| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L9380 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

L9380

TRIPLE HIGH-SIDE MOSFET DRIVER

OVERVOLTAGE CHARGE PUMP SHUT OFF

FOR V

VS

> 25V

REVERSE BATTERY PROTECTION (REFER-

RING TO THE APPLICATION CIRCUIT DIA-

GRAM)

PROGRAMMABLE OVERLOAD PROTEC-

TION FUNCTION FOR CHANNEL 1 AND 2

OPEN GROUND PROTECTION FUNCTION

FOR CHANNEL 1 AND 2

CONSTANT GATE CHARGE/DISCHARGE

CURRENT

DESCRIPTION

The L9380 device is a controller for three external

N-channel power MOS transistors in "High-Side

Switch" configuration. It is intended for relays re-

placement in automotive electric control units.

April 1998

T1

VS

N.C.

T2

PR

IN2

IN3

IN1

EN

G2

N.C.

S2

G1

S1

D2

N.C.

D1

CP

1

3

2

4

5

6

7

8

9

18

17

16

15

14

12

13

11

19

10

20

GND

G3

D98AT391

PIN CONNECTION (Top view)

SO20

ORDERING NUMBER: L9380

1/12

VS

GND

DRIVER 1

1

ENN

-

CHARGE PUMP

OVERVOLTAGE

CP

T1

VSI

IN1

+

1

VSI

T2

IN2

IN3

EN

CP

IPR

D1

S1

G1

DRIVER 2

1

ENN

-

VSI

+

1

VSI

CP

D2

S2

G2

IPR

ENN

1

VSI

CP

DRIVER 3

G3

ENN

VS

VSI

PR

I

PR

2V

REFERENCE

REG.

D98AT390

BLOCK DIAGRAM

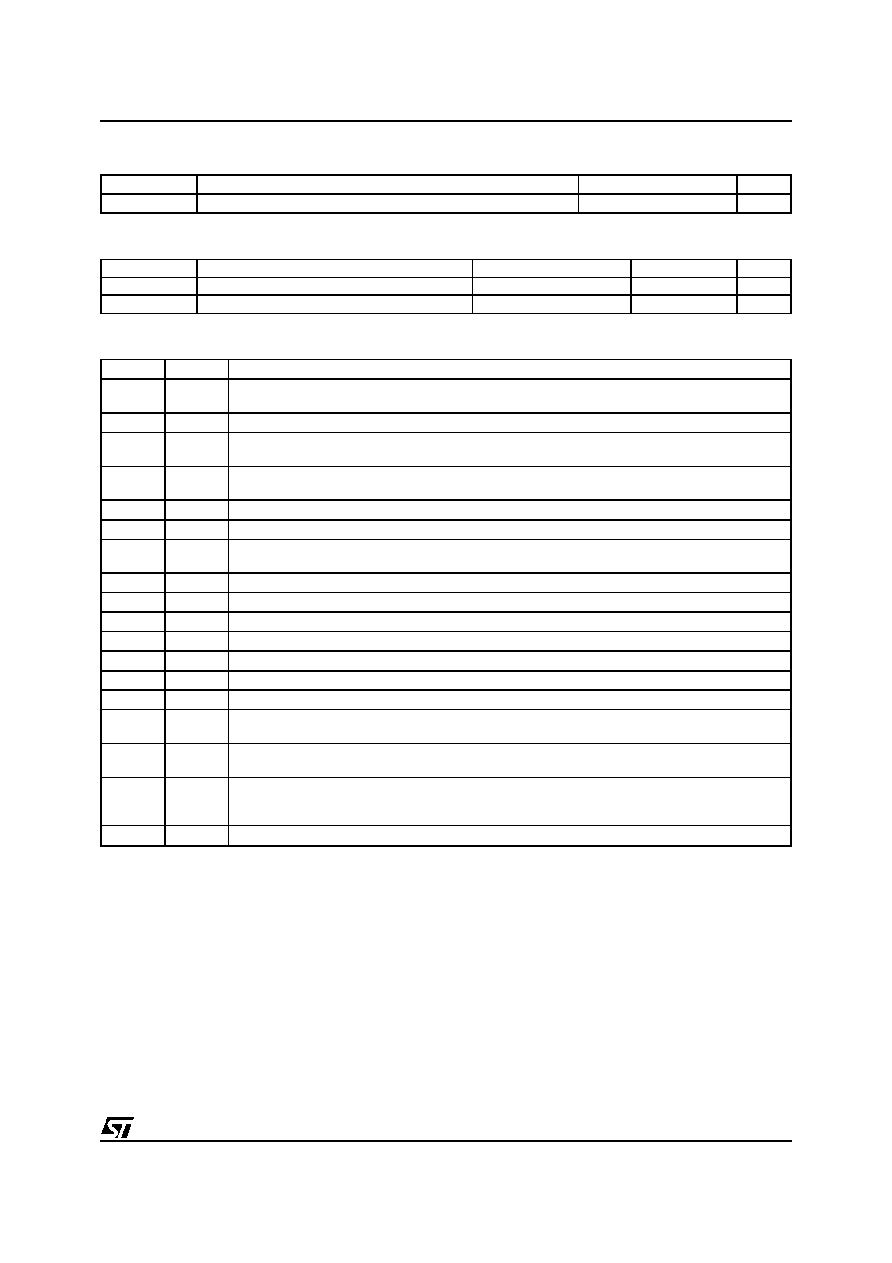

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Value

Unit

V

S

DC Supply Voltage

-0.3 to +27

V

V

S

Supply Voltage pulse (t

400ms)

45

V

V

S

/dt

Supply Voltage slope

-10 to +10

V/

µ

s

V

IN,EN

Input / Enable Voltage

-0.3 to +7

V

V

T

Timer Voltage

-0.3 to 27

V

V

D, G, S

Drain, gate, source voltage

-15 to +27

V

V

D, G, S

Drain, gate, source voltage pulse (t

400ms)

45

V

I

D, G, S

Drain, gate, source current (t

2ms)

0 to +4

mA

T

j

Operating Junction Temperature

-40 to 150

∞C

T

stg

Storage Temperature

-65 to 150

∞C

Note: ESD for all pins, except the timer pins, are according to MIL 883C, tested at 2KV, corresponds to a maximum energy dissipation of 0.2mJ.

The timer pins are tested with 800V

L9380

2/12

THERMAL DATA

Symbol

Parameter

Value

Unit

R

th j-amb

Thermal Resistance Junction to Ambient

100

∞C/W

LIFETIME

Symbol

Parameter

Condition

Value

Unit

t

B

Useful life time

V

S

= 0V

20

years

t

b

Operating life time

V

S

= 7 to 18.5V

5000

hours

PIN FUNCTIONS

N.

Name

Function

1

T1

Timer capacitor; the capacitor defines the time for the channel 1 shut down, after overload of

the external MOS transistor has been detected.

2

V

S

Supply Voltage.

4

T2

Timer capacitor; the capacitor defines the time for the channel 2 shut down, after overload of

the external MOS transistor has been detected.

5

PR

Programming resistor for overload detetcion threshold; the resistor from this pin to ground

defines the drain pin current and the charging of the timer capacitor.

6

IN3

Input 3; equal to IN1.

7

IN2

Input 2; equal to IN1.

8

IN1

Input 1; logic signal applied to this pin controls the driver 1; this pin features a current source to

assure defined high status when the pin is open.

9

EN

Enable logic signal high on this pin enables all channels

10

GND

Ground

11

G3

Gate 3 driver output; current source from CP or ground

12

G2

Gate 2 driver output; current source from CP or ground

14

S2

Source 2 sense input; monitors the source voltage.

15

S1

Source 1 sense input; monitors the source voltage.

16

G1

Gate 1 driver output; current source from CP or ground

17

D2

Drain 2 sense input; a programmable input bias current defines the drop across the external

resistor R

D1

; this drop fixes the overload threshold of the external MOS.

19

D1

Drain 1 sense input; a programmable input bias current defines the drop across the external

resistor R

D1

; this drop fixes the overload threshold of the external MOS.

20

CP

Charge pump capacitor; a alternating current source at this pin charges the connected

capacitor C

CP

to a voltage 10V higher than VS; the charge stored in this capacitor is thanused

to charge all the three gates of the power MOS transistors.

3, 13, 18

NC

Not connected

L9380

3/12

FUNCTIONAL DESCRIPTION

The Triple High-Side Power-MOS Driver features

all necessary control and protection functions to

switch on three Power-MOS transistors operating

as High-Side switches in automotive electronic

control units. The key application field is relays re-

placement in systems where high current loads,

usually motors with nominal currents of about 40A

connected to ground, has to be switched.

A high signal at the EN pin enables all three

channels. With enable low gates are clamped to

ground. In this condition the gate sink current is

higher than the specified 3mA. An enable low sig-

nal makes also a reset of the timer.

A low signal at the inputs switch on the gates of

the external MOS. A short circuit at the input

leads to permanent activation of the concerned

channel. In this case the device can be disabled

with the enable pin. The charge pump loading is

not influenced due to the enable input.

An external N-channel MOS driver in high side

configuration needs a gate driving voltage higher

than V

S

. It is generated by means of a charge

pump with integrated charge transfer capacitors

and one external charge storage capacitor C

CP

.

The charge pump is dimensioned to load a ca-

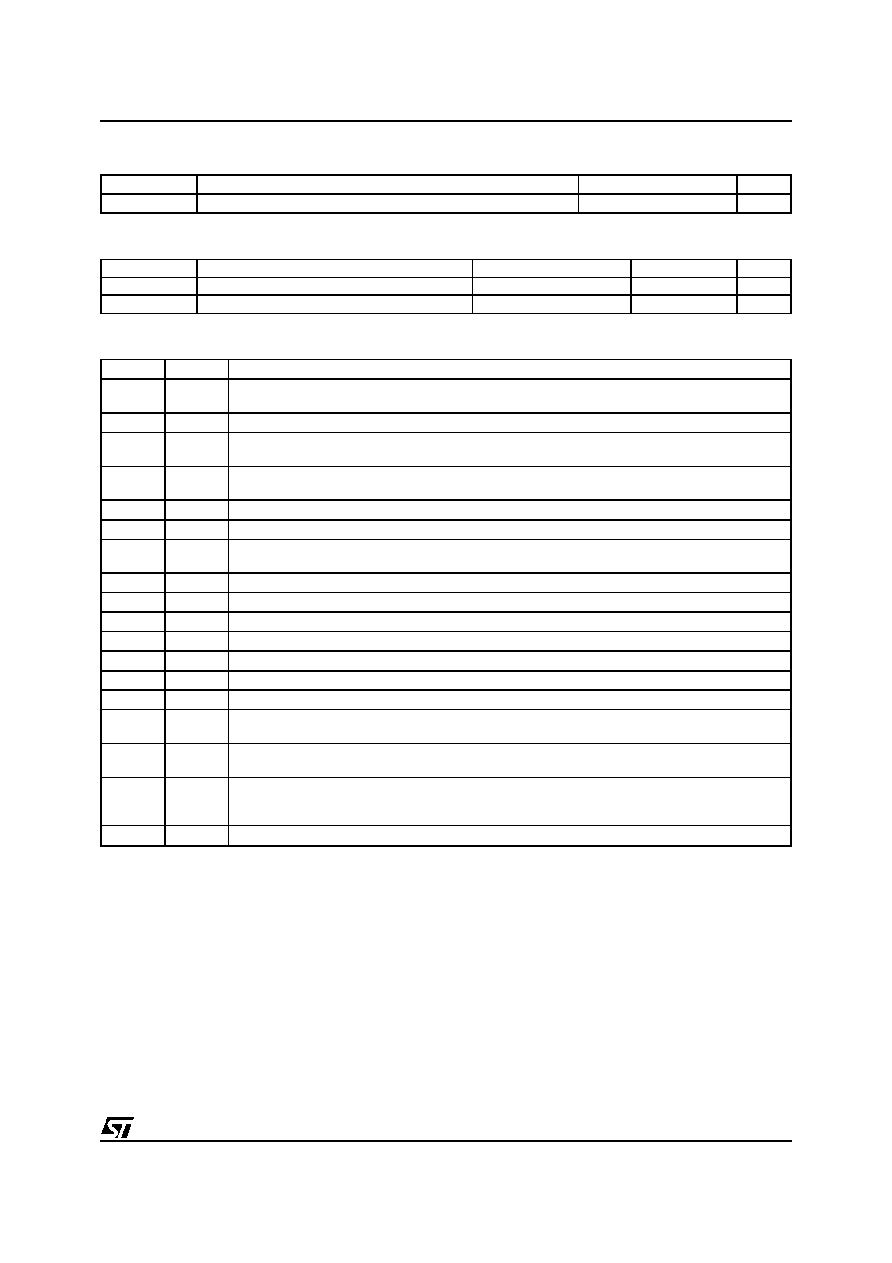

ELECTRICAL CHARACTERISTICS (7V

V

S

18.5V; -40∞C

T

J

150∞C, unless otherwise specified.)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

SUPPLY

I

VS

Static Operating Supply Current

V

S

= 14V

2.5

mA

CHARGE PUMP

V

CP

Charge Pump Voltage Above V

S

8

17

V

t

CP

Charging Time

V

CP

= V

S

+ 8V C

CP

= 100pF

200

µ

s

V

SCP off

Overvoltage Shut down

20

30

V

V

SCP hys

Overvoltage Shut down

Hysteresis

1)

50

200

1000

mV

f

CP

Charge Pump frequency

1)

100

250

400

KHz

GATE DRIVERS

I

GSo

Gate Source Current

V

G

= V

S

-5

-3

-1

mA

I

GSi

Gate Sink Current

V

G

0.8V

1

3

5

mA

DRAIN - SOURCE SENSING

V

PR

Bias Current Programming

voltage

10

µ

A

I

PR

100

µ

A; V

D

4V

1.8

2

2.2

V

I

D Leak

Drain pin leakage current

V

S

= 0V; V

D

=14V

0

5

µ

A

I

D

Drain pin bias current

V

S

V

D

+ 1V; V

D

5V

0.9 I

PR

1.1 I

PR

I

Smax

Source pin input current

V

S

V

D

+ 1V; V

D

7V

10

60

µ

A

V

HYST

Comparator Hysteresis

20

mV

TIMER

V

THi

Timer threshold high

4

4.4

4.8

V

V

TLo

Timer threshold low

0.3

0.4

0.5

V

I

T

Timer Current

IN = 5V; V

T

= 2V

IN = 0V; V

S

< V

D

;

V

D

5V; V

T

= 2V

0.4 I

PR

-0.6 I

PR

0.6 I

PR

-0.4 I

PR

INPUTS

V

LOW

Input Enable low voltage

-0.3

1

V

V

HIGH

Input Enable high voltage

3

7

V

V

INhys

Input Enable Hysteresis

(1)

50

200

500

mV

I

IN

Input source current

V

IN

3V

-30

-5

µ

A

I

EN

Enable sink current

V

EN

1V

5

30

µ

A

t

d

Transfer time IN/ENABLE

V

S

= 14V V

G

= V

S

; OPEN GATE

2.5

µ

s

NOTE: Not measured guaranteed by design

Function is given for supply voltage down to 5.5V. Function means: The channels are controlled from the

inputs, some other parameters may exceed the limit. In this case the programming voltage and timer

threshold will be lower. This leads to a lower protection threshold and time.

L9380

4/12

pacitor C

CP

of 33nF in less than 20ms up to 8V

above V

S

. The value of C

CP

depends on the input

capacitance of the external MOS and the decay

of the charge pump voltage down to that value

where no significant influence on the application

occurs.

The necessary charging time for C

CP

has to be

respected in the sequence of the input control sig-

nals. As a consequence the lower gate to source

voltage can cause a higher drop across the

Power-MOS and get into overload condition. In

this case the overload protection timer will start.

After the protection time the concerned channel

will be switched off. Channel 3 is not equipped

with an overload protection. The same situation

can occur due to a discharge of the storage ca-

pacitor caused by the gate short to ground. The

gate driver that is supplied from the pin CP, which

is the charge pump output, has a sink and source

current capability of 3mA. For a short-circuit of the

load (source to ground) the L9380 has no gate to

source limitation. The gate source protection must

be done externally.

Channel 1 and 2 provide drain to source voltage

sensing possibility with programmable shut-off

delay when the activation threshold was ex-

ceeded. This threshold V

DSmin

is set by the exter-

nal resistor R

D

. The bias current flowing through

this resistor is determined by the programming re-

sistor R

PR

. This external resistor R

PR

defines also

the charge and discharge current of the timer ca-

pacitor C

CT

. The drain to source threshold V

DSmin

and the timer shut off delay time T

off

can be cal-

culated:

V

DS

min = V

PR

(R

D

/R

PR

)

T

off

= 4.4 C

T

R

PR

V

IN

V

G

V

S

V

T

4.4V

0.4V

V

DSmin

t

d

t

d

T

off

D98AT392

Figure 4. Timing Characteristic.

I

D

I

PR

+ I

Dmax

I

Smax

I

S

V

D

> V

S

V

S

> V

D

V

S

= V

D

I

PR

0

D98AT393

Figure 5. Drain, source input current.

L9380

5/12

In application which don't use the overload pro-

tection or if one channel is not used, the Timer pin

of this channel must be connected to ground and

the drain pin with a resistor to V

bat

.

The timing characteristic illustrates the function

and the meaning of V

DSmin

and T

off

(see figure 4).

The input current of the overload sense compara-

tor is specified as I

Smax

. The sum I

PR

+ I

Dmax

gen-

erates a drop across the external resistor R

D

if

the drain pin voltage is higher than the source pin

(see Fig. 5). In the switching point the comparator

input source pin currents are equal and the half of

the specified current I

Smax

. For an offset compen-

sation equal external resistors (R

D

= R

S

) at drain

and source pin are imperative. The drain sense

comparator, which detects the overload, has a

symmetrical hysteresis of 20mV (see Fig. 6). Ex-

ceeding the source pin voltage by 10mV with re-

spect to the drain voltage forces the timer capaci-

tor to discharge. Decreasing the source pin

voltage 10mV lower than the drain pin voltage an

overload of the external MOS is detected and the

timer capacitor will be loaded. After reaching a

voltage at pin CT higher than the timer threshold

V

Thi

the influenced channel is switched off. In this

case the overload is stored in the timer capacitor.

The timer capacitor will be discharged with a

'High' signal at the input (see Fig. 4). After reach-

ing the lower timer threshold V

TLo

the overload

protection is reset and the channel is able to

switch on again.

The application diagram is shown in Fig. 7. Be-

cause of the transients present at the power lines

during operation and possible disturbances in the

system the external resistors are necessary.

Positive ISO-Pulses at Drain, Gate Source are

clamped with an active clamping structure. The

clamping voltage is less than 60V. Negative

Pulses are only clamped with the ESD-Structure

less than -15V. This transients lower than -15V

can influence the other channels.

In order to protect the transistor against overload

and gate breakdown protection diodes between

gate and source and gate and drain has to be

connected. In case of overvoltage into V

S

(V

S

>

20V) the charge pump oscillation is stopped.

Then the charge pump capacitor will be loaded by

a diode and a resistor in series up to V

S

(see

Block Diagram). In this case the channels are not

influenced. In reverse battery condition the pins

D1, D2, S1, S2 follow the battery potential down

to -13V (high impedance) and the gate driver pins

G1, G2 is referred to S1, S2. In this way it is as-

sured that M1 and M2 will not be driven into the

linear conductive mode. This protection function

is operating for V

S1

, V

S2

down to -15V. The gate

driver output G3 is referred to the D1 in this case.

This function guarantees that the source to

source connected N-Channel MOS transistors M3

and M4 remains OFF.

All the supplies and the in- and output of the PC-

Board are supplied with a 40 wires flat cable (not

used wires are left open). This cable is submitted

to the RF in the strip-line like described in DIN

40839-4 or ISO 11456-5.

The measured circuit was build up on a PCB

board with ground plane. In the frequency range

from 1MHz to 400MHz and 80% AM-modulation

of 1KHz with field strength of 200V/m no influence

to the basic function was detected on a typical de-

vice. The failure criteria is an envelope of the out-

put signal with 20% in the amplitude and 2% in

the time.

V

T

-10mV

V

Dr

+10mV

V

So

D98AT394

Figure 6. Comparator hysteresis.

L9380

6/12

VS

GND

DRIVER 1

1

ENN

-

CHARGE PUMP

OVERVOLTAGE

CP

T1

VSI

IN1

+

1

VSI

T2

IN2

IN3

EN

CP

IPR

D1

S1

G1

DRIVER 2

1

ENN

-

VSI

+

1

VSI

CP

D2

S2

G2

IPR

ENN

1

VSI

CP

DRIVER 3

G3

ENN

VS

VSI

PR

I

PR

2V

REFERENCE

REG.

C1

D2

D1

C2

C3

C4

MICROCONTROLLER

LOAD CONTROL

M1

M2

R1

R2

R3

R4

R5

R6

D3

D4

D5

D6

R7

D7

M3

M4

D8

L4

L3

L2

L1

VALUE DRIVER

U405

M

M1

M

M2

D98AT395

V

BAT

R8

Figure 7. Application Circuit.

Recommendations to the application circuit: The timer and the charge capacitors are loaded with an al-

ternating current source. A short ground connection of the charge capacitor is indispensable to avoid

electromagnetic emigrations. The dimension of the resistors RD, RG and RS have to respect the maxi-

mum current during transients at each pin.

L9380

7/12

6

10

12

14

16

V

S

(V)

8

0

10

20

t

CH

(ms)

68nF

33nF

10nF

D98AT396

Figure 8. Charge Loading Time as function of V

S

(V

cp

= 8V +V

S

)

7

17

27

V

C

(V)

0

50

100

I

CP

(

µ

A)

D98AT397

7V

10V

12V

16V

Figure 9. Charge Pump Current as function of

the Charge Voltage

-15

-10

-5

V

S

(V)

-1000

-800

-600

-400

-200

I

G

(

µ

A)

D98AT398

Figure 10. Ground Loss Protection Gate Dis-

carge Current for Source Voltage

0

1

2

3

4

V

I

(V)

-20

-15

-10

-5

I

C

(

µ

A)

D98AT399

Figure 11. Input Current as function of the Input

Voltage

24

24.5

25

25.5

V

S

(V)

20

30

V

CH

(V)

D98AT400

Figure 12. Overvoltage Shutdown of the Charge

Pump with Hysteresis

TYPICAL CHARACTERISTICS

Depending on production spread, certain deviations may occure. For limits (see pag. 4)

L9380

8/12

VS

GND

DRIVER 1

1

ENN

-

CHARGE PUMP

OVERVOLTAGE

CP

T1

VSI

IN1

+

1

VSI

T2

IN2

IN3

EN

CP

IPR

D1

S1

G1

DRIVER 2

1

ENN

-

VSI

+

1

VSI

CP

D2

S2

G2

IPR

ENN

1

VSI

CP

DRIVER 3

G3

ENN

VS

VSI

PR

I

PR

2V

REFERENCE

REG.

33

µ

F

SMT_39A

SMB7W01-200

10nF

10nF

33nF

B60N06

10K

2K

2K

10K

2K

33V

18V

33V

18V

33V

18V

D98AT401

CAR-BATTERY

1K

1K

1K

100nF

5.6V

4.7nF

2.2nF

10K

2.2nF

10K

2.2nF

10K

2K

STD17N06

5

B60N06

5

B60N06

STD17N06

STD17N06

4.7nF

5.6V

3.125Hz

6.25Hz

12.5Hz

25Hz

f

2

4.7nF

5.6V

1K

4.7nF

PC-BOARD IN RF BOX

5.6V

10

9

8

7

2m

STRIPLINE

U(t)

f

2

f

2

1K

1K

1K

EN

IN3

IN2

6

IN1

2

V

S

1

V

BAT

2.2nF

2.2nF

2.2nF

2.2nF

OUT1

3

OUT2

4

OUT3

5

ANECHOIC CHAMBER

10K

20K

BNC

BNC

+

8

9

7

6

3

4

5

10

1

2

Figure 13. Measured Circuit.

The EMS of the device was verified in the below described setup.

L9380

9/12

Figure 14: PCB Board

Electromagnetic Emission Classification (EME)

Electromagnetic Emission classes presented below are typical data found on bench test. For detailes

test description please refer to "Electromagnetic Emission (EME) Measurement of Integrated Circuits,

DC to 1GHz" of VDE/ZVEI work group 767.13 and VDE/ZVEI work group 767.14 or IEC project number

47A 1967Ed. This data is targeted to board designers to allow an estimation of emission filtering effort

required in application. All measurements are done with the EMS-board (See pages 9, 10)

Pin

EME class

Remark

VCP

G

-

w

Electromagnetic Emission and Susceptivity is not tested in production.

L9380

10/12

SO20 PACKAGE MECHANICAL DATA

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

2.35

2.65

0.093

0.104

A1

0.1

0.3

0.004

0.012

B

0.33

0.51

0.013

0.020

C

0.23

0.32

0.009

0.013

D

12.6

13

0.496

0.512

E

7.4

7.6

0.291

0.299

e

1.27

0.050

H

10

10.65

0.394

0.419

h

0.25

0.75

0.010

0.030

L

0.4

1.27

0.016

0.050

K

0 (min.)8 (max.)

1

10

11

20

A

e

B

D

E

L

K

H

A1

C

SO20MEC

h x 45∞

L9380

11/12

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-

THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

© 1998 SGS-THOMSON Microelectronics ≠ Printed in Italy ≠ All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

L9380

12/12