| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: STPS130U | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Æ

1/7

Table 1: Main Product Characteristics

I

F(AV)

1 A

V

RRM

30 V

T

j

(max)

150∞C

V

F

(max)

0.46 V

STPS130

POWER SCHOTTKY RECTIFIER

REV. 5

Table 3: Absolute Ratings (limiting values)

Symbol

Parameter

Value

Unit

V

RRM

Repetitive peak reverse voltage

30

V

I

F(RMS)

RMS forward voltage

7

A

I

F(AV)

Average forward current

T

L

= 130∞C

= 0.5

1

A

I

FSM

Surge non repetitive forward current

tp = 10ms sinusoidal

45

A

I

RRM

Repetitive peak reverse current

tp = 2µs F = 1kHz square

1

A

I

RSM

Non repetitive peak reverse current

tp = 100µs square

1

A

P

ARM

Repetitive peak avalanche power

tp = 1µs Tj = 25∞C

1200

W

T

stg

Storage temperature range

-65 to + 150

∞C

T

j

Maximum operating junction temperature *

150

∞C

dV/dt

Critical rate of rise of reverse voltage

10000

V/µs

* :

thermal runaway condition for a diode on its own heatsink

dPt ot

dTj

---------------

1

Rth j

a

≠

(

)

--------------------------

>

SMA

(JEDEC DO-214AC)

STPS130A

SMB

(JEDEC DO-214AA)

STPS130U

August 2004

FEATURES AND BENEFITS

Very low forward voltage drop for less power

dissipation

Optimized conduction/reverse losses trade-off

which means the highest yield in the

applications

Surface mount miniature packages

Avalanche capability specified

DESCRIPTION

Single Schottky rectifier suited to Switched Mode

Power Supplies and high frequency DC to DC

converters.

Packaged in SMA and SMB, this device is

especially intended for use in parallel with

MOSFETs in synchronous rectification and low

voltage secondary rectification.

Table 2: Order Codes

Part Number

Marking

STPS130A

S130

STPS130U

G12

STPS130

2/7

Table 4: Thermal Resistance

Table 5: Static Electrical Characteristics

Pulse test:

* tp = 380 µs,

< 2%

** tp = 5 ms,

< 2%

To evaluate the conduction losses use the following equation: P = 0.37 x I

F(AV)

+ 0.090 I

F

2

(RMS)

Symbol

Parameter

Value

Unit

R

th(j-l)

Junction to lead

SMA

30

∞C/W

SMB

23

Symbol

Parameter

Tests conditions

Min.

Typ

Max.

Unit

I

R

*

Reverse leakage current

T

j

= 25∞C

V

R

= V

RRM

10

µA

T

j

= 125∞C

1.5

10

mA

V

F

**

Forward voltage drop

T

j

= 25∞C

I

F

= 1A

0.55

V

T

j

= 125∞C

0.37

0.46

T

j

= 25∞C

I

F

= 2A

0.63

T

j

= 125∞C

0.45

0.55

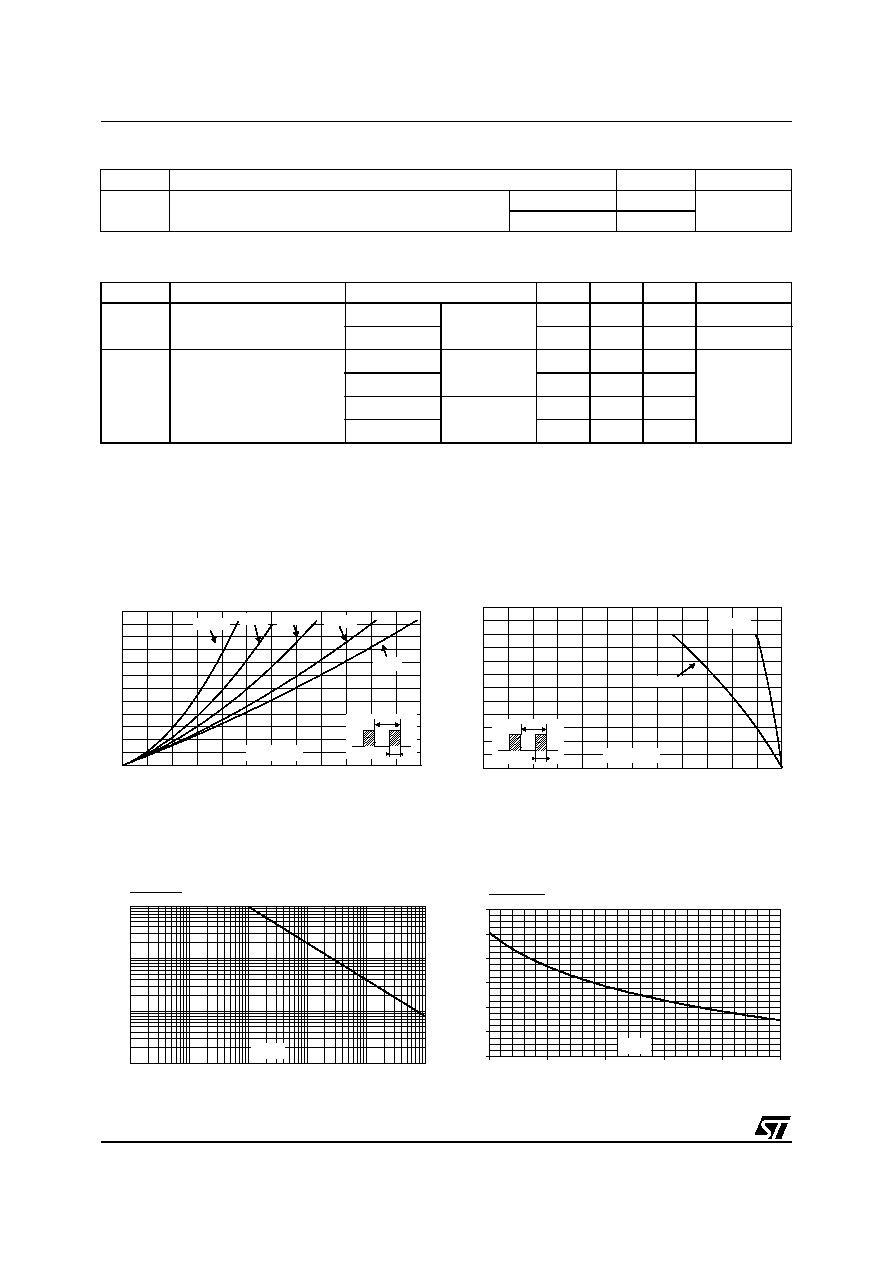

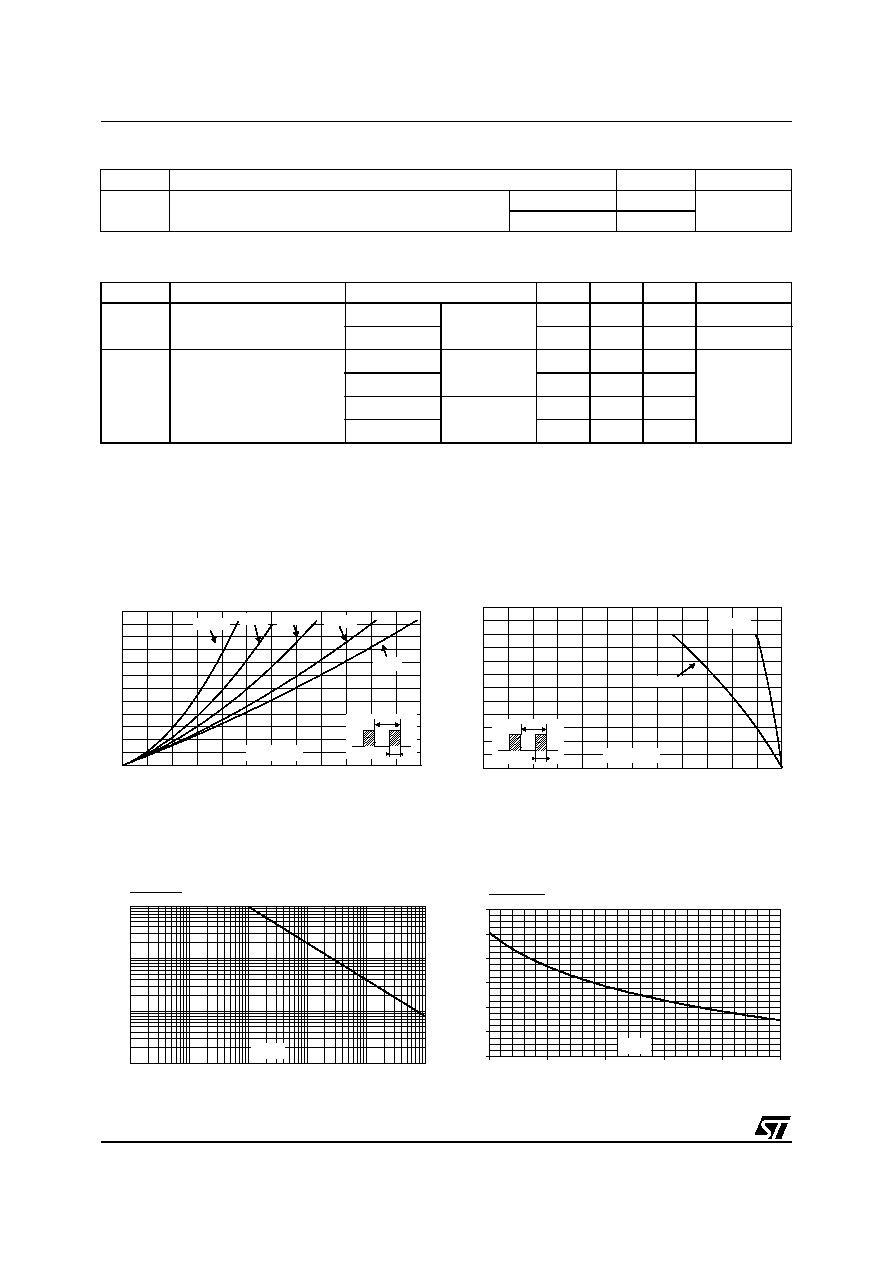

Figure 1: Average forward power dissipation

versus average forward current

Figure 2: Average forward current versus

ambient temperature (

= 0.5)

Figure 3: Normalized avalanche power

derating versus pulse duration

Figure 4: Normalized avalanche power

derating versus junction temperature

P

(W)

F(AV)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.0

0.1

0.2

0.3

0.4

0.5

0.6

T

=tp/T

tp

I

(A)

F(AV)

= 1

= 0.5

= 0.2

= 0.1

= 0.05

0

25

50

75

100

125

150

0.0

0.2

0.4

0.6

0.8

1.0

1.2

I

(A)

F(AV)

T

=tp/T

tp

R

=R

th(j-a)

th(j-I)

R

=100∞C/W

th(j-a)

T

(∞C)

amb

0.001

0.01

0.1

0.01

1

0.1

10

100

1000

1

t (µs)

p

P

(t )

P

(1µs)

ARM p

ARM

0

0.2

0.4

0.6

0.8

1

1.2

25

50

75

100

125

150

T (∞C)

j

P

(t )

P

(25∞C)

ARM p

ARM

STPS130

3/7

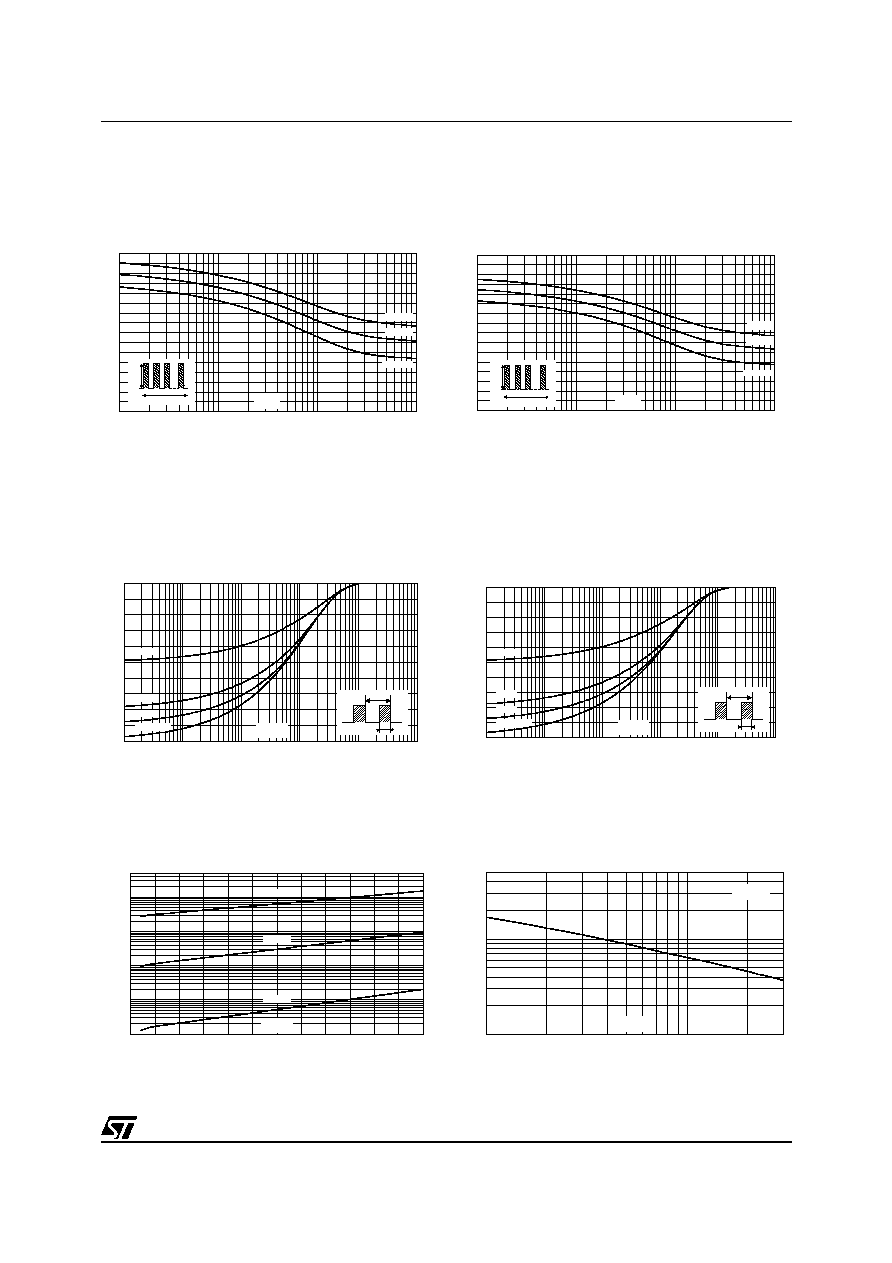

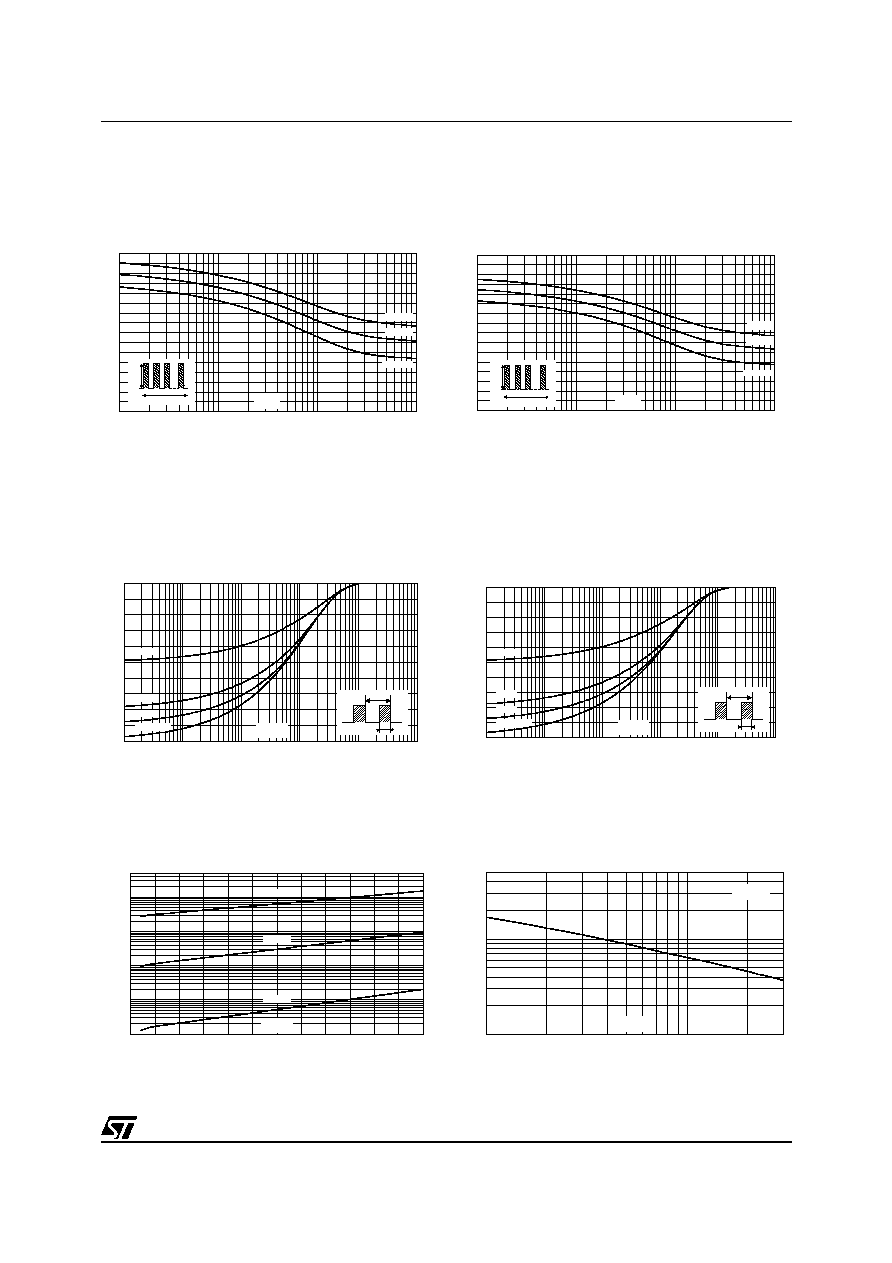

Figure 5: Non repetitive surge peak forward

current versus overload duration (maximum

values) (SMA)

Figure 6: Non repetitive surge peak forward

current versus overload duration (maximum

values) (SMB)

Figure 7: Relative variation of thermal

impedance junction to ambient versus pulse

duration (epoxy printed circuit board,

e(Cu)=35µm, recommended pad layout) (SMA)

Figure 8: Relative variation of thermal

impedance junction to ambient versus pulse

duration (epoxy printed circuit board,

e(Cu)=35µm, recommended pad layout) (SMB)

Figure 9: Reverse leakage current versus

reverse voltage applied (typical values)

Figure 10: Junction capacitance versus

reverse voltage applied (typical values)

I (A)

M

1.0E-3

1.0E-2

1.0E-1

1.0E+0

0

1

2

3

4

5

6

7

8

T =75∞C

a

T =50∞C

a

T =100∞C

a

I

M

t

=0.5

t(s)

1.0E-3

1.0E-2

1.0E-1

1.0E+0

0

1

2

3

4

5

6

7

8

I (A)

M

T =75∞C

a

T =50∞C

a

T =100∞C

a

I

M

t

=0.5

t(s)

1E-2

1E-1

1E+0

1E+1

1E+2

1E+3

0.0

0.2

0.4

0.6

0.8

1.0

Z

/R

th(j-c)

th(j-c)

T

=tp/T

tp

t (s)

p

= 0.5

= 0.2

= 0.1

Single pulse

1.0E-2

1.0E-1

1.0E+0

1.0E+1

1.0E+2

1.0E+3

0.0

0.2

0.4

0.6

0.8

1.0

Z

/R

th(j-c)

th(j-c)

T

=tp/T

tp

t (s)

p

= 0.5

= 0.2

= 0.1

Single pulse

0

5

10

15

20

25

30

1E-1

1E+0

1E+1

1E+2

1E+3

5E+3

I (µA)

R

V (V)

R

T =125∞C

j

T =70∞C

j

T =25∞C

j

1

2

5

10

20

30

10

20

50

100

200

500

C(pF)

V (V)

R

F=1MHz

T =25∞C

j

STPS130

4/7

Figure 11: Forward voltage drop versus

forward current (maximum values)

Figure 12: Thermal resistance junction to

ambient versus copper surface under each

lead (Epoxy printed circuit board FR4, copper

thickness: 35µm) (SMA)

Figure 13: Thermal resistance junction to

ambient versus copper surface under each

lead (Epoxy printed circuit board FR4, copper

thickness: 35µm) (SMB)

I

(A)

FM

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.01

0.10

1.00

10.00

V

(V)

FM

T =25∞C

j

T =75∞C

j

T =125∞C

j

0

1

2

3

4

5

0

20

40

60

80

100

120

S(Cu)(cm≤)

R

(∞C/W)

th(j-a)

P=1.5W

0

1

2

3

4

5

0

20

40

60

80

100

120

140

S(Cu)(cm≤)

R

(∞C/W)

th(j-a)

P=1.5W

STPS130

5/7

Figure 14: SMA Package Mechanical Data

Figure 15: SMA Foot Print Dimensions

(in millimeters)

E

C

L

E1

D

A1

A2

b

2.40

1.65

1.45

1.45

REF.

DIMENSIONS

Millimeters

Inches

Min.

Max.

Min.

Max.

A1

1.90

2.03

0.075

0.080

A2

0.05

0.20

0.002

0.008

b

1.25

1.65

0.049

0.065

c

0.15

0.41

0.006

0.016

E

4.80

5.60

0.189

0.220

E1

3.95

4.60

0.156

0.181

D

2.25

2.95

0.089

0.116

L

0.75

1.60

0.030

0.063