Released Process

TQTRx

GaAs MESFET Foundry Service

Semiconductors for Communications

www.triquint.com

TriQuint Semiconductor

2300 NE Brookwood Pkwy

Hillsboro, Oregon 97124

Phone: 503-615-9000

Fax: 503-615-8905

Email: info@triquint.com

Page 1 of 7; Rev 1.0 11/15/01

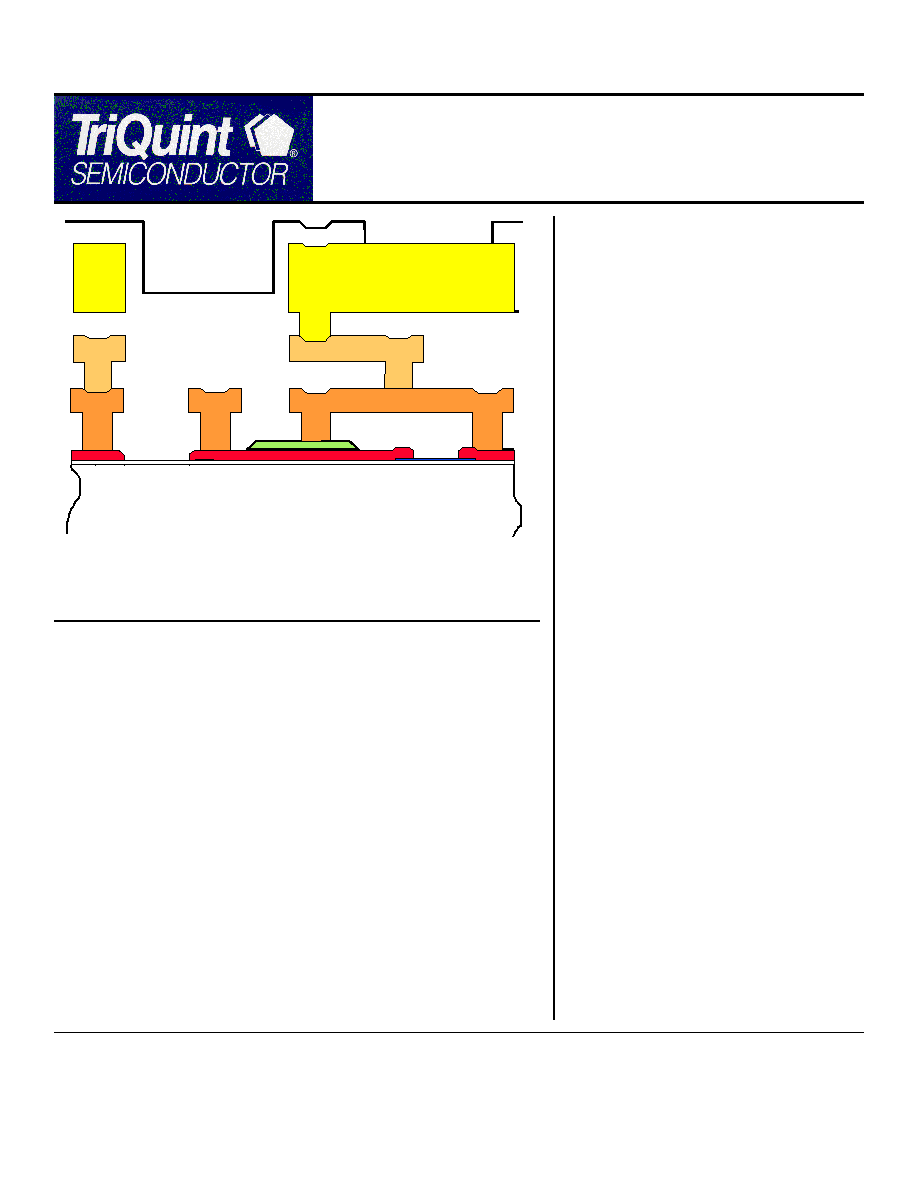

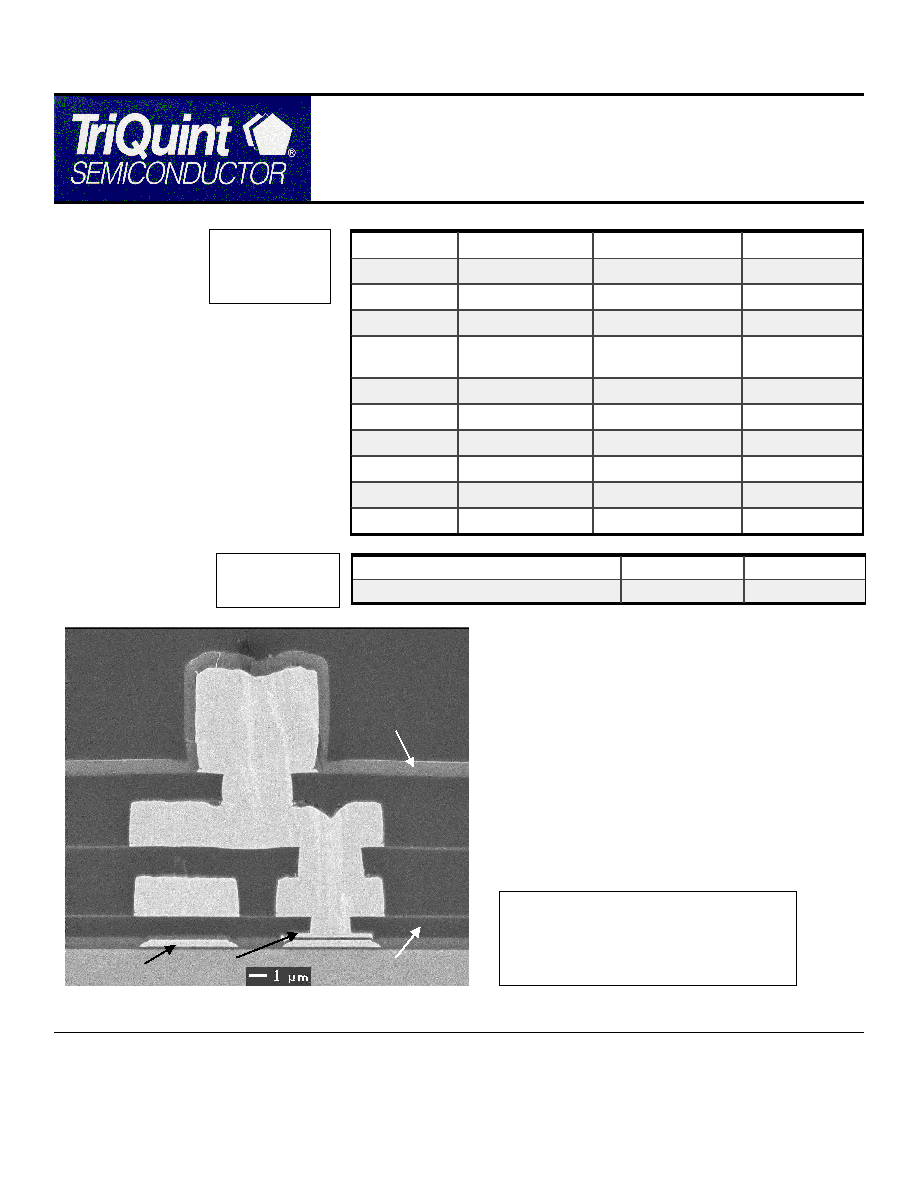

TQTRx Process Cross-Section

Production Process

TQRLC

Advanced Passives Foundry Service

Features

·

Thick 4 Layer Metal; > 9 µm total

thickness

·

High Density Interconnects:

·

3 Global

·

1 Local

·

High-Q Passives; Inductor Q >50

@ 2 GHz

·

Low Cost: Passives Only

·

Thin Film Resistors

·

Dielectric Encapsulated Metals

·

Planarized Surface;

simplified plastic packaging

·

Substrate Vias Available

·

Volume Production Process

Applications

·

Passive Components:

·

Phase Shifters

·

Baluns

·

Transformers

·

Couplers

·

Mixers

(with off-chip di-

ode arrays)

·

Circuits Requiring High-Q

Passive Elements

·

Matching Circuits

·

RF Module Front-End Filters

·

General RF and Microwave Imped-

ance Matching

General Description

TriQuint's TQRLC is a pure passives process. It is targeted at

high performance, small size passive-only circuits and utilizes

over 9 µm of gold metal. High density interconnections are ac-

complished with three thick global and one surface metal inter-

connect layers. The four metal layers are encapsulated in a high

performance, low dielectric constant material that allows wiring

flexibility and plastic packaging simplicity. Precision NiCr resis-

tors, inductors, and high value MIM capacitors are available.

The process is based on the TQTRx process, currently

TriQuint's highest volume process. The TQRLC process is

available on 150-mm (6 inch) wafers.

Semiconductors for Communications

www.triquint.com

TriQuint Semiconductor

2300 NE Brookwood Pkwy

Hillsboro, Oregon 97124

Phone: 503-615-9000

Fax: 503-615-8905

Email: info@triquint.com

Page 1 of 3; Rev 2.1 8/10/02

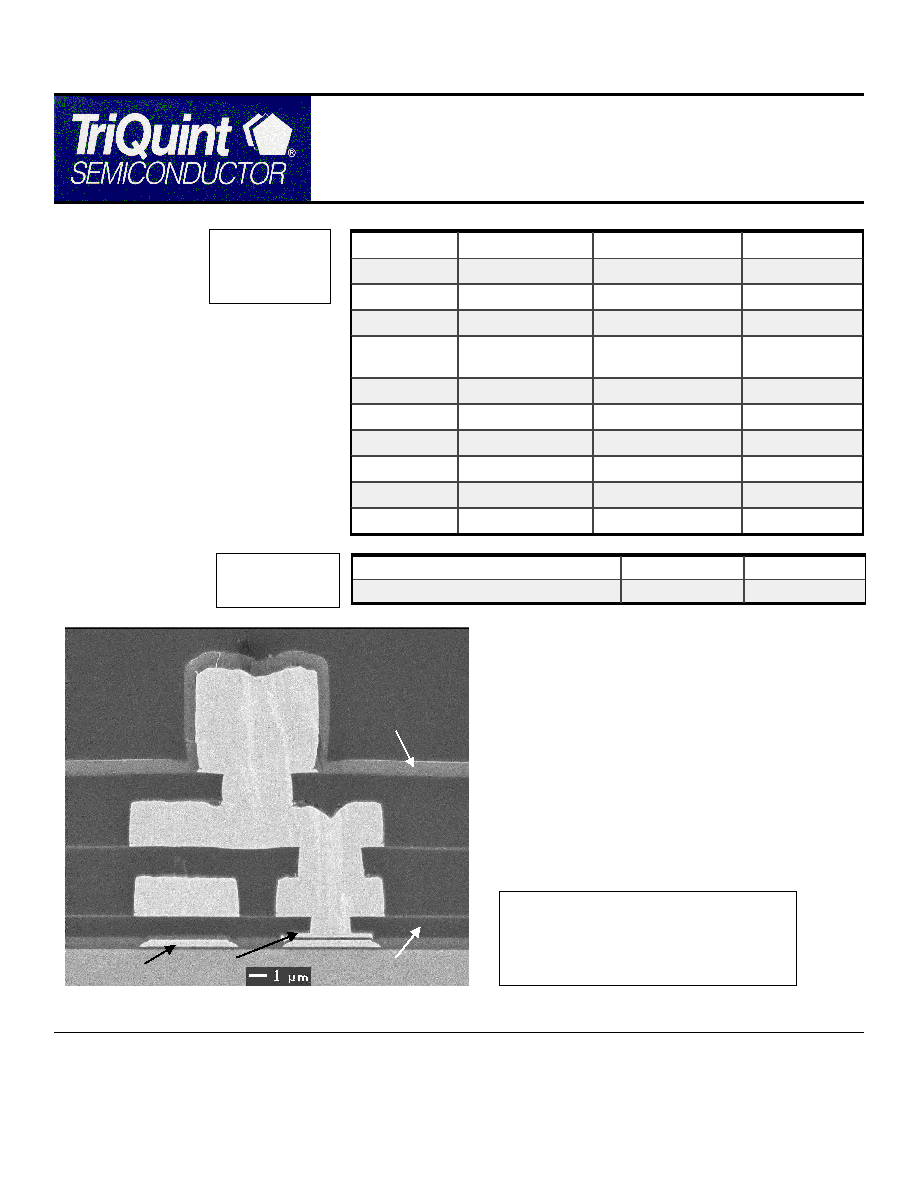

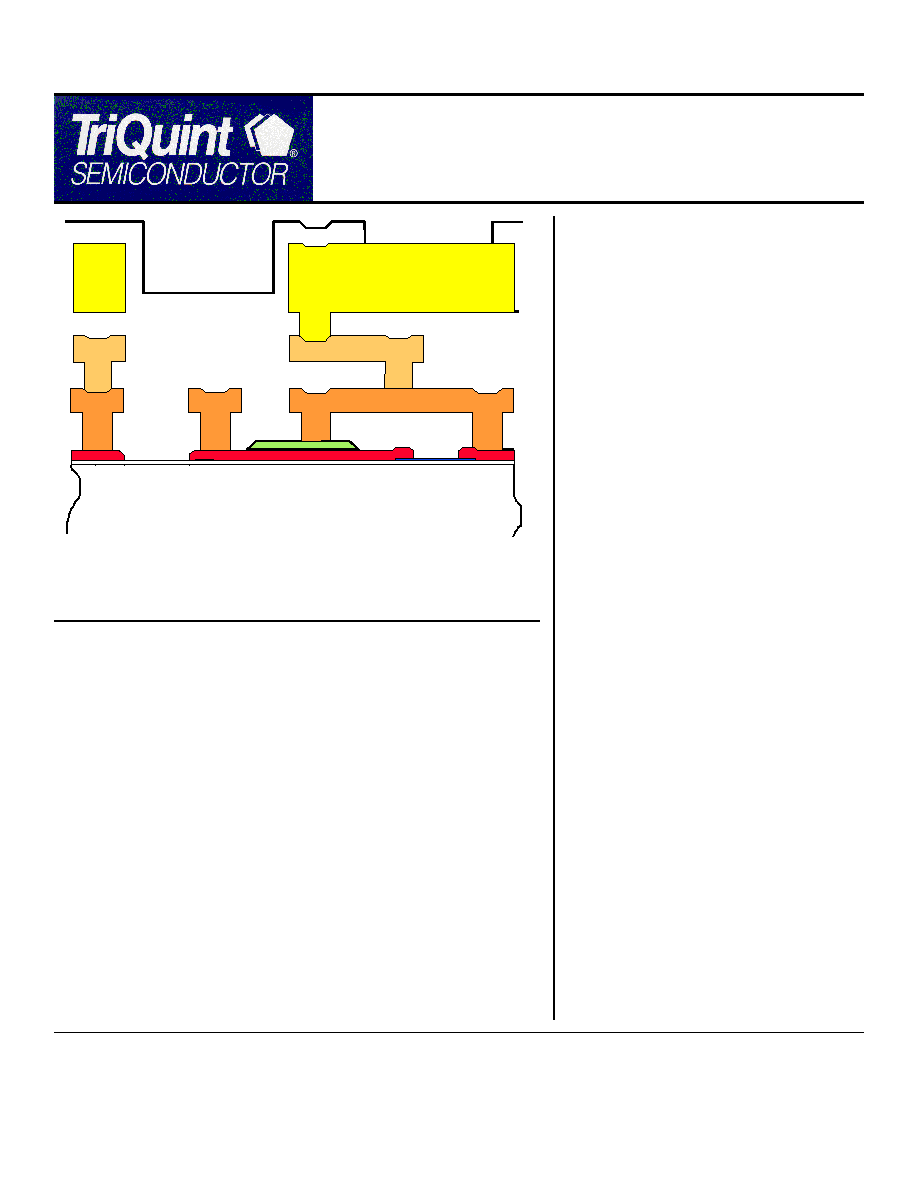

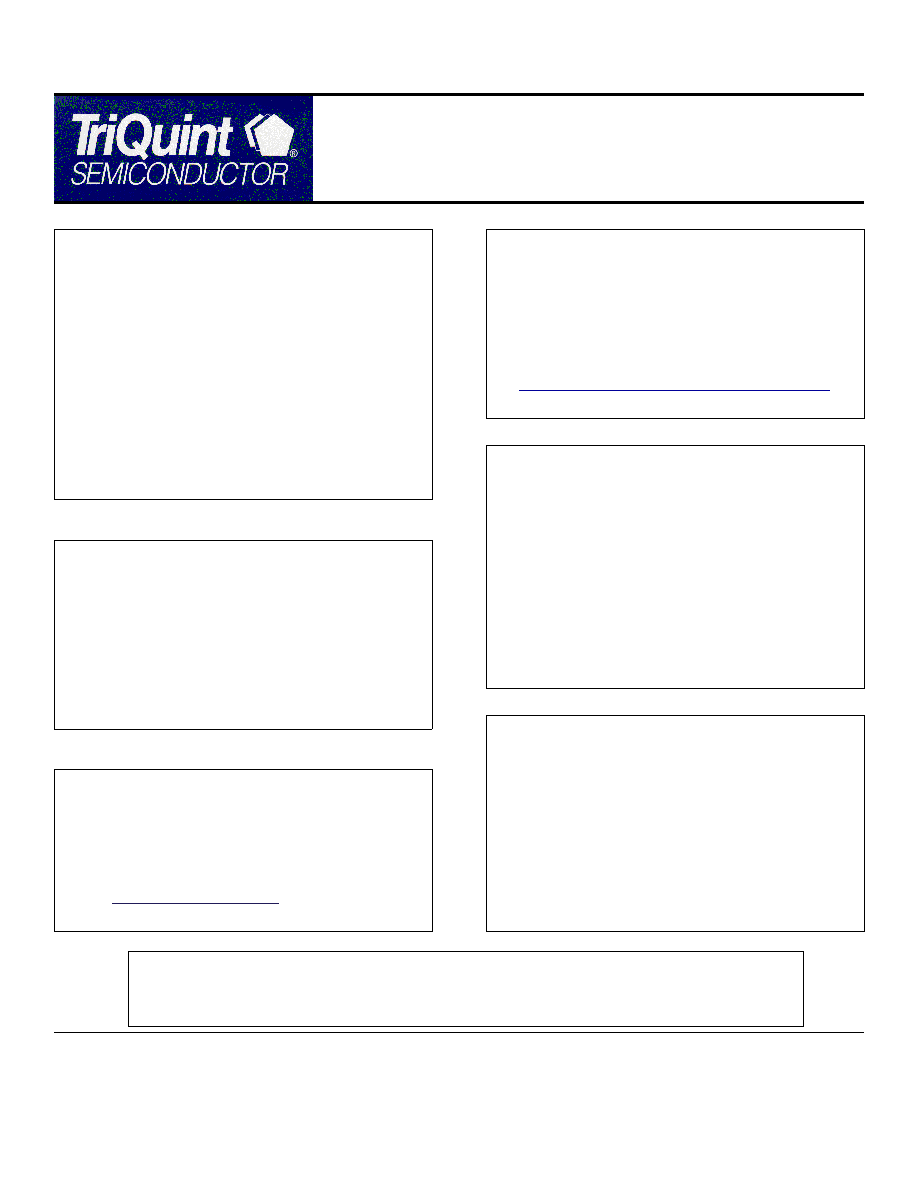

TQRLC Process Cross-Section

NiCr Resistor

MIM Capacitor

Low-cost Mechanical Grade Semi-Insulating GaAs Substrate

MIM Metal

Metal 0

Metal 1

Metal 1

Metal 1 - 2 um

Passivation Via

Metal 2

Metal 3

Dielectric

Dielectric

Metal 3 - 5 um

Metal 2 - 2 um

NiCr Resistor

MIM Capacitor

Low-cost Mechanical Grade Semi-Insulating GaAs Substrate

MIM Metal

Metal 0

Metal 1

Metal 1

Metal 1 - 2 um

Passivation Via

Metal 2

Metal 3

Dielectric

Dielectric

Metal 3 - 5 um

Metal 2 - 2 um

Released Process

TQTRx

MESFET Foundry Service

Semiconductors for Communications

www.triquint.com

TriQuint Semiconductor

2300 NE Brookwood Pkwy

Hillsboro, Oregon 97124

Phone: 503-615-9000

Fax: 503-615-8905

Email: info@triquint.com

Page 2 of 7; Rev 1.0 11/15/01

Specifications Subject to Change

Capacitor Breakdown Voltage - Design

20

V

- Typical

40

V

Maximum

Ratings

Production Process

TQRLC

Advanced Passives Foundry Service

Semiconductors for Communications

www.triquint.com

TriQuint Semiconductor

2300 NE Brookwood Pkwy

Hillsboro, Oregon 97124

Phone: 503-615-9000

Fax: 503-615-8905

Email: info@triquint.com

Page 2 of 3; Rev 2.1 8/10/02

Element

Parameter

Value

Units

Interconnects Metal Layers

Four: 0.4,2,2,5.3

µm

Space Width

Met3= 3; Met1&2= 2

µm

Trace Width

Met3= 5; Met1&2= 2

µm

BCB Dielectric Nom. Thickness

ILD1= 1 +/-0.1;

ILD2&3= 3.2 +/- 0.2

µm

Dielectric Constant

2.8

MIM Caps

Values

600

pF/mm2

Resistors

NiCr

50

Ohms/sq

Vias

Yes

Mask Layers

No Vias

12

With Vias

14

TQRLC

Process

Details

Met3

Via3

Met2

Via2

Via1

Met1

Met0

MIM

ILD3

dielectric

ILD2

dielectric

ILD1 dielectric

Passivation

Example of Metal Stack Configurations

Possible with TQRLC Process; Edge or

Parallel-Coupled Structures Through

The ILD Layers Are Also Possible.

Design Tool Status

·

Design Manual Available Now

·

Device Library of Circuit Elements includes Thin Film

Resistors, Capacitors, Inductors

·

Agilent ADS Definition File for E-M Simulation Now

·

Layout/Verification Kit for ICEditors

·

Cadence Layout Library Available Q3'02

Process Qualification

Status

·

TQRLC is a fully-released process

·

Reliability Reports

·

TQRLC Process Qualification

·

TQTRx Element Qualification Report

·

For more information on Quality and

Reliability, contact TriQuint or visit:

www.tqs.com/Manufacturing/QR/bdy_qr-pubs.htm.

Production Process

TQRLC

Advanced Passives Foundry Service

Semiconductors for Communications

www.triquint.com

TriQuint Semiconductor

2300 NE Brookwood Pkwy

Hillsboro, Oregon 97124

Phone: 503-615-9000

Fax: 503-615-8905

Email: info@triquint.com

Page 3 of 3; Rev 2.1 8/10/02

Applications Support Services

·

Tiling of GDSII Stream Files including PCM

·

Design Rule Check Services

·

Layout versus Schematic Check Services

·

Engineering Services:

·

Packaging Development

·

Test Development Engineering (on-wafer and

packaged parts)

·

Thermal Analysis Engineering

·

Yield Enhancement Engineering

·

Part Qualification Services

·

Failure Analysis

Manufacturing Services

·

Mask Making

·

Production 150 mm Wafer Fab

·

Wafer Thinning

·

Wafer Sawing

·

Substrate Vias

·

DC Die Sort Testing

·

RF On-Wafer Testing

·

Plastic Packaging

·

RF Packaged Part Testing

Please contact your local TriQuint Semiconductor Representative or

Foundry Services Staff for additional information:

E-mail: sales@triquint.com Phone: (503) 615-9000 Fax: (503) 615-8905

Prototyping and Development

·

Prototype Development Quickturn (PDQ):

·

Shared Mask Set;

·

Run Monthly;

·

Hot Lot Cycle Time;

·

Via and Non-Via Options.

·

Prototype Wafer Option (PWO):

·

Customer-specific Masks, Customer Schedule

·

2 wafers delivered

·

Hot Lot Cycle Time

·

With thinning and sawing; optional backside

vias

Training

·

GaAs Design Classes:

·

Half Day Introduction; Upon Request

·

Four Day Technical Training; Fall & Spring at

TriQuint Oregon facility

·

For Training Schedules, please visit:

www.triquint.com/foundry/