| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ICX039DLB | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

≠ 1 ≠

ICX039DLB

E96127B99

Diagonal 8mm (Type 1/2) CCD Image Sensor for CCIR Black-and-White Video Cameras

Description

The ICX039DLB is an interline CCD solid-state

image sensor suitable for CCIR black-and-white video

cameras with a diagonal 8mm (Type 1/2) system.

Smear, sensitivity, D-range, S/N and other

characteristics have been greatly improved compared

with the ICX039BLB. High sensitivity and low dark

current are achieved through the adoption of HAD

(Hole-Accumulation Diode) sensors.

This chip features a field period readout system and

an electronic shutter with variable charge-storage

time. Also, this outline is miniaturized by using

original package.

This chip is compatible with and can replace the

ICX039BLB.

Features

∑ Low smear (≠20dB compared with the ICX039BLB)

∑ High sensitivity (+3.0dB compared with the ICX039BLB)

∑ High D range (+2.5dB compared with the ICX039BLB)

∑ High S/N

∑ High resolution and low dark current

∑ Excellent antiblooming characteristics

∑ Continuous variable-speed shutter

∑ Substrate bias:

Adjustment free (external adjustment also possible with 6 to 14V)

∑ Reset gate pulse:

5Vp-p adjustment free (drive also possible with 0 to 9V)

∑ Horizontal register:

5V drive

∑ Maximum package dimensions:

13.2mm

Device Structure

∑ Interline CCD image sensor

∑ Image size:

Diagonal 8mm (Type 1/2)

∑ Number of effective pixels: 752 (H)

◊

582 (V) approx. 440K pixels

∑ Total number of pixels:

795 (H)

◊

596 (V) approx. 470K pixels

∑ Chip size:

7.95mm (H)

◊

6.45mm (V)

∑ Unit cell size:

8.6µm (H)

◊

8.3µm (V)

∑ Optical black:

Horizontal (H) direction: Front 3 pixels, rear 40 pixels

Vertical (V) direction : Front 12 pixels, rear 2 pixels

∑ Number of dummy bits:

Horizontal 22

Vertical 1 (even fields only)

∑ Substrate material:

Silicon

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

16 pin DIP (Ceramic)

Pin 1

V

3

40

2

12

Pin 9

H

Optical black position

(Top View)

≠ 2 ≠

ICX039DLB

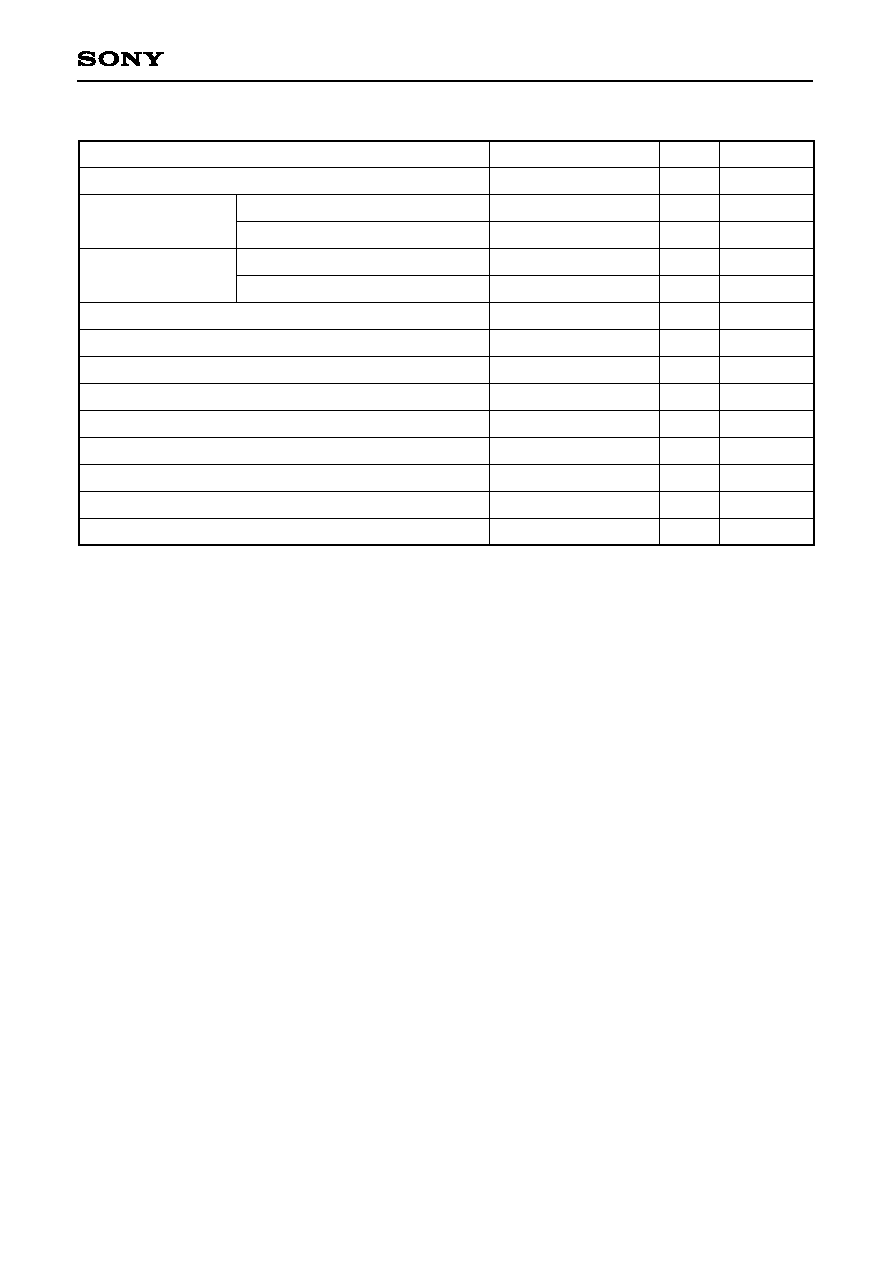

Pin No.

Symbol

Description

Pin No.

Symbol

Description

1

2

3

4

5

6

7

8

V

4

V

3

V

2

SUB

V

1

V

L

V

DD

V

OUT

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Substrate clock

Vertical register transfer clock

Protective transistor bias

Output circuit supply voltage

Signal output

9

10

11

12

13

14

15

16

V

GG

V

SS

GND

RD

RG

V

DSUB

H

1

H

2

Output circuit gate bias

Output circuit source

GND

Reset drain bias

Reset gate clock

Substrate bias circuit supply voltage

Horizontal register transfer clock

Horizontal register transfer clock

1

2

3

4

5

6

7

8

Note)

Note) : Photo sensor

Horizontal Register

V

e

r

t

i

c

a

l

R

e

g

i

s

t

e

r

V

L

V

1

S

U

B

V

2

V

3

V

4

V

D

D

V

O

U

T

V

G

G

V

D

S

U

B

V

S

S

G

N

D

R

D

R

G

H

1

H

2

11

12

13

14

15

16

9

10

Block Diagram and Pin Configuration

(Top View)

Pin Description

≠ 3 ≠

ICX039DLB

Item

≠0.3 to +50

≠0.3 to +18

≠55 to +10

≠15 to +20

to +10

to +15

to +17

≠17 to +17

≠10 to +15

≠55 to +10

≠65 to +0.3

≠0.3 to +30

≠30 to +80

≠10 to +60

V

V

V

V

V

V

V

V

V

V

V

V

∞C

∞C

1

Ratings

Unit

Remarks

Absolute Maximum Ratings

1 +27V (Max.) when clock width < 10µs, clock duty factor < 0.1%.

Substrate clock

SUB

≠ GND

V

DD

, V

RD

, V

DSUB

, V

OUT

, V

SS

≠ GND

Supply voltage

V

DD

, V

RD

, V

DSUB

, V

OUT

, V

SS

≠

SUB

V

1

, V

2

, V

3

, V

4

≠ GND

Clock input voltage

V

1

, V

2

, V

3

, V

4

≠

SUB

Voltage difference between vertical clock input pins

Voltage difference between horizontal clock input pins

H

1

, H

2

≠ V

4

RG

, V

GG

≠ GND

RG

, V

GG

≠

SUB

V

L

≠

SUB

Pins other than GND and

SUB

≠ V

L

Storage temperature

Operating temperature

≠ 4 ≠

ICX039DLB

Item

V

DD

V

RD

V

GG

V

SS

V

L

V

DSUB

V

SUB

V

SUB

14.55

14.55

1.75

6.0

≠3

15.0

15.0

2.0

3

4

15.45

15.45

2.25

14.0

+3

V

V

V

V

%

V

RD

= V

DD

5

5

Symbol

Min.

Typ.

Max.

Unit

Remarks

Bias Conditions 2 [when used in substrate bias external adjustment mode]

Output circuit supply voltage

Reset drain voltage

Output circuit gate voltage

Output circuit source

Protective transistor bias

Substrate bias circuit supply voltage

Substrate voltage adjustment range

Substrate voltage adjustment precision

3

V

L

setting is the V

VL

voltage of the vertical transfer clock waveform, or the same power supply as the V

L

power supply for the V driver should be used. (When CXD1267AN is used.)

4

Connect to GND or leave open.

5

The setting value of the substrate voltage (V

SUB

) is indicated on the back of the image sensor by a special

code. When adjusting the substrate voltage externally, adjust the substrate voltage to the indicated

voltage. The adjustment precision is ±3%. However, this setting value has not significance when used in

substrate bias internal generation mode.

V

SUB

code -- one character indication

Code and optimal setting correspond to each other as follows.

DC Characteristics

Item

Output circuit supply current

I

DD

5.0

10.0

mA

Symbol

Min.

Typ.

Max.

Unit

Remarks

V

SUB

code

Optimal setting 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5 13.0 13.5 14.0

E

f

G

h

J

K

L

m

N

P

Q

R

S

T

U

V

W

<Example> "L"

V

SUB

= 9.0V

Item

V

DD

V

RD

V

GG

V

SS

V

L

V

DSUB

SUB

14.55

14.55

1.75

14.55

15.0

15.0

2.0

1

15.0

2

15.45

15.45

2.25

15.45

V

V

V

V

V

RD

= V

DD

Symbol

Min.

Typ.

Max.

Unit

Remarks

Bias Conditions 1 [when used in substrate bias internal generation mode]

Output circuit supply voltage

Reset drain voltage

Output circuit gate voltage

Output circuit source

Protective transistor bias

Substrate bias circuit supply voltage

Substrate clock

Grounded with 390

resistor

1

V

L

setting is the V

VL

voltage of the vertical transfer clock waveform, or the same power supply as the V

L

power supply for the V driver should be used. (When CXD1267AN is used.)

2

Do not apply a DC bias to the substrate clock pin, because a DC bias is generated within the CCD.

Grounded with 390

resistor

≠ 5 ≠

ICX039DLB

Item

Readout clock voltage

V

VT

V

VH1

, V

VH2

V

VH3

, V

VH4

V

VL1

, V

VL2

,

V

VL3

, V

VL4

V

V

I V

VH1

≠ V

VH2

I

V

VH3

≠ V

VH

V

VH4

≠ V

VH

V

VHH

V

VHL

V

VLH

V

VLL

V

H

V

HL

V

RGL

V

RG

V

RGLH

≠ V

RGLL

V

SUB

14.55

≠0.05

≠0.2

≠9.6

8.3

≠0.25

≠0.25

4.75

≠0.05

4.5

23.0

15.0

0

0

≠9.0

9.0

5.0

0

1

5.0

24.0

15.45

0.05

0.05

≠8.5

9.65

0.1

0.1

0.1

0.5

0.5

0.5

0.5

5.25

0.05

5.5

0.8

25.0

V

V

V

V

Vp-p

V

V

V

V

V

V

V

Vp-p

V

V

Vp-p

V

Vp-p

1

2

2

2

2

2

2

2

2

2

2

2

3

3

4

4

4

5

V

VH

= (V

VH1

+ V

VH2

)/2

V

VL

= (V

VL3

+ V

VL4

)/2

V

V

= V

VH

n ≠ V

VL

n (n = 1 to 4)

High-level coupling

High-level coupling

Low-level coupling

Low-level coupling

Low-level coupling

Horizontal transfer

clock voltage

Reset gate clock

voltage

1

Substrate clock voltage

Vertical transfer clock

voltage

Symbol

Min.

Typ. Max. Unit

Waveform

diagram

Remarks

Item

Symbol

Min.

Typ. Max. Unit

Waveform

diagram

Remarks

1

Input the reset gate clock without applying a DC bias. In addition, the reset gate clock can also be driven

with the following specifications.

Reset gate clock

voltage

V

RGL

V

RG

≠0.2

8.5

0

9.0

0.2

9.5

V

Vp-p

4

4

Clock Voltage Conditions

≠ 6 ≠

ICX039DLB

Clock Equivalent Circuit Constant

Item

Capacitance between vertical transfer clock

and GND

C

V1

, C

V3

C

V2

, C

V4

C

V12

, C

V34

C

V23

, C

V41

C

H1

C

H2

C

HH

C

RG

C

SUB

R

1

, R

2

, R

3

, R

4

R

GND

1800

2200

450

270

64

62

47

8

400

68

15

pF

pF

pF

pF

pF

pF

pF

pF

pF

Capacitance between vertical transfer clocks

Capacitance between horizontal transfer clock

and GND

Capacitance between horizontal transfer clocks

Capacitance between reset gate clock and GND

Capacitance between substrate clock and GND

Vertical transfer clock series resistor

Vertical transfer clock ground resistor

Symbol

Min.

Typ.

Max.

Unit Remarks

H

2

H

1

C

H1

C

H2

C

HH

V

1

C

V12

V

2

V

4

V

3

C

V34

C

V23

C

V41

C

V1

C

V2

C

V4

C

V3

R

GND

R

4

R

1

R

3

R

2

Vertical transfer clock equivalent circuit

Horizontal transfer clock equivalent circuit

≠ 7 ≠

ICX039DLB

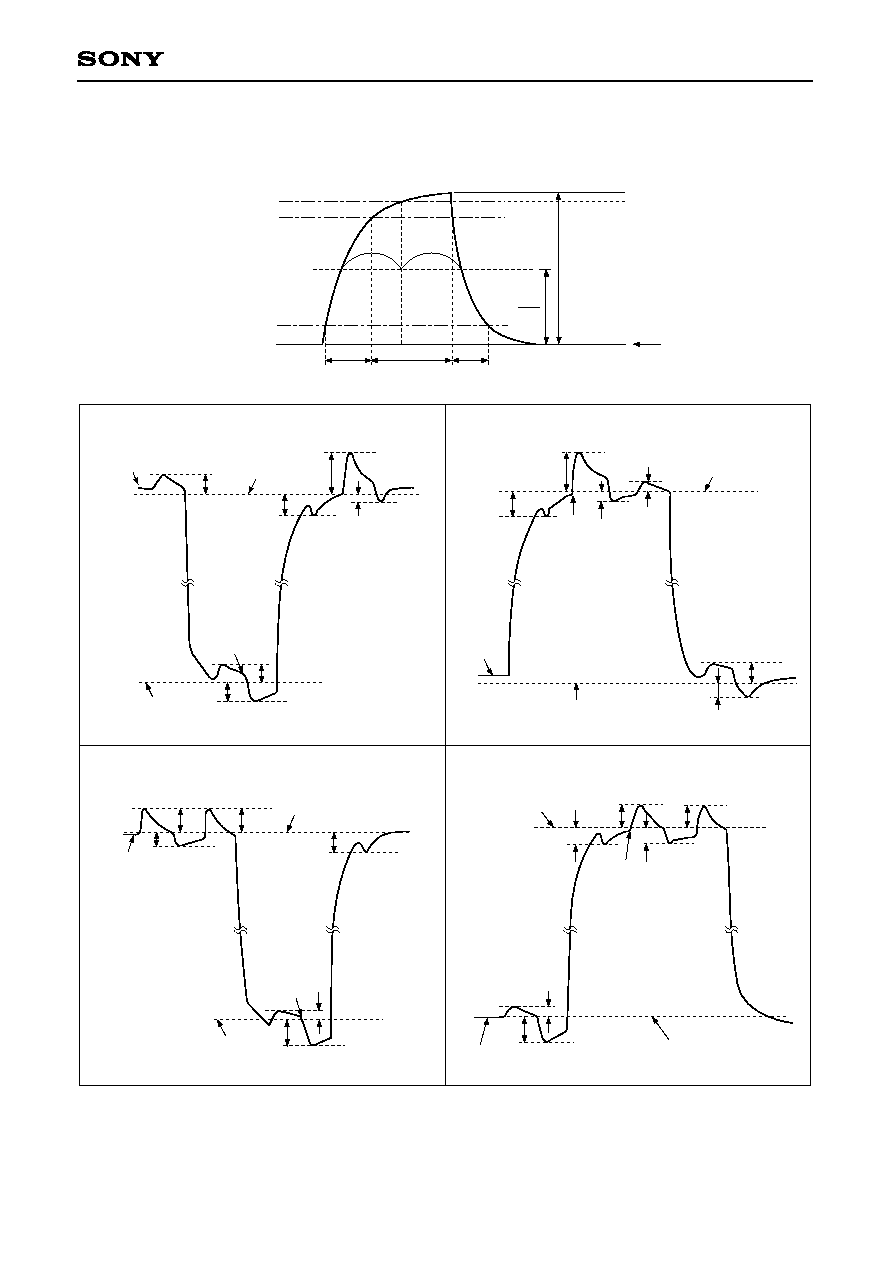

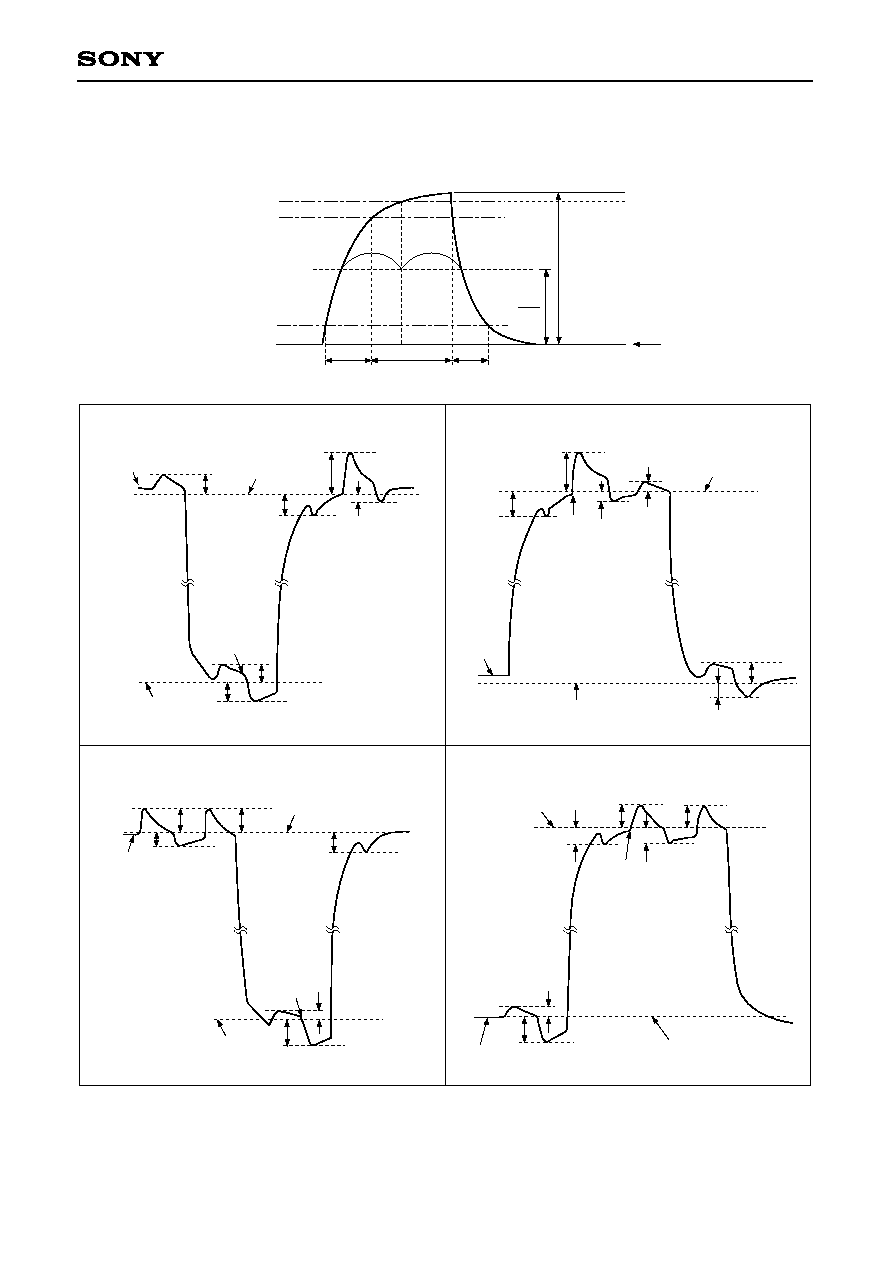

Drive Clock Waveform Conditions

(1) Readout clock waveform

(2) Vertical transfer clock waveform

II

II

100%

90%

10%

0%

V

VT

tr

twh

tf

M

0V

M

2

V

1

V

3

V

2

V

4

V

VHH

V

VH

V

VHL

V

VHH

V

VHL

V

VH1

V

VL1

V

VLH

V

VLL

V

VL

V

VHH

V

VH3

V

VHL

V

VH

V

VHH

V

VHL

V

VL3

V

VL

V

VLL

V

VLH

V

VHH

V

VHH

V

VH

V

VHL

V

VHL

V

VH2

V

VLH

V

VL2

V

VLL

V

VL

V

VHH

V

VHH

V

VHL

V

VH4

V

VHL

V

VH

V

VL

V

VLH

V

VLL

V

VL4

V

VH

= (V

VH1

+ V

VH2

)/2

V

VL

= (V

VL3

+ V

VL4

)/2

V

V

= V

VH

n ≠ V

VL

n (n = 1 to 4)

≠ 8 ≠

ICX039DLB

(3) Horizontal transfer clock waveform

tr

twh

tf

90%

10%

twl

V

H

V

HL

(4) Reset gate clock waveform

Point A

twl

V

RG

V

RGH

V

RGL

+ 0.5V

V

RGL

+2.5V

V

RGLH

RG waveform

V

RGLL

H

1

waveform

twh

tr

tf

V

RGLH

is the maximum value and V

RGLL

is the minimum value of the coupling waveform during the period from

Point A in the above diagram until the rising edge of RG. In addition, V

RGL

is the average value of V

RGLH

and

V

RGLL

.

V

RGL

= (V

RGLH

+ V

RGLL

)/2

Assuming V

RGH

is the minimum value during the interval twh, then:

V

RG

= V

RGH

≠ V

RGL

≠ 9 ≠

ICX039DLB

(5) Substrate clock waveform

90%

100%

10%

0%

V

SUB

tr

twh

tf

M

M

2

V

SUB

Clock Switching Characteristics

Item

Readout clock

Vertical transfer

clock

During

imaging

During parallel-

serial

conversion

Reset gate clock

Substrate clock

V

T

V

1

, V

2

,

V

3

, V

4

H

H

1

H

2

RG

SUB

2.3

11

1.5

2.5

20

5.38

13

1.8

20

5.38

51

0.5

15

0.01

0.01

3

19

0.5

0.5

15

15

0.01

0.01

3

250

19

0.5

µs

ns

ns

µs

ns

µs

During

readout

1

2

During drain

charge

Symbol

twh

Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Min. Typ. Max.

twl

tr

tf

Unit

Remarks

1 When vertical transfer clock driver CXD1267AN is used.

2 tf

tr ≠ 2ns.

Item

Horizontal transfer clock

H

1

, H

2

16

20

ns

3

Symbol

two

Min.

Typ.

Max.

Unit

Remarks

3 The overlap period for twh and twl of horizontal transfer clocks H

1

and H

2

is two.

H

o

r

i

z

o

n

t

a

l

t

r

a

n

s

f

e

r

c

l

o

c

k

≠ 10 ≠

ICX039DLB

Image Sensor Characteristics

(Ta = 25∞C)

Item

Sensitivity

Saturation signal

Smear

Video signal shading

Dark signal

Dark signal shading

Flicker

Lag

S

Vsat

Sm

SH

Vdt

Vdt

F

Lag

500

720

600

0.00032 0.00056

20

25

2

1

2

0.5

mV

mV

%

%

%

mV

mV

%

%

1

2

3

4

4

5

6

7

8

Ta = 60∞C

Zone 0 and

I

Zone 0 to

II

'

Ta = 60∞C

Ta = 60∞C

Symbol

Min.

Typ.

Max.

Unit

Measurement method

Remarks

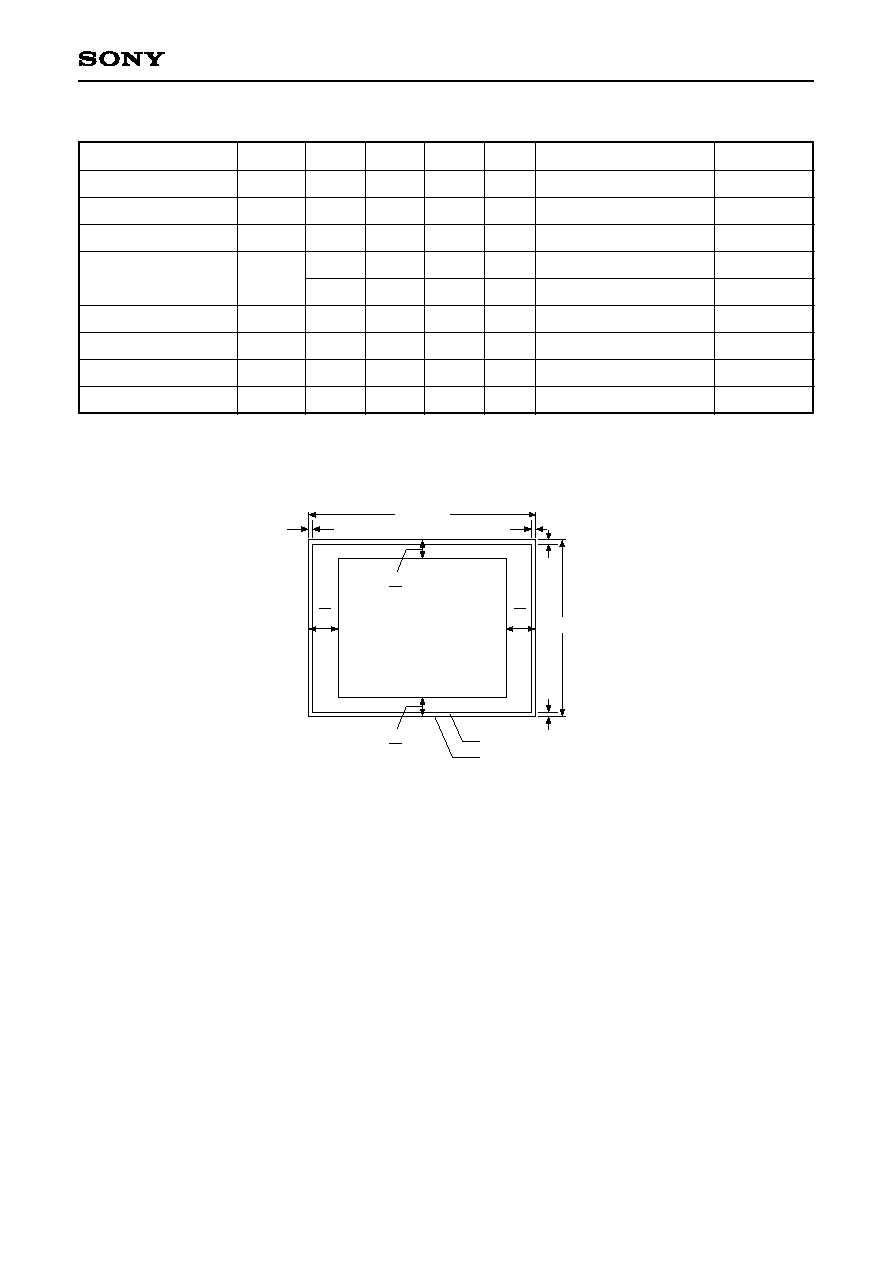

Zone Definition of Video Signal Shading

6

8

582 (V)

12

12

752 (H)

V

10

H

8

H

8

V

10

Effective pixel region

Zone 0,

I

Zone

II

,

II

'

Ignored region

≠ 11 ≠

ICX039DLB

Image Sensor Characteristics Measurement Method

Measurement conditions

1) In the following measurements, the device drive conditions are at the typical values of the bias and clock

voltage conditions. (When used with substrate bias external adjustment, set the substrate voltage to the

value indicated on the device.)

2) In the following measurements, spot blemishes are excluded and, unless otherwise specified, the optical

black (OB) level is used as the reference for the signal output, and the value measured at point [

A] in the

drive circuit example is used.

Definition of standard imaging conditions

1) Standard imaging condition

I

:

Use a pattern box (luminance: 706cd/m

2

, color temperature of 3200K halogen source) as a subject.

(Pattern for evaluation is not applicable.) Use a testing standard lens with CM500S (t = 1.0mm) as an IR cut

filter and image at F8. The luminous intensity to the sensor receiving surface at this point is defined as the

standard sensitivity testing luminous intensity.

2) Standard imaging condition

II

:

Image a light source (color temperature of 3200K) with a uniformity of brightness within 2% at all angles.

Use a testing standard lens with CM500S (t = 1.0mm) as an IR cut filter. The luminous intensity is adjusted

to the value indicated in each testing item by the lens diaphragm.

1. Sensitivity

Set to standard imaging condition

I

. After selecting the electronic shutter mode with a shutter speed of

1/250 s, measure the signal output (Vs) at the center of the screen and substitute the value into the

following formula.

2. Saturation signal

Set to standard imaging condition

II

. After adjusting the luminous intensity to 10 times the intensity with the

average value of the signal output, 200mV, measure the minimum value of the signal output.

3. Smear

Set to standard imaging condition

II

. With the lens diaphragm at F5.6 to F8, adjust the luminous intensity to

500 times the intensity with the average value of the signal output, 200mV. When the readout clock is

stopped and the charge drain is executed by the electronic shutter at the respective H blankings, measure

the maximum value (VSm [mV]) of the signal output and substitute the value into the following formula.

4. Video signal shading

Set to standard imaging condition

II

. With the lens diaphragm at F5.6 to F8, adjust the luminous intensity so

that the average value of the signal output is 200mV. Then measure the maximum (Vmax [mV]) and

minimum (Vmin [mV]) values of the signal output and substitute the values into the following formula.

SH = (Vmax ≠ Vmin)/200

◊

100 [%]

Sm =

◊

100 [%] (1/10V method conversion value)

◊

◊

200

VSm

500

1

10

1

S = Vs

◊

[mV]

50

250

≠ 12 ≠

ICX039DLB

5. Dark signal

Measure the average value of the signal output (Vdt [mV]) with the device ambient temperature 60∞C and

the device in the light-obstructed state, using the horizontal idle transfer level as a reference.

6. Dark signal shading

After measuring 5, measure the maximum (Vdmax [mV]) and minimum (Vdmin [mV]) values of the dark

signal output and substitute the values into the following formula.

Vdt = Vdmax ≠ Vdmin [mV]

7. Flicker

Set to standard imaging condition

II

. Adjust the luminous intensity so that the average value of the signal

output is 200mV, and then measure the difference in the signal level between fields (

Vf [mV]). Then

substitute the value into the following formula.

F = (

Vf/200)

◊

100 [%]

8. Lag

Adjust the signal output value generated by strobe light to 200mV. After setting the strobe light so that it

strobes with the following timing, measure the residual signal (Vlag). Substitute the value into the following

formula.

Lag = (Vlag/200)

◊

100 [%]

Vlag (lag)

Signal output 200mV

Light

FLD

V1

Strobe light

timing

Output

≠ 13 ≠

ICX039DLB

1

5

V

X

S

U

B

X

V

2

X

V

1

X

S

G

1

X

V

3

X

S

G

2

X

V

4

H

2

H

1

R

G

0

.

0

1

≠

9

V

3

.

3

/

1

6

V

1

M

1

1

0

0

k

1

/

3

5

V

2

2

/

1

6

V

2

2

/

2

0

V

C

X

D

1

2

6

7

A

N

2

0

1

9

1

8

1

7

1

6

1

5

1

4

1

3

1

2

1

1

1

2

3

4

5

6

7

8

9

1

0

1

2

3

4

5

6

7

8

1

6

1

5

1

4

1

3

1

2

1

1

3

9

0

4

7

/

6

.

3

V

3

.

3

/

2

0

V

0

.

0

1

0

.

0

1

1

8

0

k

1

/

6

.

3

V

2

7

k

3

.

9

k

C

C

D

O

U

T

[

A

]

1

0

0

H

2

H

1

RG

RD

GN

D

Vs

s

V

DS

UB

V

GG

V

4

V

3

V

2

SU

B

V

1

V

L

V

DD

V

OU

T

I

C

X

0

3

9

D

L

B

1

0

9

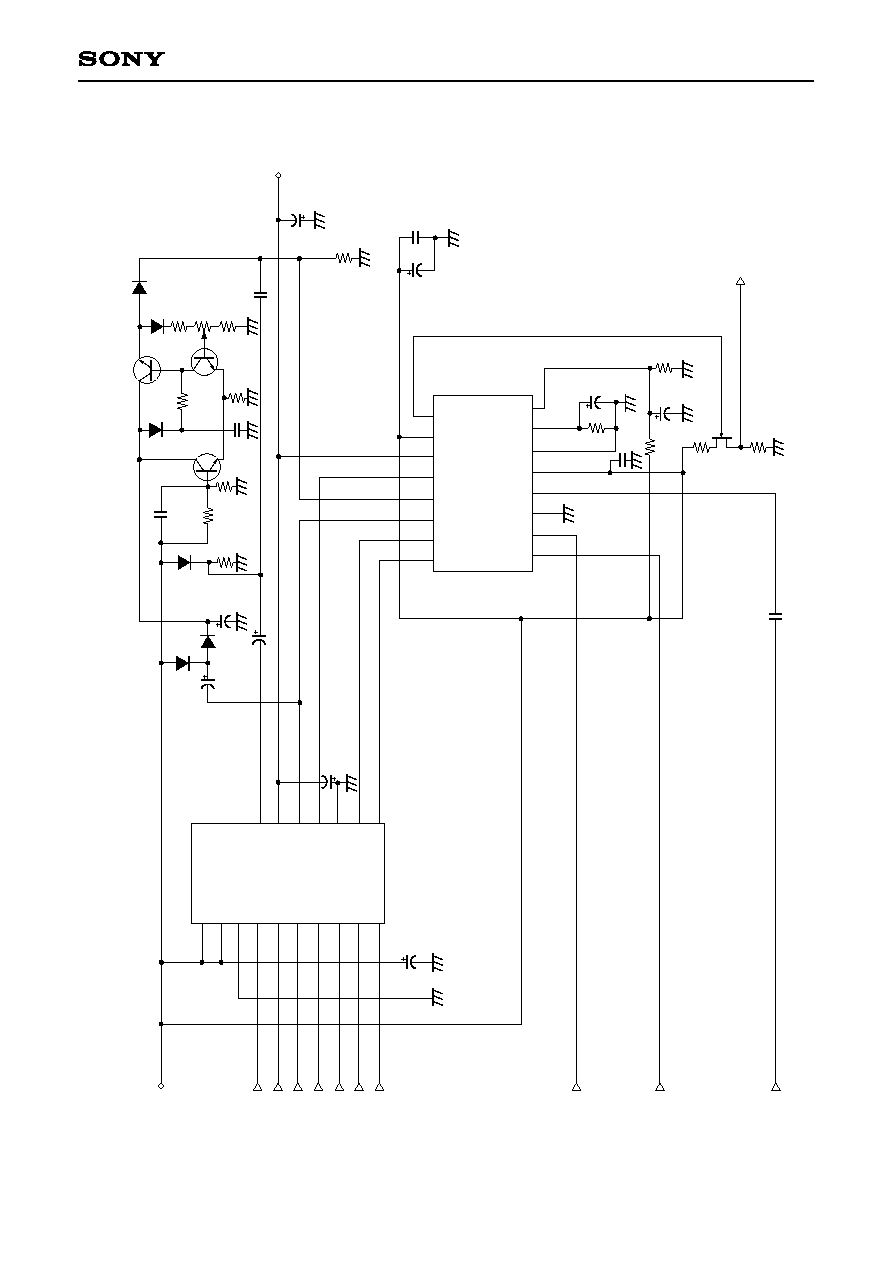

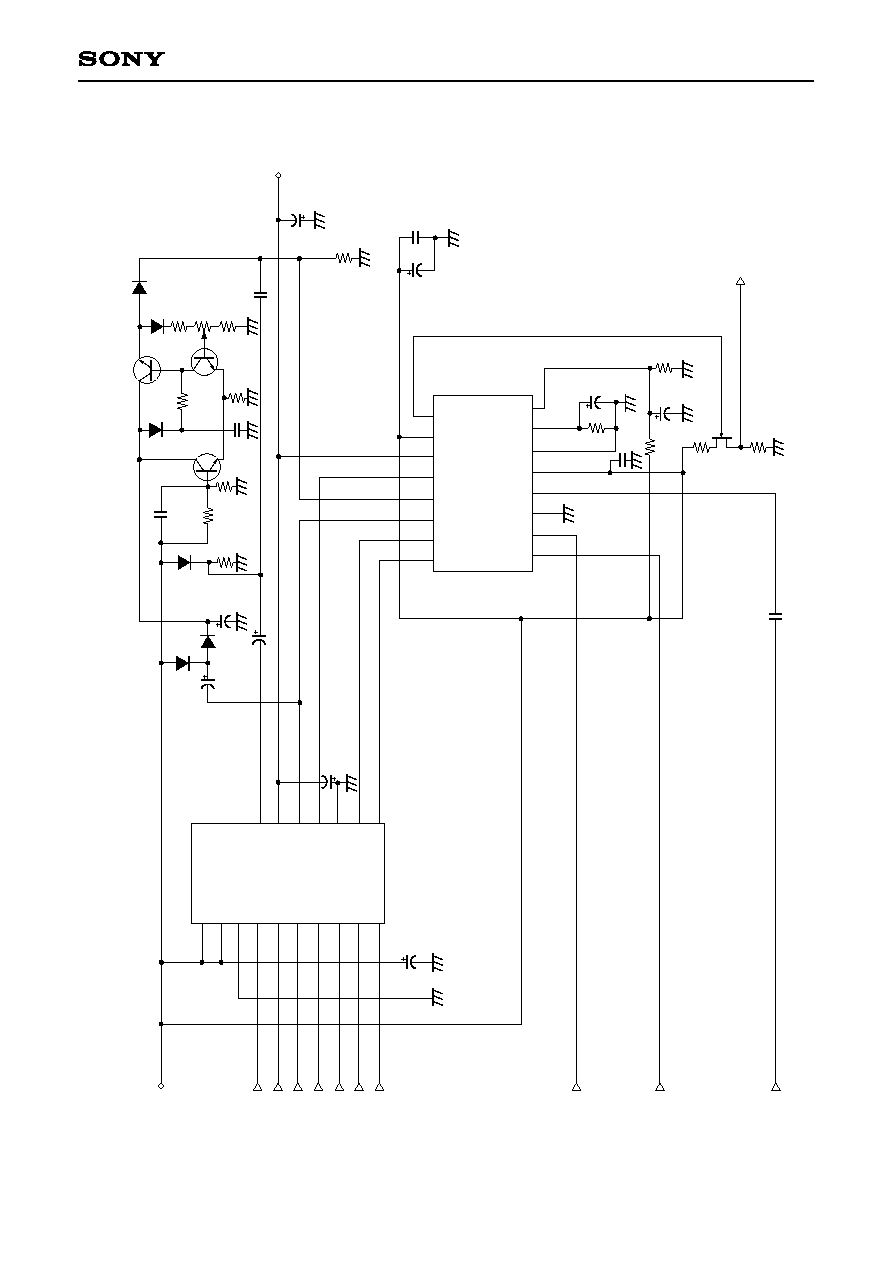

Drive Circuit 1 (substrate bias internal generation mode)

≠ 14 ≠

ICX039DLB

1

5

V

X

S

U

B

X

V

2

X

V

1

X

S

G

1

X

V

3

X

S

G

2

X

V

4

H

2

H

1

R

G

0

.

0

1

≠

9

V

3

.

3

/

1

6

V

1

M

1

5

k

4

7

k

1

5

k

0

.

1

3

9

k

0

.

1

2

7

0

k

2

7

k

5

6

k

0

.

1

1

0

0

k

1

/

3

5

V

1

/

3

5

V

1

/

3

5

V

2

2

/

1

6

V

2

2

/

2

0

V

C

X

D

1

2

6

7

A

N

2

0

1

9

1

8

1

7

1

6

1

5

1

4

1

3

1

2

1

1

1

2

4

5

6

7

8

9

1

0

1

2

3

4

5

6

7

8

9

1

0

1

6

1

5

1

4

1

3

1

2

1

1

3

9

0

4

7

/

6

.

3

V

3

.

3

/

2

0

V

0

.

0

1

0

.

0

1

1

8

0

k

1

/

6

.

3

V

2

7

k

3

.

9

k

C

C

D

O

U

T

[

A

]

1

0

0

H

2

H

1

RG

RD

GN

D

Vs

s

V

DS

UB

V

GG

V

4

V

3

V

2

SU

B

V

1

V

L

V

DD

V

OU

T

3

I

C

X

0

3

9

D

L

B

Drive Circuit 2 (substrate bias external adjustment mode)

≠ 15 ≠

ICX039DLB

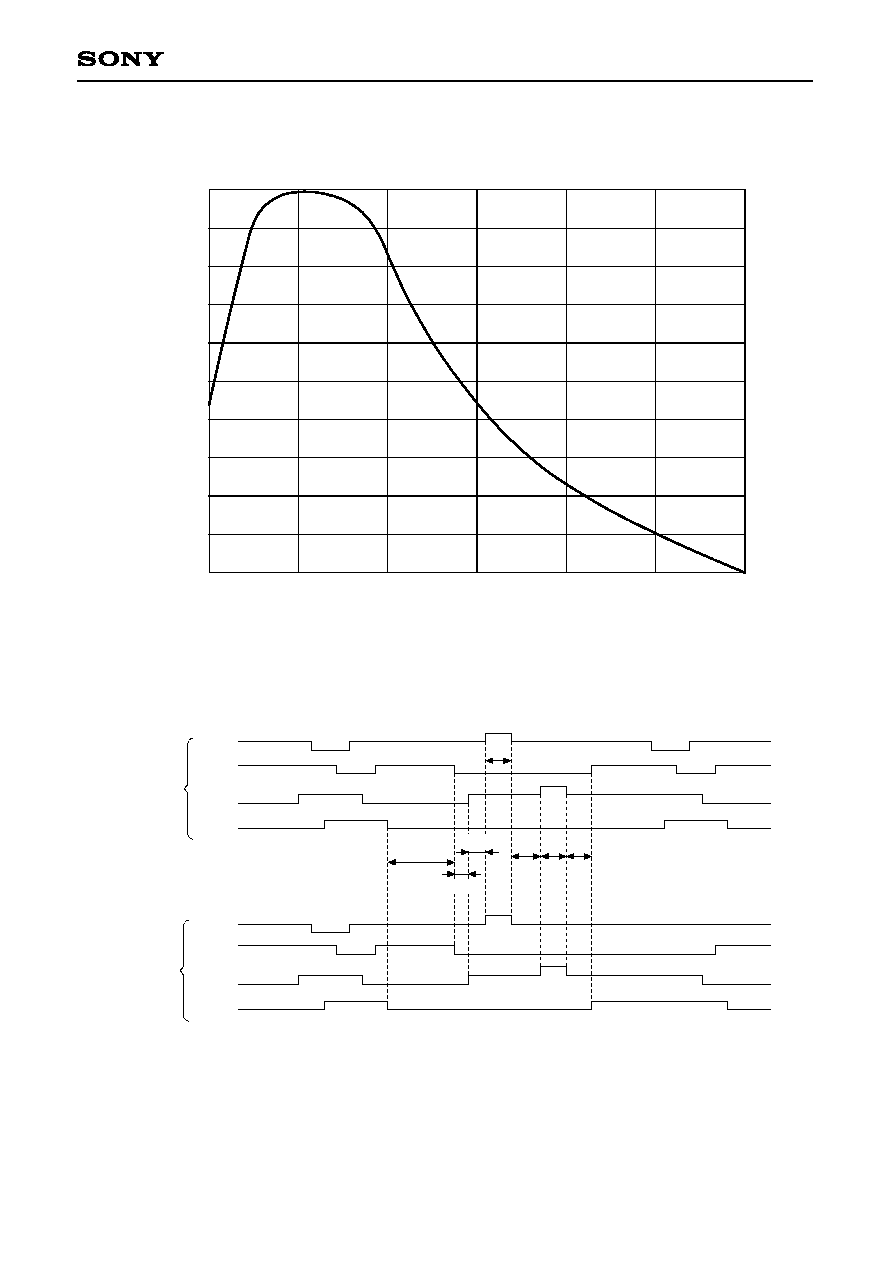

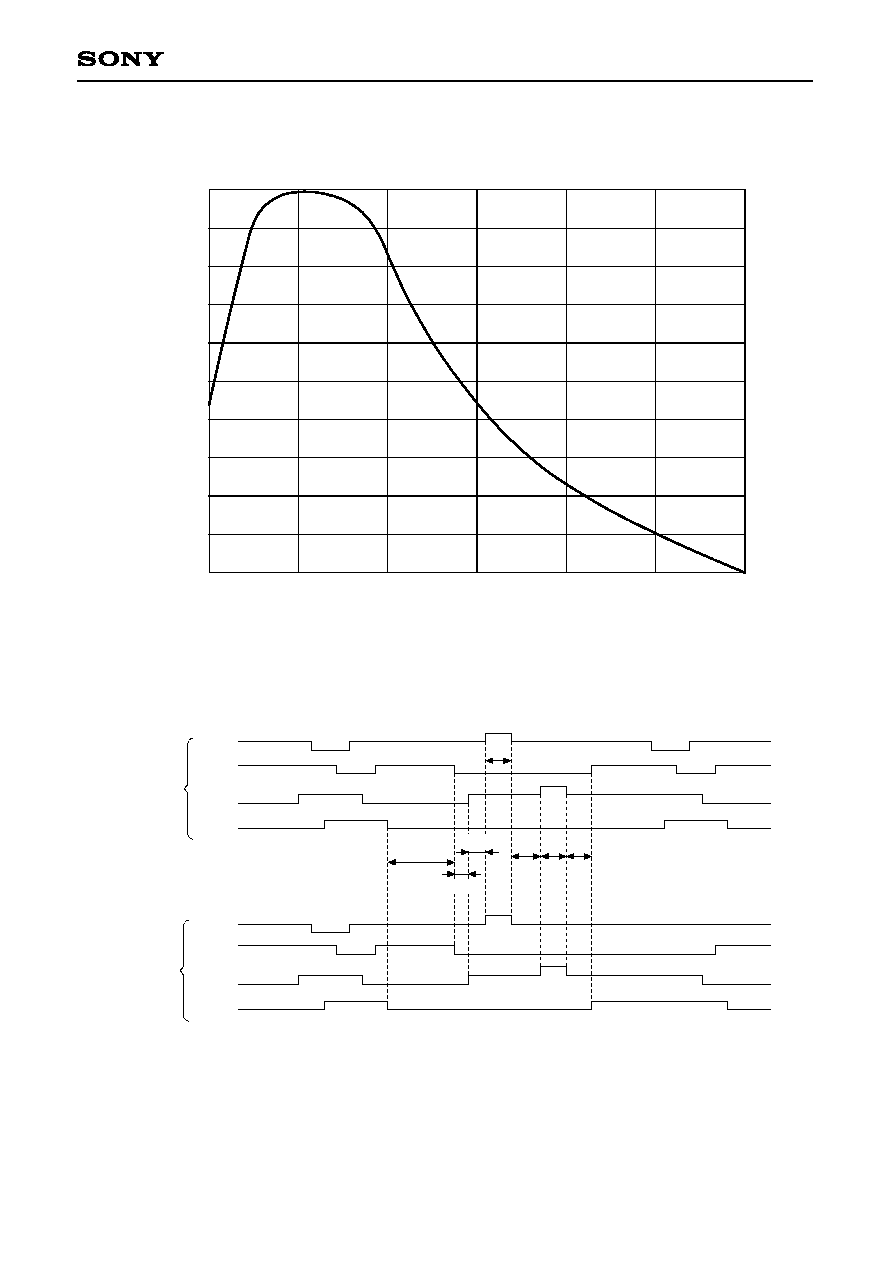

Spectral Sensitivity Characteristics

(Includes lens characteristics, excludes light source characteristics)

Wave Length [nm]

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

R

e

l

a

t

i

v

e

R

e

s

p

o

n

s

e

400

800

500

900

600

1000

700

Sensor Readout Clock Timing Chart

unit : µs

Odd Field

Even Field

V1

V2

V3

V4

V1

V2

V3

V4

2.5

2.6 2.5 2.5

1.5

33.6

0.2

≠ 16 ≠

ICX039DLB

Drive Timing Chart (Vertical Sync)

F

L

D

V

D

B

L

K

H

D

V

1

V

2

V

3

V

4

C

C

D

O

U

T

62

0

62

5

1

2

3

4

5

15

20

25

31

0

32

0

33

5

33

0

34

0

5

8

1

5

8

2

1

3

5

2

4

6

1

3

5

2

4

6

5

8

2

5

8

1

2

1

4

3

6

5

10

31

5

32

5

2

1

4

3

6

5

≠ 17 ≠

ICX039DLB

Drive Timing Chart (Horizontal Sync)

74

5

75

0

1

3

5

10

20

30

40

1

2

3

5

10

20

22

1

2

3

1

2

3

10

20

H

D

B

L

K

H

1

H

2

R

G

V

1

V

2

V

3

V

4

S

U

B

75

2

≠ 18 ≠

ICX039DLB

Notes on Handling

1) Static charge prevention

CCD image sensors are easily damaged by static discharge. Before handling be sure to take the following

protective measures.

a) Either handle bare handed or use non-chargeable gloves, clothes or material. Also use conductive

shoes.

b) When handling directly use an earth band.

c) Install a conductive mat on the floor or working table to prevent the generation of static electricity.

d) Ionized air is recommended for discharge when handling CCD image sensors.

e) For the shipment of mounted substrates, use boxes treated for the prevention of static charges.

2) Soldering

a) Make sure the package temperature does not exceed 80∞C.

b) Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a grounded

30W soldering iron and solder each pin in less than 2 seconds. For repairs and remount, cool

sufficiently.

c) To dismount an image sensor, do not use solder suction equipment. When using an electric desoldering

tool, use a thermal controller of the zero cross On/Off type and connect it to ground.

3) Dust and dirt protection

Image sensors are packed and delivered by taking care of protecting its glass plates from harmful dust and

dirt. Clean glass plates with the following operation as required, and use them.

a) Operate in clean environments (around class 1000 is appropriate).

b) Do not either touch glass plates by hand or have any object come in contact with glass surfaces. Should

dirt stick to a glass surface, blow it off with an air blower. (For dirt stuck through static electricity ionized

air is recommended.)

c) Clean with a cotton bud and ethyl alcohol if grease stained. Be careful not to scratch the glass.

d) Keep in a case to protect from dust and dirt. To prevent dew condensation, preheat or precool when

moving to a room with great temperature differences.

e) When protective tape is applied before shipping, just before use remove the tape applied for

electrostatic protection. Do not reuse the tape.

4) Do not expose to strong light (sun rays) for long periods. For continuous using under cruel condition

exceeding the normal using condition, consult our company.

5) Exposure to high temperature or high humidity will affect the characteristics. Accordingly, avoid storage or

usage in such conditions.

6) CCD image sensors are precise optical equipment that should not be subject to too much mechanical

shocks.

≠ 19 ≠

ICX039DLB

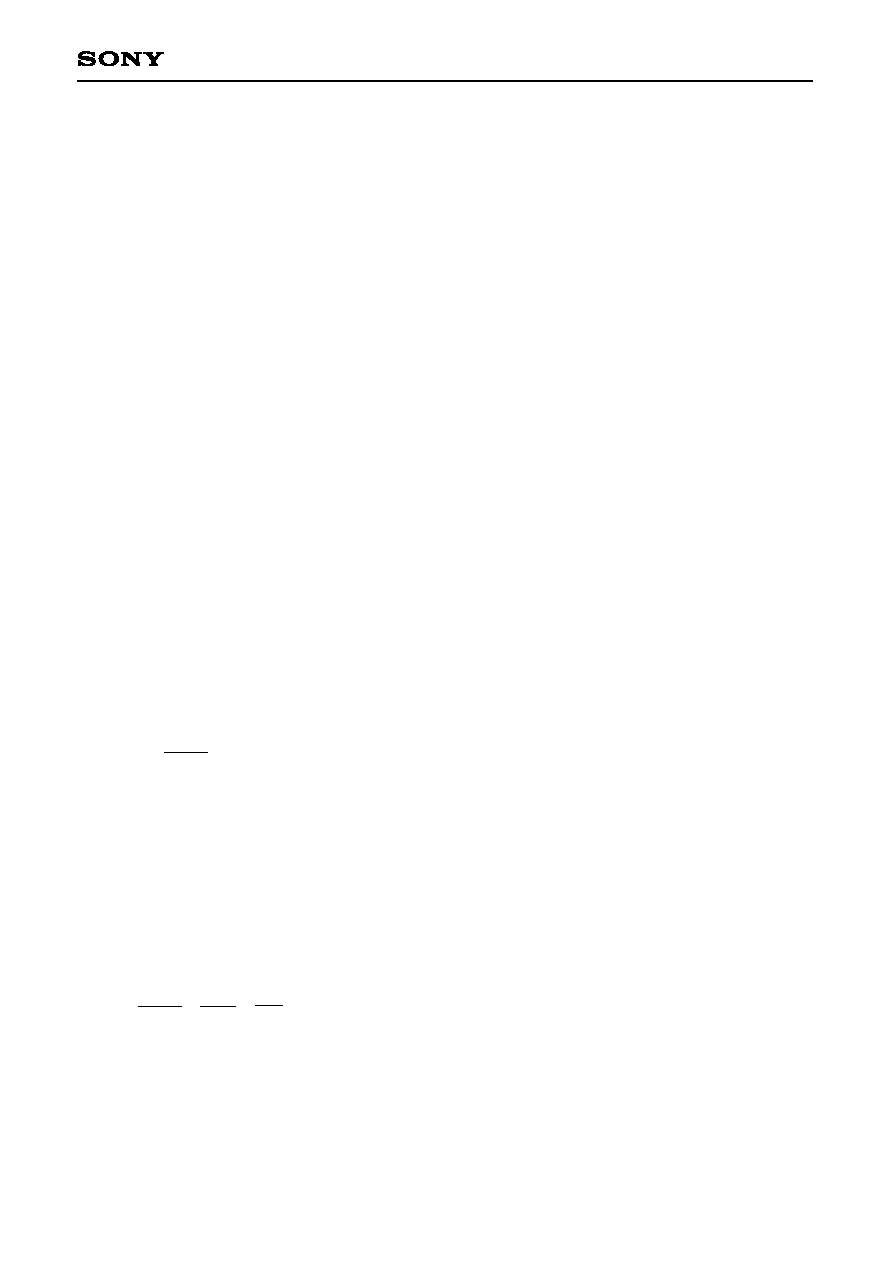

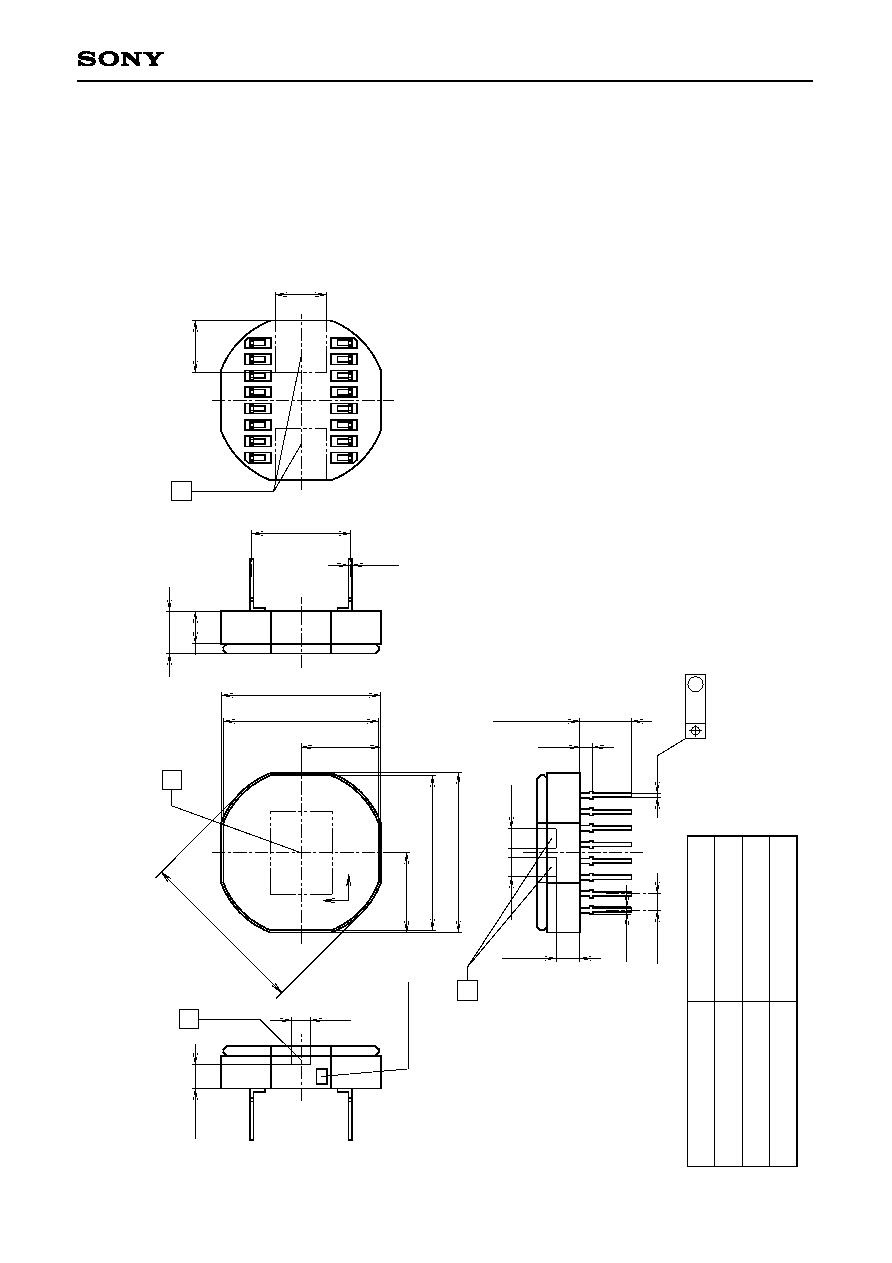

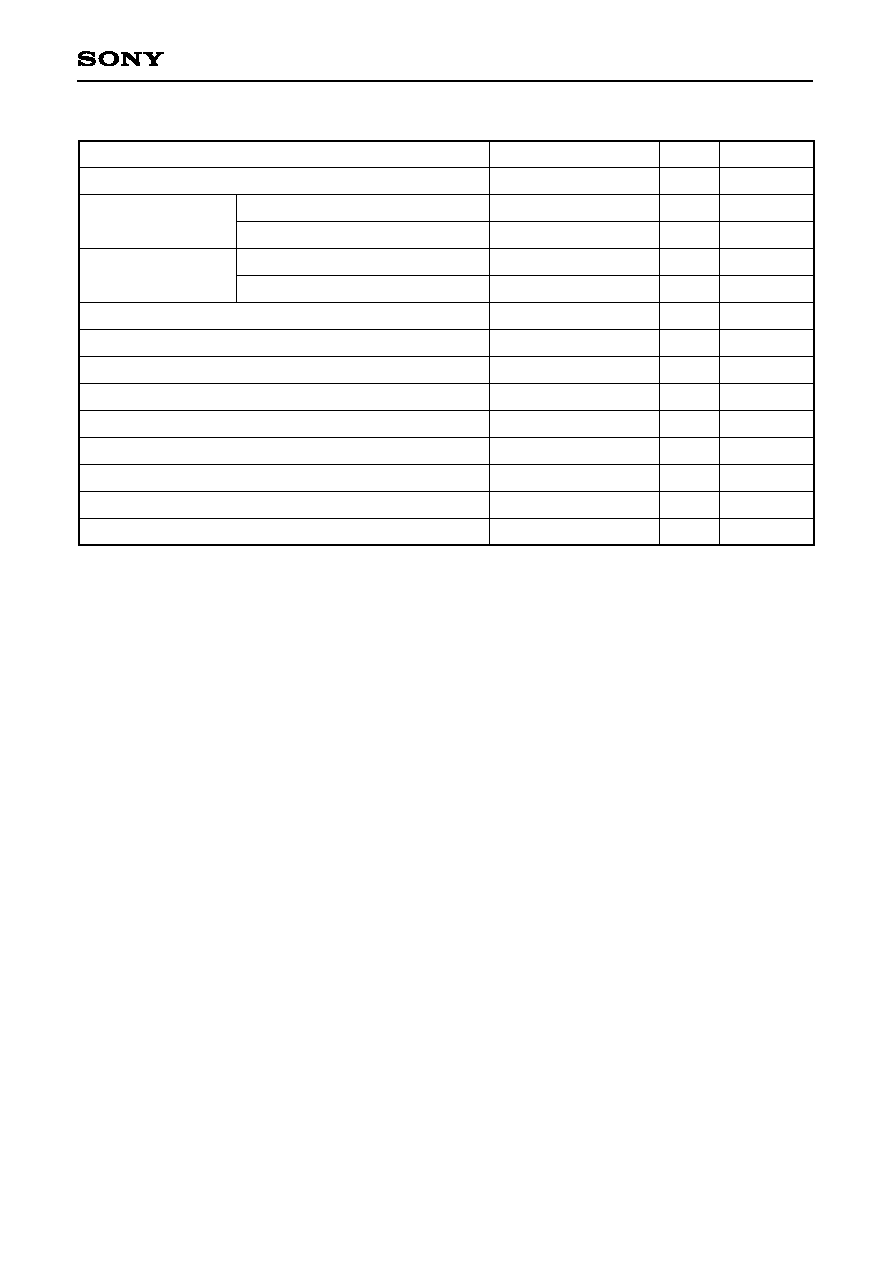

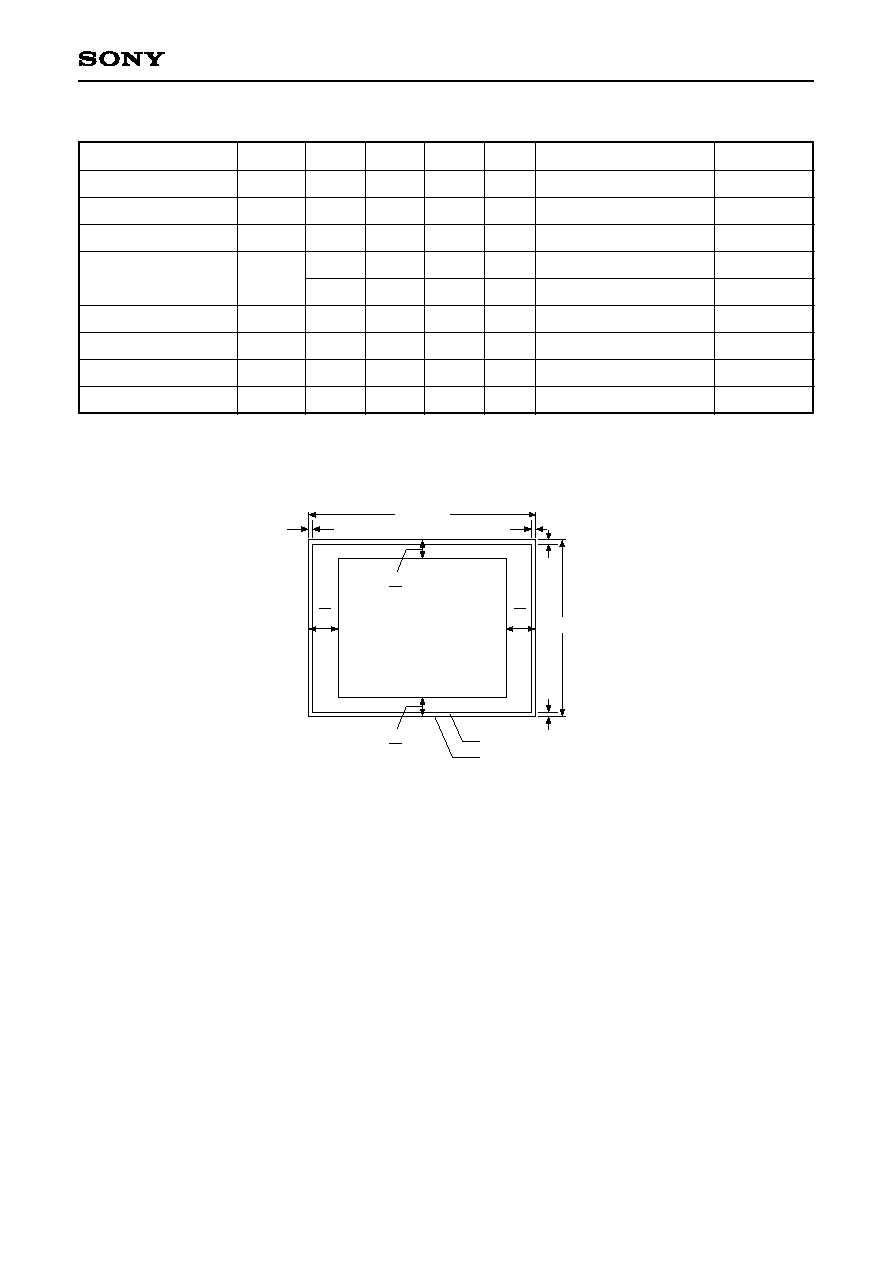

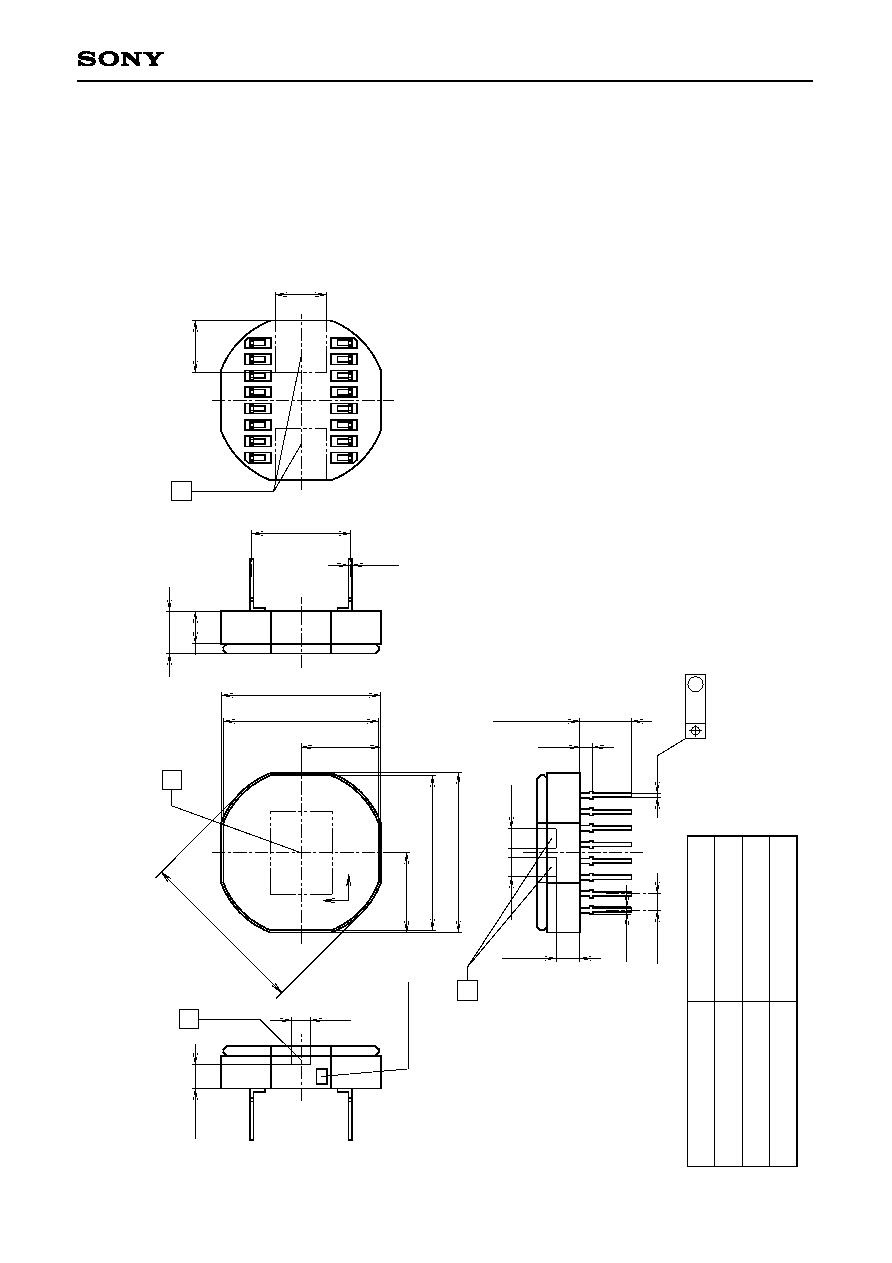

Package Outline

Unit: mm

P

A

C

K

A

G

E

S

T

R

U

C

T

U

R

E

1

6

p

i

n

D

I

P

(

3

0

0

m

i

l

)

1

s

t

.

p

i

n

I

n

d

e

x

H

V

6

.

1

7

5

1

2

.

0

±

0

.

1

5

1

2

.

3

5

±

0

.

3

13

.2

±

0

.3

1

.

8

4

1.5

1

.

5

0

.

7

1

.

5

3

.

2

9

±

0

.

3

2

.

5

4

7.6

2

0.2

5

4

.

0

4.0

4.0

±

0

.2

1.0

0

.

3

1

.

2

7

0

.

6

1.8

4

1

8

9

1

6

6.1

75

12

.0

±

0

.1

5

12

.3

5 ±

0

.3

8

1

1

6

9

1

.

"

A

"

i

s

t

h

e

c

e

n

t

e

r

o

f

t

h

e

e

f

f

e

c

t

i

v

e

i

m

a

g

e

a

r

e

a

.

2

.

T

h

e

p

o

i

n

t

"

B

"

o

f

t

h

e

p

a

c

k

a

g

e

i

s

t

h

e

h

o

r

i

z

o

n

t

a

l

r

e

f

e

r

e

n

c

e

.

T

h

e

p

o

i

n

t

"

B

'

"

o

f

t

h

e

p

a

c

k

a

g

e

i

s

t

h

e

v

e

r

t

i

c

a

l

r

e

f

e

r

e

n

c

e

.

3

.

T

h

e

b

o

t

t

o

m

"

C

"

o

f

t

h

e

p

a

c

k

a

g

e

i

s

t

h

e

h

e

i

g

h

t

r

e

f

e

r

e

n

c

e

.

4

.

T

h

e

c

e

n

t

e

r

o

f

t

h

e

e

f

f

e

c

t

i

v

e

i

m

a

g

e

a

r

e

a

r

e

l

a

t

i

v

e

t

o

t

h

e

c

e

n

t

e

r

o

f

t

h

e

p

a

c

k

a

g

e

(

)

i

s

(

H

,

V

)

=

(

0

,

0

)

±

0

.

1

5

m

m

.

5

.

T

h

e

r

o

t

a

t

i

o

n

a

n

g

l

e

o

f

t

h

e

e

f

f

e

c

t

i

v

e

i

m

a

g

e

a

r

e

a

r

e

l

a

t

i

v

e

t

o

H

a

n

d

V

i

s

±

1

∞

.

6

.

T

h

e

h

e

i

g

h

t

f

r

o

m

t

h

e

b

o

t

t

o

m

"

C

"

t

o

t

h

e

e

f

f

e

c

t

i

v

e

i

m

a

g

e

a

r

e

a

i

s

1

.

4

1

±

0

.

1

5

m

m

.

7

.

T

h

e

t

i

l

t

o

f

t

h

e

e

f

f

e

c

t

i

v

e

i

m

a

g

e

a

r

e

a

r

e

l

a

t

i

v

e

t

o

t

h

e

b

o

t

t

o

m

"

C

"

i

s

l

e

s

s

t

h

a

n

6

0

µ

m

.

8

.

T

h

e

t

h

i

c

k

n

e

s

s

o

f

t

h

e

c

o

v

e

r

g

l

a

s

s

i

s

0

.

7

5

m

m

,

a

n

d

t

h

e

r

e

f

r

a

c

t

i

v

e

i

n

d

e

x

i

s

1

.

5

.

C

e

n

t

e

r

o

f

t

h

e

p

a

c

k

a

g

e

:

T

h

e

c

e

n

t

e

r

i

s

h

a

l

f

w

a

y

b

e

t

w

e

e

n

t

w

o

p

a

i

r

s

o

f

o

p

p

o

s

i

t

e

s

i

d

e

s

,

a

s

m

e

a

s

u

r

e

d

f

r

o

m

"

B

"

,

"

B

'

"

.

0

.

3

C

~

~

A

B

~

B

'

~

~

P

A

C

K

A

G

E

M

A

T

E

R

I

A

L

L

E

A

D

T

R

E

A

T

M

E

N

T

L

E

A

D

M

A

T

E

R

I

A

L

P

A

C

K

A

G

E

W

E

I

G

H

T

C

e

r

a

m

i

c

G

O

L

D

P

L

A

T

I

N

G

4

2

A

L

L

O

Y

0

.

9

g

M