1/9

STPS20L45CF/CW/CT/CFP/CG

July 2003 - Ed: 3C

LOW DROP POWER SCHOTTKY RECTIFIER

Æ

Dual center tap Schottky rectifiers designed for

high frequency switched mode power supplies and

DC to DC converters.

These devices are intended for use in low voltage,

high

frequency

inverters,

free-wheeling

and

polarity protection applications.

DESCRIPTION

s

LOW FORWARD VOLTAGE DROP MEANING

VERY SMALL CONDUCTION LOSSES

s

LOW SWITCHING LOSSES ALLOWING HIGH

FREQUENCY OPERATION

s

INSULATED

PACKAGE:

ISOWATT220AB,

TO-220FPAB

Insulating voltage = 2000V DC

Capacitance = 12pF

s

AVALANCHE CAPABILITY SPECIFIED

FEATURES AND BENEFITS

Symbol

Parameter

Value

Unit

V

RRM

Repetitive peak reverse voltage

45

V

I

F(RMS)

RMS forward current

30

A

I

F(AV)

Average forward

current

TO-220AB / D

2

PAK

TO-247

Tc = 135∞C

= 0.5

Per diode

Per device

10

20

A

ISOWATT220AB

TO-220FPAB

Tc = 115∞C

= 0.5

Per diode

Per device

10

20

A

I

FSM

Surge non repetitive forward current

tp = 10 ms Sinusoidal

180

A

I

RRM

Peak repetitive reverse current

tp=2 µs square F=1kHz

1

A

I

RSM

Non repetitive peak reverse current

tp = 100 µs square

2

A

P

ARM

Repetitive peak avalanche power

tp = 1µs

Tj = 25∞C

4000

W

T

stg

Storage temperature range

- 65 to + 150

∞C

Tj

Maximum operating junction temperature *

150

∞C

dV/dt

Critical rate of rise of reverse voltage

10000

V/µs

ABSOLUTE RATINGS (limiting values, per diode)

I

F(AV)

2 x 10 A

V

RRM

45 V

Tj (max)

150∞C

V

F

(max)

0.5 V

MAJOR PRODUCTS CHARACTERISTICS

A1

K

A2

A1

K

A2

ISOWATT220AB

STPS20L45CF

TO-247

STPS20L45CW

K

A1

A2

TO-220AB

STPS20L45CT

* :

dPtot

dTj

Rth j

a

<

-

1

(

)

thermal runaway condition for a diode on its own heatsink

A1

K

A2

A1

A2

K

TO-220FPAB

STPS20L45CFP

K

A1

A2

D

2

PAK

STPS20L45CG

STPS20L45CF/CW/CT/CFP/CG

2/9

Symbol

Parameter

Tests Conditions

Min.

Typ.

Max.

Unit

I

R

*

Reverse leakage

current

Tj = 25∞C

V

R

= V

RRM

0.2

mA

Tj = 125∞C

65

130

mA

V

F

*

Forward voltage drop

Tj = 25

∞

C

I

F

= 10 A

0.55

V

Tj = 125∞C

I

F

= 10 A

0.44

0.5

Tj = 25

∞

C

I

F

= 20 A

0.73

Tj = 125∞C

I

F

= 20 A

0.62

0.72

Pulse test : * tp = 380 µs,

< 2%

To evaluate the conduction losses use the following equation :

P = 0.28 x I

F(AV)

+ 0.022 I

F

2

(RMS)

STATIC ELECTRICAL CHARACTERISTICS (per diode)

Symbol

Parameter

Value

Unit

R

th(j-c)

Junction to case

ISOWATT220AB

TO-220FPAB

Per diode

Total

Coupling

4.5

3.5

2.5

∞C/W

R

th(j-c)

Junction to case

TO-247

Per diode

Total

Coupling

2.2

1.20

0.3

∞C/W

R

th(j-c)

Junction to case

TO-220AB

D

2

PAK

Per diode

Total

Coupling

2.2

1.3

0.3

∞C/W

THERMAL RESISTANCES

0

2

4

6

8

10

12

14

0

1

2

3

4

5

6

7

8

IF(av) (A)

PF(av)(W)

= 0.2

= 0.5

= 1

= 0.05

= 0.1

T

=tp/T

tp

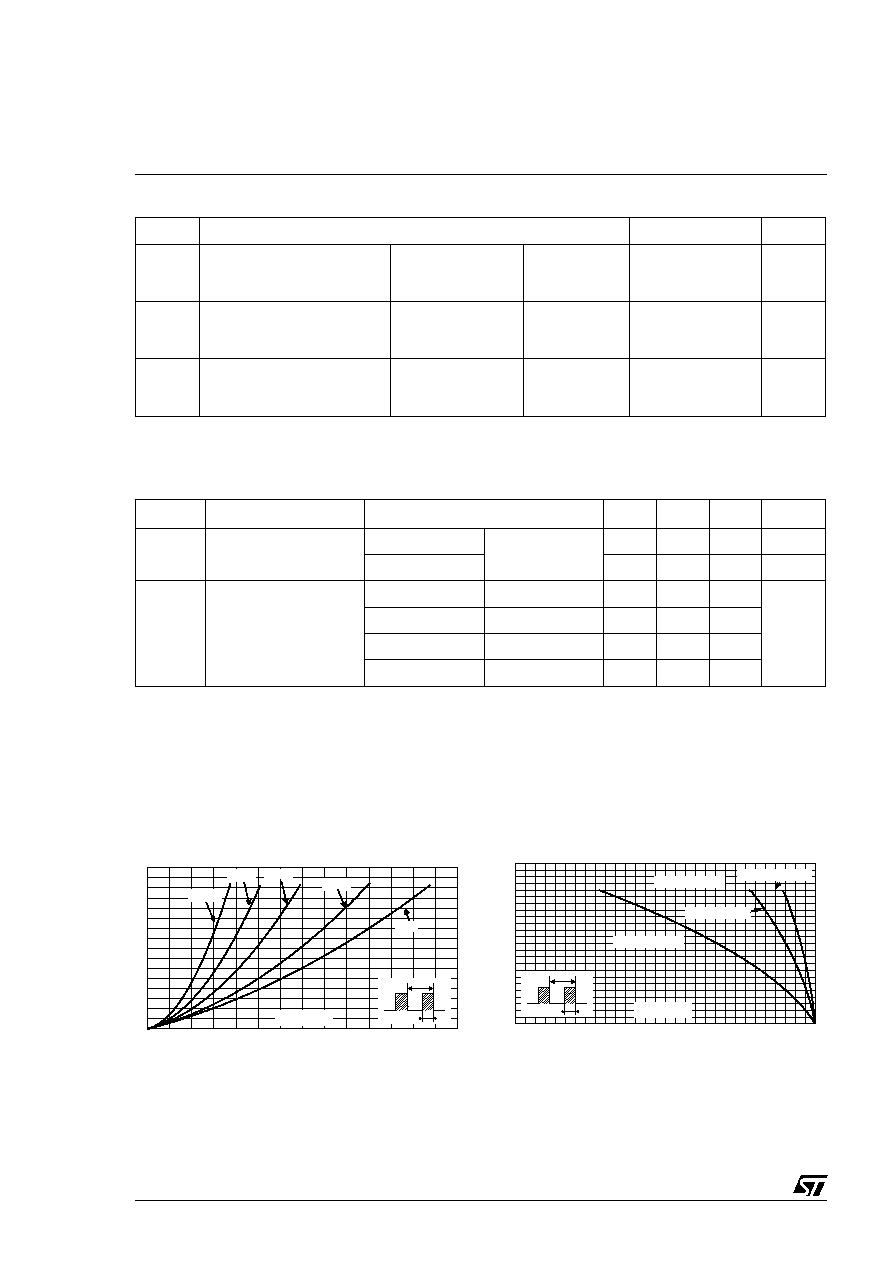

Fig. 1: Average forward power dissipation versus

average forward current (per diode).

0

25

50

75

100

125

150

0

1

2

3

4

5

6

7

8

9

10

11

12

IF(av)(A)

Rth(j-a)=15∞C/W

Rth(j-a)=Rth(j-c)

TO-220AB/TO-247

ISOWATT220AB

T

=tp/T

tp

Tamb(∞C)

Fig. 2: Average forward current versus ambient

temperature(

= 0.5, per diode).

When the diodes 1 and 2 are used simultaneously :

Tj(diode 1) = P(diode1) x R

th(j-c)

(Per diode) + P(diode 2) x R

th(c)

STPS20L45CF/CW/CT/CFP/CG

3/9

1E-3

1E-2

1E-1

1E+0

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

= 0.1

= 0.2

= 0.5

Single pulse

T

=tp/T

tp

Fig. 6-1: Relative variation of thermal impedance

junction to case versus pulse duration (TO-220AB,

TO-247, D

2

PAK).

1E-3

1E-2

1E-1

1E+0

1E+1

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

T

=tp/T

tp

= 0.1

= 0.2

= 0.5

Single pulse

Fig. 6-2: Relative variation of thermal impedance

junction

to

case

versus

pulse

duration

(ISOWATT220AB, TO-220FPAB).

1E-3

1E-2

1E-1

1E+0

0

10

20

30

40

50

60

70

80

90

100

IM(A)

Tc=25∞C

Tc=100∞C

Tc=50∞C

I

M

t

=0.5

t(s)

Fig. 5-2: Non repetitive surge peak forward

current versus overload duration (maximum

values,

per

diode,

ISOWATT220AB,

TO-220FPAB).

1E-3

1E-2

1E-1

1E+0

0

20

40

60

80

100

120

140

IM(A)

Tc=25∞C

Tc=125∞C

Tc=75∞C

t(s)

I

M

t

=0.5

Fig. 5-1: Non repetitive surge peak forward

current versus overload duration (maximum

values,

per

diode,

TO-220AB,

TO-247,

D

2

PAK).

0

0.2

0.4

0.6

0.8

1

1.2

0

25

50

75

100

125

150

T (∞C)

j

P

(t )

P

(25∞C)

ARM p

ARM

Fig. 4: Normalized avalanche power derating

versus junction temperature.

0.001

0.01

0.1

0.01

1

0.1

10

100

1000

1

t (µs)

p

P

(t )

P

(1µs)

ARM p

ARM

Fig. 3: Normalized avalanche power derating

versus pulse duration.

STPS20L45CF/CW/CT/CFP/CG

4/9

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0.1

1.0

10.0

100.0

IFM(A)

Tj=75∞C

Tj=25∞C

Tj=125∞C

Typical values

Tj=150∞C

VFM(V)

Fig. 9: Forward voltage drop versus forward

current (maximum values) (per diode).

0

4

8

12

16

20

24

28

32

36

40

0

10

20

30

40

50

60

70

80

S(Cu) (cm≤)

Rth(j-a) (∞C/W)

Fig. 10: Thermal resistance junction to ambient

versus copper surface under tab (Epoxy printed cir-

cuit board FR4, copper thickness: 35µm) (D

2

PAK).

0

5

10

15

20

25

30

35

40

45

1E-3

1E-2

1E-1

1E+0

1E+1

1E+2

2E+2

VR(V)

IR(mA)

Tj=75∞C

Tj=25∞C

Tj=125∞C

Tj=150∞C

Fig. 7: Reverse leakage current versus reverse

voltage applied (typical values, per diode).

1

2

5

10

20

50

100

1000

2000

VR(V)

C(pF)

F=1MHz

Tj=25∞C

Fig. 8: Junction capacitance versus reverse

voltage applied (typical values, per diode).

STPS20L40CF/CW/CT

5/9

s

Cooling method : C

s

Recommended torque value : 0.55 m.N

s

Maximum torque value : 0.70 m.N

PACKAGE MECHANICAL DATA

ISOWATT220AB

REF.

DIMENSIONS

Millimeters

Inches

Min.

Max.

Min.

Max.

A

4.40

4.60

0.173

0.181

B

2.50

2.70

0.098

0.106

D

2.50

2.75

0.098

0.108

E

0.40

0.70

0.016

0.028

F

0.75

1.00

0.030

0.039

F1

1.15

1.70

0.045

0.067

F2

1.15

1.70

0.045

0.067

G

4.95

5.20

0.195

0.205

G1

2.40

2.70

0.094

0.106

H

10.00

10.40

0.394

0.409

L2

16.00 typ.

0.630 typ.

L3

28.60

30.60

1.125

1.205

L4

9.80

10.60

0.386

0.417

L6

15.90

16.40

0.626

0.646

L7

9.00

9.30

0.354

0.366

Diam

3.00

3.20

0.118

0.126