| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ICX424AQ | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

≠ 1 ≠

E01Z29A25-PS

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

ICX424AQ

16 pin DIP (Plastic)

Optical black position

(Top View)

2

8

V

H

Pin 1

Pin 9

31

2

Diagonal 6mm (Type 1/3) Progressive Scan CCD Image Sensor with Square Pixel for Color Cameras

Description

The ICX424AQ is a diagonal 6mm (Type 1/3) interline

CCD solid-state image sensor with a square pixel

array which supports VGA format. Progressive scan

allows all pixels signals to be output independently

within approximately 1/60 second. This chip features

an electronic shutter with variable charge-storage

time which makes it possible to realize full-frame still

images without a mechanical shutter. High sensitivity

and low dark current are achieved through the

adoption of the HAD (Hole-Accumulation Diode)

sensors.

This chip is suitable for applications such as FA

and surveillance cameras.

Features

∑ Progressive scan allows individual readout of the image signals

from all pixels.

∑ High vertical resolution still images without a mechanical shutter

∑ Square pixel

∑ Supports VGA format

∑ Horizontal drive frequency: 24.54MHz

∑ No voltage adjustments (reset gate and substrate bias are not

adjusted.)

∑ R, G, B primary color mosaic filters on chip

∑ High resolution, high color reproductivity, high sensitivity, low dark

current

∑ Continuous variable-speed shutter

∑ Low smear

∑ Excellent anti-blooming characteristics

∑ Horizontal register: 5.0V drive

∑ 16-pin high precision plastic package (enables dual-surface standard)

Device Structure

∑ Interline CCD image sensor

∑ Image size:

Diagonal 6mm (Type 1/3)

∑ Number of effective pixels: 659 (H)

◊

494 (V) approx. 330K pixels

∑ Total number of pixels:

692 (H)

◊

504 (V) approx. 350K pixels

∑ Chip size:

5.79mm (H)

◊

4.89mm (V)

∑ Unit cell size:

7.4µm (H)

◊

7.4µm (V)

∑ Optical black:

Horizontal (H) direction: Front 2 pixels, rear 31 pixels

Vertical (V) direction:

Front 8 pixels, rear 2 pixels

∑ Number of dummy bits:

Horizontal 16

Vertical 5

∑ Substrate material:

Silicon

Wfine CCD is trademark of Sony corporation.

Represents a CCD adopting progressive scan, primary color filter and square pixel.

≠ 2 ≠

ICX424AQ

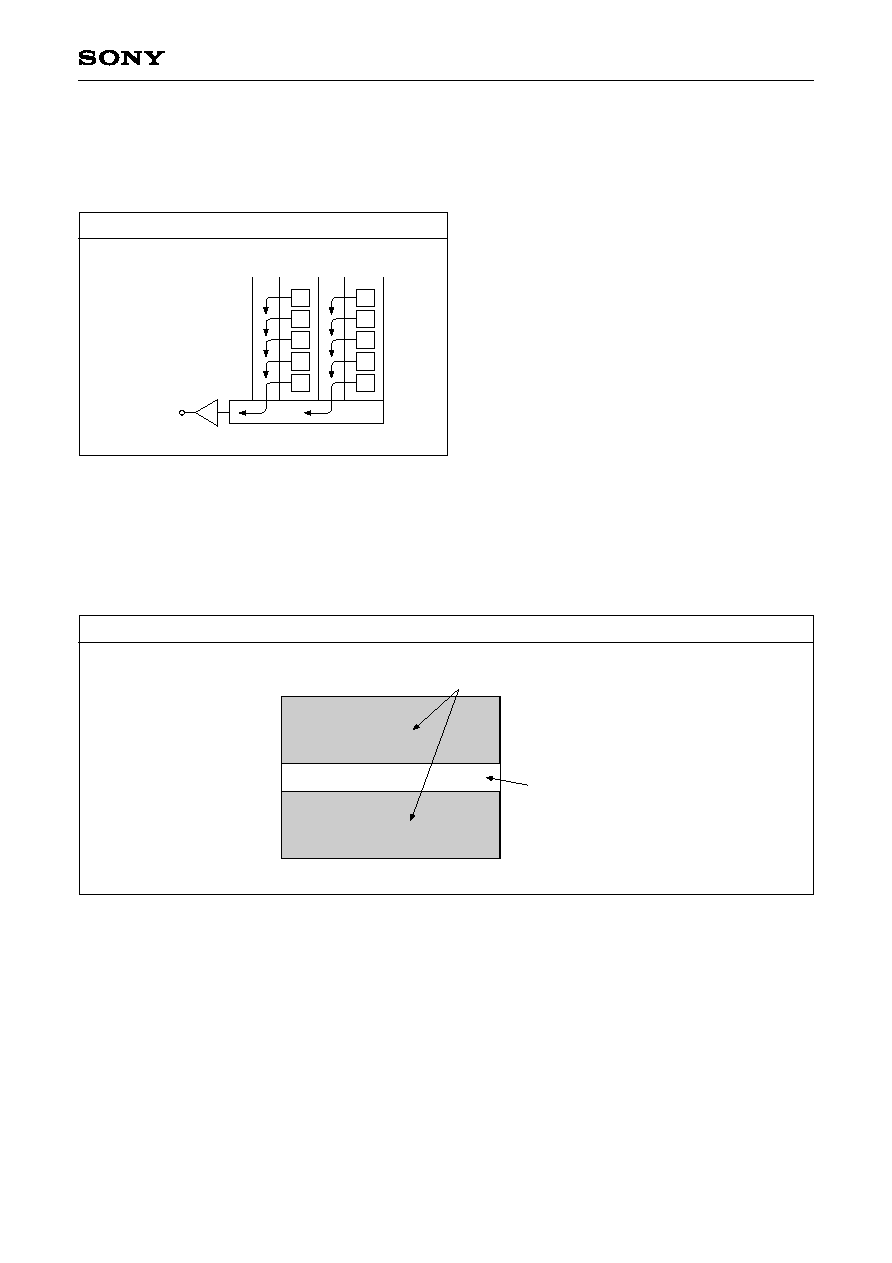

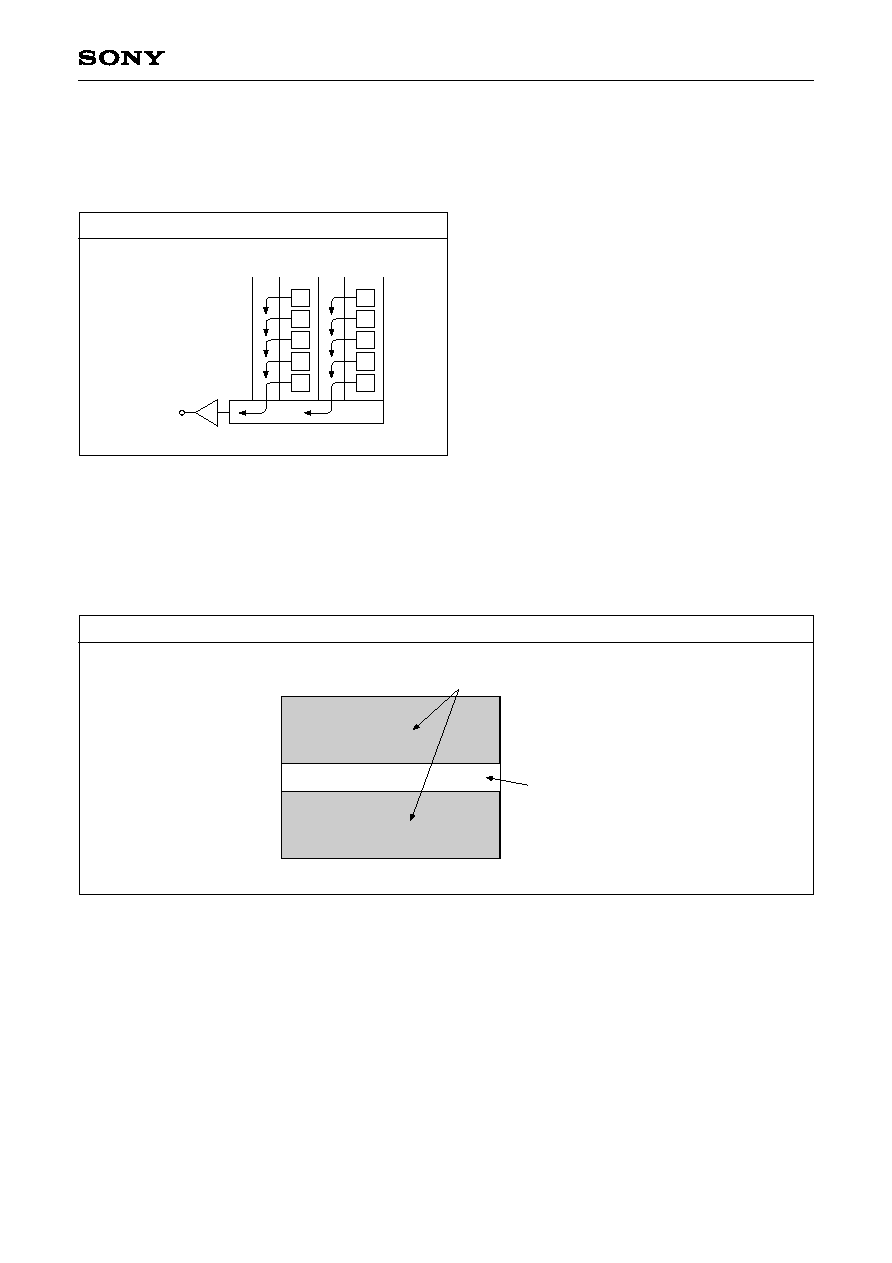

Block Diagram and Pin Configuration

(Top View)

Pin No.

Symbol

Description

Pin No.

Symbol

Description

1

2

3

4

5

6

7

8

V

3

V

2

V

1

NC

GND

C

GG

GND

V

OUT

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

GND

Output amplifier gate

1

GND

Signal output

9

10

11

12

13

14

15

16

V

DD

SUBCIR

GND

SUB

V

L

RG

H

1

H

2

Supply voltage

Supply voltage for the substrate

voltage generation

GND

Substrate clock

Protective transistor bias

Reset gate clock

Horizontal register transfer clock

Horizontal register transfer clock

Pin Description

1

DC bias is applied within the CCD, so that this pin should be grounded externally through a capacitance

of 1000pF.

Note)

Note) : Photo sensor

8

7

6

5

4

3

2

1

V

OUT

GND

C

GG

GND

NC

V

1

V

2

V

3

11

12

13

14

15

16

GND

10

SUBCIR

9

V

DD

SUB

V

L

RG

H

1

H

2

Horizontal register

V

e

r

tical register

B

G

B

G

B

G

G

R

G

R

G

R

B

G

B

G

B

G

G

R

G

R

G

R

≠ 3 ≠

ICX424AQ

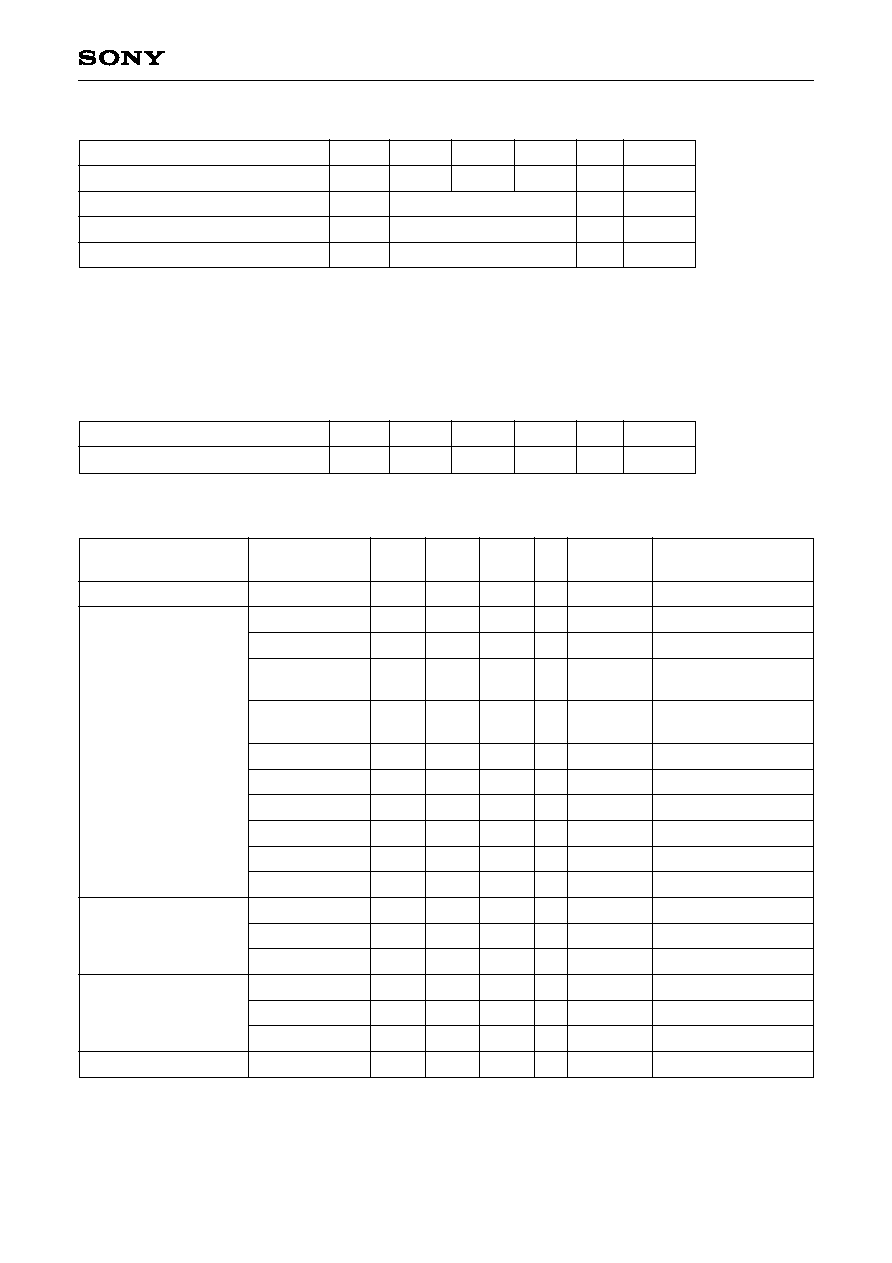

Absolute Maximum Ratings

Item

V

DD

, V

OUT

, C

GG

, SUBCIR ≠ GND

V

DD

, V

OUT

, C

GG

, SUBCIR ≠

SUB

V

1

, V

2

, V

3

≠ GND

V

1

, V

2

, V

3

≠

SUB

Substrate clock

SUB ≠ GND

Supply voltage

Clock input voltage

Voltage difference between vertical clock input pins

Voltage difference between horizongal clock input pins

H

1

, H

2

≠ V

3

H

1

, H

2

≠ GND

H

1

, H

2

≠

SUB

V

L

≠

SUB

V

2

, V

3

≠ V

L

RG ≠ GND

V

1

, H

1

, H

2

, GND ≠ VL

Storage temperature

Performance guarantee temperature

Operating temperature

≠0.3 to +36

≠0.3 to +18

≠22 to +9

≠15 to +16

to +10

to +15

to +16

≠16 to +16

≠10 to +15

≠55 to +10

≠65 to +0.3

≠0.3 to +27.5

≠0.3 to +20.5

≠0.3 to +17.5

≠30 to +80

≠10 to +60

≠10 to +75

V

V

V

V

V

V

V

V

V

V

V

V

V

V

∞C

∞C

∞C

2

Ratings

Unit

Remarks

2

+24V (Max.) when clock width < 10µs, clock duty factor < 0.1%.

+16V (Max.) is guaranteed for power-on and power-off.

≠ 4 ≠

ICX424AQ

Clock Voltage Conditions

Bias Conditions

1

V

L

setting is the V

VL

voltage of the vertical transfer clock waveform, or the same voltage as the V

L

power

supply for the V driver should be used.

2

Set SUBCIR pin to open when applying a DC bias to the substrate clock pin.

3

Do not apply a DC bias to the reset gate clock pins, because a DC bias is generated within the CCD.

DC Characteristics

Supply current

Item

I

DD

Symbol

7

Min.

Unit

Remarks

Typ.

Max.

mA

Readout clock voltage

Vertical transfer clock

voltage

Horizontal transfer

clock voltage

Reset gate clock

voltage

Substrate clock voltage

Item

V

VT

V

VH02

V

VH1

, V

VH2

, V

VH3

V

VL1

, V

VL2

, V

VL3

V

VL1

, V

VL2

, V

VL3

V

1

, V

2

, V

3

| V

VL1

≠ V

VL3

|

V

VHH

V

VHL

V

VLH

V

VLL

V

H

V

HL

V

CR

V

RG

V

RGLH

≠ V

RGLL

V

RGL

≠ V

RGLm

V

SUB

Symbol

14.55

≠0.05

≠0.2

≠7.8

≠8.0

6.8

4.75

≠0.05

0.8

4.5

21.5

Min.

15.0

0

0

≠7.5

≠7.5

7.5

5.0

0

2.5

5.0

22.5

Typ.

15.45

0.05

0.05

≠7.2

≠7.0

8.05

0.1

1.0

2.3

1.0

1.0

5.25

0.05

5.5

0.8

0.5

23.5

Max.

Unit

1

2

2

2

2

2

2

2

2

2

2

3

3

3

4

4

4

5

Waveform

Diagram

V

VH

= V

VH02

V

VL

= V

VL1

(V

VL3

)/2

(During 24.54MHz)

V

VL

= V

VL1

(V

VL3

)/2

(During 12.27MHz)

High-level coupling

High-level coupling

Low-level coupling

Low-level coupling

Cross-point voltage

Low-level coupling

Low-level coupling

Remarks

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

Supply voltage

Protective transistor bias

Substrate clock

Reset gate clock

Item

V

DD

V

L

SUB

RG

Symbol

15.0

1

2

3

Min.

V

Unit

Remarks

Typ.

Max.

14.55

15.45

9

≠ 5 ≠

ICX424AQ

Clock Equivalent Circuit Constants

C

V1

C

V2

C

V3

C

V12

C

V23

C

V31

C

H1

, C

H2

C

HH

C

RG

C

SUB

R

1

, R

2

R

3

R

GND

R

H1

, R

H2

R

RG

Symbol

Capacitance between vertical transfer clock and GND

Capacitance between vertical transfer clocks

Capacitance between horizontal transfer clock and GND

Capacitance between horizontal transfer clocks

Capacitance between reset gate clock and GND

Capacitance between substrate clock and GND

Vertical transfer clock series resistor

Vertical transfer clock ground resistor

Horizontal transfer clock series resistor

Reset gate clock series resistor

Item

Min.

3900

3300

3300

1000

1000

1000

47

30

6

560

33

18

100

10

39

Typ.

Max.

pF

pF

pF

pF

pF

pF

pF

pF

pF

pF

Unit

Remarks

Horizontal transfer clock equivalent circuit

Reset gate clock equivalent circuit

Vertical transfer clock equivalent circuit

V

3

R

GND

C

V3

C

V1

C

V2

C

V23

C

V31

C

V12

R

3

R

1

R

2

V

2

V

1

H

1

H

2

C

H1

C

H2

C

HH

R

H2

R

H1

RG

R

RG

C

RG

≠ 6 ≠

ICX424AQ

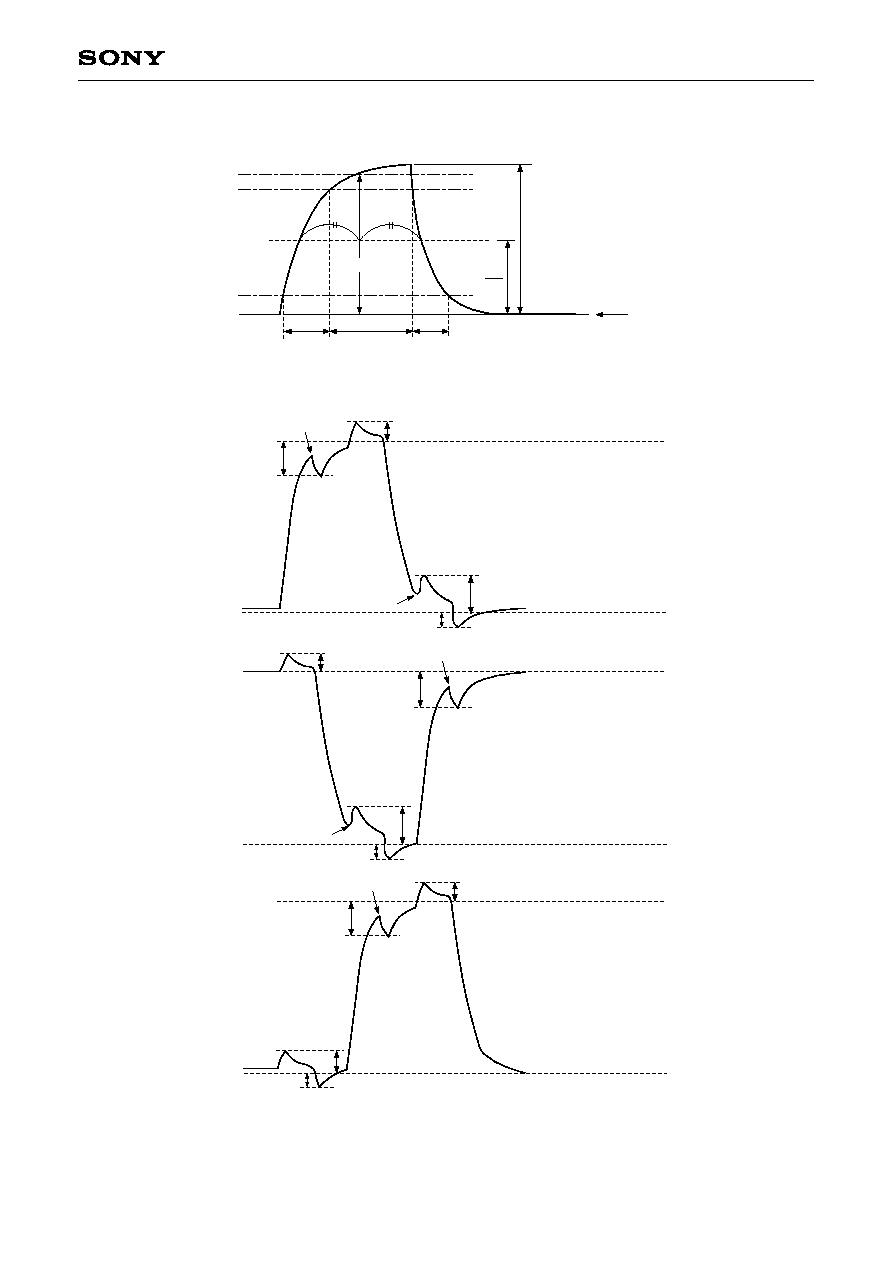

Drive Clock Waveform Conditions

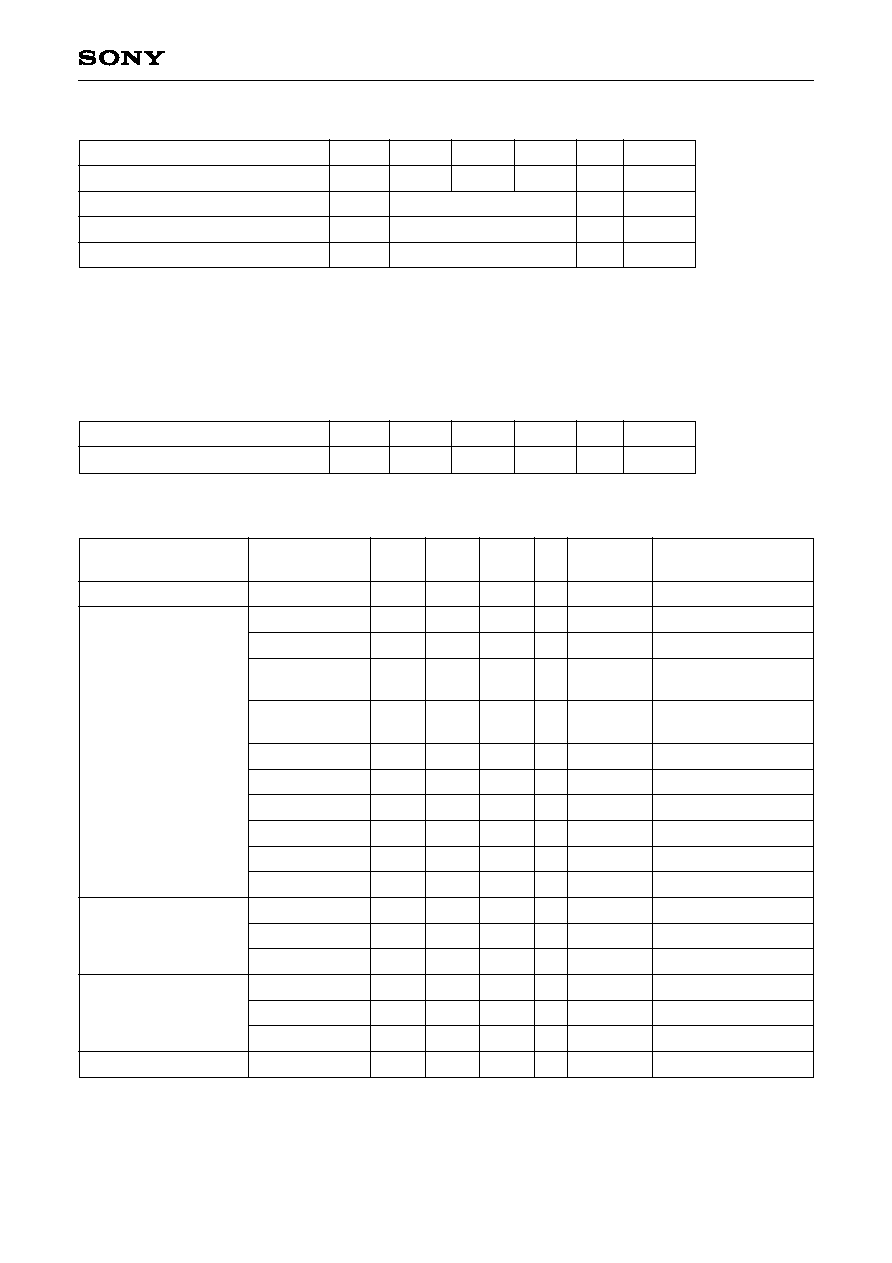

(1) Readout clock waveform

(2) Vertical transfer clock waveform

100%

90%

10%

0%

tr

tf

0V

twh

M

2

M

V

VT

Note) Readout clock is used by composing vertical transfer clocks V

2

and V

3

.

V

VLH

V

VL03

V

VLL

V

VH

= V

VH02

V

VL

= (V

VL01

+ V

VL03

)/2

V

VL3

= V

VL03

V

VL

V

VH1

V

VHH

V

VH

V

VHL

V

VLH

V

VL1

V

VL01

V

VL

V

VLL

V

VH3

V

VHH

V

VH

V

VHL

V

VLH

V

VL2

V

VLL

V

VL

V

VH

V

VHH

V

VH02

V

VH2

V

VHL

V

V1

= V

VH1

≠ V

VL01

V

V2

= V

VH02

≠ V

VL2

V

V3

= V

VH3

≠ V

VL03

V

1

V

T

V

2

V

3

≠ 7 ≠

ICX424AQ

H

2

H

1

two

twh

tr

tf

90%

10%

twl

V

CR

V

HL

V

H

V

H

2

RG waveform

V

RGLH

V

RGLL

V

RGLm

V

RGH

tr

tf

twh

twl

V

RGL

Point A

V

RG

V

SUB

(A bias generated within the CCD)

100%

90%

10%

0%

tr

tf

twh

M

2

M

V

SUB

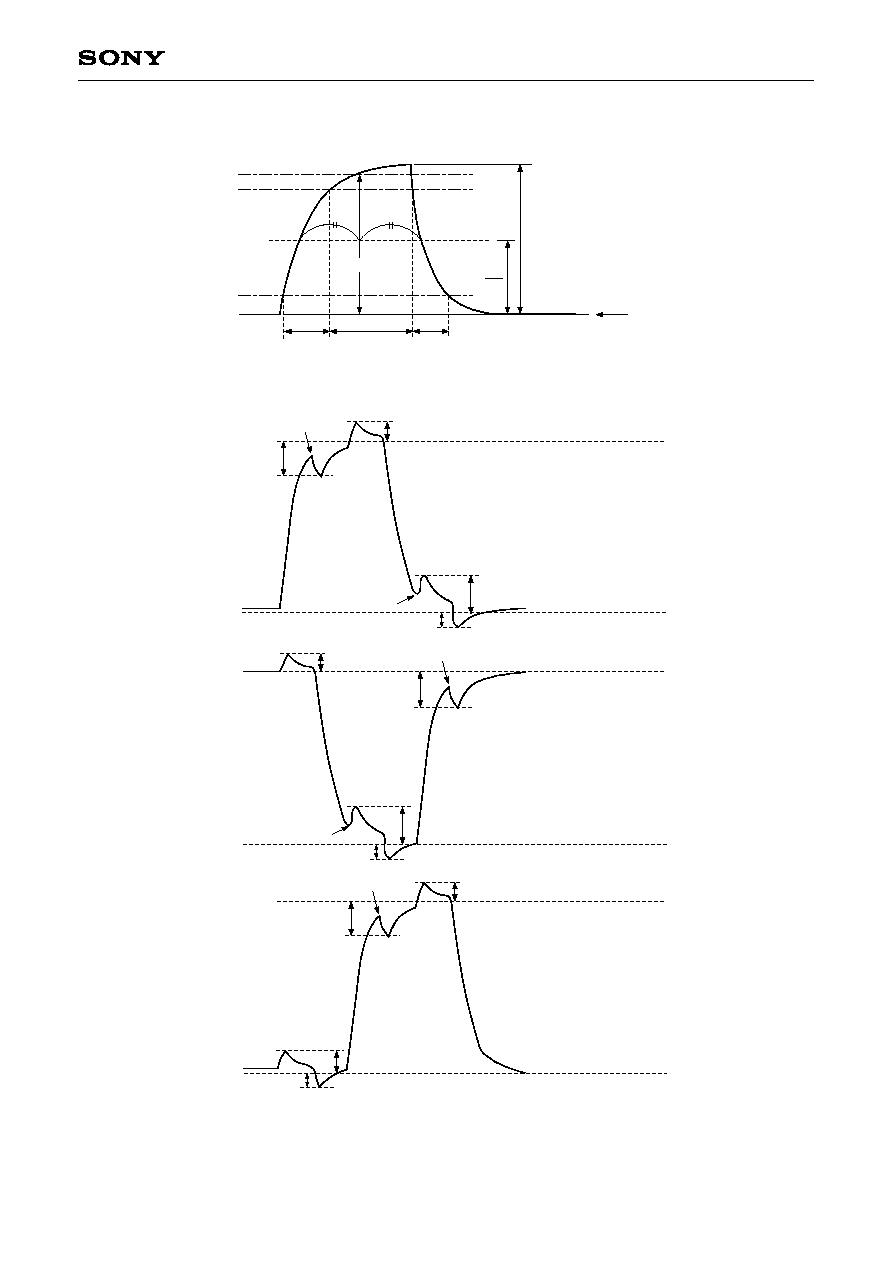

(3) Horizontal transfer clock waveform

Cross-point voltage for the H

1

rising side of the horizontal transfer clocks H

1

and H

2

waveforms is V

CR

.

The overlap period for twh and twl of horizontal transfer clocks H

1

and H

2

is two.

(4) Reset gate clock waveform

V

RGLH

is the maximum value and V

RGLL

is the minimum value of the coupling waveform during the period from

Point A in the above diagram until the rising edge of RG.

In addition, V

RGL

is the average value of V

RGLH

and V

RGLL

.

V

RGL

= (V

RGLH

+ V

RGLL

)/2

Assuming V

RGH

is the minimum value during the interval twh, then:

V

RG

= V

RGH

≠ V

RGL

Negative overshoot level during the falling edge of RG is V

RGLm

.

(5) Substrate clock waveform

H

1

, H

2

RG

SUB

≠ 8 ≠

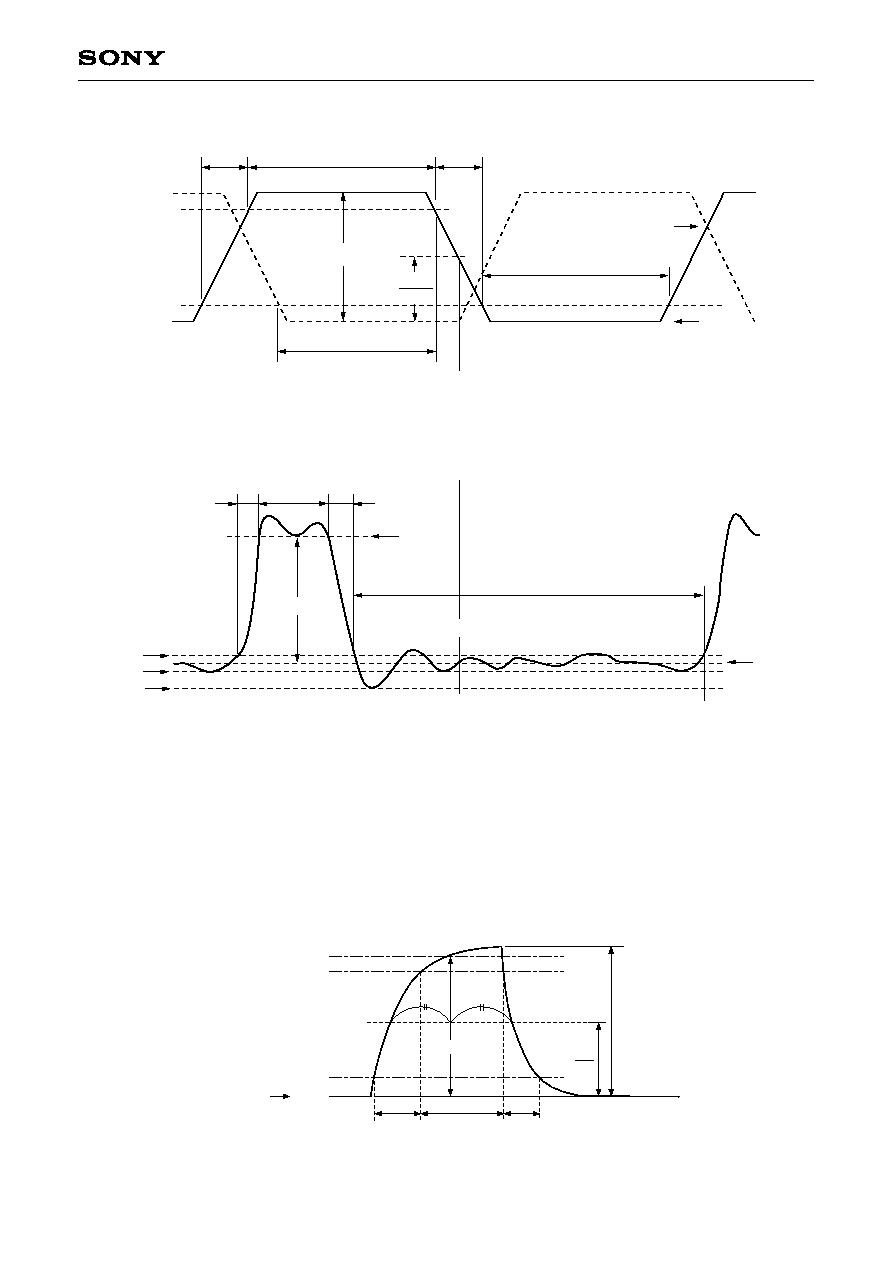

ICX424AQ

1

The overlap period of twh and twl of horizontal transfer clocks H

1

and H

2

is two.

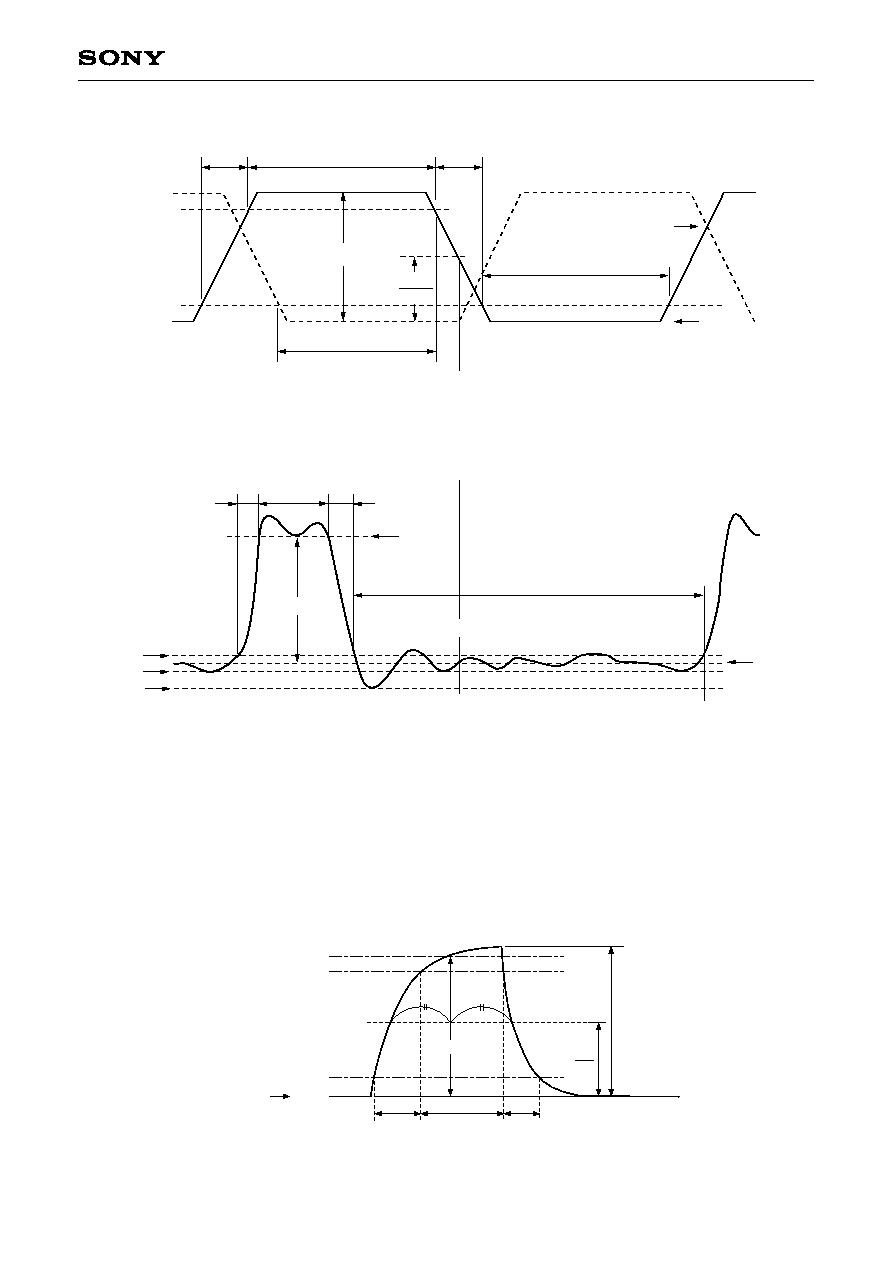

Clock Switching Characteristics (Horizontal drive frequency: 24.54MHz)

Min.

twh

Typ. Max. Min. Typ. Max. Min. Typ. Max. Min. Typ. Max.

twl

tr

tf

2.3

10.5

10.5

6

0.75

2.5

14.6

14.6

8

0.9

10.5

10.5

14.6

14.6

25.8

0.5

6.4

6.4

4

10.5

10.5

0.5

15

0.5

6.4

6.4

3

250

10.5

10.5

0.5

Unit

µs

ns

ns

ns

µs

Remarks

During

readout

When using

CXD3400N

tf

tr ≠ 2ns

During drain

charge

Item

Readout clock

Vertical transfer

clock

Horizontal

transfer clock

Reset gate clock

Substrate clock

Symbol

V

T

V

1

, V

2

,

V

3

H

1

H

2

RG

SUB

Min.

two

Typ. Max.

10.5 14.6

Unit

ns

Remarks

Item

Horizontal transfer clock

Symbol

H

1

, H

2

1

Clock Switching Characteristics (Horizontal drive frequency: 12.27MHz)

Min.

twh

Typ. Max. Min. Typ. Max. Min. Typ. Max. Min. Typ. Max.

twl

tr

tf

4.6

24

26.5

11

1.5

5.0

30

31.5

13

1.8

25

25

31.5

30

62.5

0.5

10

10

3

17.5

15

0.5

15

0.5

10

10

3

350

17.5

15

0.5

Unit

µs

ns

ns

ns

µs

Remarks

During

readout

When using

CXD3400N

tf

tr ≠ 2ns

During drain

charge

Item

Readout clock

Vertical transfer

clock

Horizontal

transfer clock

Reset gate clock

Substrate clock

Symbol

V

T

V

1

, V

2

,

V

3

H

1

H

2

RG

SUB

Min.

two

Typ. Max.

21.5 25.5

Unit

ns

Remarks

Item

Horizontal transfer clock

Symbol

H

1

, H

2

1

≠ 9 ≠

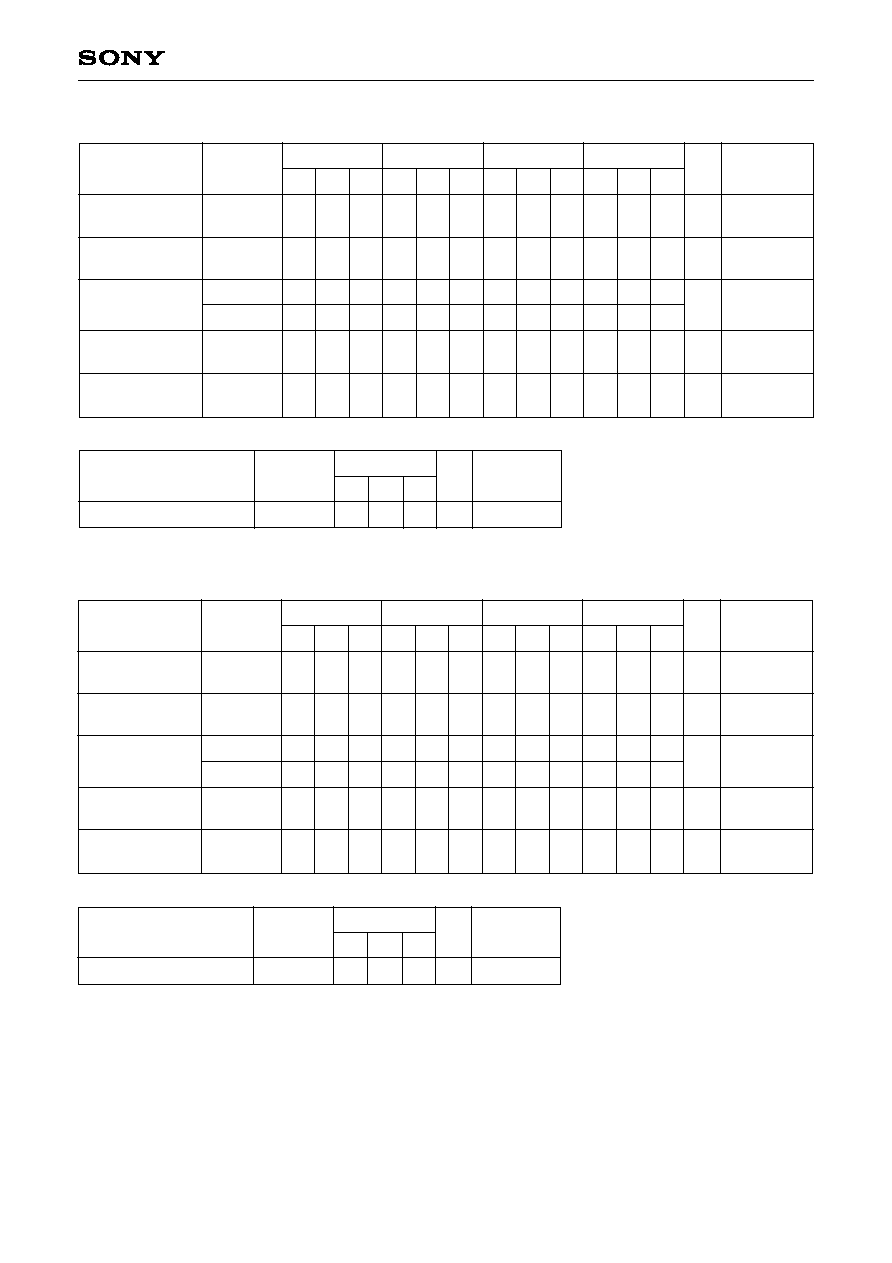

ICX424AQ

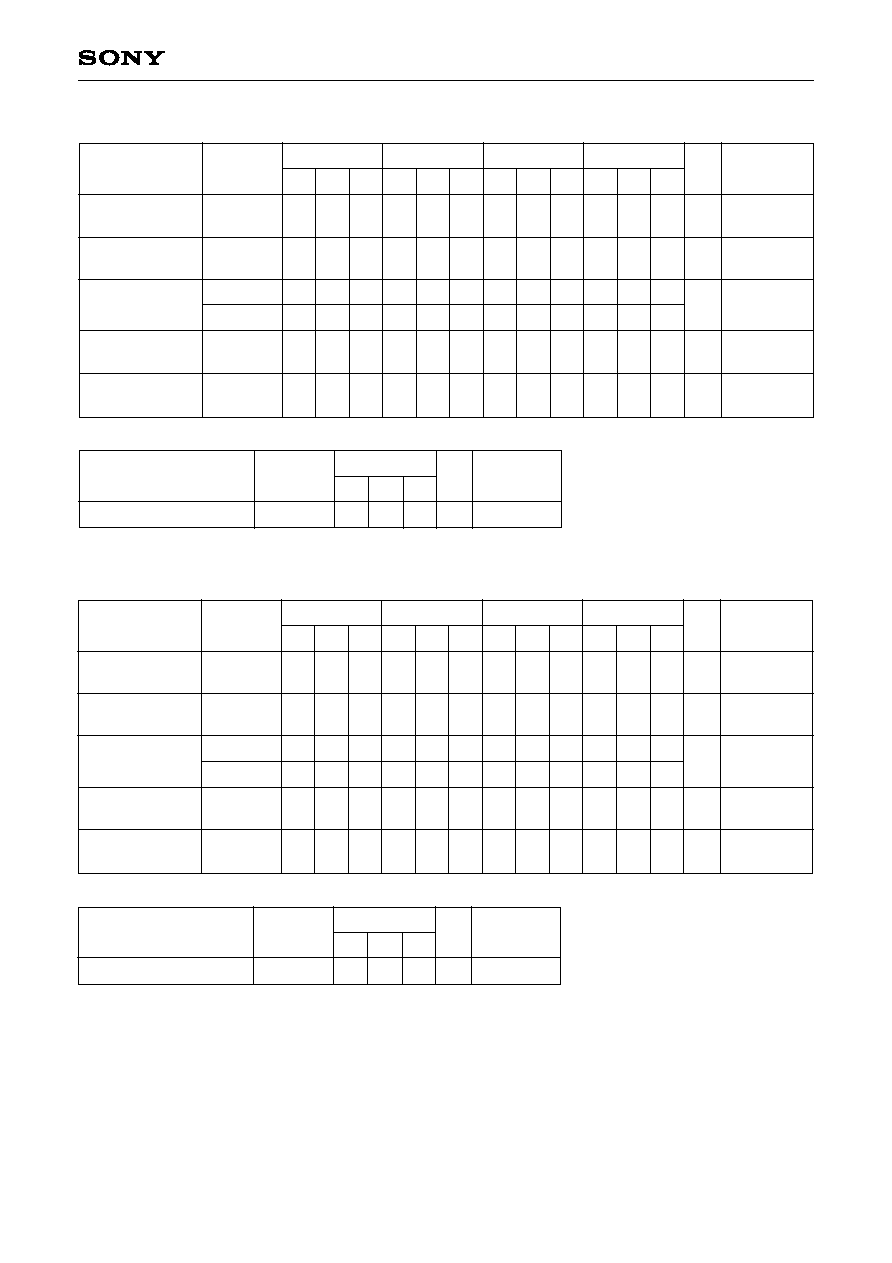

Image Sensor Characteristics

(Ta = 25∞C)

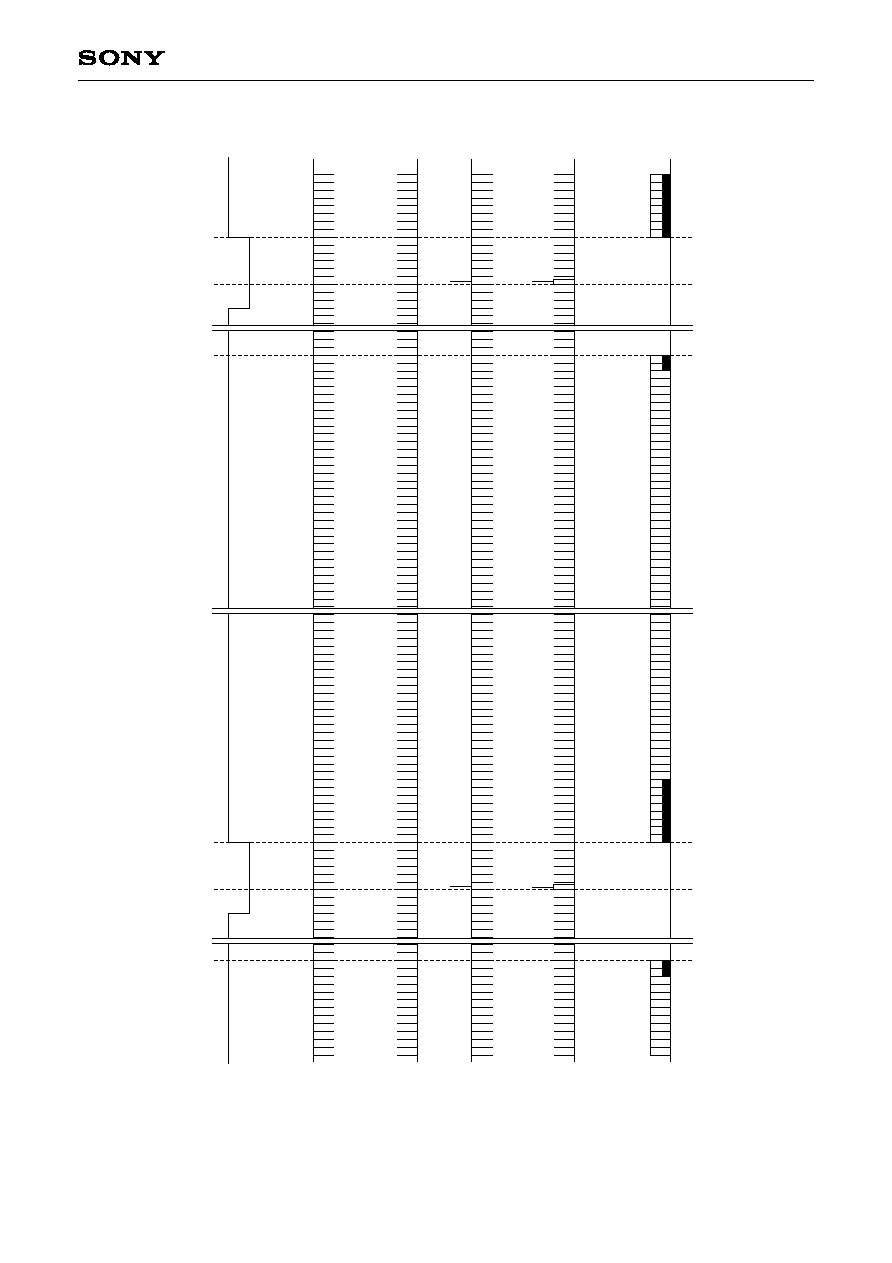

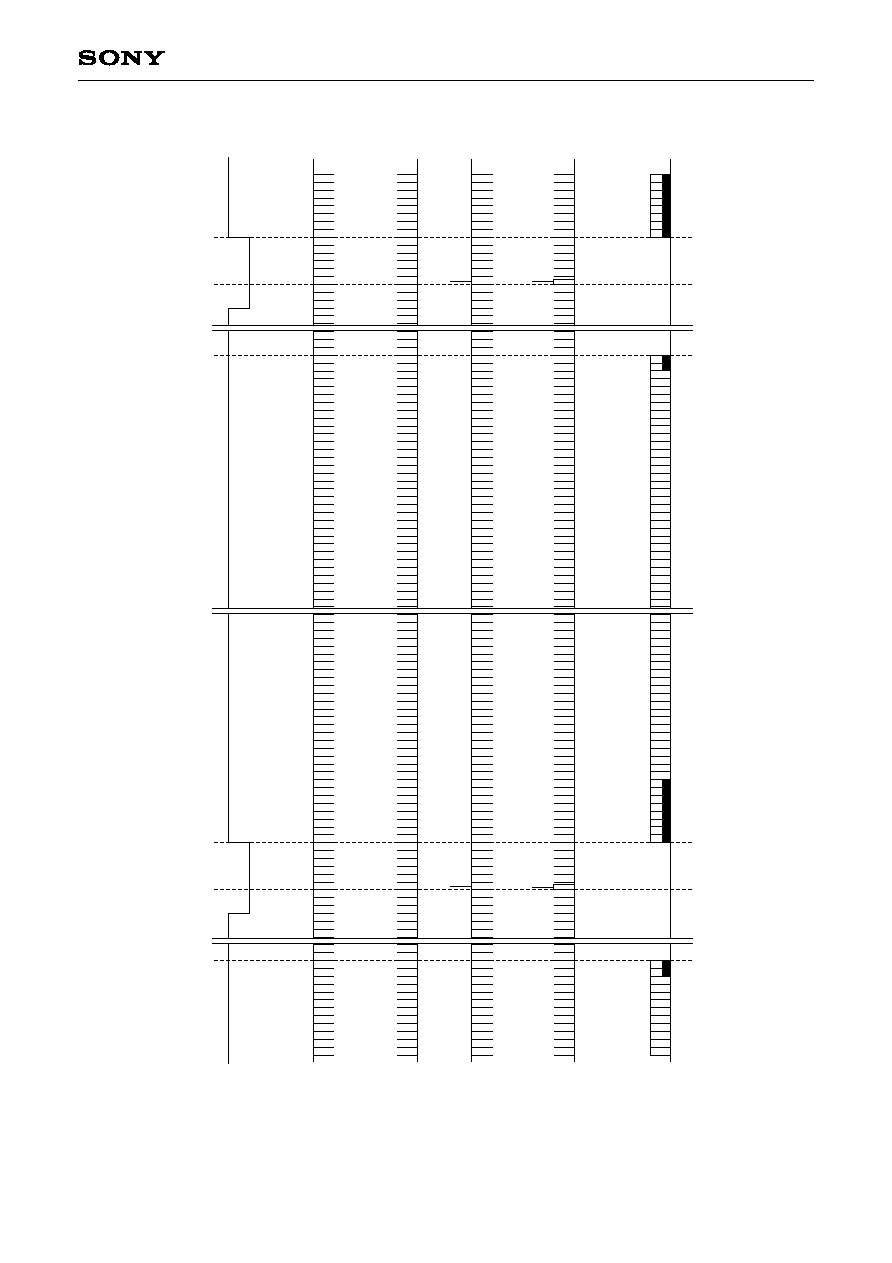

Zone Definition of Video Signal Shading

Measurement System

Note) Adjust the amplifier gain so that the gain between [

A] and [

B], and between [

A] and [

C] equals 1.

Item

G Sensitivity

Sensitivity

comparison

Saturation signal

Smear

Video signal shading

Uniformity between

video signal channels

Dark signal

Dark signal shading

Line crawl G

Line crawl R

Line crawl B

Lag

Symbol

Sg

Rr

Rb

Vsat

Sm

SHg

Srg

Sbg

Vdt

Vdt

Lcg

Lcr

Lcb

Lag

Min.

600

0.4

0.3

500

Typ.

750

0.55

0.45

≠100

Max.

0.7

0.6

≠92

20

25

8

8

2

0.5

3.8

3.8

3.8

0.5

Unit

mV

mV

dB

%

%

%

%

mV

mV

%

%

%

%

Measurement

method

1

1

1

2

3

4

4

5

5

6

7

8

8

8

9

Remarks

1/30s accumulation

Ta = 60∞C

Zone 0 and

I

Zone 0 to

II

'

Ta = 60∞C

Ta = 60∞C

Note) All image sensor characteristic data noted above is for operation in 1/60s progressive scan mode.

12

V

10

12

12

10

Ignored region

Effective pixel region

Zone 0,

I

Zone

II

,

II

'

V

10

H

8

H

8

659 (H)

494 (V)

CCD

C.D.S

S/H

S/H

AMP

CCD signal output [

A]

Gr/Gb channel signal output [

B]

R/B channel signal output [

C]

Gr/Gb

R/B

≠ 10 ≠

ICX424AQ

Image Sensor Characteristics Measurement Method

Measurement conditions

(1) In the following measurements, the device drive conditions are at the typical values of the bias and clock

voltage conditions.

(2) In the following measurements, spot blemishes are excluded and, unless otherwise specified, the optical

black level (OB) is used as the reference for the signal output, which is taken as the value of the Gr/Gb

channel signal output or the R/B channel signal output of the measurement system.

Color coding of this image sensor & Readout

The primary color filters of this image sensor are arranged in

the layout shown in the figure on the left (Bayer arrangement).

Gr and Gb denote the G signals on the same line as the R

signal and the B signal, respectively.

Gb

B

Gb

B

R

Gr

R

Gr

Gb

B

Gb

B

R

Gr

R

Gr

Horizontal register

Color Coding Diagram

All pixels signals are output successively in a 1/60s period.

The R signal and Gr signal lines and Gb signal and B signal lines are output successively.

≠ 11 ≠

ICX424AQ

1. Progressive scan mode

In this mode, all pixel signals are output in non-interlace format in 1/60s.

All pixel signals within the same exposure period are read out simultaneously, making this mode suitable for

high resolution image capturing.

Image sensor readout mode

The diagram below shows the output methods for the following two readout modes.

(1) Progressive scan mode

2. Center scan mode

This is the center scan mode using the progressive scan method.

The undesired portions are swept by vertical register high-speed transfer, and the picture center portion is

cut out.

There are the mode (120 frames/s) which outputs 222 lines of an output line portion, and the mode

(240 frames/s) which outputs 76 lines.

(2) Center scan mode

Undesired portions (Swept by vertical register high-speed transfer)

Picture center cut-out portion

V

OUT

R

G

R

R

G

G

B

B

G

G

≠ 12 ≠

ICX424AQ

Definition of standard imaging conditions

(1) Standard imaging condition

I

:

Use a pattern box (luminance: 706cd/m

2

, color temperature of 3200K halogen source) as a subject.

(Pattern for evaluation is not applicable.) Use a testing standard lens with CM500S (t = 1.0mm) as an IR

cut filter and image at F5.6. The luminous intensity to the sensor receiving surface at this point is defined

as the standard sensitivity testing luminous intensity.

(2) Standard imaging condition

II

:

Image a light source (color temperature of 3200K) with a uniformity of brightness within 2% at all angles.

Use a testing standard lens with CM500S (t = 1.0mm) as an IR cut filter. The luminous intensity is adjusted

to the value indicated in each testing item by the lens diaphragm.

1. G Sensitivity,sensitivity comparison

Set to standard imaging condition

I

. After setting the electronic shutter mode with a shutter speed of

1/100s, measure the signal outputs (V

Gr,

V

Gb,

V

R

and

V

B

) at the center of each Gr, Gb, R and B channel

screens, and substitute the values into the following formula.

V

G

= (V

Gr

+ V

Gb

)/2

Sg = V

G

◊

[mV]

Rr = V

R

/V

G

Rb = V

B

/V

G

2. Saturation signal

Set to standard imaging condition

II

. After adjusting the luminous intensity to 20 times the intensity with the

average value of the Gr signal output, 150mV, measure the minimum values of the Gr, Gb, R and B signal

outputs.

3. Smear

Set to standard imaging condition

II

. With the lens diaphragm at F5.6 to F8, first adjust the average value of

the Gr signal output to 150mV. Measure the average values of the Gr signal output, Gb signal output, R

signal output and B signal output (Gra, Gba, Ra and Ba), and then adjust the luminous intensity to 500

times the intensity with average value of the Gr signal output, 150mV. After the readout clock is stopped and

the charge drain is executed by the electronic shutter at the respective H blankings, measure the maximum

value (V

sm

[mV]), independent of the Gr, Gb, R and b signal outputs, and substitute the values into the

following formula.

Sm = 20

◊

log

(

Vsm

˜

◊

◊

)

[dB] (1/10V method conversion value)

4. Video signal shading

Set to standard imaging condition

II

. With the lens diaphragm at F5.6 to F8, adjust the luminous intensity so

that the average value of the Gr signal output is 150mV. Then measure the maximum (Grmax [mV]) and

minimum (Grmin [mV]) values of the Gr signal output and substitute the values into the following formula.

SHg = (Grmax ≠Grmin)/150

◊

100 [%]

100

30

1

500

Gra + Gba + Ra + Ba

4

1

10

≠ 13 ≠

ICX424AQ

5. Uniformity between video signal channels

After measuring 4, measure the maximum (Rmax [mV]) and minimum (Rmin [mV]) values of the R signal

and the maximum (Bmax [mV]) and minimum (Bmin [mV]) values of the B signal, and substitute the values

into the following formula.

Srg = | (Rmax ≠ Rmin)/150 |

◊

100 [%]

Sbg = | (Bmax ≠ Bmin)/150 |

◊

100 [%]

6. Dark signal

Measure the average value of the signal output (Vdt [mV]) with the device ambient temperature 60∞C and

the device in the light-obstructed state, using the horizontal idle transfer level as a reference.

7. Dark signal shading

After measuring 6, measure the maximum (Vdmax [mV]) and minimum (Vdmin [mV]) values of the dark

signal output and substitute the values into the following formula.

Vdt = Vdmax ≠ Vdmin [mV]

8. Line crawls

Set to standard imaging condition

II

. Adjust the luminous intensity so that the average value of the Gr signal

output is 150mV, and then insert R, G, and B filters and measure the difference between G signal lines

(

Glr, Glg, Glb [mV]).as well as the average value of the G signal output (Gar, Gag, Gab). Substitute the

values into the following formula.

Lci =

◊

100 [%] (i = w, r, g, b)

9. Lag

Adjust the Gr signal output value generated by strobe light to 150mV. After setting the strobe light so that it

strobes with the following timing, measure the residual signal (Vlag). Substitute the value into the following

formula.

Lag = (Vlag/150)

◊

100 [%]

Light

Signal output 150mV

Vlag (lag)

VD

V2

Strobe light

timing

Output

Gli

Gai

≠ 14 ≠

ICX424AQ

Drive Cir

cuit

XSUB

XV3

XSG3

XV2

XSG2

XV1

H

2

H

1

RG

CCD

OUT

≠7.5V

0.1

0.1

0.1

1000p

0.1

0.01

2200p

3.3/16V

3.3/20V

0.1

1/35V

100k

1M

4.7k

2SC4250

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

ICX424

(BO

TT

OM VIEW)

V

3

V

2

V

1

NC

GND

C

GG

GND

V

OUT

H

2

H

1

RG

V

L

SUB

GND

SUBCIR

V

DD

11

12

13

14

15

16

17

18

19

20

10

9

8

7

6

5

4

3

2

1

CXD3400N

15V

3.3V

≠ 15 ≠

ICX424AQ

Spectral Sensitivity Characteristics (Includes lens characteristics, excludes light source characteristics)

400

1.0

B

G

R

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

450

500

550

Wave Length [nm]

Relativ

e Response

600

650

700

≠ 16 ≠

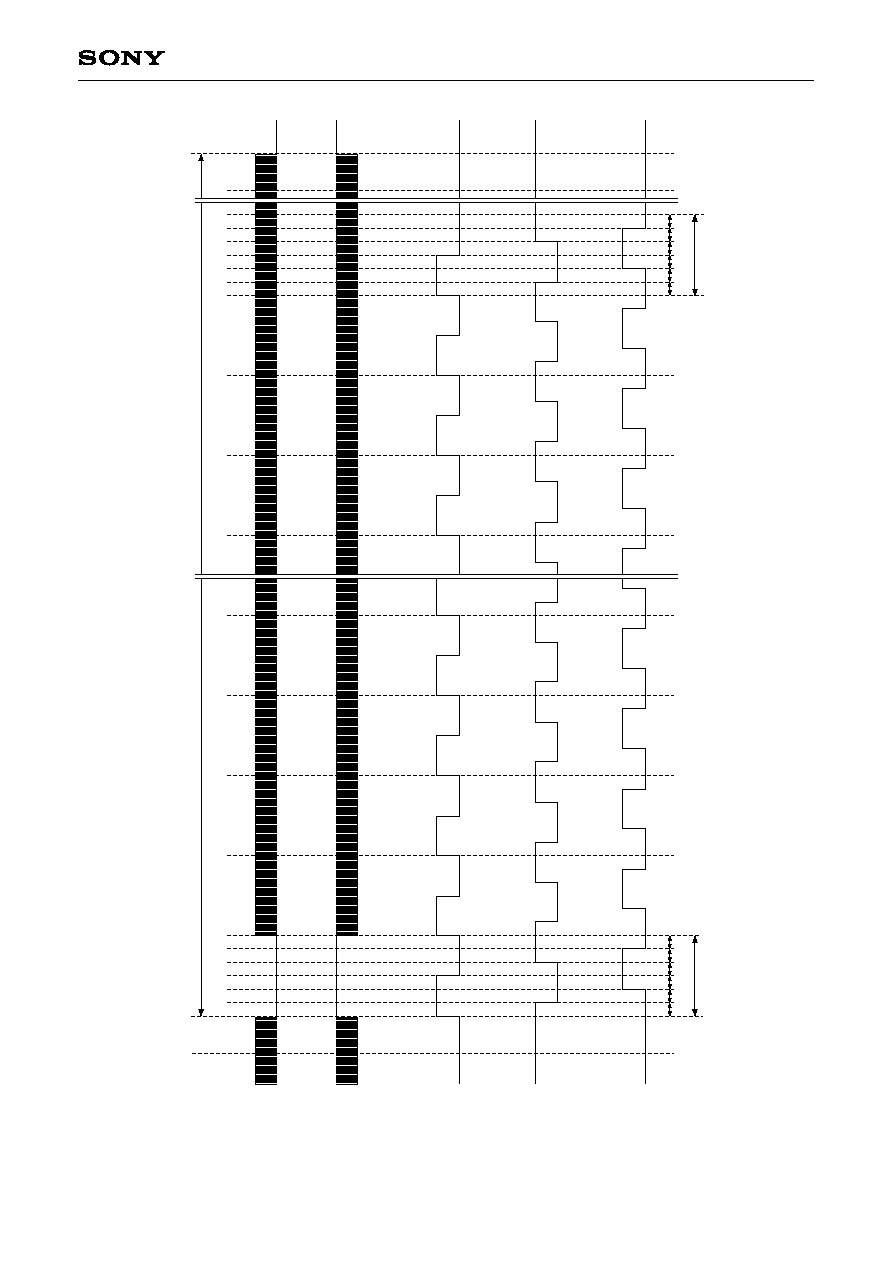

ICX424AQ

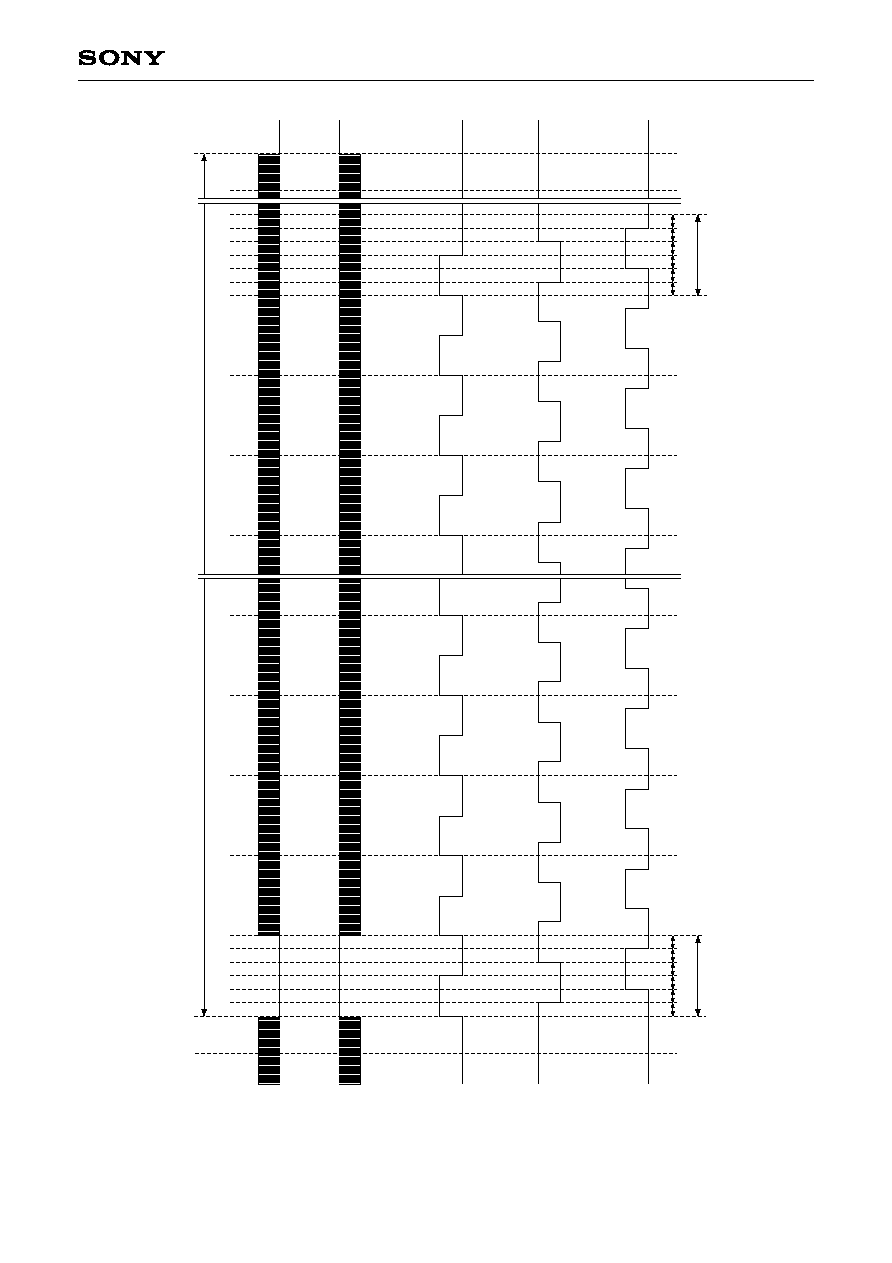

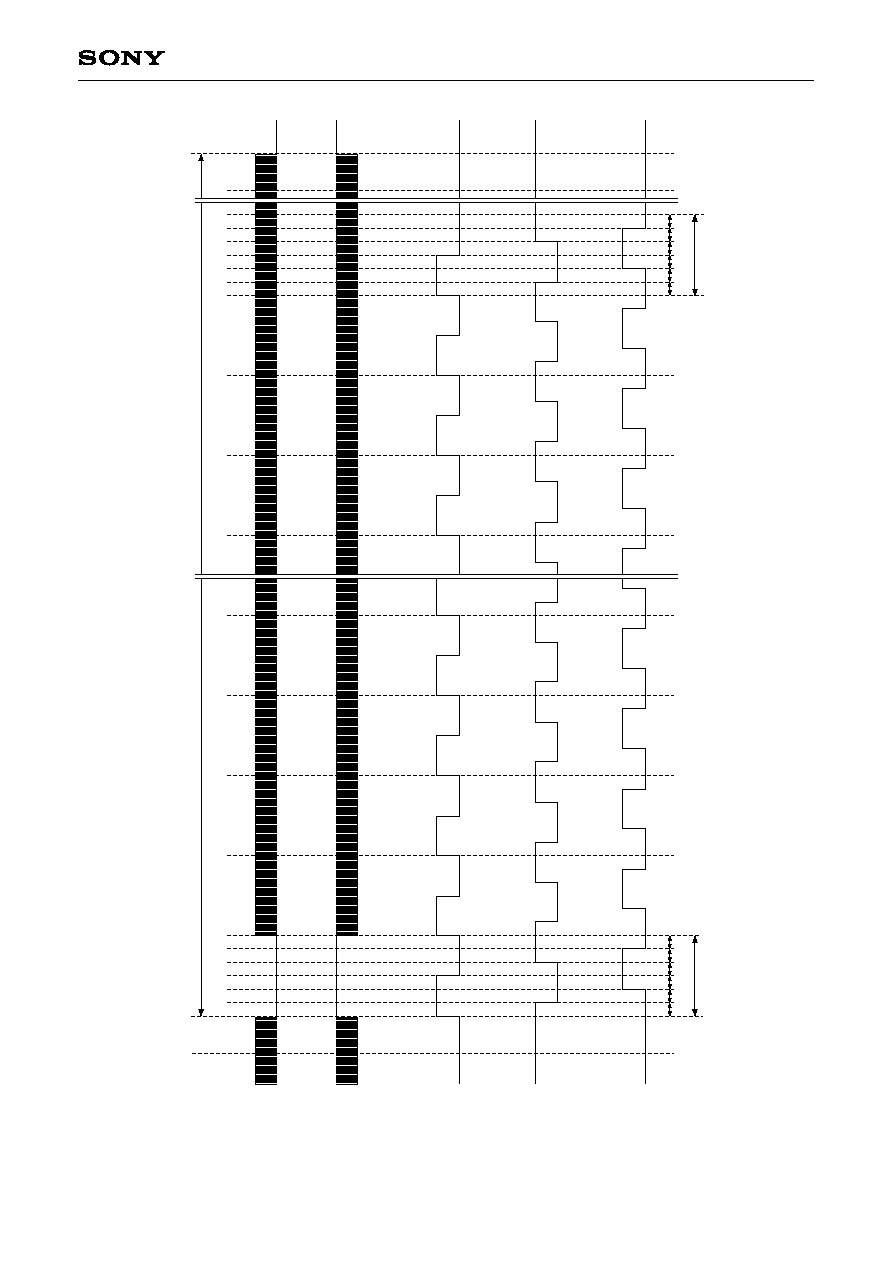

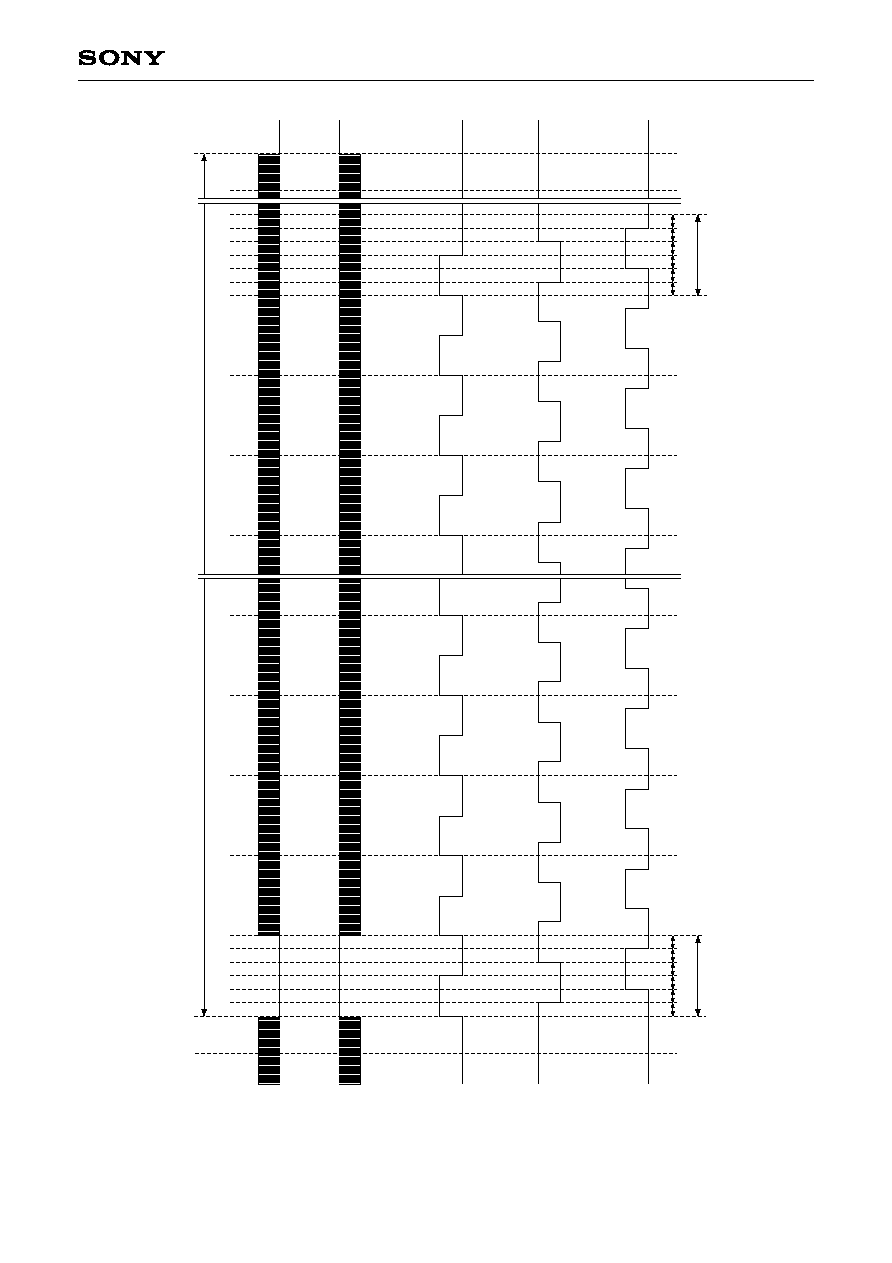

Drive

Timing Char

t (V

e

r

tical Sync) Pr

ogressive Scan Mode

494

1

2

6

5

494

1

2

7

8

1

2

3

4

6

5

7

8

1

2

3

4

1

2

3

VD

HD

"a"

V1

V2

V3

OUT

525

510

1

7

508

510

1

525

7

≠ 17 ≠

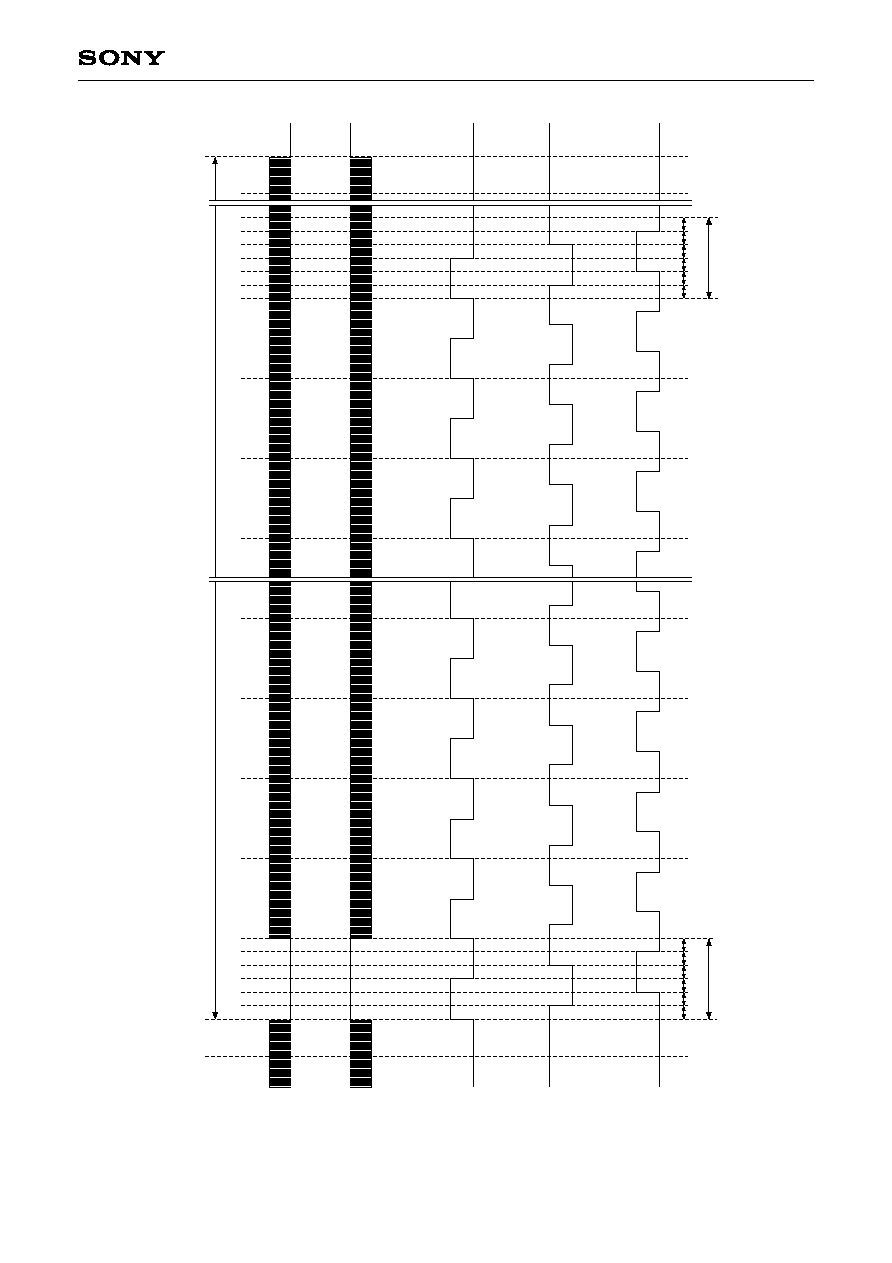

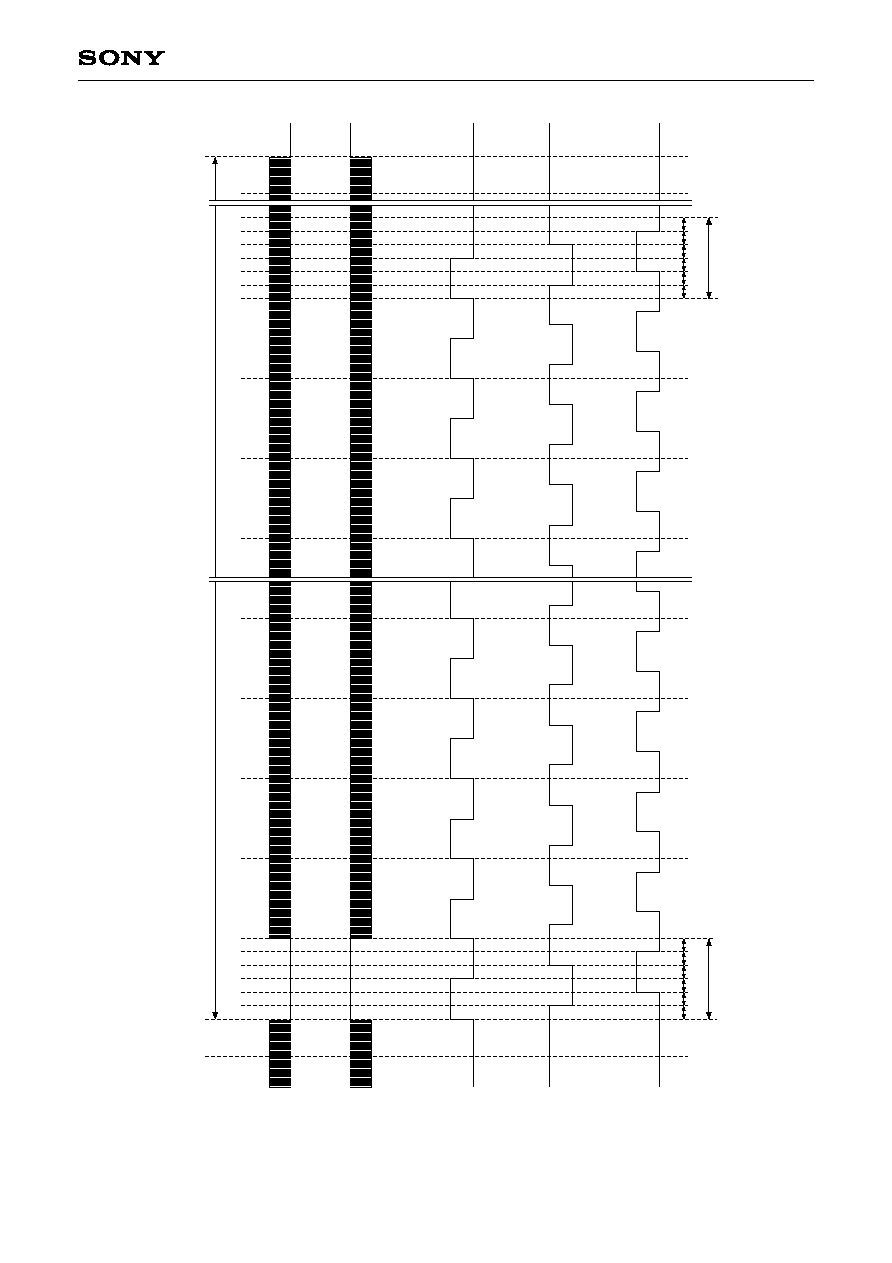

ICX424AQ

Drive

Timing Char

t (V

e

r

tical Sync "a" Enlar

g

ed) Pr

ogressive Scan Mode/Center Scand Mode

"a" Enlar

g

e

d

12

12

12

12

12

12

12

12

12

12

12

12

50

62

520

582

H1

V1

V2

V3

≠ 18 ≠

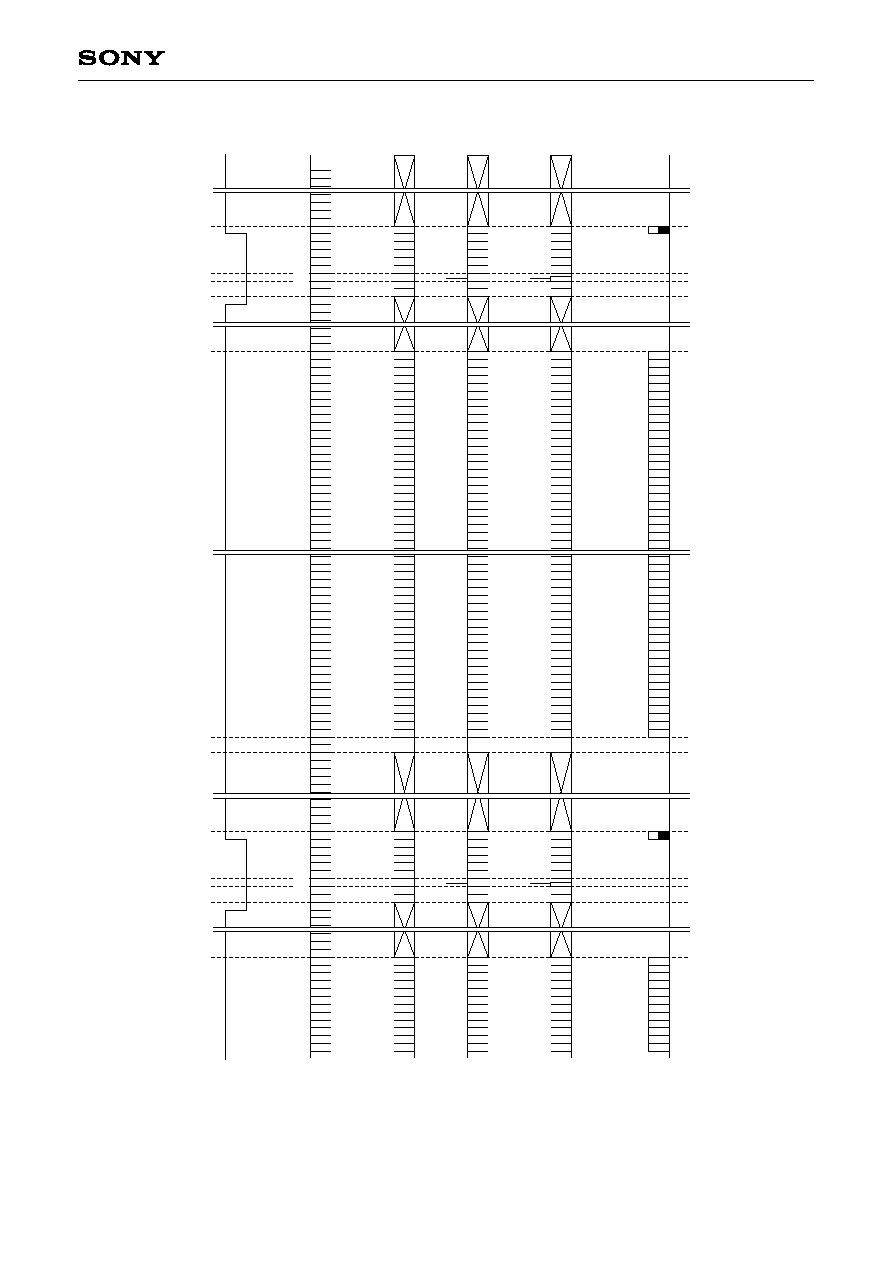

ICX424AQ

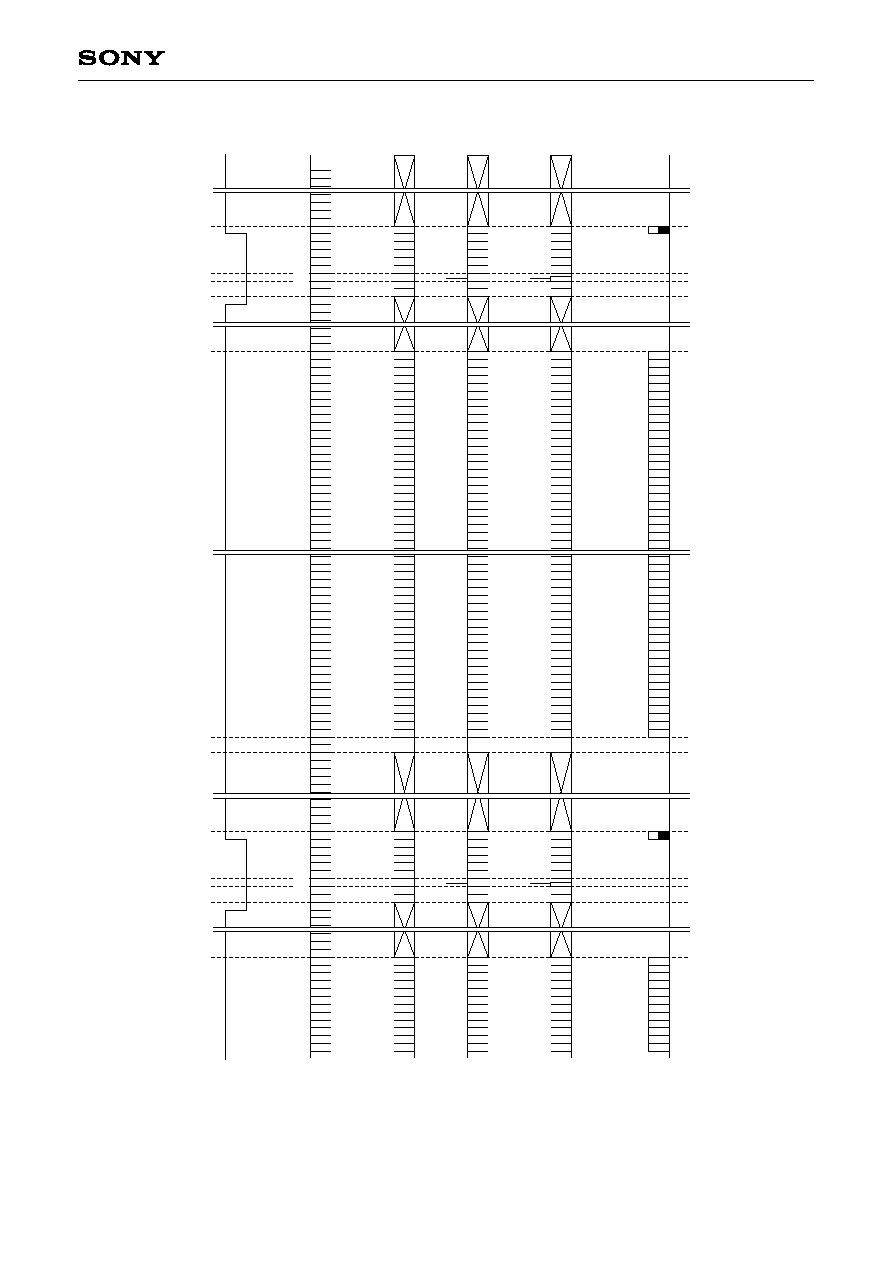

Drive

Timing Char

t (Horizontal Sync) Pr

ogressive Scan Mode

1

1

36

36

1

1

12

1

36

24

12

12

1

1

24

36

1

1

1

12

3

780

1

1

35

1

123

125

107

72

1

16

CLK

H1

H2

SHP

SHD

V1

V2

V3

SUB

RG

37

≠ 19 ≠

ICX424AQ

Drive

Timing Char

t (V

e

r

tical Sync) Center Scan Mode 1

356

357

136

137

1

356

357

1

VD

HD

"d"

"

b"

"c"

V1

V2

V3

OUT

"a"

"d"

"

b"

"a"

246

245

261

262

1

2

3

4

5

6

7

8

20

21

24

246

245

261

262

1

2

3

4

5

6

7

8

≠ 20 ≠

ICX424AQ

Drive

Timing Char

t (Horizontal Sync) Center Scan Mode 1 (Frame Shift) ("b")

12

12

12

12

#1

12

12

12

12

12

12

12

12

H1

H2

V1

V2

V3

#142

35

72

10920 bits = 14H

≠ 21 ≠

ICX424AQ

Drive

Timing Char

t (Horizontal Sync) Center Scan Mode 1 (High-speed Sweep) ("d")

12

12

12

12

#1

12

12

12

12

12

12

12

12

H1

H2

V1

V2

V3

#167

35

72

12480 bits = 16H

≠ 22 ≠

ICX424AQ

Drive

Timing Char

t (V

e

r

tical Sync) Center Scan Mode 2

283

284

209

210

1

283

284

1

VD

HD

"d"

"

b"

"c"

V1

V2

V3

OUT

"a"

"d"

"

b"

"a"

106

105

130

131

1

2

3

4

5

6

7

8

30

27

26

129

106

105

130

131

1

2

3

4

5

6

7

8

129

≠ 23 ≠

ICX424AQ

Drive

Timing Char

t (Horizontal Sync) Center Scan Mode 2 (Frame Shift) ("b")

12

12

12

12

#1

12

12

12

12

12

12

12

12

H1

H2

V1

V2

V3

#215

35

72

15600 bits = 20H

≠ 24 ≠

ICX424AQ

Drive

Timing Char

t (Horizontal Sync) Center Scan Mode 2 (High-speed Sweep) ("d")

12

12

12

12

#1

12

12

12

12

12

12

12

12

H1

H2

V1

V2

V3

#255

35

72

18720 bits = 24H

≠ 25 ≠

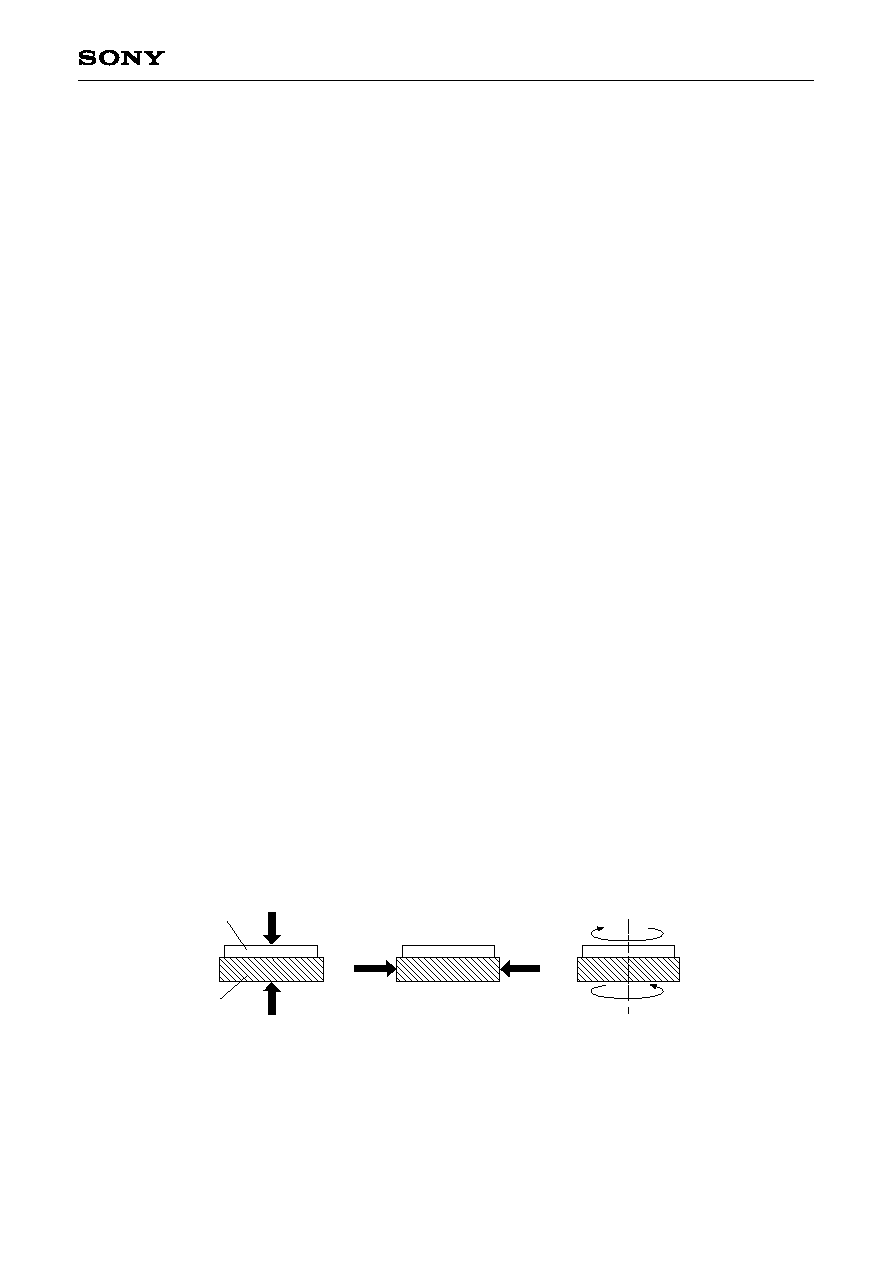

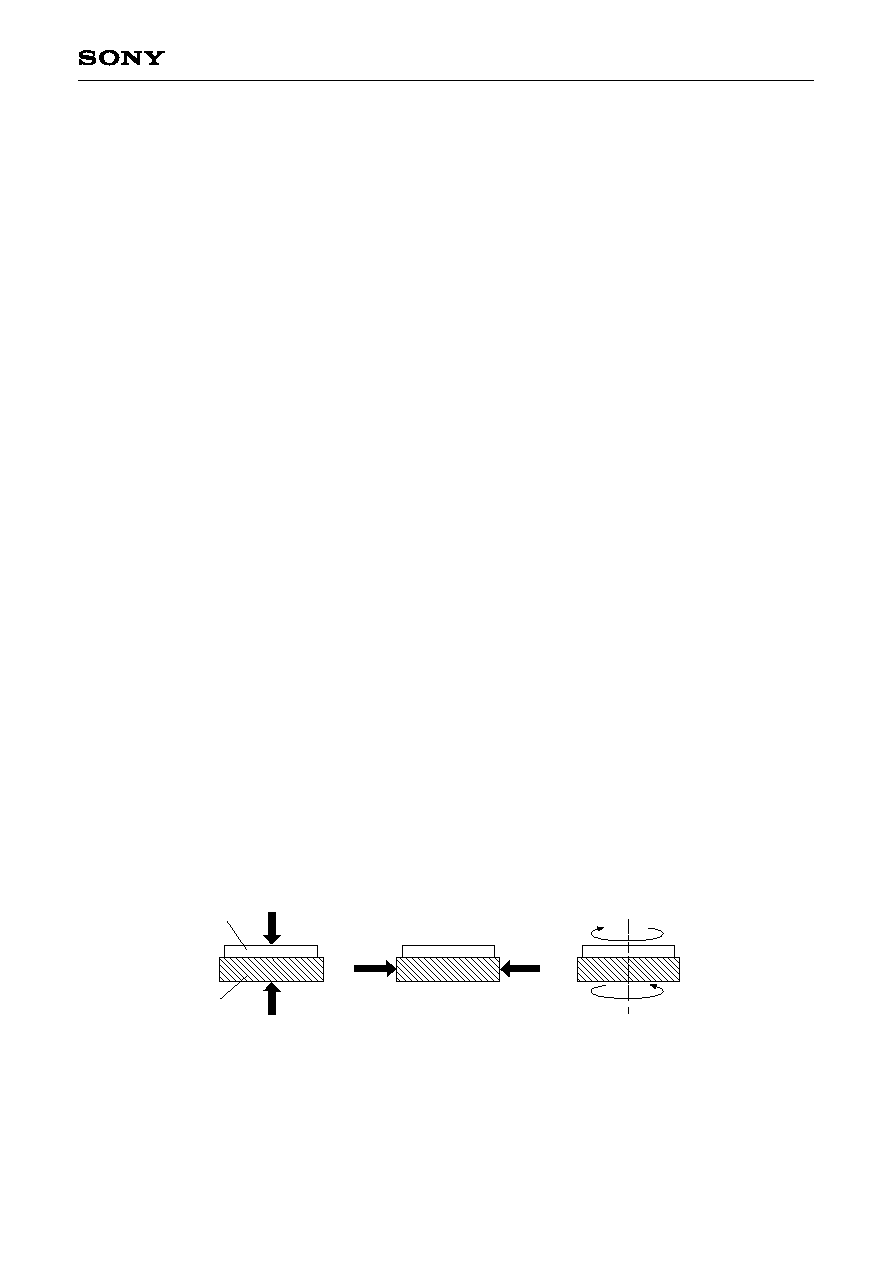

ICX424AQ

Plactic package

Cover glass

Compressive strength

50N

50N

1.2Nm

Torsional strength

Notes on Handling

1) Static charge prevention

CCD image sensors are easily damaged by static discharge. Before handling be sure to take the following

protective measures.

a) Either handle bare handed or use non-chargeable gloves, clothes or material.

Also use conductive shoes.

b) When handling directly use an earth band.

c) Install a conductive mat on the floor or working table to prevent the generation of static electricity.

d) Ionized air is recommended for discharge when handling CCD image sensors.

e) For the shipment of mounted substrates, use boxes treated for the prevention of static charges.

2) Soldering

a) Make sure the package temperature does not exceed 80∞C.

b) Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a 30W

soldering iron with a ground wire and solder each pin in less than 2 seconds. For repairs and remount,

cool sufficiently.

c) To dismount an image sensor, do not use a solder suction equipment. When using an electric desoldering

tool, use a thermal controller of the zero-cross On/Off type and connect it to ground.

3) Dust and dirt protection

Image sensors are packed and delivered by taking care of protecting its glass plates from harmful dust and

dirt. Clean glass plates with the following operations as required, and use them.

a) Perform all assembly operations in a clean room (class 1000 or less).

b) Do not either touch glass plates by hand or have any object come in contact with glass surfaces. Should

dirt stick to a glass surface, blow it off with an air blower. (For dirt stuck through static electricity ionized

air is recommended.)

c) Clean with a cotton bud and ethyl alcohol if grease stained. Be careful not to scratch the glass.

d) Keep in a case to protect from dust and dirt. To prevent dew condensation, preheat or precool when

moving to a room with great temperature differences.

e) When a protective tape is applied before shipping, just before use remove the tape applied for

electrostatic protection. Do not reuse the tape.

4) Installing (attaching)

a) Remain within the following limits when applying a static load to the package. Do not apply any load

more than 0.7mm inside the outer perimeter of the glass portion, and do not apply any load or impact to

limited portions. (This may cause cracks in the package.)

b) If a load is applied to the entire surface by a hard component, bending stress may be generated and the

package may fracture, etc., depending on the flatness of the bottom of the package. Therefore, for

installation, use either an elastic load, such as a spring plate, or an adhesive.

≠ 26 ≠

ICX424AQ

c) The adhesive may cause the marking on the rear surface to disappear, especially in case the regulated

voltage value is indicated on the rear surface. Therefore, the adhesive should not be applied to this area,

and indicated values should be transferred to other locations as a precaution.

d) The notch of the package is used for directional index, and that can not be used for reference of fixing.

In addition, the cover glass and seal resin may overlap with the notch of the package.

e) If the leads are bent repeatedly and metal, etc., clash or rub against the package, the dust may be

generated by the fragments of resin.

f) Acrylate anaerobic adhesives are generally used to attach CCD image sensors. In addition, cyano-

acrylate instantaneous adhesives are sometimes used jointly with acrylate anaerobic adhesives.

(reference)

5) Others

a) Do not expose to strong light (sun rays) for long periods, color filters will be discolored. When high

luminance objects are imaged with the exposure level control by electronic-iris, the luminance of the

image-plane may become excessive and discolor of the color filter will possibly be accelerated. In such a

case, it is advisable that taking-lens with the automatic-iris and closing of the shutter during the power-off

mode should be properly arranged. For continuous using under cruel condition exceeding the normal

using condition, consult our company.

b) Exposure to high temperature or humidity will affect the characteristics. Accordingly avoid storage or

usage in such conditions.

c) Brown stains may be seen on the bottom or side of the package. But this does not affect the CCD

characteristics.

≠ 27 ≠

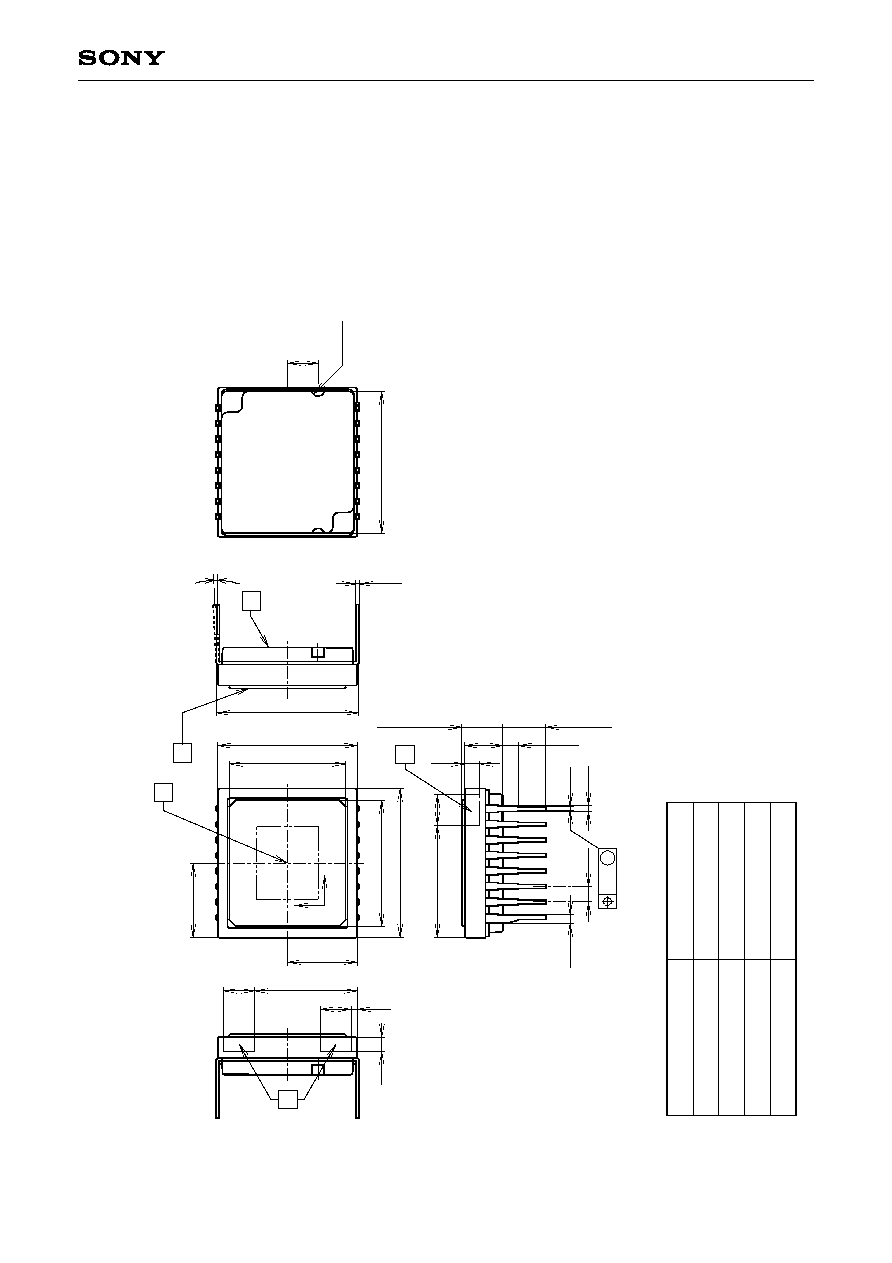

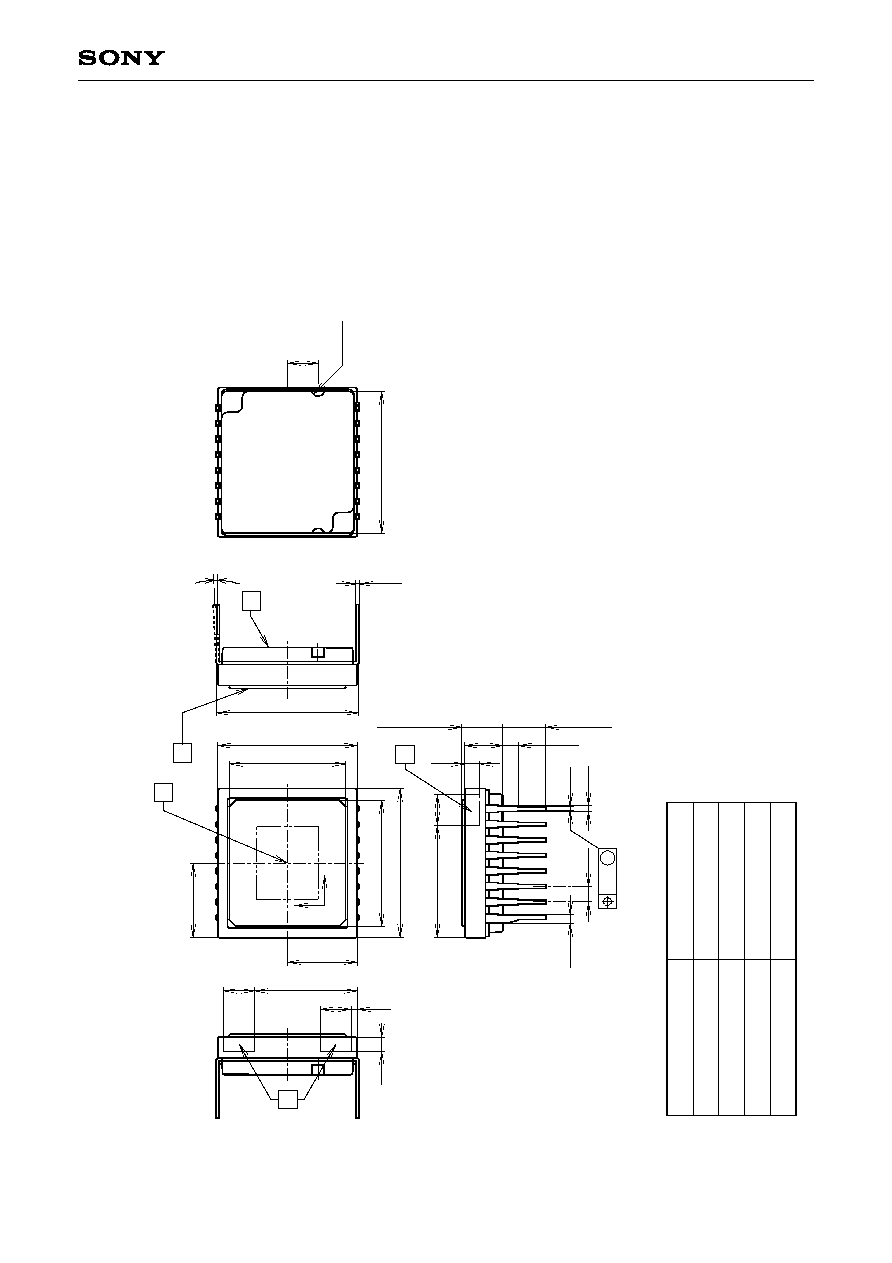

ICX424AQ

Sony Corporation

P

a

c

k

ag

e Outline

Unit:

mm

0.3

16 pin DIP (450mil)

H

V

2.5

2.5

8.4

0.5

1.2

5.7

6.1

10.3

12.2 ±

0.1

9.5

11.4 ± 0.1

11.43

0.25

0∞ to 9∞

8

1

16

9

2-R0.5

2.5

11.6

9.2

2.5

1.2

3.35 ± 0.15

3.1

1.27

3.5 ± 0.3

0.46

0.3

1.27

0.69

(F

or the first pin only)

1.

"A"

is the center of the eff

e

ctiv

e image area.

2.

The tw

o points

"B"

of the pac

kage are the hor

iz

ontal ref

e

rence

.

The point

"B'"

of the pac

k

age is the v

e

r

tical ref

e

rence

.

3.

The bottom

"C"

of the pac

kage

, and the top of the co

v

e

r glass

"D"

are the height ref

e

rence

.

4.

The center of the eff

e

ctiv

e image area relativ

e to

"B"

and

"B'"

is (H,

V) = (6.1, 5.7) ± 0.15mm.

5.

The rotation angle of the eff

ectiv

e image area relativ

e to H and

V is ± 1∞

.

6.

The height from the bottom

"C"

to the eff

ectiv

e image area is 1.41 ± 0.10mm.

The height from the top of the co

v

e

r glass

"D"

to the eff

ectiv

e image area is 1.94 ± 0.15mm.

7.

The tilt of the eff

e

ctiv

e image area relativ

e to the bottom

"C"

is less than 50µm.

The tilt of the eff

e

ctiv

e image area relativ

e to the top

"D"

of the co

v

e

r glass is less than 50µm.

8.

The thic

kness of the co

v

er glass is 0.75mm, and the refr

activ

e inde

x is 1.5.

9.

The notches on the bottom of the pac

kage are used only f

o

r directional inde

x, the

y

m

u

st

not be used f

o

r ref

e

rence of fixing.

C

B

A

D

M

B'

~

~

~

P

A

CKA

GE STR

UCTURE

P

A

CKA

GE MA

TERIAL

LEAD TREA

TMENT

LEAD MA

TERIAL

P

A

CKA

GE MASS

DRA

WING NUMBER

Plastic

GOLD PLA

TING

42 ALLO

Y

AS-C2.2-01(E)

0.90g