0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 1 of 6; 9/24/02

Specifications are subject to change.

Features

∑

0.25-µm amplifier transistors

∑

0.25-µm switch transistors

∑

0.25-µm, 2-µm and 4-µm diodes

∑

High-Q passives

∑

3 MIM capacitance densities

∑

TaN resistors

∑

GaAs resistors

∑

High-density interconnects

∑

3 metal layers

∑

Air bridges

∑

Substrate vias

∑

Protective overcoat

∑

Operation up to V

d

= 9 V

Applications

∑

Up to 20 GHz

∑

Communications

∑

Military

∑

Power amplifiers

∑

Driver amplifiers

∑

Low-noise amplifiers

∑

AGC amplifiers

∑

Limiting amplifiers

∑

Transimpedance amplifiers

∑

Differential amplifiers

∑

Digital and analog phase shifters

∑

Digital and analog attenuators

∑

Mixers (up and down converters)

∑

Multipliers

∑

Switches

∑

Oscillators

General Description

The 0.25-µm XKu pHEMT 3MI (3-metal-interconnect)

process utilizes T-gates in conjunction with a pHEMT ma-

terial structure. This process is optimized for high-power

applications through 20 GHz. The process demonstrates

comparable power density and gain to the 0.25-µm mmW

pHEMT 3MI process at X-band frequencies and similar bias

conditions. However, the 0.25-µm XKu pHEMT offers a

higher breakdown voltage allowing higher bias voltages to

be applied to deliver higher power densities. Passives in-

clude 3 thick-metal interconnect layers, precision TaN re-

sistors, GaAs resistors, through-substrate vias and 3 MIM

capacitance densities. The via-under-cap process aids in

size compaction and offers excellent grounds at higher fre-

quencies. Air bridges produce minimal interconnect capaci-

tance. The protective overcoat layer provides environ-

mental robustness.

PROTECTIVE OVERCOAT

4.0 µm METAL 2

2.0 µm METAL 1

2000 ≈ NITRIDE 2

MIM METAL

500 ≈ NITRIDE 1

0.75 µm METAL 0

TaN RESISTOR

500 ≈ NITRIDE 0

T-GATE

ACTIVE REGION

OHMIC METAL (EXCEPT VIA)

SEMI-INSULATING GaAs SUBSTRATE

VIA UNDER CAP

0.25-µm 3MI Process Cross Section

0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 2 of 6; 9/24/02

Specifications are subject to change.

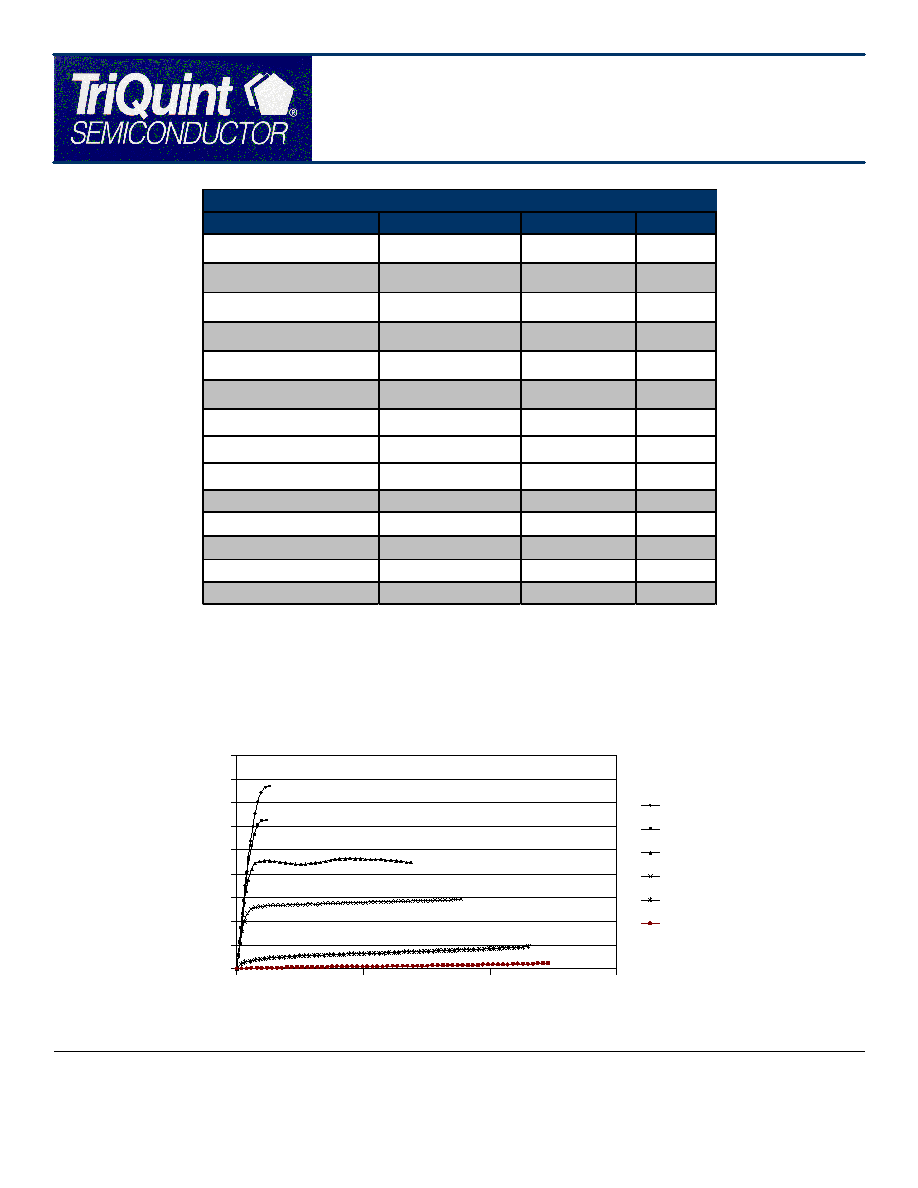

0.25-µm XKu pHEMT 3MI

DC Characteristics

300-µm FET

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

0

5

10

15

Vds (V)

Ids (A)

Vgs = 0.7 V

Vgs = 0.3 V

Vgs = 0 V

Vgs = -0.3 V

Vgs = -0.7 V

Vgs = -0.9 V

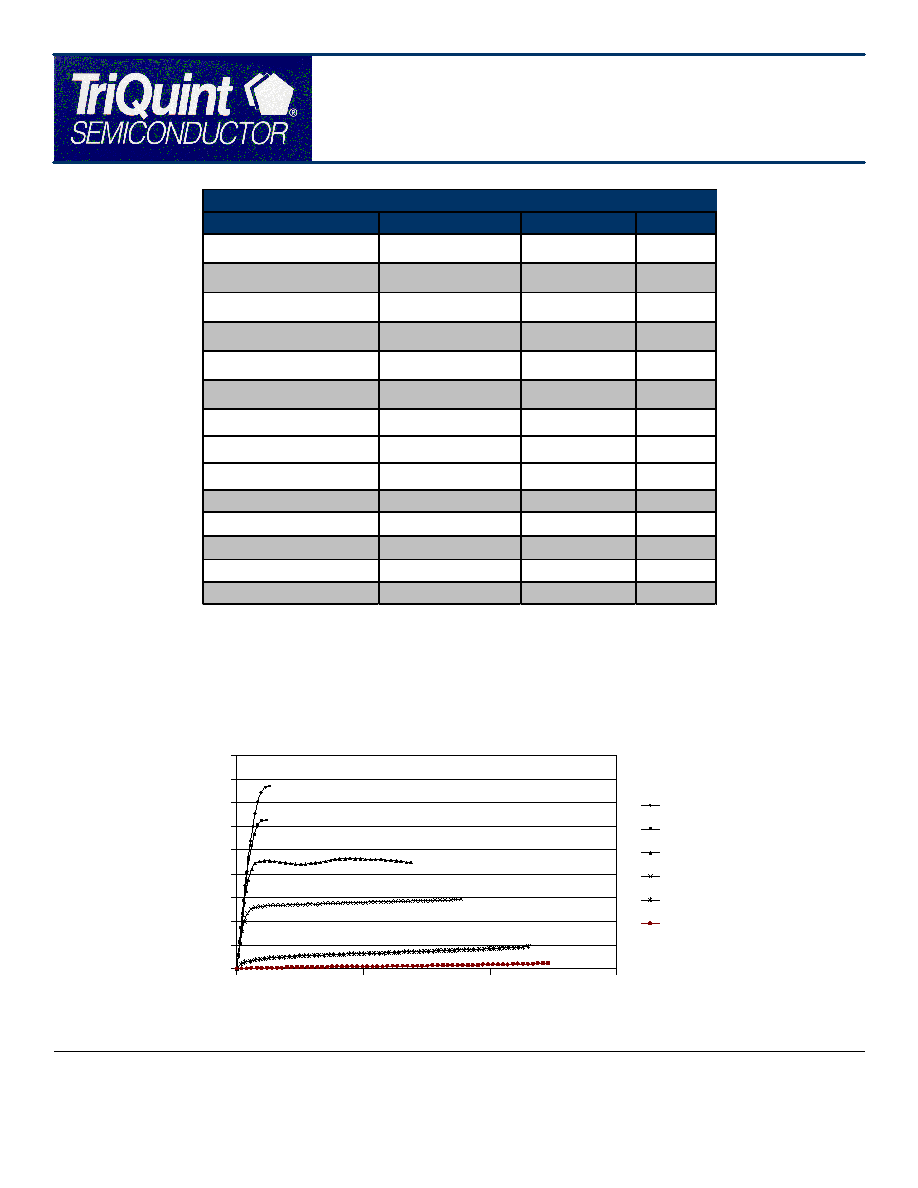

Element

Parameter

Typical Value

Units

FETs

I

dss

285

mA/mm

I

max

510

mA/mm

G

m

375

mS/mm

V

bd

-21

V

V

p

-1

V

F

t (peak)

60

GHz

MIM capacitors

density

240

pF/mm

2

300

pF/mm

2

1200

pF/mm

2

Capacitors over vias

yes

TaN resistors

sheet resistance

50

V

/sq

GaAs resistors

sheet resistance

160

V

/sq

Vias

yes

Substrate

thickness

100

µm

0.25-µm XKu pHEMT 3MI Process Details

0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 3 of 6; 9/24/02

Specifications are subject to change.

0.25-µm XKu pHEMT 3MI

Minimum Noise Figure

1000-µm FET @ 3 Volts, 75 mA

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0

5

10

15

20

25

30

Frequency (GHz)

NFmin (dB)

0.25-µm XKu pHEMT 3MI

Maximum Available Gain/Stable Gain (MAG/MSG)

1000-µm FET @ 9 Volts, 75 mA

0

5

10

15

20

25

0

10

20

30

Frequency (GHz)

MAG/MSG (dB)

0

0.2

0.4

0.6

0.8

1

1.2

1.4

Stability Factor (K)

0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 4 of 6; 9/24/02

Specifications are subject to change.

0.25-µm XKu pHEMT 3MI

Power Tuned Load

1000-µm FET @ 9 Volts, 10 GHz

15

20

25

30

35

10

15

20

25

Pin (dBm)

Pout (dBm)

20

30

40

50

60

PAE (%)

0.25-µm XKu pHEMT 3MI

Efficiency Tuned Load

1000-µm FET @ 9 Volts, 10 GHz

15

20

25

30

35

10

15

20

25

Pin (dBm)

Pout (dBm)

20

30

40

50

60

PAE (%)

0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 5 of 6; 9/24/02

Specifications are subject to change.

Gate Pitch (µm) Gate Fingers FET Sizes (µm)

12 18

10

600

26 26

4

300

26 26

8

640 & 800

26 26

10

1000 & 1200

26 26

12

1440

32 32

8

800

32 32

10

1000

32 32

12

960, 1440 & 1800

FET Models Available

0.25-µm XKu pHEMT 3MI

Process Data Sheet

Semiconductors for Communications, Space and Military

www.TriQuint.com

500 West Renner Road

Richardson, Texas 75080

Phone: 972-994-8200

Foundry: 972-994-4545

Email: info@triquint.com

Page 6 of 6; 9/24/02

Specifications are subject to change.

Prototyping and Development

∑

Prototype Chip Option (PCO)

∑

Shared mask set

∑

Run often

∑

Backside via process included

∑

PCM (process control monitor) qualified

wafers

∑

For PCO schedules, please visit

http://

www.triquint.com/prodserv/divisions/

foundry/new/proto_sched_pco.cfm

∑

Prototype Wafer Option (PWO)

∑

Customer-specific masks

∑

Customer schedule

∑

2 wafers delivered

∑

Backside vias included

∑

PCM (process control monitor) qualified

wafers

Process Status

∑

0.25-µm XKu pHEMT 3MI is fully released and

qualified

Contact TriQuint or visit

http://www.triquint.com/company/quality/

for more information on quality and reliability.

Manufacturing Services

∑

Mask making

∑

Wafer thinning

∑

Wafer dicing

∑

Substrate vias

∑

DC die-sort testing

∑

RF on-wafer testing

∑

Final visual testing

Design Tools

∑

Device libraries of circuit elements:

∑

FETs

∑

Thin-film and implanted resistors

∑

Capacitors

∑

Inductors

∑

Agilent ADS design kit

∑

MASC Library

Training

∑

GaAs design classes:

∑

Half-day introduction upon request

∑

3 day technical training upon request at

the TriQuint Texas facility

Applications Services

∑

Tiling of GDSII stream files including PCM

(process control monitor)

∑

Design rule checking

∑

Layout versus schematic checking

∑

Engineering:

∑

On-wafer DC test

∑

On-wafer RF test

∑

Thermal analysis

∑

Yield enhancement

∑

Part qualification

∑

Failure analysis