| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: UCC3952 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

1

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

D

Protects Sensitive Lithium-Ion Cells From

Overcharging and Over-Discharging

D

Dedicated for One-Cell Applications

D

Integrated Low-Impedance MOSFET Switch

and Sense Resistor

D

Precision Trimmed Overcharge and

Overdischarge Voltage Limits

D

Extremely Low Power Drain

D

3-A Current Capacity

D

Overcurrent and Short-Circuit Protection

D

Reverse Charger Protection

D

Thermal Protection

description

The UCC3952 monolithic BiCMOS lithium≠ion

battery protection circuit increases the useful

operating life of a one-cell rechargeable battery

pack. Cell protection features include internally

trimmed charge and discharge voltage limits,

discharge current limit with a delayed shutdown,

and an ultra-low-current sleep mode state when

the cell is discharged. Additional features include

an on-chip MOSFET for reduced external compo-

nent count and a charge pump for reduced power

losses while charging or discharging a low-cell-

voltage battery pack. This protection circuit

requires one external capacitor and can operate

and safely shut down in a short circuit condition.

Copyright

©

2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

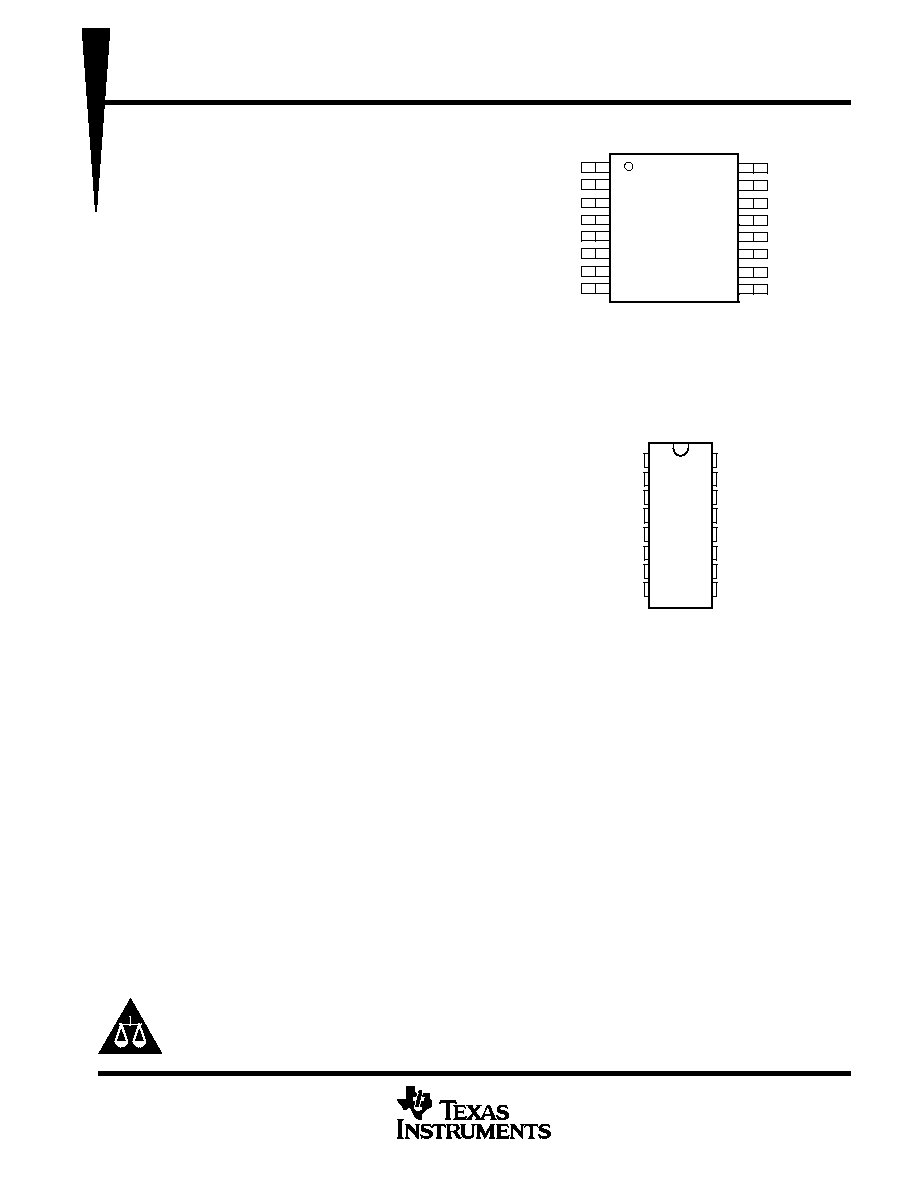

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

TCLK

NC

BNEG

BNEG

BNEG

BNEG

BNEG

BNEG

PACK+

CBPS

NC

PACK≠

PACK≠

PACK≠

PACK≠

PACK≠

PW PACKAGE

(TOP VIEW)

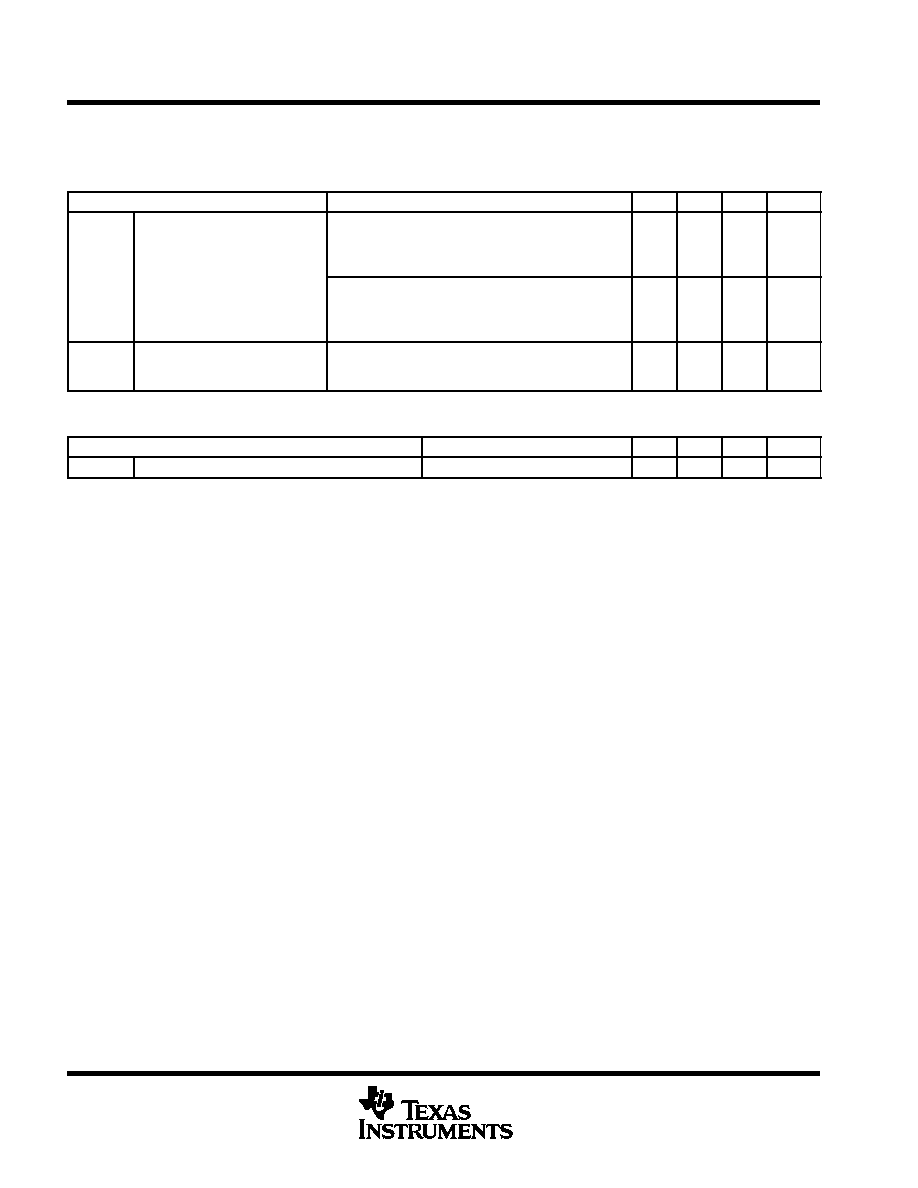

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

DP PACKAGE

(TOP VIEW)

TCLK

NC

NC

SUB

SUB

BNEG

BNEG

BNEG

PACK+

CBPS

NC

SUB

SUB

PACK≠

PACK≠

PACK≠

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

2

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

application diagram

1

3

2

4

5

7

6

8

16

14

15

13

12

10

11

9

0.1

µ

F

3 k

TCLK

N/C

BNEG

BNEG

BNEG

BNEG

BNEG

BNEG

PACK ≠

NC

CBPS

PACK +

LOAD

CHARGER

+

PACK ≠

PACK ≠

PACK ≠

PACK ≠

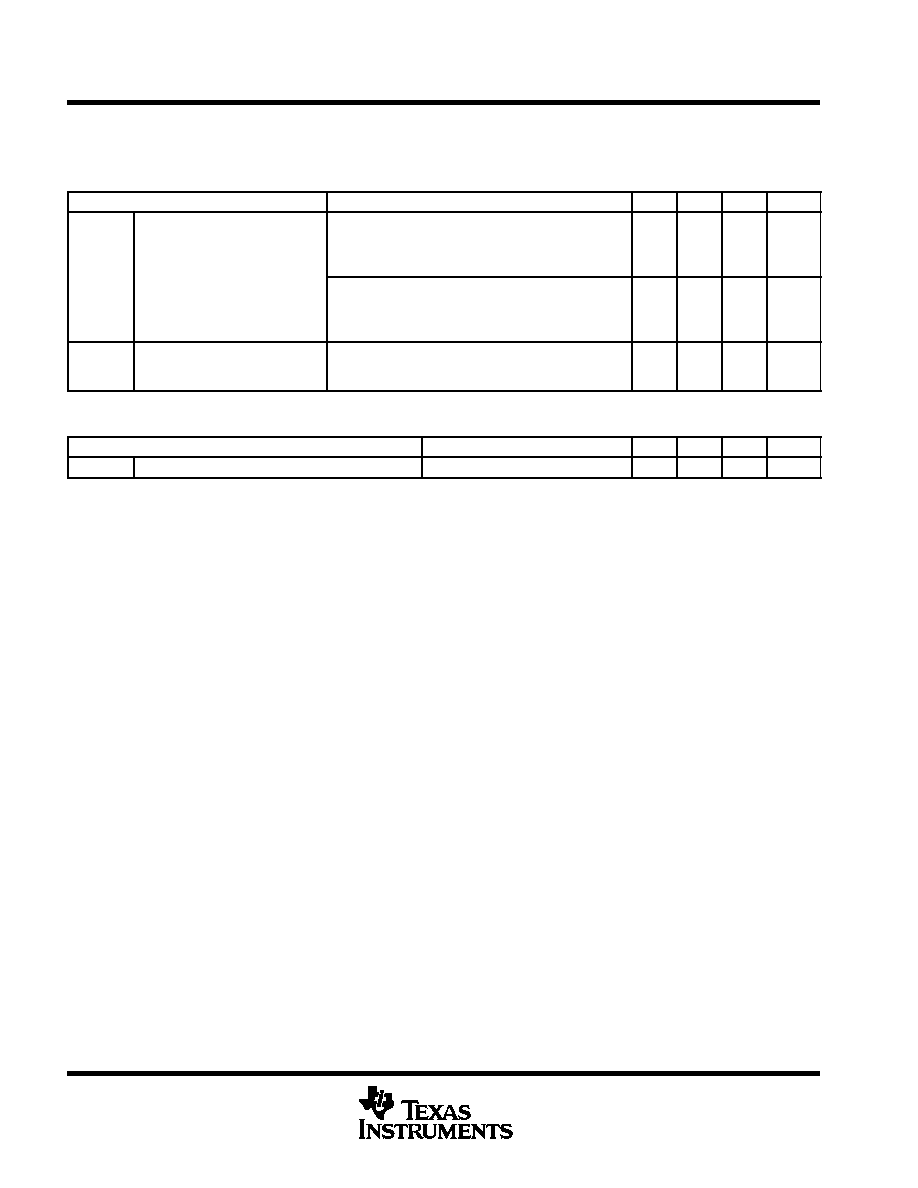

AVAILABLE OPTIONS

PACKAGES

TA

TSSOP≠16 (PW)

SOIC≠16 (DP)

UCC3952PW≠1

UCC3952DP≠1

≠20

∞

C to 70

∞

C

UCC3952PW≠2

UCC3952DP≠2

≠20

∞

C to 70

∞

C

UCC3952PW≠3

UCC3952DP≠3

UCC3952PW≠4

UCC3952DP≠4

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

3

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Supply voltage (PACK+ to BNEG)

7 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum forward voltage (PACK+ to PACK≠)

16 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum reverse voltage (where PACK+ to BNEG = 5V)

≠8 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum cell continuous charge current

3 A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction temperature, T

J

≠55

∞

C to 150

∞

C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Temperature range, T

stg

≠65

∞

C to 150

∞

C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under "recommended operating conditions" is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: Currents are positive into, negative out of the specified terminal. Consult Packaging Section of Data Book for thermal limitations and

considerations of packages. All voltages are referenced to GND.

electrical characteristics, T

A

= ≠20

∞

C to 70

∞

C, all voltages are with respect to BNEG (unless

otherwise stated)

state transition threshold

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

UCC3952≠1

4.15

4.20

4.25

V

Normal to overcharge voltage

UCC3952≠2

4.20

4.25

4.30

V

V(OV)

Normal to overcharge voltage

UCC3952≠3

4.25

4.30

4.35

V

UCC3952≠4

4.30

4.35

4.40

UCC3952≠1

3.85

3.90

3.95

V

Overcharge to normal recovery

UCC3952≠2

3.90

3.95

4.00

V

V(OVR)

Overcharge to normal recovery

voltage

UCC3952≠3

3.95

4.00

4.05

V

g

UCC3952≠4

4.00

4.05

4.10

V(UV)

Normal to undercharge

2.25

2.35

2.45

V

V(UVR)

Undercharge to normal recovery

2.55

2.65

2.75

V

td(OD)

Overcharge delay time

10

25

40

ms

short circuit protection

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

I(THLD)

Discharge current limit

PACK+ = 3.7 V

3.0

6.0

A

td(DLY)

Discharge current delay

PACK+ = 3.7 V, II = 6 A

1

3.0

ms

R(RESET)

Discharge current reset resistance

PACK+ = 3.7 V

7.5

M

bias

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

IDD

Supply current

V(UV) < V(PACK) < V(OV)

5

8

µ

A

IDD(OV)

Operating supply current in overvoltage

V(OV) < V(PACK)

11

24

µ

A

I(SD)

Shutdown current

V(PACK) = 2.0 V

2.5

µ

A

V(min)

Minimum cell voltage when all circuits are fully

functional

1.7

V

td(OV)

Overvoltage delay time

1

2

s

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

4

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

electrical characteristics, T

A

= ≠20

∞

C to 70

∞

C, all voltages are with respect to BNEG (unless

otherwise stated) (continued)

FET switch

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

V

Voltage at PACK

PACK+ > VOV ,

I(SWITCH) = 1 mA to 2 A,

Battery overcharged state switch permits discharge

current only.

100

400

mV

V(PACK≠)

Voltage at PACK≠

PACK+ = 2.5V,

I(SWITCH) = ≠1 mA to ≠2 A,

Battery overdischarged state switch permits charge

current only.

≠600

≠100

mV

RON

Series resistance of the device

PACK+ = 2.5 V,

In normal mode (when not in OV or UV). This value

includes package and bondwire resistance.

50

75

m

thermal shutdown

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

T(SD)

Thermal shutdown temperature (see Note 2)

135

∞

C

NOTE 2: This parameter is ensured by design and is not production tested.

detailed description

pin descriptions

BNEG

Connect the negative terminal of the battery to this pin.

PACK+

Connect to the positive terminal of the battery. This pin is available to the user.

CBPS

This power supply bypass pin is connected to PACK+ through an internal 3-k

resistor. An external 0.1-

µ

F

capacitor must be connected between this pin and BNEG.

PACK≠

The negative terminal of the battery pack (negative terminal available to the user). The internal FET switch

connects this terminal to the BNEG terminal to give the battery pack user appropriate access to the battery. In

an overcharged state, only discharge current is permitted. In an overdischarged state, only charge current is

permitted.

SUB (DP Package Only)

Do not connect. These pins must be electrically isolated from all other pins. The SUB pins may be soldered to

an isolated copper pad for heatsinking. However, most applications do not require heatsinking.

TCLK

Production test mode pin. This pin is used to provide a high-frequency clock to the IC during production testing.

In an application, this pin is left unconnected or tied to BNEG.

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

5

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

APPLICATION INFORMATION

12

10

11

9

7

8

2

14

5

3

4

1

16

15

6

V

PUMP

TDLS

1mS

SETD

RST

SYSTEM

CLOCK

GENERATOR

SEL

4≠1

MUX

V

UV

V

OV

V

UVR

V

OVR

THRESHOLD

COMPARATOR

THERMAL

SHUTDOWN

50mV

50mV

2M

3k

1.5V

PACK+

CBPS

TCLK

BNEG

BNEG

BNEG

BNEG

BNEG

BNEG

PACK≠

PACK≠

PACK≠

PACK≠

PACK≠

NC

N/C

T

DEL

1SEC

T

DEL

10mS

STATE

MACHINE

LOGIC

OV

UV

CLK

13

Figure 1. Detailed Block Diagram

battery voltage monitoring

The battery cell voltage is sampled every 8 ms by connecting a resistor divider across it and comparing the

resulting voltage to a precision internal reference voltage. Under normal conditions (cell voltage is below

overvoltage threshold and above undervoltage threshold), the UCC3952 consumes less than 10

µ

A of current

and the internal MOSFET is fully turned on with the aid of a charge pump.

When the cell voltage falls below the undervoltage threshold for two consecutive samples, the IC disconnects

the load from the battery pack and enters a super-low-power mode. The pack remains in this state until it detects

the application of a charger, at which point charging is enabled. The requirement of two consecutive readings

below the undervoltage threshold filters out momentary drops in cell voltage due to load transients, preventing

nuisance trips.

If the cell voltage exceeds the overvoltage threshold for 1 second, charging is disabled; however, discharge

current is still allowed. This feature of the IC is explained further in the

controlled charge/discharge mode section

of this document.

UCC3952-1, UCC3952-2, UCC3952-3, UCC3952-4

Single Cell Lithium Ion Battery Protection IC

SLUS400D ≠ AUGUST 2000

6

POST OFFICE BOX 655303

∑

DALLAS, TEXAS 75265

APPLICATION INFORMATION

overcurrent monitoring and protection

Discharge current is continuously monitored via an internal sense resistor. In the event of excessive current,

an overcurrent condition is declared if the high current (over 3 A) persists for over 1 ms. This delay allows for

charging of the system bypass capacitors without tripping the overcurrent protection. A 0.1-

µ

F capacitor on the

CBPS pin provides momentary holdup for the IC to assure proper operation in the event that a hard short

suddenly pulls the cell voltage below the minimum operating voltage.

Once an overcurrent condition has been declared, the internal MOSFET turns off. To return the device to normal

operation, the UCC3952 requires a load impedance greater than 7.5 M

across PACK+ to PACK≠. This

impedance is typically achieved by removing the battery pack from the system. At this point, the pack returns

to its normal state of operation.

controlled charge/discharge mode

When the chip senses an overvoltage condition, it prevents any additional charging, but allows discharge. This

is accomplished by activating a linear control loop, which controls the gate of the MOSFET based on the

differential voltage across its drain-to-source terminals. The linear loop attempts to regulate the differential

voltage across the MOSFET to 100 mV. When a light load is applied to the part, the loop adjusts the impedance

of the MOSFET to maintain 100 mV across it. As the load increases, the impedance of the MOSFET is

decreased to maintain the 100-mV control. At heavy loads (still below the overcurrent limit), the loop does not

maintain regulation and drives the gate of the MOSFET to the battery voltage (not the charge-pump output

voltage). The MOSFET R

DS(on)

in the overvoltage state is higher than RDS(on) during normal operation. The

voltage drop (and associated power loss) across the internal MOSFET in this mode of operation is still

significantly lower than the typical solution of two external back-to-back MOSFETs, where the body diode is

conducting.

When the chip senses an undervoltage condition, it disconnects the load from the battery pack and shuts itself

down to minimize current drain from the battery. Several circuits remain powered and detect placement of the

battery pack into a charger. Once the charger presence is detected, the linear loop is activated and the chip

allows charging current into the battery. This linear control mode of operation is in effect until the battery voltage

reaches a level of V

UVR

, at which time normal operation is resumed.

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer's applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI's publication of information regarding any third

party's products or services does not constitute TI's approval, warranty or endorsement thereof.

Copyright

©

2000, Texas Instruments Incorporated