3

411 COL173

B

759.5

754.3

364 COL220

G

2799.3

754.3

412 COL172

G

716.1

754.3

365 COL219

SEG73

R

2755.9

754.3

413 COL171

SEG57

R

672.7

754.3

366 COL218

B

2712.5

754.3

414 COL170

B

629.3

754.3

367 COL217

G

2669.1

754.3

415 COL169

G

585.9

754.3

368 COL216

SEG72

R

2625.7

754.3

416 COL168

SEG56

R

542.5

754.3

SSD1770

Rev 1.00 P 9/61

Sep 2003

Solomon Systech

Pad #

Pad Name

Signal

Color

X-pos

Y-pos

Pad #

Pad Name

Signal

Color X-pos

Y-pos

417 COL167

B

499.1

754.3

465 COL119

B

-1584.1

754.3

418 COL166

G

455.7

754.3

466 COL118

G

-1627.5

754.3

419 COL165

SEG55

R

412.3

754.3

467 COL117

SEG39

R

-1670.9

754.3

420 COL164

B

368.9

754.3

468 COL116

B

-1714.3

754.3

421 COL163

G

325.5

754.3

469 COL115

G

-1757.7

754.3

422 COL162

SEG54

R 282.1

754.3

470 COL114

SEG38

R -1801.1

754.3

423 COL161

B

238.7

754.3

471 COL113

B

-1844.5

754.3

424 COL160

G

195.3

754.3

472 COL112

G

-1887.9

754.3

425 COL159

SEG53

R

151.9

754.3

473 COL111

SEG37

R

-1931.3

754.3

426 COL158

B

108.5

754.3

474 COL110

B

-1974.7

754.3

427 COL157

G

65.1

754.3

475 COL109

G

-2018.1

754.3

428 COL156

SEG52

R

21.7

754.3

476 COL108

SEG36

R

-2061.5

754.3

429 COL155

B

-21.7

754.3

477 COL107

B

-2104.9

754.3

430 COL154

G

-65.1

754.3

478 COL106

G

-2148.3

754.3

431 COL153

SEG51

R

-108.5

754.3

479 COL105

SEG35

R

-2191.7

754.3

432 COL152

B

-151.9

754.3

480 COL104

B

-2235.1

754.3

433 COL151

G

-195.3

754.3

481 COL103

G

-2278.5

754.3

434 COL150

SEG50

R

-238.7

754.3

482 COL102

SEG34

R

-2321.9

754.3

435 COL149

B

-282.1

754.3

483 COL101

B

-2365.3

754.3

436 COL148

G

-325.5

754.3

484 COL100

G

-2408.7

754.3

437 COL147

SEG49

R

-368.9

754.3

485 COL99

SEG33

R

-2452.1

754.3

438 COL146

B

-412.3

754.3

486 COL98

B

-2495.5

754.3

439 COL145

G

-455.7

754.3

487 COL97

G

-2538.9

754.3

440 COL144

SEG48

R

-499.1

754.3

488 COL96

SEG32

R

-2582.3

754.3

441 COL143

B

-542.5

754.3

489 COL95

B

-2625.7

754.3

442 COL142

G

-585.9

754.3

490 COL94

G

-2669.1

754.3

443 COL141

SEG47

R

-629.3

754.3

491 COL93

SEG31

R

-2712.5

754.3

444 COL140

B

-672.7

754.3

492 COL92

B

-2755.9

754.3

445 COL139

G

-716.1

754.3

493 COL91

G

-2799.3

754.3

446 COL138

SEG46

R

-759.5

754.3

494 COL90

SEG30

R

-2842.7

754.3

447 COL137

B

-802.9

754.3

495 COL89

B

-2886.1

754.3

448 COL136

G

-846.3

754.3

496 COL88

G

-2929.5

754.3

449 COL135

SEG45

R

-889.7

754.3

497 COL87

SEG29

R

-2972.9

754.3

450 COL134

B

-933.1

754.3

498 COL86

B

-3016.3

754.3

451 COL133

G

-976.5

754.3

499 COL85

G

-3059.7

754.3

452 COL132

SEG44

R

-1019.9

754.3

500 COL84

SEG28

R

-3103.1

754.3

453 COL131

B

-1063.3

754.3

501 COL83

B

-3146.5

754.3

454 COL130

G

-1106.7

754.3

502 COL82

G

-3189.9

754.3

455 COL129

SEG43

R

-1150.1

754.3

503 COL81

SEG27

R

-3233.3

754.3

456 COL128

B

-1193.5

754.3

504 COL80

B

-3276.7

754.3

457 COL127

G

-1236.9

754.3

505 COL79

G

-3320.1

754.3

458 COL126

SEG42

R

-1280.3

754.3

506 COL78

SEG26

R

-3363.5

754.3

459 COL125

B

-1323.7

754.3

507 COL77

B

-3406.9

754.3

460 COL124

G

-1367.1

754.3

508 COL76

G

-3450.3

754.3

461 COL123

SEG41

R

-1410.5

754.3

509 COL75

SEG25

R

-3493.7

754.3

462 COL122

B

-1453.9

754.3

510 COL74

B

-3537.1

754.3

463 COL121

G

-1497.3

754.3

511 COL73

G

-3580.5

754.3

464 COL120

SEG40

R

-1540.7

754.3

512 COL72

SEG24

R

-3623.9

754.3

Solomon Systech

Sep 2003

P 10/61 Rev 1.00

SSD1770

Pad #

Pad Name

Signal

Color

X-pos

Y-pos

Pad #

Pad Name

Signal

Color X-pos

Y-pos

513 COL71

B

-3667.3

754.3

561 COL23

B

-5750.5

754.3

514 COL70

G

-3710.7

754.3

562 COL22

G

-5793.9

754.3

515 COL69

SEG23

R

-3754.1

754.3

563 COL21

SEG7

R

-5837.3

754.3

516 COL68

B

-3797.5

754.3

564 COL20

B

-5880.7

754.3

517 COL67

G

-3840.9

754.3

565 COL19

G

-5924.1

754.3

518 COL66

SEG22

R -3884.3

754.3

566 COL18

SEG6

R -5967.5

754.3

519 COL65

B

-3927.7

754.3

567 COL17

B

-6010.9

754.3

520 COL64

G

-3971.1

754.3

568 COL16

G

-6054.3

754.3

521 COL63

SEG21

R

-4014.5

754.3

569 COL15

SEG5

R

-6097.7

754.3

522 COL62

B

-4057.9

754.3

570 COL14

B

-6141.1

754.3

523 COL61

G

-4101.3

754.3

571 COL13

G

-6184.5

754.3

524 COL60

SEG20

R

-4144.7

754.3

572 COL12

SEG4

R

-6227.9

754.3

525 COL59

B

-4188.1

754.3

573 COL11

B

-6271.3

754.3

526 COL58

G

-4231.5

754.3

574 COL10

G

-6314.7

754.3

527 COL57

SEG19

R

-4274.9

754.3

575 COL9

SEG3

R

-6358.1

754.3

528 COL56

B

-4318.3

754.3

576 COL8

B

-6401.5

754.3

529 COL55

G

-4361.7

754.3

577 COL7

G

-6444.9

754.3

530 COL54

SEG18

R

-4405.1

754.3

578 COL6

SEG2

R

-6488.3

754.3

531 COL53

B

-4448.5

754.3

579 COL5

B

-6531.7

754.3

532 COL52

G

-4491.9

754.3

580 COL4

G

-6575.1

754.3

533 COL51

SEG17

R

-4535.3

754.3

581 COL3

SEG1

R

-6618.5

754.3

534 COL50

B

-4578.7

754.3

582 COL2

B

-6661.9

754.3

535 COL49

G

-4622.1

754.3

583 COL1

G

-6705.3

754.3

536 COL48

SEG16

R

-4665.5

754.3

584 COL0

SEG0

R

-6748.7

754.3

537 COL47

B

-4708.9

754.3

538 COL46

G

-4752.3

754.3

539 COL45

SEG15

R

-4795.7

754.3

540 COL44

B

-4839.1

754.3

541 COL43

G

-4882.5

754.3

542 COL42

SEG14

R

-4925.9

754.3

543 COL41

B

-4969.3

754.3

544 COL40

G

-5012.7

754.3

545 COL39

SEG13

R

-5056.1

754.3

546 COL38

B

-5099.5

754.3

547 COL37

G

-5142.9

754.3

548 COL36

SEG12

R

-5186.3

754.3

549 COL35

B

-5229.7

754.3

550 COL34

G

-5273.1

754.3

551 COL33

SEG11

R

-5316.5

754.3

552 COL32

B

-5359.9

754.3

553 COL31

G

-5403.3

754.3

554 COL30

SEG10

R

-5446.7

754.3

555 COL29

B

-5490.1

754.3

556 COL28

G

-5533.5

754.3

557 COL27

SEG9

R

-5576.9

754.3

558 COL26

B

-5620.3

754.3

559 COL25

G

-5663.7

754.3

560 COL24

SEG8

R

-5707.1

754.3

SSD1770

Rev 1.00 P 11/61 Sep 2003

Solomon Systech

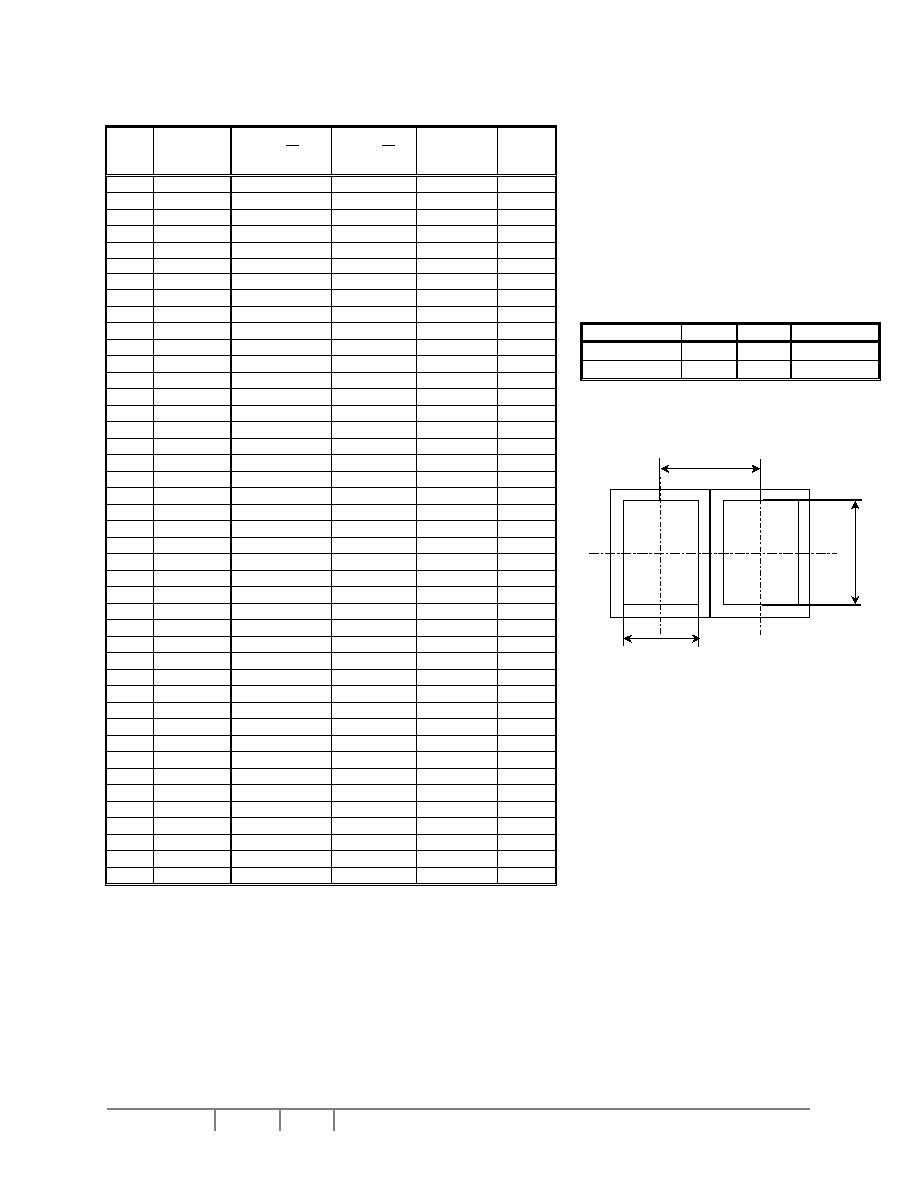

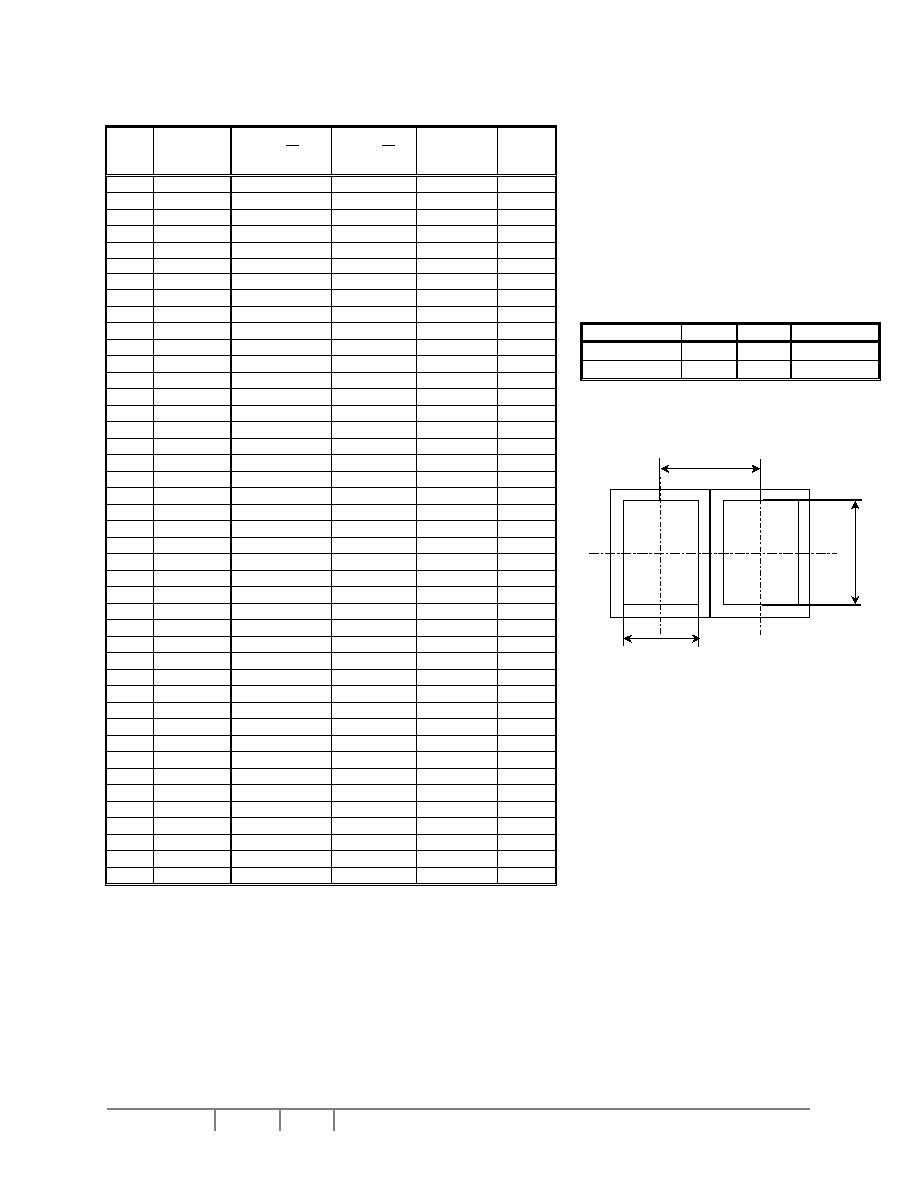

X

Y

Pad pitch

Pad # Pad Name

Signal

(

80

MUX68/

=

V

DD

) - 68mux

Signal

(

80

MUX68/

=

V

SS

) ≠ 80mux

X-pos Y-pos

585 ROW40

Non Select Signal

COM40 -6922.3

754.3

586 ROW41

Non Select Signal

COM41 -6965.7

754.3

587 ROW42

Non Select Signal

COM42 -7009.1

754.3

588 ROW43

Non Select Signal

COM43 -7052.5

754.3

589 ROW44

Non Select Signal

COM44 -7095.9

754.3

590 ROW45

Non Select Signal

COM45 -7139.3

754.3

591 ROW46

COM34

COM46

-7182.7

754.3

592 ROW47

COM35

COM47

-7226.1

754.3

593 ROW48

COM36

COM48

-7269.5

754.3

594 ROW49

COM37

COM49

-7312.9

754.3

595 ROW50

COM38

COM50

-7356.3

754.3

596 ROW51

COM39

COM51

-7399.7

754.3

597 ROW52

COM40

COM52

-7443.1

754.3

598 ROW53

COM41

COM53

-7486.5

754.3

599 ROW54

COM42

COM54

-7529.9

754.3

600 ROW55

COM43

COM55

-7573.3

754.3

601 ROW56

COM44

COM56

-7616.7

754.3

602 ROW57

COM45

COM57

-7660.1

754.3

603 ROW58

COM46

COM58

-7703.5

754.3

604 ROW59

COM47

COM59

-7746.9

754.3

605 ROW60

COM48

COM60

-7790.3

754.3

606 ROW61

COM49

COM61

-7833.7

754.3

607 ROW62

COM50

COM62

-7877.1

754.3

608 ROW63

COM51

COM63

-7920.5

754.3

609 ROW64

COM52

COM64

-7963.9

754.3

610 ROW65

COM53

COM65

-8007.3

754.3

611 ROW66

COM54

COM66

-8050.7

754.3

612 ROW67

COM55

COM67

-8094.1

754.3

613 ROW68

COM56

COM68

-8137.5

754.3

614 ROW69

COM57

COM69

-8180.9

754.3

615 ROW70

COM58

COM70

-8224.3

754.3

616 ROW71

COM59

COM71

-8267.7

754.3

617 ROW72

COM60

COM72

-8311.1

754.3

618 ROW73

COM61

COM73

-8354.5

754.3

619 ROW74

COM62

COM74

-8397.9

754.3

620 ROW75

COM63

COM75

-8441.3

754.3

621 ROW76

COM64

COM76

-8484.7

754.3

622 ROW77

COM65

COM77

-8528.1

754.3

623 ROW78

COM66

COM78

-8571.5

754.3

624 ROW79

COM67

COM79

-8614.9

754.3

625 ICONS

ICONS

ICONS

-8658.3

754.3

626 DUMMY

-8701.7

754.3

627 DUMMY

-8745.1

754.3

Bump Size

PAD#

X [um] Y [um] Pad pitch [um]

Pad 1-229

56

92

76.2

Pad 230 - 627 28

130

43.4

Solomon Systech

Sep 2003

P 12/61 Rev 1.00

SSD1770

6 PIN

DESCRIPTION

6.1

CS

This pin is the chip selection input. The chip is enabled for MCU communication only when CS is pulled

low.

6.2

RES

This pin is the reset signal input. Initialization of the chip is started once the reset pin is pulled low. The

minimum pulse width for reset sequence is 10us.

6.3 D/

C

This pin is Data/Command control pin. When the pin is pulled high, the input at D

7

-D

0

is treated as display

data. When the pin is pulled low, the input at D

7

-D

0

will be transferred to the command register.

6.4 R/

W

(

WR

)

This pin is MCU interface input. When 6800 interface mode is selected, this pin will be used as

Read/Write (

R/W

) selection input. Read mode will be carried out when this pin is pulled high and write

mode when this pin is pulled low.

When 8080 interface mode is selected, this pin is the Write (

WR

) control signal input. Data write

operation is initiated when this pin is pulled low and the chip is selected.

6.5 E(

RD

)

This pin is MCU interface input. When 6800 interface mode is selected, this pin will be used as the Enable

(E) signal. Read/ write operation is initiated when this pin is pulled high and the chip is selected.

When 8080 interface mode is selected, this pin is the Read (

RD

) control signal input. Data read operation

is initiated when this pin is pulled low and the chip is selected.

6.6 PS0 ≠ PS1

These pins are the bus interface mode selection input. Different bus interface can be selected changing

the setting of these pins.

PS1 PS0 MPU

Interface

L

H

8-bit 8080 parallel interface

H

H

8-bit 6800 parallel interface

H

L

3-lines serial peripheral interface (SPI) ≠ 9 bits SPI

L

L

4-lines serial peripheral interface (SPI)

Note1: For serial applications, D

0

≠ D

5

,

R/W ( WR )

,

E( RD )

are recommended to connect V

DD

.

Note2: Read back operation is only available in parallel mode

6.7

80

MUX68/

This pin is used to select the Mux ratio of the LCD driver. When

MUX68/( 80 )

is equal to V

DD

, COM0

~COM33 are mapped to ROW0~ROW33 and COM46~COM79 are mapped to ROW34~ROW67 of the

memory. When

MUX68/( 80 )

is equal to V

SS

, COM0~COM79 are mapped to ROW0~ROW79.

6.8 D

7

-D

0

These pins are the 8-bit bi-directional data bus in parallel interface mode. D

7

is the MSB while D

0

is the

LSB. When serial mode selected, D

7

is the serial data input SDA and D

6

is the serial clock input SCK.

SSD1770

Rev 1.00 P 13/61 Sep 2003

Solomon Systech

6.9 VL

REF

This pin is the ground of operation amplifier V

L4

and V

L5

. In normal power mode, it must connect to V

SS

. In

low power mode, it must connect to V

CI

and V

L4

must greater than 4V. Please refer to Figure 5 on page

20 for the detail.

6.10 VH

REF

This pin is the power supply pin of the operation amplifier V

L3

. It must connect to V

OUT

.

6.11 V

CIX2

This pin is internal reference pin. It must connect to V

CI

.

6.12 V

DD

This pin is the system power supply pin of the logic block.

6.13 V

DDIO

This pin is the system power supply pin of I/O buffer. Please refer to Figure 24 on page 59 for connection

example.

6.14 V

CI

This pin is the reference voltage input for internal DC-DC converter. The DC-DC converter output is

equals to the multiple factor (3X, 4X, 5X or 6X) times V

CI

with respect to V

SS

. The maximum output

voltage will limit the max. V

OUT

characteristic.

Note: Voltage at this input pin must be larger than or equal to V

DD

. (V

CI

V

DD

)

6.15 V

SS

This pin is the ground of logic.

6.16 RV

SS

This pin is the ground of Vref.

6.17 CV

SS

This pin is the ground of analog.

6.18 V

OUT

This is the most positive voltage supply pin of the chip. It can be supplied externally or generated by the

internal DC-DC converter. If the internal DC-DC converter generates the voltage level at V

OUT

, the voltage

level is used for internal referencing only. The voltage level at V

OUT

pin is not used for driving external

circuitry.

Solomon Systech

Sep 2003

P 14/61 Rev 1.00

SSD1770

6.19 V

L5,

V

L4,

V

L3

and V

L2

LCD driving voltages. They can be supplied externally or generated by the internal bias divider. They

have the following relationship:

V

OUT

> V

L5

> V

L4

> V

L3

> V

L2

> V

SS

Table 3 ≠ V

OUT

> V

L5

> V

L4

> V

L3

> V

L2

> V

SS

Relationship

1 : a bias

V

L5

(a-1)/a

*

V

OUT

V

L4

(a-2)/a * V

OUT

V

L3

2/a * V

OUT

V

L2

1/a * V

OUT

6.20 ROW0 ≠ ROW79

These pins provide the driving signals, COMMON, to the LCD panel.

6.21 COL0 ≠ COL311

These pins provide the LCD driving signals, SEGMENT, to the LCD panel. The Red, Green, Blue colors

signal are sent out from the SEGMENT output at the same time. The output voltage level of these pins is

V

DD

during sleep mode or standby mode.

6.22 ICON

This pin provides the driving signals, COMMON icon line.

6.23 CL

This pin is the system clock I/O. This pin is the external clock input for the device, which is enabled by

using extended command. It should be left open under normal operation. The internal oscillator will be

used after power on reset.

6.24 M

This pin is used for cascade purpose only. It should be left open under normal operation.

6.25 SYN

This pin is used for cascade purpose only. It should be left open under normal operation.

6.26 BUSY

This pin will be high during RAM buffer read/write operation and during graphic commands executing.

System programmer should read this pin (low is ready, high is busy) before sending next RAM buffer

related command (e.g. RAM write ≠ 5CH; RAM read ≠ 5DH OR any graphic commands)

6.27 TEST0~TEST17

These pins are used for internal only and should be left open, any connection is not allowed.

6.28 Dummy

There is a floating dummy pad without any internal circuitry connection.

SSD1770

Rev 1.00 P 15/61 Sep 2003

Solomon Systech

7 FUNCTIONAL BLOCK DESCRIPTIONS

7.1 Microprocessor Interface Logic

The Microprocessor Interface unit consists of three functional blocks for driving the 6800-series parallel

interface, 8080-series parallel interface, 3-lines serial peripheral interface and 4-lines serial peripheral

interface. The selection of different interface is done by PS0 to PS1 pins. Please refer to the pin

descriptions on page 12.

a) MPU Parallel 6800-series Interface

The parallel Interface consists of 8 bi-directional data pins (D

7

≠ D

0

), R/

W

, D/

C

, E,

CS

. R/

W

(

WR

) input high indicates a read operation from the Graphical Display Data RAM (GDDRAM) or

the status register. R/

W

input low indicates a write operation to Display Data RAM or Internal

Command Registers depending on the status of D/

C

input. The E input serves as data latch

signal (clock) when high provided that

CS

is low. Please refer to Figure 19to Figure 20 on page

54 to 55 for Parallel Interface Timing Diagram of 6800-series microprocessors. In order to match

the operating frequency of the GDDRAM with that of the MCU, some pipeline processing is

internally performed which requires the insertion of a dummy read before the first actual display

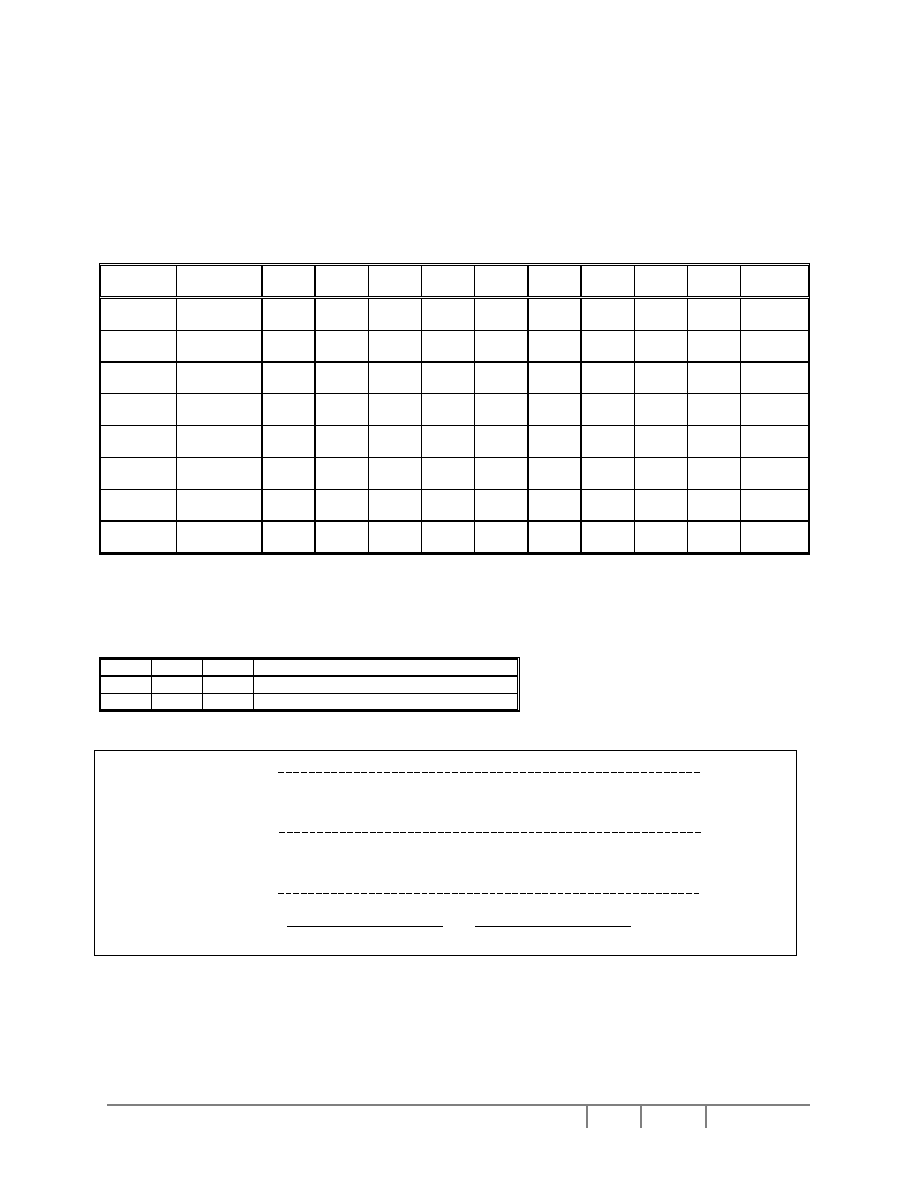

data read. This is shown in the following diagram.

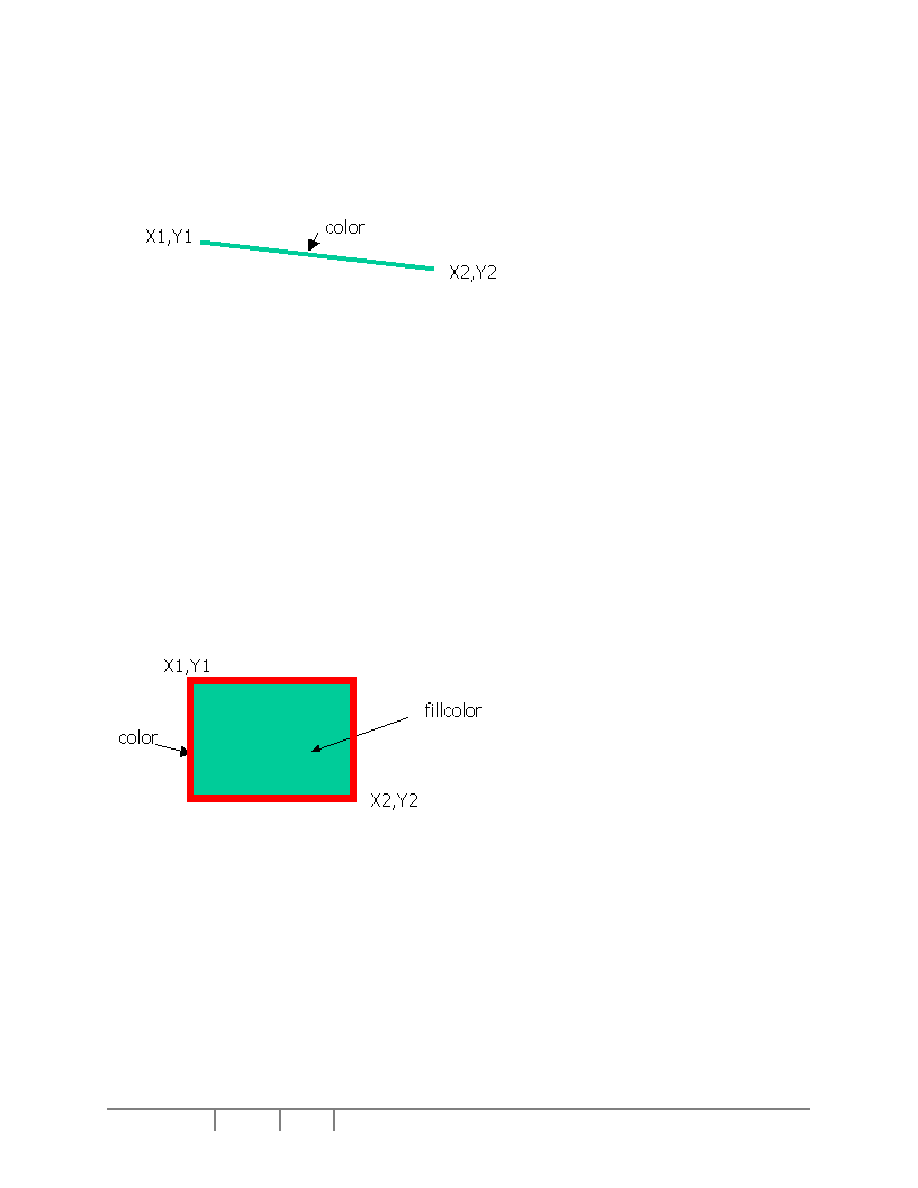

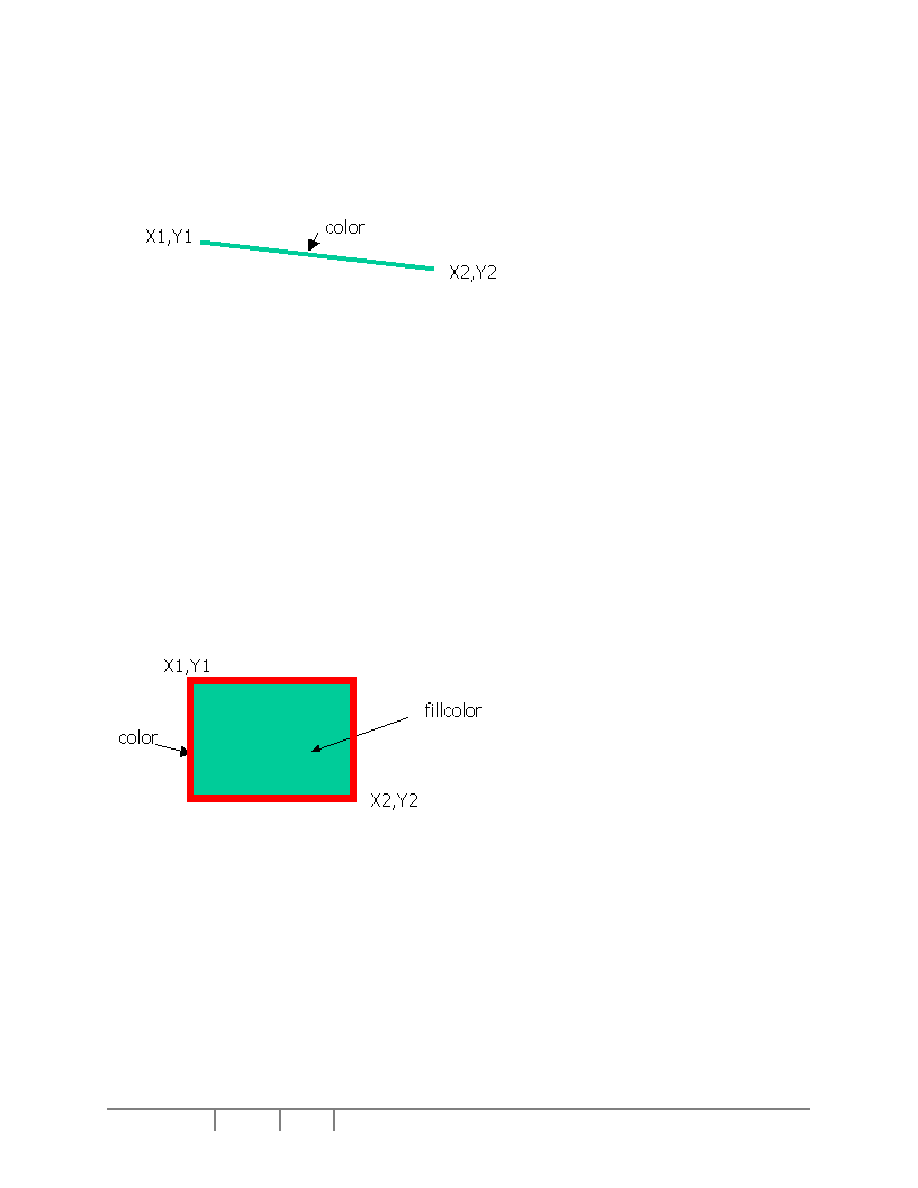

Figure 3 ≠ Display Data

b) MPU Parallel 8080-series Interface

The parallel interface consists of 8 bi-directional data pins D

7

≠ D

0

,

RD

,

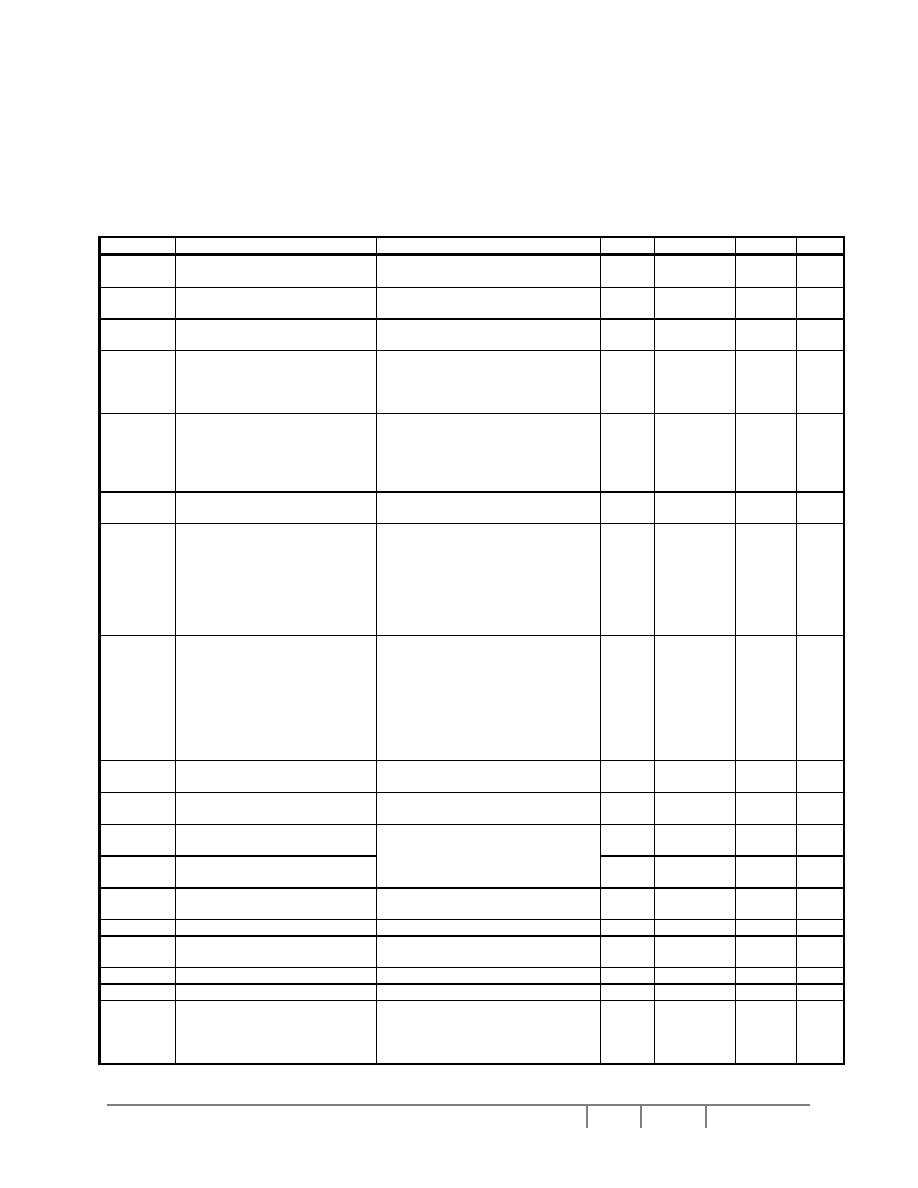

WR

,

D/ C

,

CS

.

RD

input

serves as data read latch signal (clock) when low provided that

CS

is low. Whether reading the

display data from GDDRAM or reading the status from the status register is controlled by

D/ C

.

WR

input serves as data write latch signal (clock) when low provided that

CS

is low. Whether

writing the display data to the GDDRAM or writing the command to the command register is

controlled by

D/ C

. A dummy read is also required before the first actual display data read for

8080-series interface.

c) MPU 4-lines Serial Peripheral Interface

The 4-lines serial peripheral Interface consists of serial clock SCK, serial data SDA,

D/ C

,

CS

.

SDA is shifted into 8-bit shift register on every rising edge of SCK in the order of data bit 7, data

bit 6 ...... data bit 0.

D/ C

is sampled on every eighth clock to determine whether the data byte in

the shift register is written to the Display Data RAM or command register at the same clock.

Please refer to Figure 21 on page 56 for serial interface timing.

write column address

dummy read

data read1

data read 2

data read 3

N

n

n+1

n+2

E( RD )

R/W ( WR )

DATA BUS

Solomon Systech

Sep 2003

P 16/61 Rev 1.00

SSD1770

d) MPU 3-lines Serial Peripheral Interface

The operation is similar to 4-lines serial peripheral interface while

D/ C

is not used. There are

altogether 9-bits will be shifted into the shift register on every ninth clock in sequence:

D/ C

bit, D

7

to D

0

bit. The

D/ C

bit (first bit of the sequential data) will determine the following data byte in the

shift register is written to the Display Data RAM (

D/ C

bit = 1) or the command register (

D/ C

bit =

0).

6800 ≠ series Parallel

Interface

8080 ≠ series Parallel

Interface

3-lines or 4-lines Serial

peripheral Interface

Data Read

8-bits

8-bits

No

Data Write

8-bits

8-bits

8-bits

Command Read

Status only

Status only

No

Command Write

Yes

Yes

Yes

Table 4 ≠ Data bus selection modes

SSD1770

Rev 1.00 P 17/61 Sep 2003

Solomon Systech

7.2 Reset

Circuit

This block is integrated into the Microprocessor Interface Logic which includes Power On Reset circuitry

and the hardware reset pin,

RES

. Both of these having the same reset function. Once the

RES

pin

receives a negative reset pulse, all internal circuitry will start to initialize. The minimum pulse width for

completing the reset sequence is 10us. The status of the chip after reset is given by:

When

RES

input is low, the chip is initialized to the following:

1.

Display

ON/OFF:

Display

is

OFF

2.

Normal/Inverse

Display:

Normal

Display

3. COM Scan Direction:

COM0 -> COM67/COM79

4.

Internal

Oscillator:

Disable

5. Reference Voltage Generation Circuit:

Disable

6. Voltage regulator and Voltage Follower:

Disable

7.

Booster

level:

6X

8. Bias ratio:

1/7(68 Mux) / 1/8 (80 Mux)

9.

Multiplex

ratio:

68

/

80

Mux

10.

Contrast

level:

32

11.

Internal

regulator

gain:

2.84

12. Average temperature gradient:

-0.2%/

o

C

13.

Partial

display

mode:

Disable

Start

COM

address:

0

End

COM

address:

0

14. Area Scroll set

Top

block

address:

0

Bottom

block

address:

0

Number of specified block:

0

Area scroll mode:

Whole screen scroll mode

15. Scroll start set

Start

block

address:

0

16. Data Scan Direction

Normal/inverse display of page address:

Normal

Normal/inverse display of column address:

Normal

Address-scan

direction:

Column

direction

RGB

arrangement:

RGB

Gray-scale

setup:

8

gray-scale

17. Start Page Address set:

0

18. End Page Address set:

0

19. Start Column address set:

0

20. End Column address set:

0

21. Select PWM/FRC

2-bit PWM + 2 bit FRC mode

Solomon Systech

Sep 2003

P 18/61 Rev 1.00

SSD1770

7.3 Command

Decoder

This module determines whether the input data is interpreted as data or command. Data is directed to this

module based upon the input of the

D/ C

pin. If

D/ C

pin is high, data is written to Graphic Display data

RAM (GDDRAM). If it is low, the input at D

7

≠ D

0

is interpreted as a Command and it will be decoded. The

decoded command will be written to the corresponding command register.

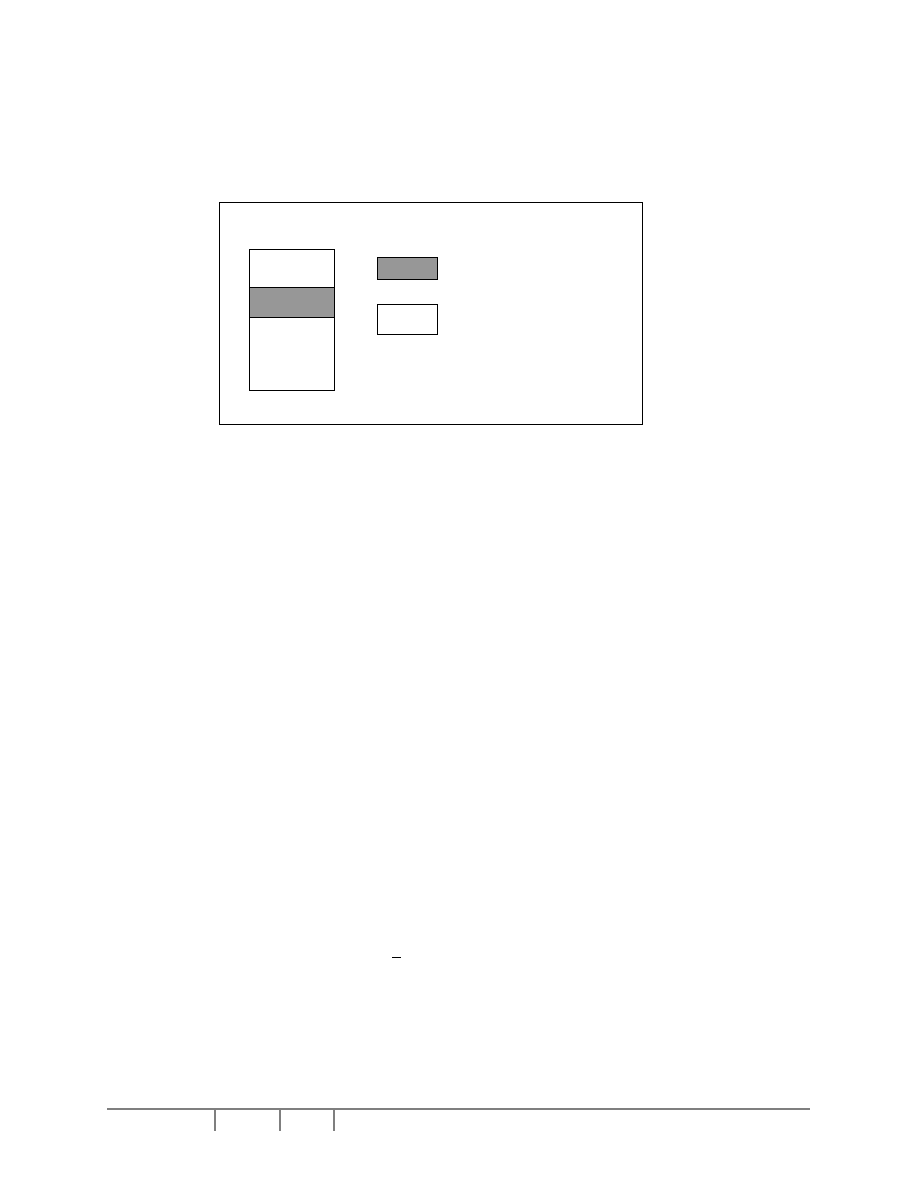

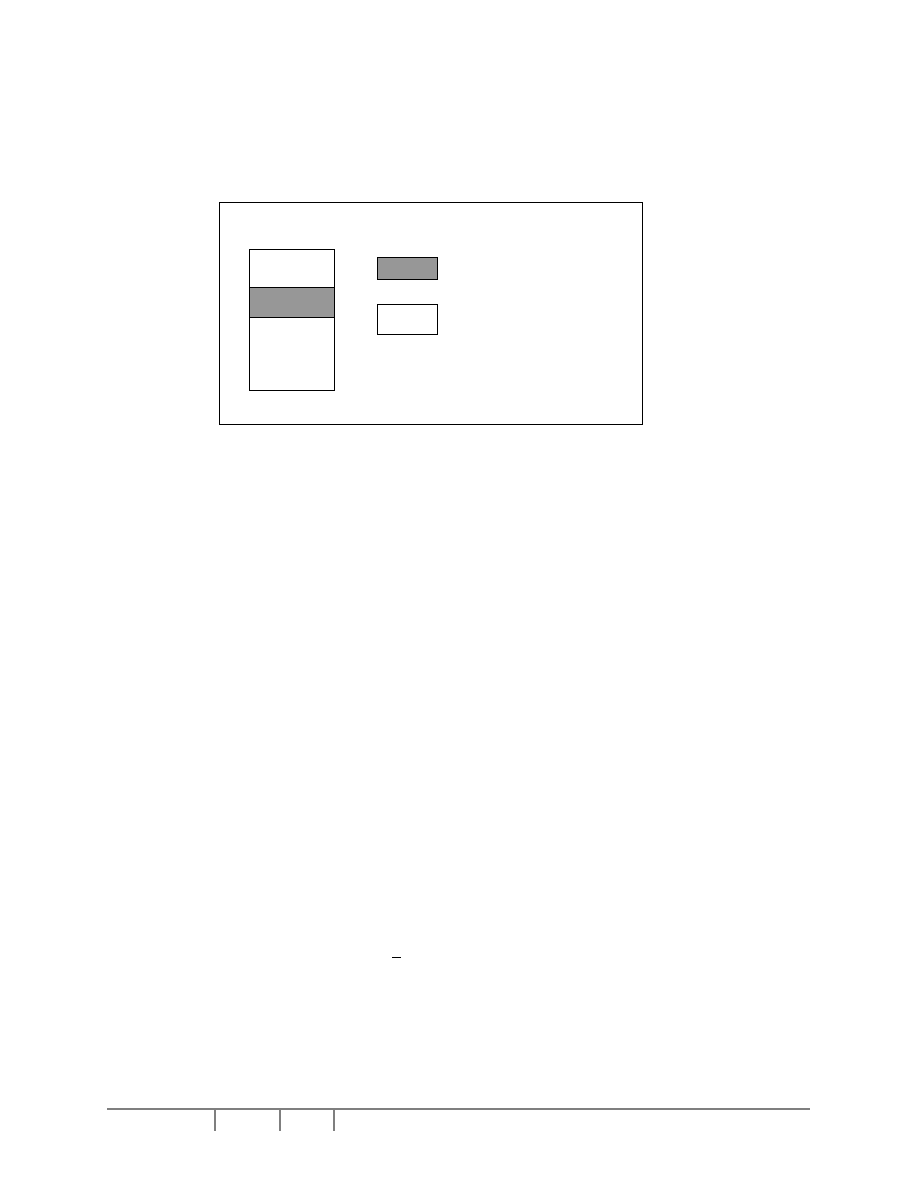

7.4 Graphic Display Data RAM (GDDRAM)

The GDDRAM is a bit mapped static RAM holding the bit pattern to be displayed. The size of the RAM is

312 (104 RGB) x 81 x 4 = 101088 bits. Figure 4 on page 19 is a description of the GDDRAM address

map. For mechanical flexibility, re-mapping on both Segment and Common outputs can be selected by

software. Please refer to the command "Data Output/Scan direction" in Table 5 on page 22 for detail

description.

Four pages of display data form a RAM address block and stored in the GDDRAM. Each block will form

the fundamental units of scrolling addresses. Various types of area scrolling can be performed by

software program according to the command "Set area Scroll" and "Set Scroll Start" in Table 11 on page

36.

In order to ease the access of the red, green and blue color data; the 8-bits color data (Red: 3 bits,

Green: 3 bits, Blue: 2 bits) is converted to 4-bits data (P10, P11, P12, P13). The 4-bits data are stored

into the GDDRAM such that the data are located in the appropriate RAM locations according to the gray

scale settings. Please refer to the description section of the command "Set Data Output/Scan Direction"

on page 22.

SSD1770

Rev 1.00 P 19/61 Sep 2003

Solomon Systech

each cell contains 4-bits data

COMMON

BLOCK PAGE

OUTPUT

0

COM0

1

COM1

2

COM2

3

COM3

4

COM4

5

COM5

6

COM6

7

COM7

8

COM8

9

COM9

10

COM10

11

COM11

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

64

COM64

65

COM65

66

COM66

67

COM67

68

COM68

69

COM69

70

COM70

71

COM71

72

COM72

73

COM73

74

COM74

75

COM75

76

COM76

77

COM77

78

COM78

79

COM79

20

ICON

ICON

......................

COL0

COL1

COL2

COL3

COL4

COL5

COL6

COL7

COL8

......................

COL303

COL304

COL305

COL306

COL307

COL308

COL309

COL310

COL311

Notes: Page and SEGMENT data scan direction depend on Data Output Scan Direction Setting.

Data Output Scan Directin setting cannot affect the Block scan direction.

SEG

0

Mapping depends

on COM Output

scan direction

setting

SEG

1

0

3

SEG

1

0

2

SEGMENT

COLUMN

DATA

0

1

2

16

SEG

1

SEG

2

SEG

1

0

1

17

18

19

Figure 4 ≠ Display Data RAM Map

Solomon Systech

Sep 2003

P 20/61 Rev 1.00

SSD1770

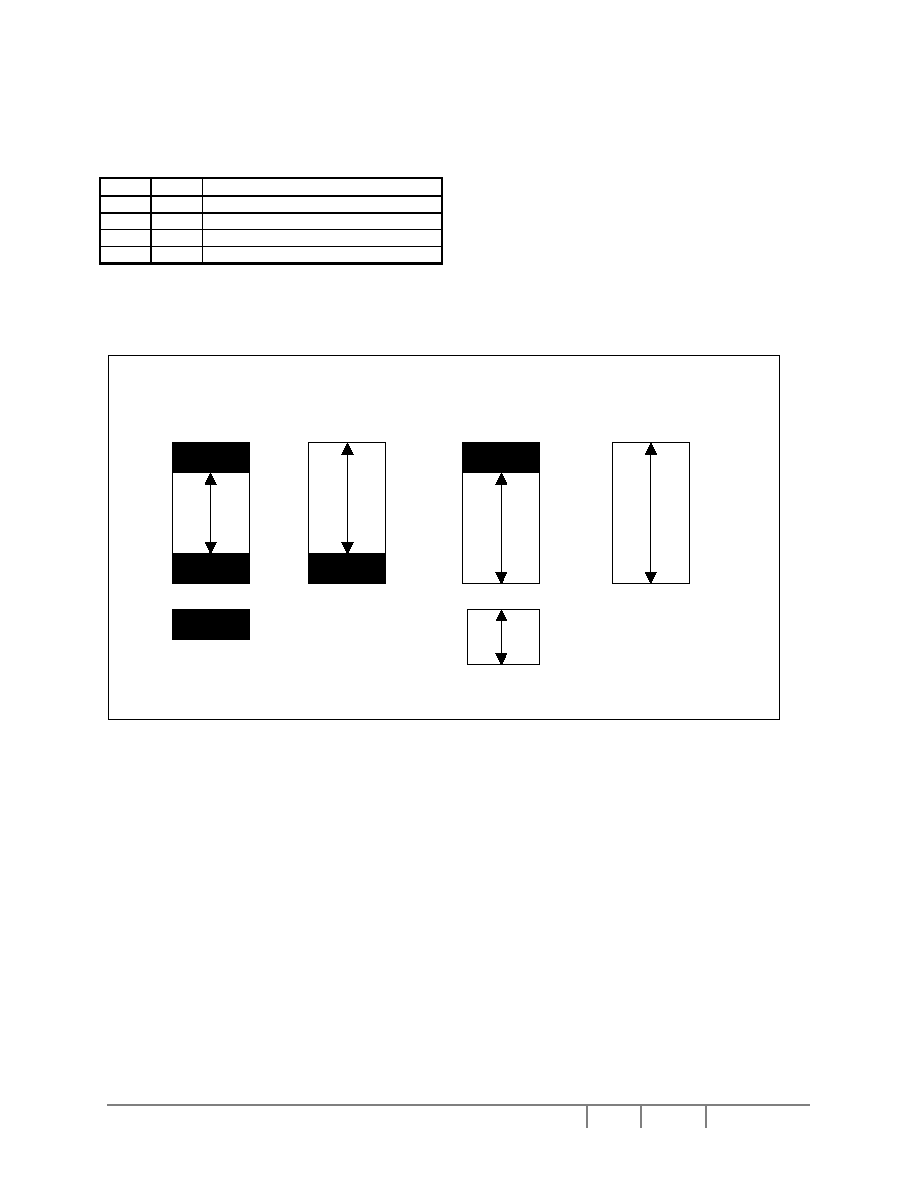

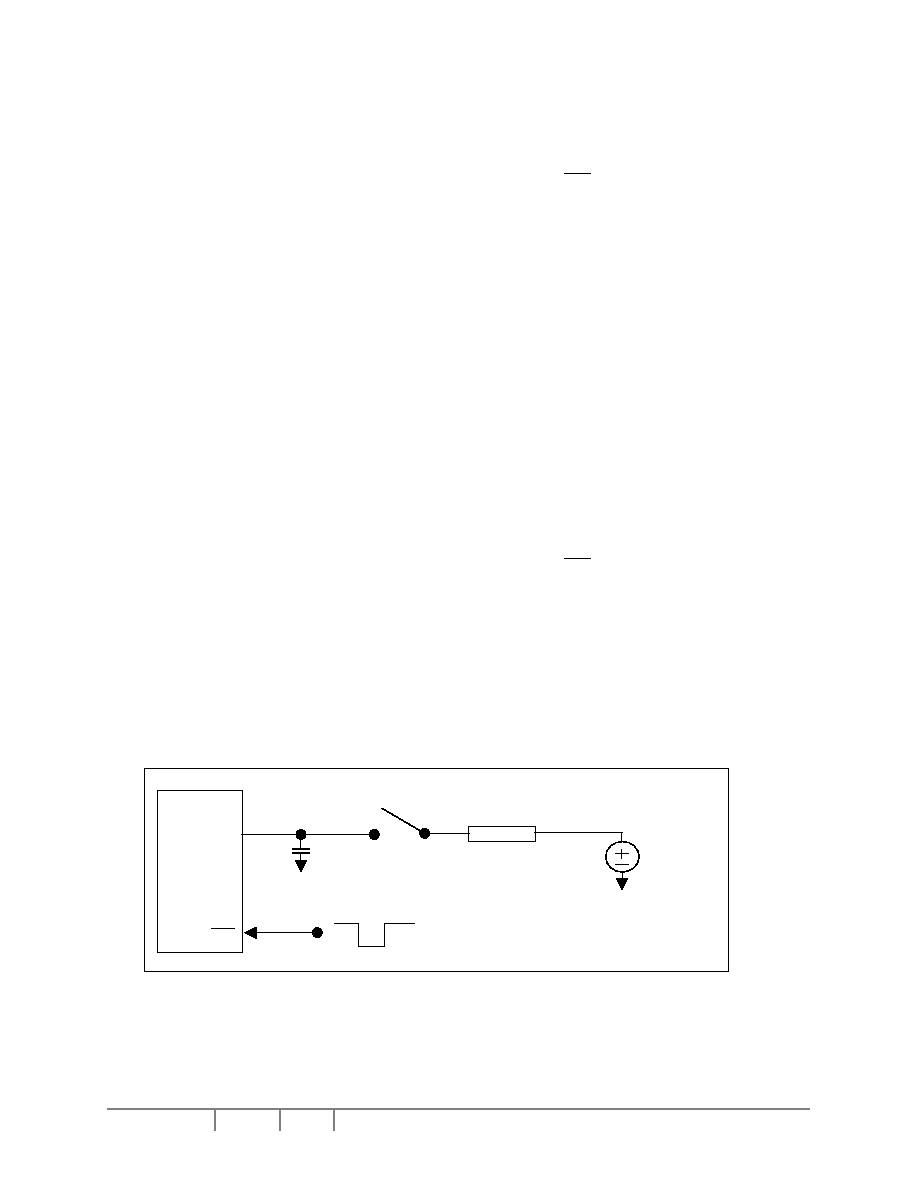

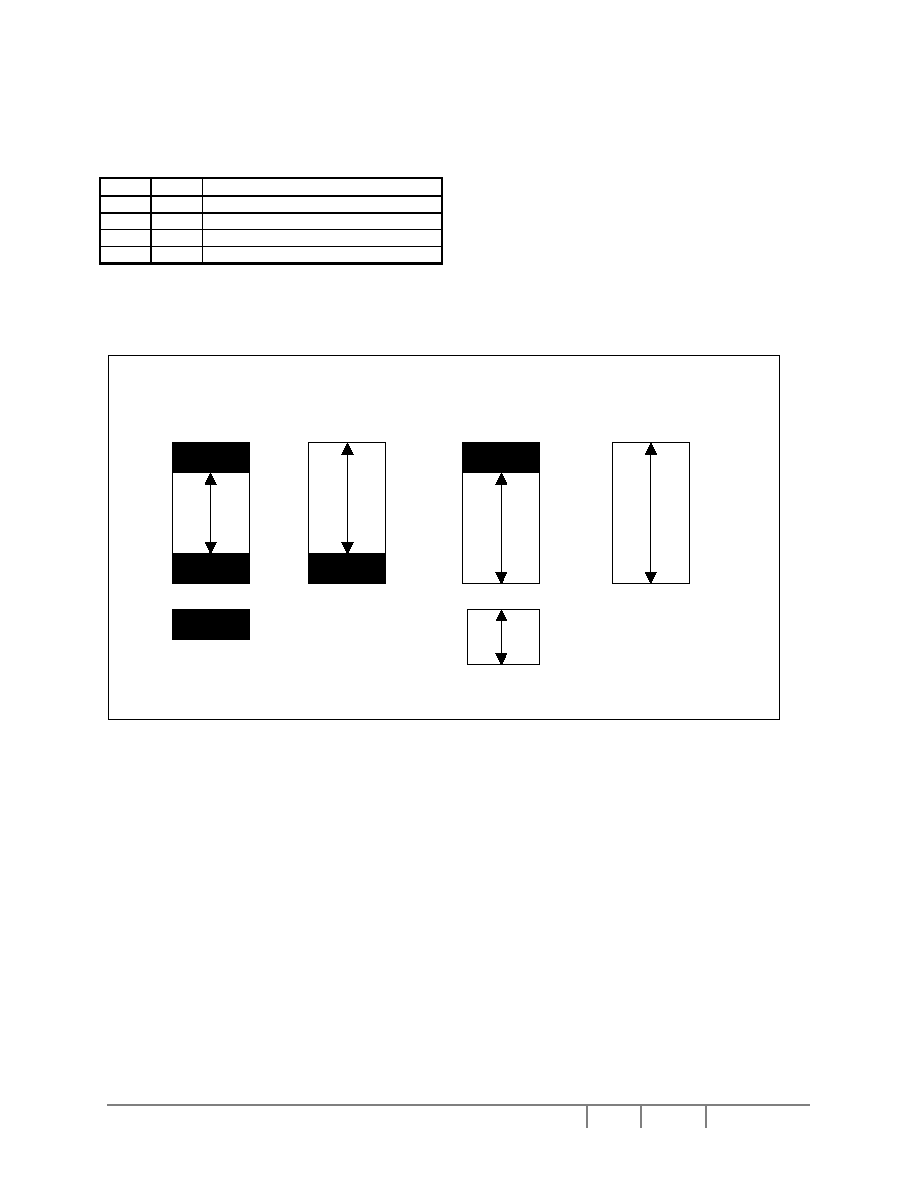

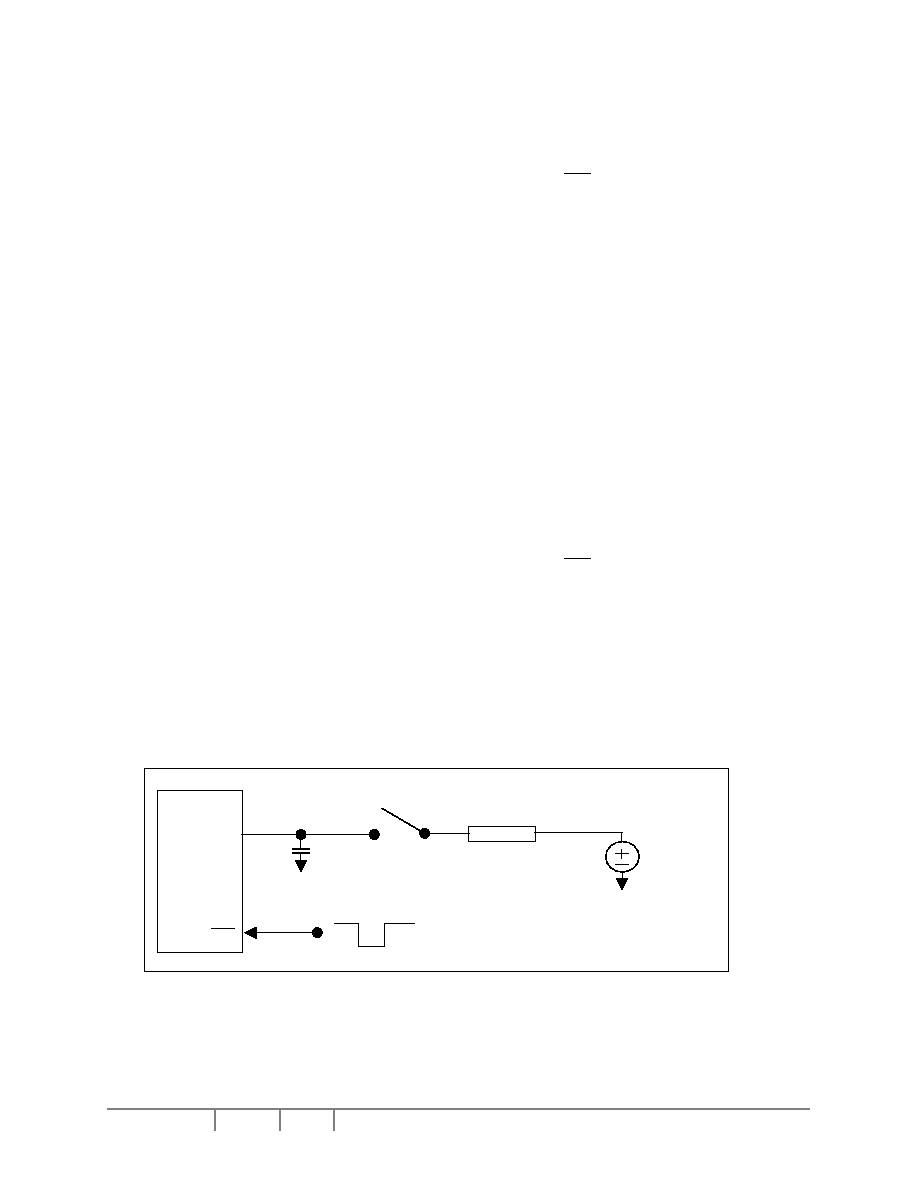

7.5 LCD Driving Voltage Generator and Regulator

This module generates the LCD voltage needed for display output. It takes a single supply input and

generates necessary bias voltages. It consists of:

1.

3X, 4X, 5X and 6X DC-DC voltage converter

2.

Bias Divider - If the output op-amp buffer option in Set Power Control Register command is enabled, this

circuit block will divide the regulator output (V

OUT

) to give the LCD driving levels (V

L2

≠ V

L5

).

The divider does not require external capacitors to reduce the external hardware and pin counts, power

configuration of op-amp is shown on below figure.

3.

Contrast Control ≠ Software control of 64 voltage levels of LCD voltage.

4.

Bias Ratio Selection circuitry ≠ Software control of 1/4 to 1/8 bias ratio to match the characteristic of LCD

panel.

5.

Self adjust temperature compensation circuitry ≠ Provide 4 different compensation grade selections to

satisfy the various liquid crystal temperature grades. The grading can be selected by software control.

Defaulted temperature coefficient (TC) value is ≠0.2%/∞C.

Figure 5 ≠ SSD1770 Hardware Configurations

V

OUT

VH

REF

V

DD

V

CI

V

CIX2

VL

REF

V

SS

+

+

SSD1770

Normal Power Mode

Recommended capacitance value:

C

1

: 1uF ~ 2.2uF

C

2

: 2.2uF ~ 4.7uF

C

1

C

2

V

OUT

VH

REF

V

DD

V

CI

V

CIX2

VL

REF

V

SS

+

+

SSD1770

Low Power Mode

In Low Power Mode, V

L4

must > 4V

Recommended capacitance value:

C

1

: 1uF ~ 2.2uF

C

2

: 2.2uF ~ 4.7uF

C

1

C

2

SSD1770

Rev 1.00 P 21/61 Sep 2003

Solomon Systech

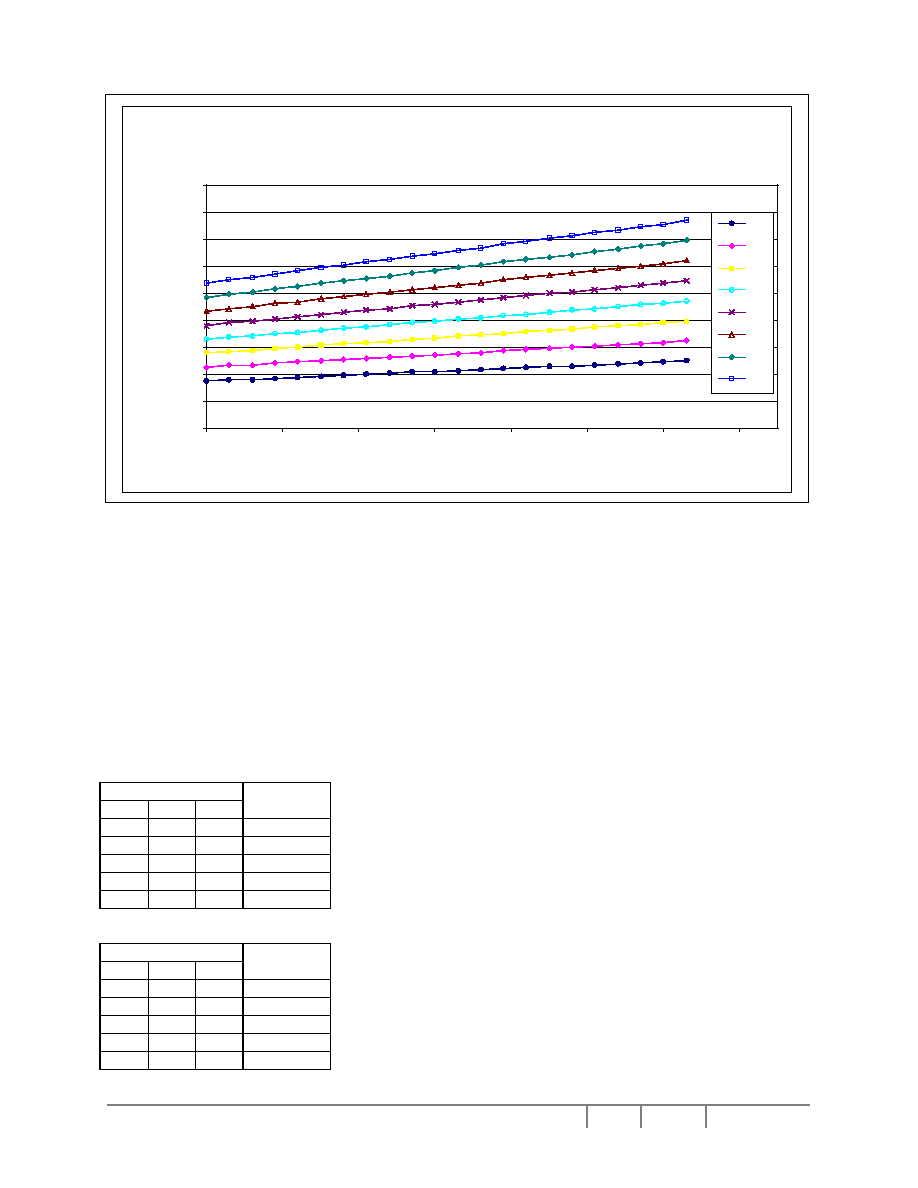

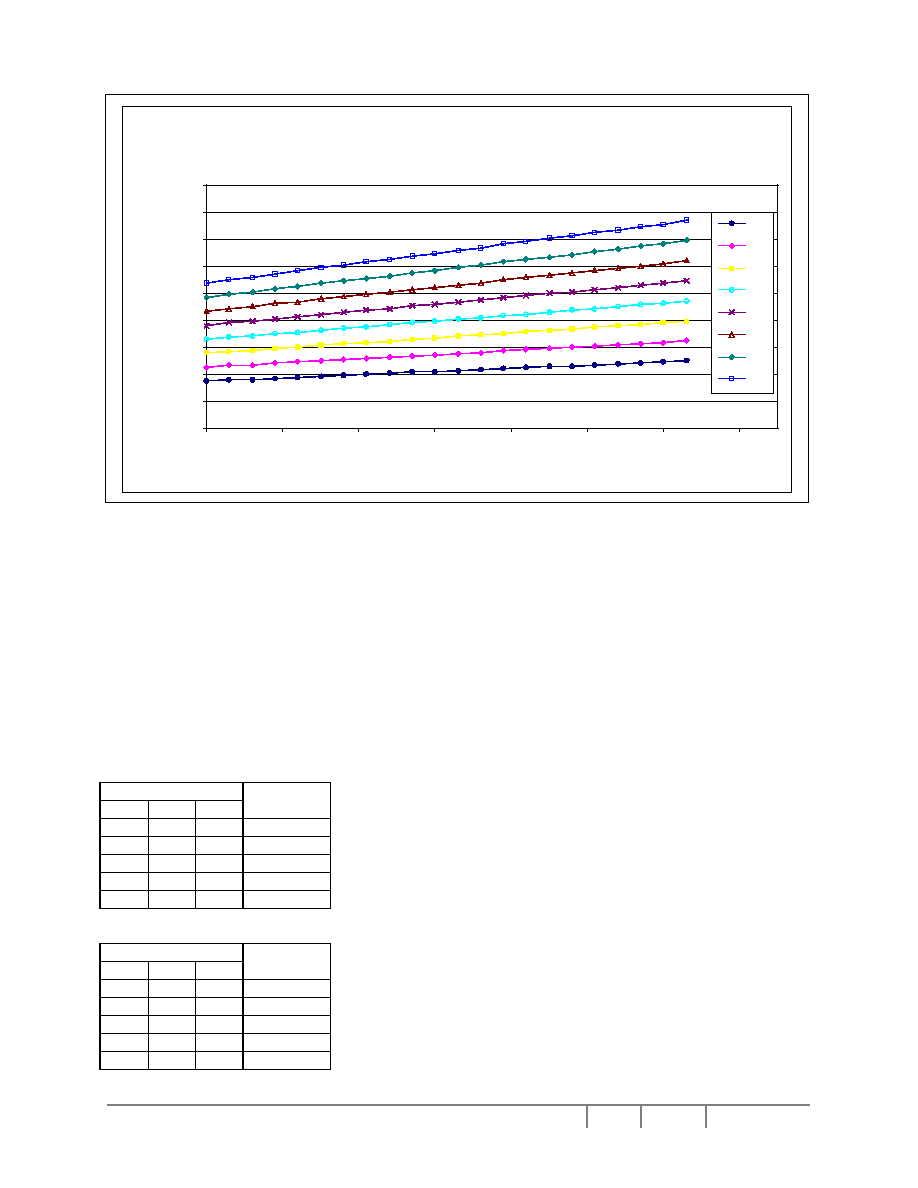

7.6 Oscillator

Circuit

This module is an On-Chip low power RC oscillator circuitry (Figure 6). The oscillator generates the clock

for the DC-DC voltage converter. This clock is also used in the Display Timing Generator.

Figure 6 ≠ Oscillator structural block diagram

7.7 Display Data Latch

This block is a series of latches carrying the display signal information. These latches hold the data, which

will be fed to the HV Buffer Cell and Level Selector to output the required voltage level.

7.8 HV Buffer Cell (Level Shifter)

This block is embedded in the Segment/Common Driver Circuits. HV Buffer Cell works as a level shifter,

which translates the low voltage output signal to the required driving voltage. The output is shifted out with

reference to the internal FRM clock, which comes from the Display Timing Generator. The voltage levels

are given by the level selector, which is synchronized with the internal M signal.

7.9 Level

Selector

This block is embedded in the Segment/Common Driver circuits. Level Selector is a control of the display

synchronization. Display voltage levels can be separated into two sets and used with different cycles.

Synchronization is important since it selects the required LCD voltage level to the HV Buffer Cell, which in

turn outputs the COM or SEG LCD waveform.

enable

Oscillation Circuit

enable

Buffer

Internal resistor

OSC2

OSC1

Oscillator

enable

(CL)

Solomon Systech

Sep 2003

P 22/61 Rev 1.00

SSD1770

8 COMMAND

TABLE

Table 5 ≠ COMMAND TABLE (D/

C

= 0, R/

W

(

WR

) = 0, E=1(

RD

= 1) unless specific setting is stated)

Bit Pattern

Command

Description

(

C

/

D

= 0) 00010101

(

C

/

D

= 1) X

7

X

6

X

5

X

4

X

3

X

2

X

1

X

0

(

C

/

D

= 1) Y

7

Y

6

Y

5

Y

4

Y

3

Y

2

Y

1

Y

0

Set Column

Address

Set the start column address by X

7

X

6

X

5

X

4

X

3

X

2

X

1

X

0

Set the end column address by Y

7

Y

6

Y

5

Y

4

Y

3

Y

2

Y

1

Y

0.

Column address = 00000000b (POR)

In 8-levels gray scale mode, column address is in a range of 0~103.

In 16-level gray scale mode, column address is in a range of 0~51.

(

C

/

D

= 0) 01110101

(

C

/

D

= 1) X

7

X

6

X

5

X

4

X

3

X

2

X

1

X

0

(

C

/

D

= 1) Y

7

Y

6

Y

5

Y

4

Y

3

Y

2

Y

1

Y

0

Set Page Address

Set the start page address by X

7

X

6

X

5

X

4

X

3

X

2

X

1

X

0

Set the end page address by Y

7

Y

6

Y

5

Y

4

Y

3

Y

2

Y

1

Y

0.

Page address = 00000000b (POR)

(

C

/

D

= 0) 10111011

(

C

/

D

= 1) *****X

2

X

1

X

0

Set COM Output

Scan Direction

80

/

68

MUX

= V

SS

X

2

X

1

X

0

ROW0..ROW33 ROW34..ROW39 ROW40..ROW45 ROW46..ROW79

0 0 0

COM0->COM33 COM34->COM39 COM40->COM45 COM46->COM79 (POR)

0 0 1

COM0->COM33 COM34->COM39 COM79<-COM64 COM63<-COM40

0 1 0

COM39<-COM6 COM5<-COM0 COM40->COM45 COM46->COM79

0 1 1

COM39<-COM6 COM5<-COM0 COM79<-COM64 COM63<-COM40

80

/

68

MUX

= V

DD

X

2

X

1

X

0

ROW0..ROW33 ROW34..ROW39 ROW40..ROW45 ROW46..ROW79

0 0 0

COM0->COM33 NON SELECT OUTPUT COM34->COM67 (POR)

0 0 1

COM0->COM33 NON SELECT OUTPUT COM67<-COM34

0 1 0

COM33<-COM0 NON SELECT OUTPUT COM34->COM67

0 1 1

COM33<-COM0 NON SELECT OUTPUT COM67<-COM34

(

C

/

D

= 0) 10111100

(

C

/

D

= 1) *****P12 P11 P10

(

C

/

D

= 1) *****P22 P21 P20

(

C

/

D

= 1) *****P32 P31 P30

Set Data Output

Scan Direction

a) Normal or Reverse page/column/scan directions

P10 = 0: set page address to normal display (POR)

P10 = 1: set page address to inverse display

P11 = 0: set column address to normal rotation (POR)

P11 = 1: set column address to inverse rotation

P12 = 0: set scan direction to column scan (POR)

P12 = 1: set scan direction to page scan

Please refer to the Figure 9 on page 33 for detail description of

column/page scan direction modes

b) RGB color arrangement

P22, P21, P20: The control bits are used for setting the (RGB) color

arrangement of segment output, 000 is POR value. Please refer to the

Figure 10 on page 34 for detail mapping of the segment output.

c) Gray-scale selection

P32 P31 P30

Gray-scale modes

0 0 1 8-levels gray scale mode (POR)

0 1 0 16-levels gray scale mode (Type A)

Please refer to the Table 12 on page 27 to Table 15 on page 30 for

detail description of different gray-scale selection modes.

Remarks: "*" denote DON'T CARE bit

SSD1770

Rev 1.00 P 23/61 Sep 2003

Solomon Systech

Remarks: "*" denote DON'T CARE bit

Bit Pattern

Command

Description

(

C

/

D

= 0) 11001110

(

C

/

D

= 1) **** X

31

X

21

X

11

X

01

(

C

/

D

= 1) **** X

32

X

22

X

12

X

02

:

:

(

C

/

D

= 1) **** X

38

X

28

X

18

X

08

(

C

/

D

= 1) **** X

39

X

29

X

19

X

09

:

:

(

C

/

D

= 1) ****X

316

X

216

X

116

X

016

(

C

/

D

= 1) ****X

317

X

217

X

117

X

017

:

:

(

C

/

D

= 1) ****X

320

X

220

X

120

X

020

Set Color Look Up

Table

N DB

3

DB

2

DB

1

DB

0

color position

1 X

3N

X

2N

X

1N

X

0N

Intermediate red tone 000

2 X

3N

X

2N

X

1N

X

0N

Intermediate red tone 001

: :

: :

8 X

3N

X

2N

X