| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: STTH5R06D | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Æ

1/9

Table 1: Main Product Characteristics

I

F(AV)

5 A

V

RRM

600 V

T

j

175∞C

V

F

(typ)

1.4 V

t

rr

(max)

40 ns

STTH5R06

TURBO 2 ULTRAFAST HIGH VOLTAGE RECTIFIER

Table 3: Absolute Ratings (limiting values)

Symbol

Parameter

Value

Unit

V

RRM

Repetitive peak reverse voltage

600

V

I

F(RMS)

RMS forward voltage

TO-220AC / TO-220FPAC / D

2

PAK

20

A

DPAK

10

I

F(AV)

Average forward current

TO-220AC / DPAK

/ D

2

PAK

Tc = 135∞C

= 0.5

5

A

TO-220FPAC

Tc = 105∞C

= 0.5

5

I

FSM

Surge non repetitive forward current

tp = 10ms sinusoidal

50

A

T

stg

Storage temperature range

-65 to + 175

∞C

T

j

Maximum operating junction temperature

175

∞C

K

A

TO-220AC

STTH5R06D

K

A

TO-220FPAC

STTH5R06FP

K

A

NC

D

2

PAK

STTH5R06G

K

A

NC

DPAK

STTH5R06B

September 2004

REV. 4

FEATURES AND BENEFITS

Ultrafast switching

Low reverse recovery current

Low thermal resistance

Reduces switching losses

DESCRIPTION

The STTH5R06, which is using ST Turbo 2 600V

technology, is specially suited as boost diode in

continuous mode power factor corrections and

hard switching conditions. This device is also

intended for use as a free wheeling diode in power

supplies and other power switching applications.

Table 2: Order Codes

Part Number

Marking

STTH5R06D

STTH5R06D

STTH5R06FP

STTH5R06FP

STTH5R06B

STTH5R06B

Part Number

Marking

STTH5R06B-TR

STTH5R06B

STTH5R06G

STTH5R06G

STTH5R06G-TR

STTH5R06G

STTH5R06

2/9

Table 4: Thermal Resistance

Table 5: Static Electrical Characteristics

Pulse test:

* tp = 5 ms,

< 2%

** tp = 380 µs,

< 2%

To evaluate the conduction losses use the following equation: P = 1.164 x I

F(AV)

+ 0.128 I

F

2

(RMS)

Table 6: Dynamic Characteristics

Symbol

Parameter

Value (max).

Unit

R

th(j-c)

Junction to case

TO-220AC / DPA / D

2

PAK

3.0

∞C/W

TO-220FPAC

5.5

Symbol

Parameter

Test conditions

Min.

Typ

Max.

Unit

I

R

*

Reverse leakage current T

j

= 25∞C

V

R

= V

RRM

20

µA

T

j

= 125∞C

25

250

V

F

**

Forward voltage drop

T

j

= 25∞C

I

F

= 5A

2.9

V

T

j

= 125∞C

1.4

1.8

Symbol

Parameter

Test conditions

Min.

Typ Max.

Unit

t

rr

Reverse recovery

time

T

j

= 25∞C

I

F

= 0.5A Irr = 0.25A I

R

=1A

25

ns

I

F

= 1A dI

F

/dt = -50 A/µs V

R

=30V

40

I

RM

Reverse recovery

current

T

j

= 125∞C I

F

= 5A V

R

= 400V

dI

F

/dt = -200 A/µs

5.0

6.0

A

S factor Softness factor

0.35

Qrr

Reverse recovery

charges

110

nC

t

fr

Forward recovery

time

T

j

= 25∞C

I

F

= 5A dI

F

/dt = 40 A/µs

V

FR

= 1.1 x V

Fmax

150

ns

V

FP

Forward recovery

voltage

T

j

= 25∞C

I

F

= 5A dI

F

/dt = 40 A/µs

V

FR

= 1.1 x V

Fmax

4.5

V

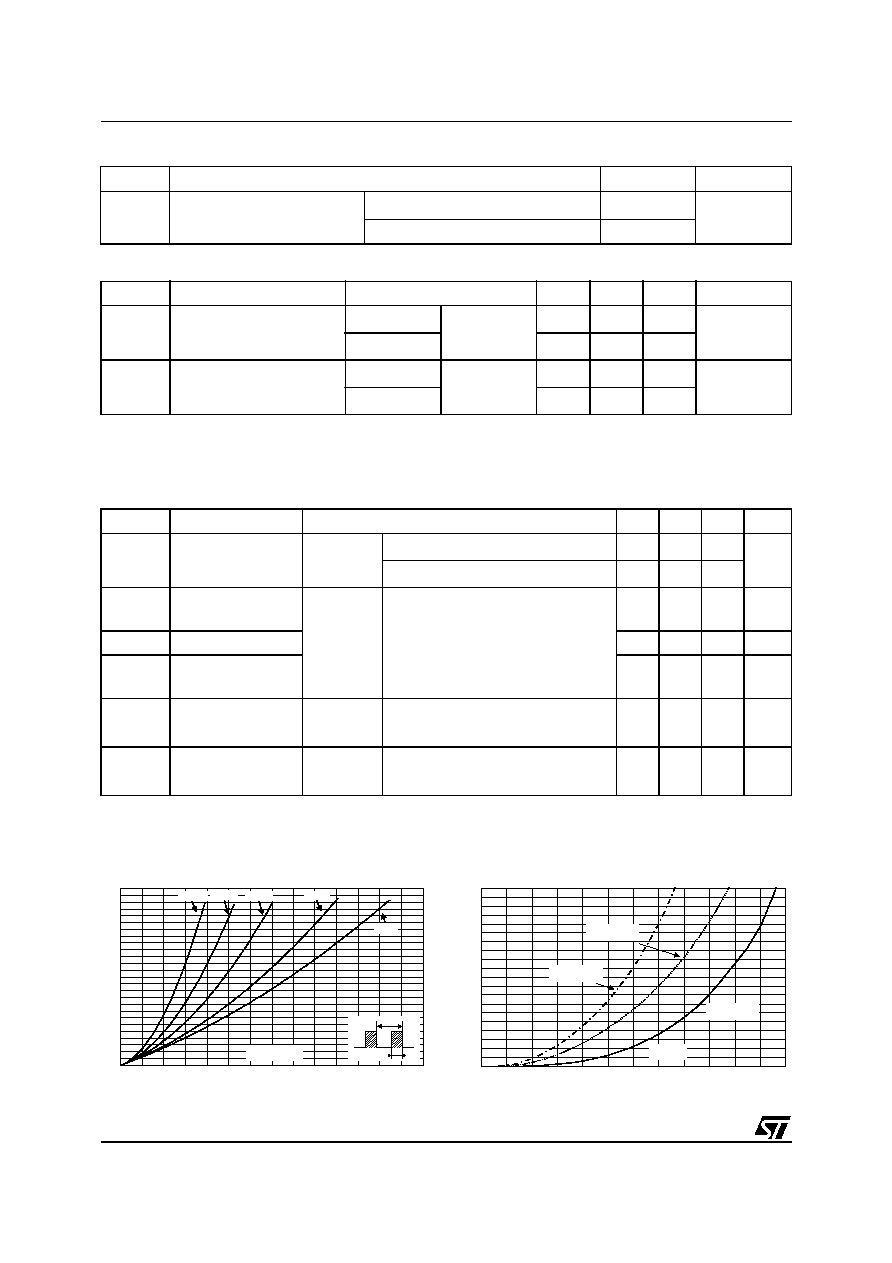

Figure 1: Conduction losses versus average

current

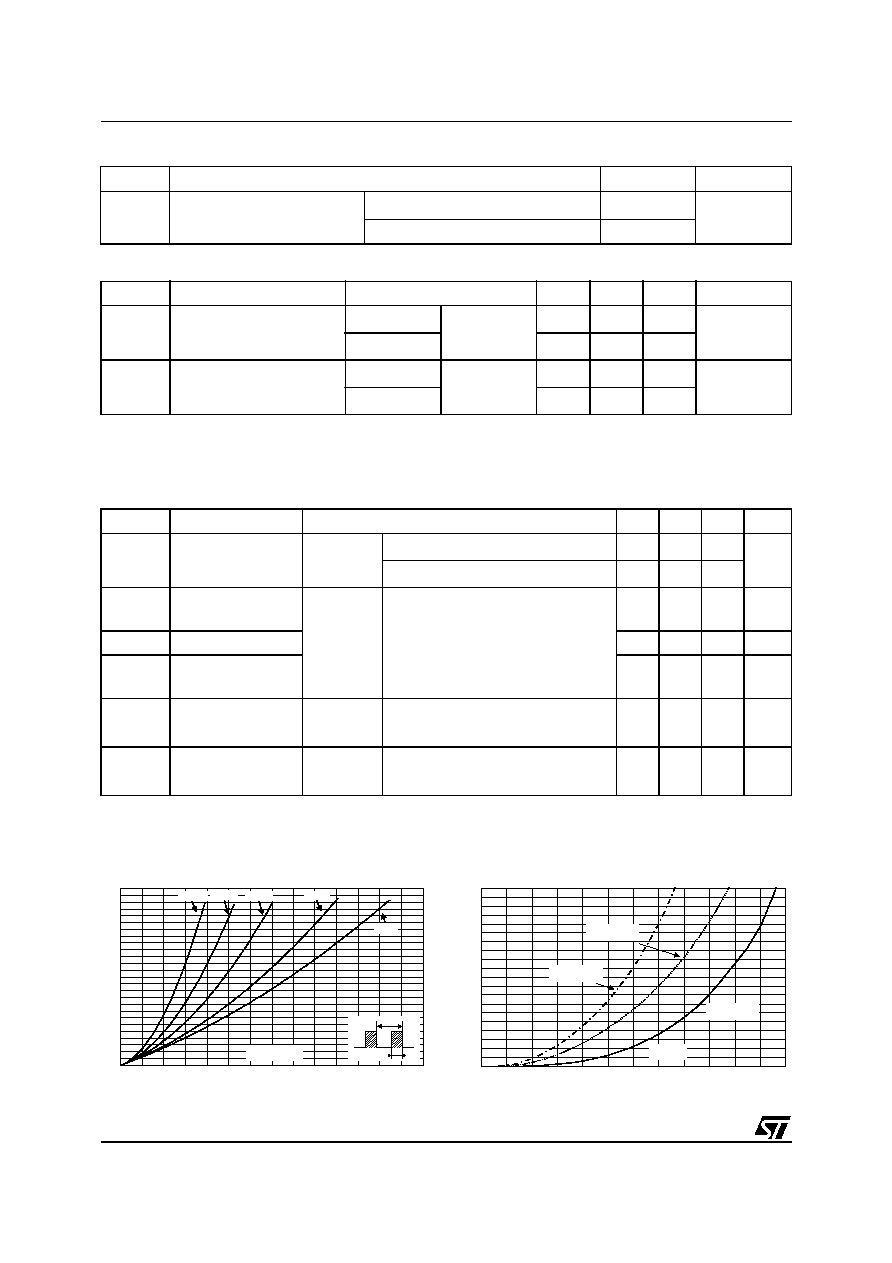

Figure 2: Forward voltage drop versus forward

current

0

1

2

3

4

5

6

7

8

9

10

11

12

13

0

1

2

3

4

5

6

7

P(W)

T

=tp/T

tp

= 0.05 = 0.1

= 0.2

= 0.5

= 1

I

(A)

F(AV)

0

5

10

15

20

25

30

35

40

45

50

0

1

2

3

4

5

6

I

(A)

FM

V

(V)

FM

T =25∞C

(maximum values)

j

T =125∞C

(maximum values)

j

T =125∞C

(typical values)

j

STTH5R06

3/9

Figure 3: Relative variation of thermal

impedance junction to case versus pulse

duration (TO-220AC, DPAK, D

2

PAK)

Figure 4: Relative variation of thermal

impedance junction to case versus pulse

duration (TO-220FPAC)

Figure 5: Peak reverse recovery current versus

dI

F

/dt (90% confidence)

Figure 6: Reverse recovery time versus dI

F

/dt

(90% confidence)

Figure 7: Reverse recovery charges versus

dI

F

/dt (90% confidence)

Figure 8: Softness factor versus dI

F

/dt (typical

values)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.E-03

1.E-02

1.E-01

1.E+00

T

=tp/T

tp

= 0.5

= 0.2

= 0.1

Single pulse

Z

/R

th(j-c)

th(j-c)

t (s)

p

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.E-03

1.E-02

1.E-01

1.E+00

1.E+01

T

=tp/T

tp

= 0.5

= 0.2

= 0.1

Single pulse

Z

/R

th(j-c)

th(j-c)

t (s)

p

0

2

4

6

8

10

12

14

16

18

20

22

0

200

400

600

800

1000

I

(A)

RM

dI /dt(A/µs)

F

I =2 x I

F

F(AV)

I =I

F

F(AV)

I =0.5 x I

F

F(AV)

I =0.25 x I

F

F(AV)

V =400V

T =125∞C

R

j

0

10

20

30

40

50

60

70

80

0

200

400

600

800

1000

t (ns)

rr

dI /dt(A/µs)

F

V =400V

T =125∞C

R

j

I =2 x I

F

F(AV)

I =I

F

F(AV)

I =0.5 x I

F

F(AV)

0

50

100

150

200

250

300

350

0

200

400

600

800

1000

Q (nC)

rr

V =400V

T =125∞C

R

j

dI /dt(A/µs)

F

I =2 x I

F

F(AV)

I =I

F

F(AV)

I =0.5 x I

F

F(AV)

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0

200

400

600

800

1000

S factor

I =I

T =125∞C

F

F(AV)

j

V =400V

R

dI /dt(A/µs)

F

STTH5R06

4/9

Figure 9: Relative variations of dynamic

parameters versus junction temperature

Figure 10: Transient peak forward voltage

versus dI

F

/dt (90% confidence)

Figure 11: Forward recovery time versus dI

F

/dt

(90% confidence)

Figure 12: Junction capacitance versus

reverse voltage applied (typical values)

Figure 13: Thermal resistance junction to

ambient versus copper surface under tab

(epoxy FR4, e

CU

=35µm) (DPAK and D

2

PAK)

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

25

50

75

100

125

I

RM

Q

RR

S factor

T (∞C)

j

I =I

Reference: T =125∞C

F

F(AV)

j

V =400V

R

0

2

4

6

8

10

12

14

16

18

20

0

100

200

300

400

500

V

(V)

FP

dI /dt(A/µs)

F

I =I

T =125∞C

F

F(AV)

j

0

20

40

60

80

100

120

0

100

200

300

400

500

t (ns)

fr

dI /dt(A/µs)

F

I =I

T =125∞C

F

F(AV)

j

V

=1.1 x V max.

FR

F

10

100

1

10

100

1000

C(pF)

V (V)

R

F=1MHz

V

=30mV

T =25∞C

OSC

RMS

j

0

10

20

30

40

50

60

70

80

90

100

0

2

4

6

8

10

12

14

16

18

20

S(Cu)(cm≤)

R

(∞C/W)

th(j-a)

STTH5R06

5/9

Figure 14: DPAK Package Mechanical Data

Figure 15: DPAK Foot Print Dimensions

(in millimeters)

6.7

6.7

3

3

1.6

1.6

2.3

2.3

REF.

DIMENSIONS

Millimeters

Inches

Min.

Max

Min.

Max.

A

2.20

2.40

0.086

0.094

A1

0.90

1.10

0.035

0.043

A2

0.03

0.23

0.001

0.009

B

0.64

0.90

0.025

0.035

B2

5.20

5.40

0.204

0.212

C

0.45

0.60

0.017

0.023

C2

0.48

0.60

0.018

0.023

D

6.00

6.20

0.236

0.244

E

6.40

6.60

0.251

0.259

G

4.40

4.60

0.173

0.181

H

9.35

10.10

0.368

0.397

L2

0.80 typ.

0.031 typ.

L4

0.60

1.00

0.023

0.039

V2

0∞

8∞

0∞

8∞