| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: X9470V24I | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Preliminary Information

REV 11.16 3/20/03

1 of 25

www.xicor.com

Preliminary Information

RF Power Amplifier (PA) Bias Controller

X9470

FEATURES

∑ Programmable Bias Controller IC for Class A and

AB LDMOS Power Amplifiers

∑ Adaptive System on Chip Solution

∑ Bias Current Calibration to better than ±4%

using Reference Trim DCP

∑ Automatic Bias Point Tracking and Calibration

-- I

DQ

Sensing and Tracking

--Programmable Instrumentation Amplifier to

Scale Wide Range of I

DQ

--Programmable Gate Bias Driver

--All Programmable settings are Nonvolatile

--All Settings Recalled at Power Up.

∑ 28V Maximum V

DD

∑ 2 Wire Interface for Programming Bias Setting

and Optimizing I

DQ

Set Point

∑ Bias Level Comparator

∑ Shutdown Control pin for PA Signal

∑ Slave address to allow for multiple devices

∑ 24-pin TSSOP Package

∑ Applications: Cellular Base Stations (GSM,

UMTS, CDMA, EDGE), TDD applications, Point-

to-multipoint, and other RF power transmission

systems

DESCRIPTION

The Xicor X9470 RF PA Bias Controller contains all of

the necessary analog components to sense the PA

drain current through an external sense resistor and

automatically control the gate bias voltage of an

LDMOS PA. The external sense resistor voltage is

amplified by an instrumentation amplifier and the out-

put of the amplifier along with an external reference

voltage is fed to the inputs of a comparator. The com-

parator output indicates which direction the LDMOS

gate bias voltage will move in the next calibration

cycle. System calibration is accomplished by enabling

the X9470 and providing a clock to the SCL pin. The

LDMOS drain current can be maintained constant over

temperature and aging changes by periodic calibra-

tion. The VOUT pin can be used to monitor the aver-

age power by tracking the drain current. Up to eight

X9470 or additional Xicor Digital Potentiometers can

be controlled via a two-wire serial bus.

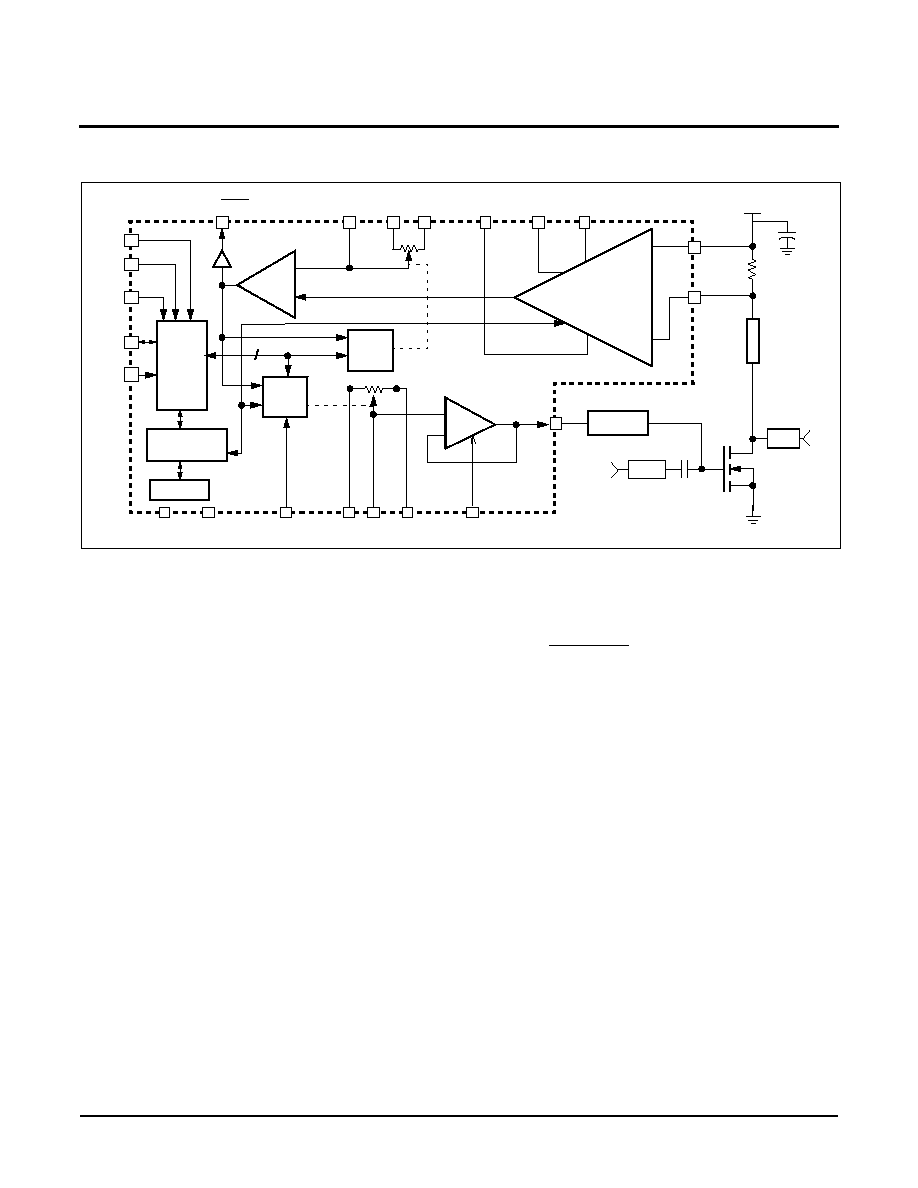

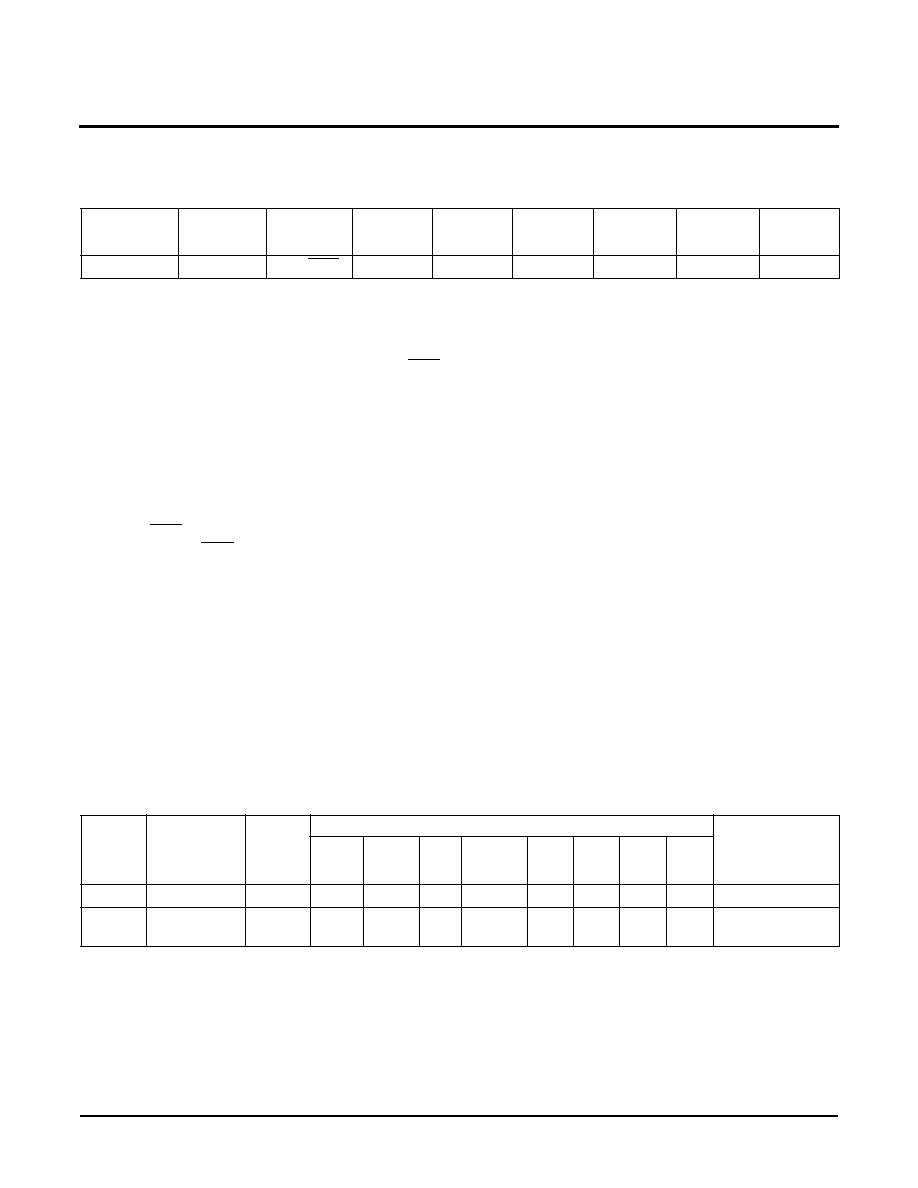

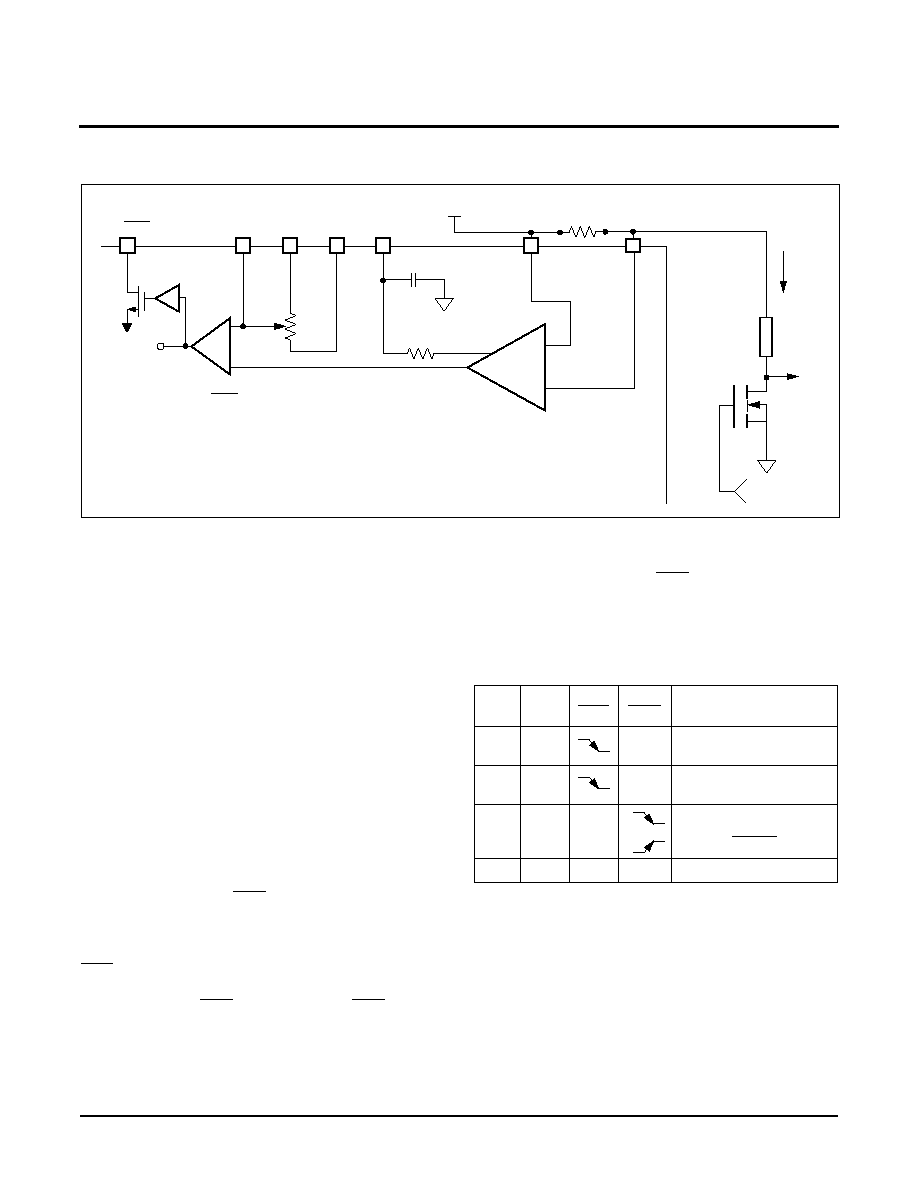

TYPICAL APPLICATION

A0

A2

VCC

VSS

V+

AGND

Comparator

choke

RF PA in

R

SENSE

V

DD

V

REF

V

SENSE+

V

BIAS

INC/DEC

Instrumentation

Amplifier

V

CS

V

OUT

V

SENSE≠

R

REF

RW

REF

RL

REF

SHDN

+

≠

EEPROM

SCL

SDA

A1

Vbias

control

VREF

control

I2C

interface

Control &

Status Registers

RF

out

RH

REF

R

BIAS

VP

RH

BIAS

RL

BIAS

RW

BIAS

FILTER

V

BIAS (Unbuffered)

RF Impedance

Matching

C

BULK

Class A Example

Preliminary Information

2 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

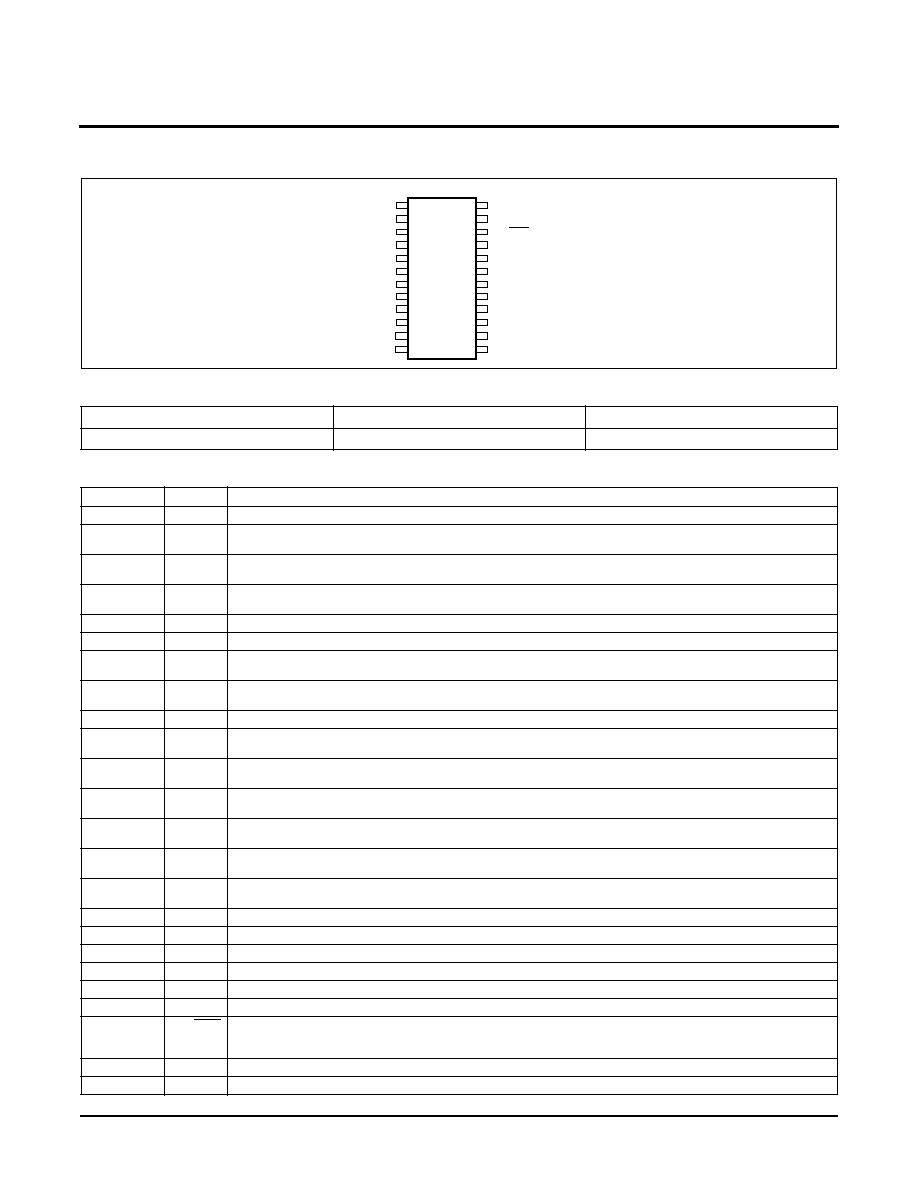

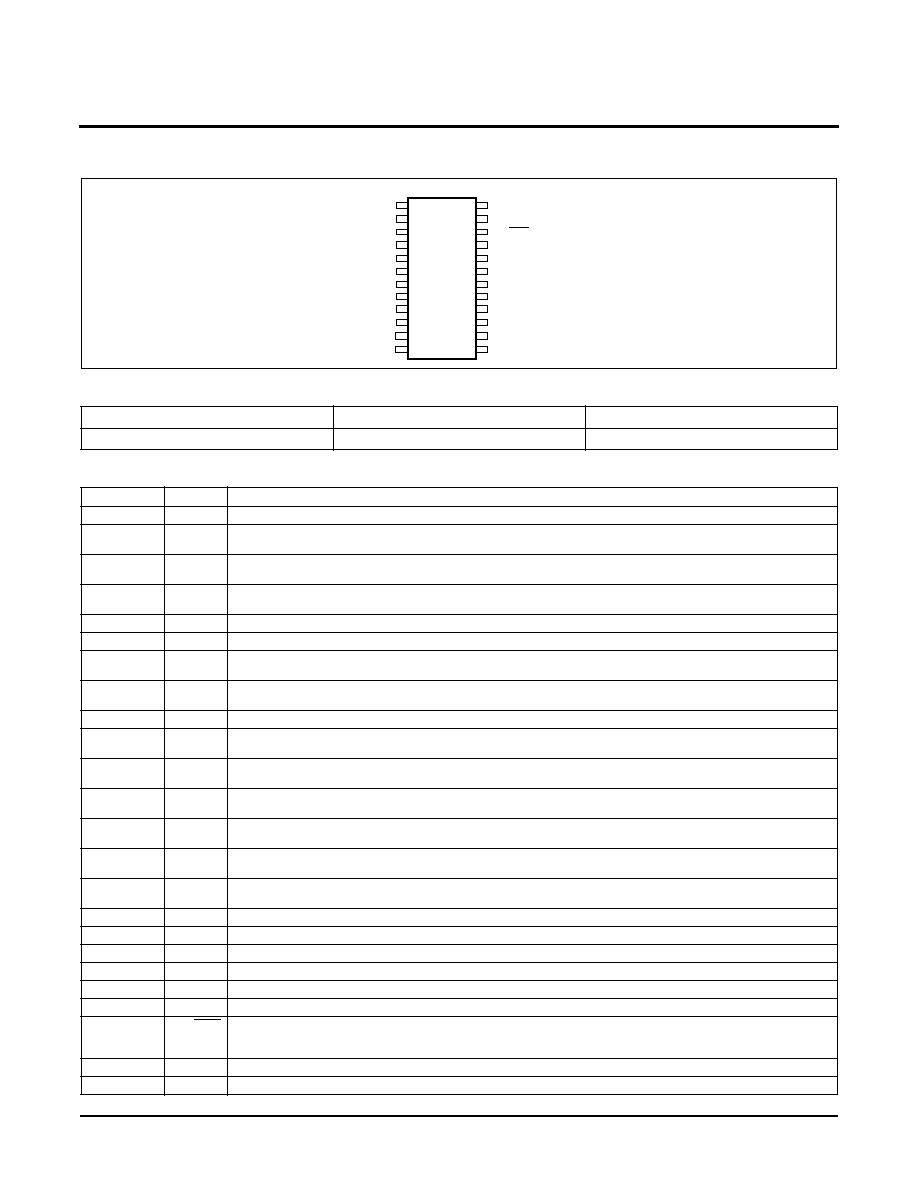

PIN CONFIGURATION

ORDERING INFORMATION

PIN DESCRIPTIONS

Part Number

Temperature Range

Package

X9470V24I

-40∞C TO 85∞C

24-Lead TSSOP

TSSOP pin

Symbol

Brief Description

1

V

SENSE+

Positive sense voltage input terminal

2

RH

REF

Upper Terminal of Potentiometer, called the R

REF

potentiometer. The voltage applied to this pin will determine the

upper voltage limit of the adjustment for the Up/Down threshold of the comparator.

3

RL

REF

Lower Terminal of Potentiometer, called the R

REF

potentiometer. The voltage applied to this pin will determine the

lower voltage limit of the adjustment for the Up/Down threshold of the comparator.

4

RW

REF

Wiper Terminal of Potentiometer, called the R

REF

potentiometer. The voltage on this pin will be the threshold for

the Up/Down comparator. Also referred to as the V

REF

of the comparator.

5

AGND

Analog ground to allow single point grounding external to the package to minimize digital noise.

6

VSS

System (Digital) Ground Reference

7

CS

Chip Select. This input enables bias calibration adjustments to the R

BIAS

potentiometer. CMOS input with internal

pull-down.

8

SCL

Dual function. Function 1: The increment control input. Increments or decrements the R

BIAS

potentiometer.

Function 2: Serial Data Clock Input. Requires external pull-up.

9

SDA

Serial Data Input. Bi-directional 2-wire interface. Requires external pull-up.

10

RH

BIAS

Upper Terminal of Potentiometer, called the R

BIAS

potentiometer. The voltage applied to this pin will determine the

upper limit of the bias voltage to the PA (or V

BIAS

pin).

11

RW

BIAS

Wiper Terminal of Potentiometer, called the R

BIAS

potentiometer. This voltage is the equivalent to the unbuffered

voltage that will appear at the V

BIAS

pin.

12

RL

BIAS

Lower Terminal of Potentiometer, called the R

BIAS

potentiometer. The voltage applied to this pin will determine the

lower limit of the bias voltage to the PA (or V

BIAS

pin).

13

A0

External address pin which allows for a hardware slave address selection of this device.

This pin has an internal pull-down.

14

A1

External address pin which allows for a hardware slave address selection of this device.

This pin has an internal pull-down.

15

A2

External address pin which allows for a hardware slave address selection of this device.

This pin has an internal pull-down.

16

VSS

System (Digital) Ground Reference

17

V

BIAS

This is the bias output voltage pin and is used to drive the filter network to the PA gate.

18

V

CC

System (Digital) Supply Voltage

19

V

CC

System (Digital) Supply Voltage

20

V +

Positive voltage supply for the instrumentation amplifier and other analog circuits.

21

V

OUT

Instrumentation Amplifier output that is 20x or 50x the voltage across the Rsense pins.

22

INC/DEC

Status output that indicates the state of the comparator. When this pin is HIGH, the RBIAS potentiometer will in-

crement; when the pin is LOW, the RBIAS potentiometer will decrement. This pin is open drain and requires ex-

ternal resistor pull-up.

23

SHDN

Shutdown the output op amp. When SHDN is active (HIGH), the V

BIAS

pin is pulled LOW.

24

V

SENSE-

Negative sense voltage Input terminal

V

OUT

RW

REF

V+

TSSOP

1

2

3

4

5

6

7

14

20

19

18

17

16

15

X9470

V

sense+

V

sense-

RH

REF

RL

REF

VSS

AGND

SHDN

INC/DEC

V

CC

A2

RH

BIAS

V

CC

SDA

SCL

V

BIAS

VSS

CS

8

9

10

13

RL

BIAS

RW

BIAS

11

12

A0

A1

24

23

22

21

Preliminary Information

3 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

ABSOLUTE MAXIMUM RATINGS*

Voltage on V+ (referenced to AGND)....................... 7V

Voltage on VCC (reference to VSS)......................... 7V

Voltage on all RH, RW, RL pins

(reference to AGND): ........................................... 7V

Voltage on Vsense+ or

Vsense- (reference to AGRND).......................... 30V

Voltage on SDA, CS, SCL, SHDN

(reference to AGND) ............... -0.3V to (Vcc + 0.3V)

Current into Output Pin:

..........................................±

5mA

Continuous Power Dissipation:........................ 500mW

Operating Temperature range: ...............-40

∞

C to +85

∞

C

Junction Temperature:........................................... 150

∞

C

Storage Temperature......................... -65

∞

C to +150

∞

C

Lead Temperature (Soldering, 10 seconds): ..... 300

∞

C

*COMMENT

Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device.

This is a stress rating only and the functional operation

of the device at these or any other conditions above

those listed in the operational sections of this specifi-

cation is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect

device reliability.

ELECTRICAL CHARACTERISTICS

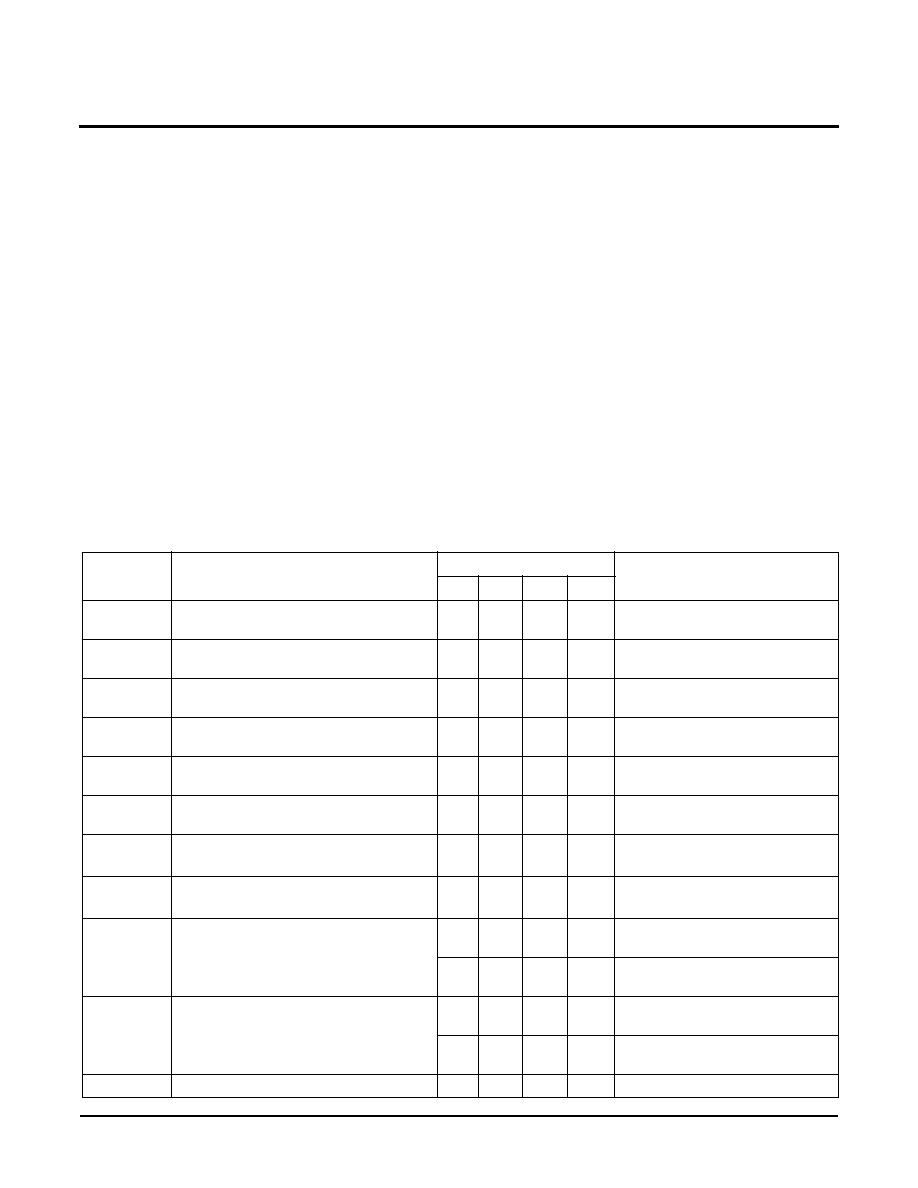

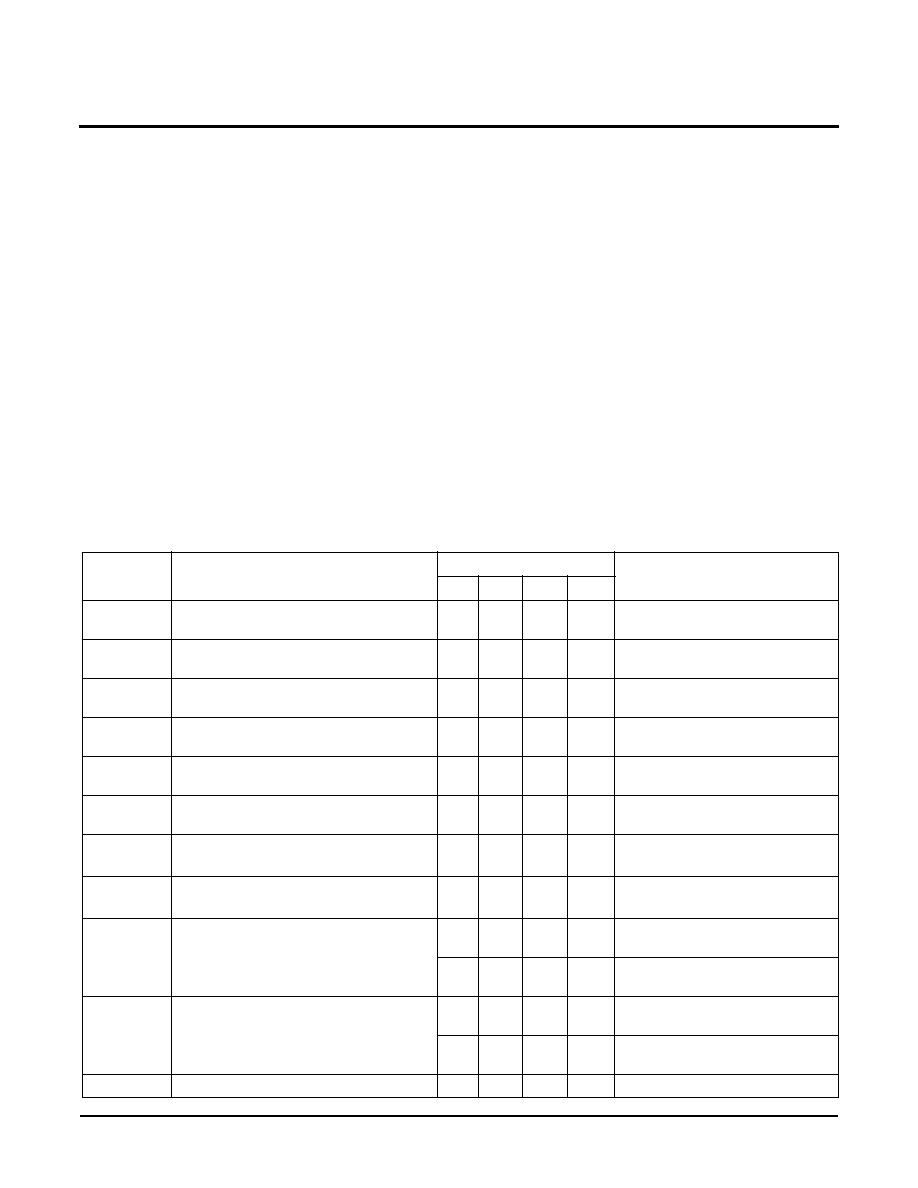

INSTRUMENTATION AMPLIFIER

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min. Typ. Max. Units

V

IN

(10)

Common Mode Input Voltage on

V

SENSE+

and V

SENSE-

pins

20

28

V

Gain 1

Gain from V

SENSE

to V

OUT

(2)

20

V/V

Measured with Status

Register bit SR0=0

Gain 2

Gain from V

SENSE

to V

OUT

(2)

50

V/V

Measured with Status

Register bit SR0=1

V

RANGE1

Differential voltage sense range be-

tween V

SENSE+

and V

SENSE-

for gain 1

60

90

mV

Gain = 20

V

RANGE2

Differential voltage sense range be-

tween V

SENSE+

and V

SENSE-

for gain 2

40

60

mV

Gain = 50

V

OS

Input Offset Voltage

0.5

mV

V

SENSE

= 40mV to 90mV

T

A

= 25∞C

Av1

Gain 1 Error

Gain = 20 (4)

1.5

%

V

SENSE

= 60mV to 90mV

T

A

= 25 to 85∞C, Gain = 20

Av2

Gain 2 Error

Gain = 50 (4)

1.5

%

V

SENSE

= 40mV to 60mV

T

A

= 25 to 85∞C, Gain = 50

Avt1

Total Error, Gain 1

Gain = 20 (5)

-6

1.5

6

%

V

SENSE

= 60mV to 90mV

T

A

= 85∞C, Gain = 20

10

%

V

SENSE

= 60mV to 90mV

T

A

= 25 to 85∞C, Gain = 20

Avt2

Total Error, Gain 2

Gain = 50 (5)

-6

1.5

6

%

V

SENSE

= 40mV to 60mV

T

A

= 85∞C, Gain = 50

10

%

V

SENSE

= 40mV to 60mV

T

A

= 25 to 85∞C, Gain = 50

At

Long Term Drift

2

%

Avt1 or Avt2

Preliminary Information

4 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

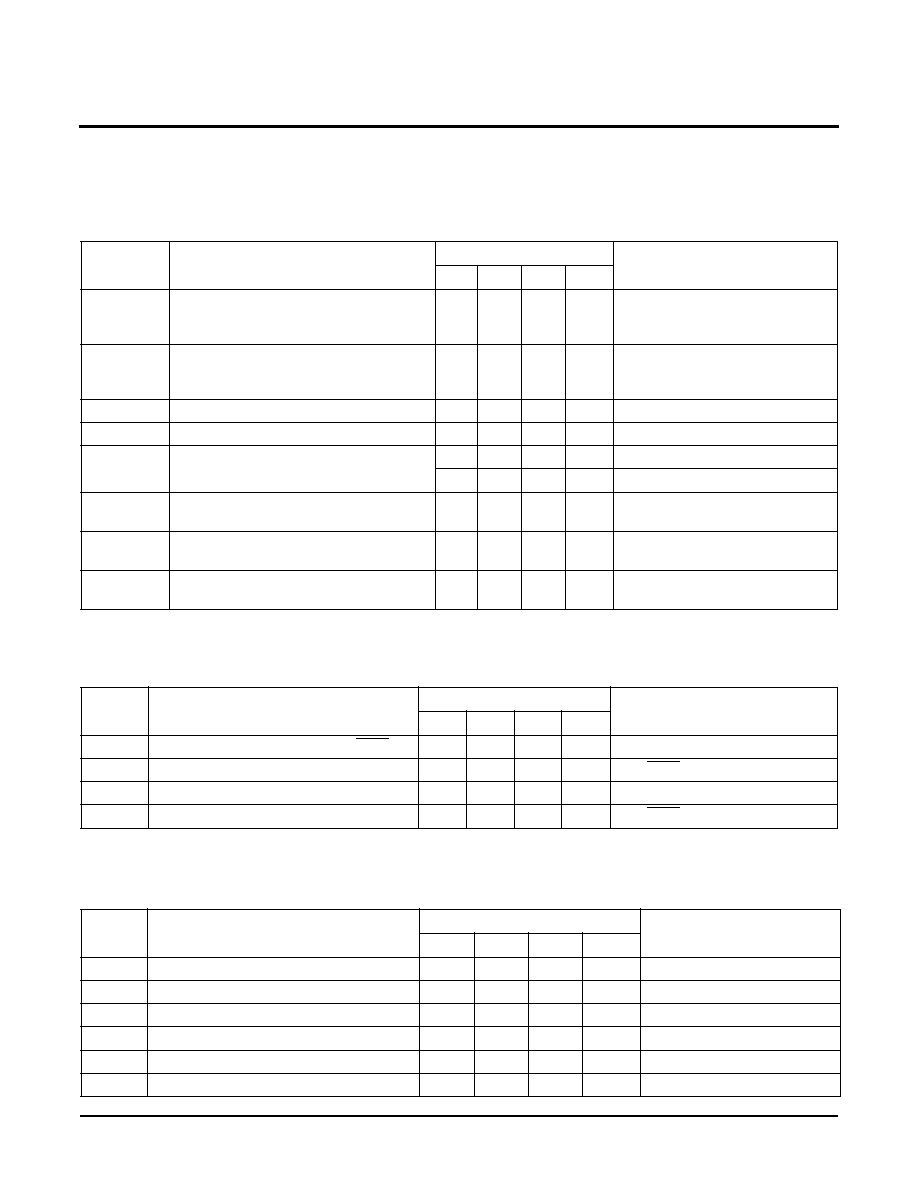

COMPARATOR

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C, unless

otherwise noted.)

SR

(10)

Slew Rate of Instrumentation Amp

0.2

V/µS

V

SENSE

= 20mV step,

Cout = 10pF Measured at

V

OUT

(1,3)

T

settle

(10)

Setting time of Instrumentation Amp

5.0

µS

V

SENSE

= 20mV step, Cout =

10pF, settling to 1% of final value

Measured at V

OUT

(1,3)

CMRR

Common Mode Rejection Ratio

40

dB

For both Gain 1 and Gain 2

PSRR

Power Supply Rejection Ratio

55

dB

For both Gain 1 and Gain 2

V

OUT

Range

V

OUT

Voltage Swing

0.3

1.8

V

Gain = 20

0.3

3.0

V

Gain = 50

V

OUT

Noise

(10)

V

OUT

Voltage Noise, rms

3

mV

Gain = 20

I

VSENSE

(10)

V

SENSE+

, V

SENSE-

Input Bias

Current

250

µA

T

A

= 25∞C

C

VSENSE

(10)

V

SENSE+

, V

SENSE-

Input

Capacitance

10

pF

Each Input

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max. Units

VOL

Output Voltage Low on the

INC/DEC

pin

0.4

V

IOL = 1mA

Io

(10)

Output sink Current

3

mA

INC/DEC

pin, open drain

Vos

(10)

Input Hysteresis

20

mV

Vcc = 5 V

Tpd

(10)

Response Time for propagation delay

2

µS

INC/DEC

pin with 2K

pull up

VREF DCP CIRCUIT BLOCK

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max.

Units

R

TOTAL

End to End Resistance

8

10

12

K

Number Taps or Positions

64

V

RH

RH

REF

Terminal Voltage

AGND

V

+

V

AGND

= 0V

V

RL

RL

REF

Terminal Voltage

AGND

V

+

V

AGND

= 0V

V

RW

RW

REF

Terminal Voltage

AGND

V

+

V

AGND

= 0V

Power Rating

(10)

2.5

mW

R

TOTAL

=10 K

ELECTRICAL CHARACTERISTICS

INSTRUMENTATION AMPLIFIER (CONTINUED)

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min. Typ. Max. Units

Preliminary Information

5 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

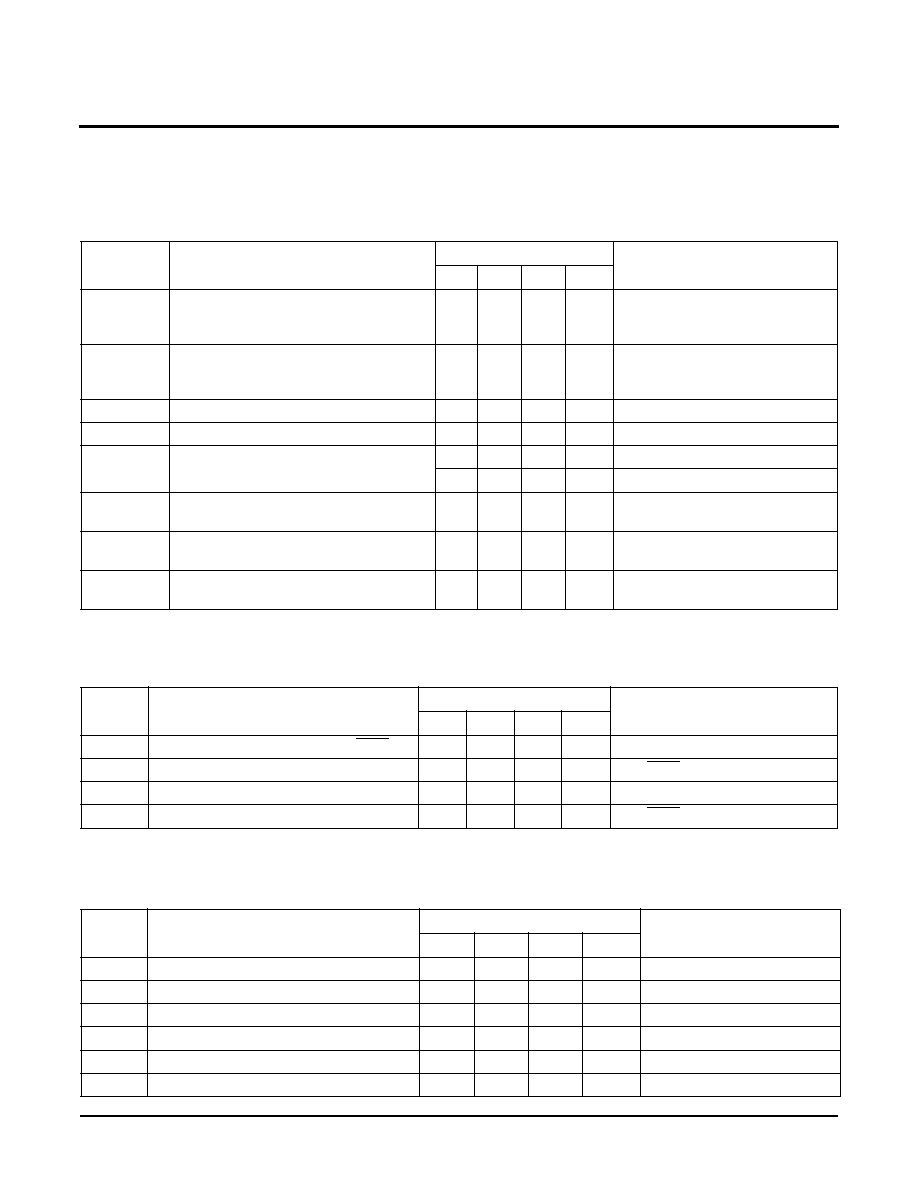

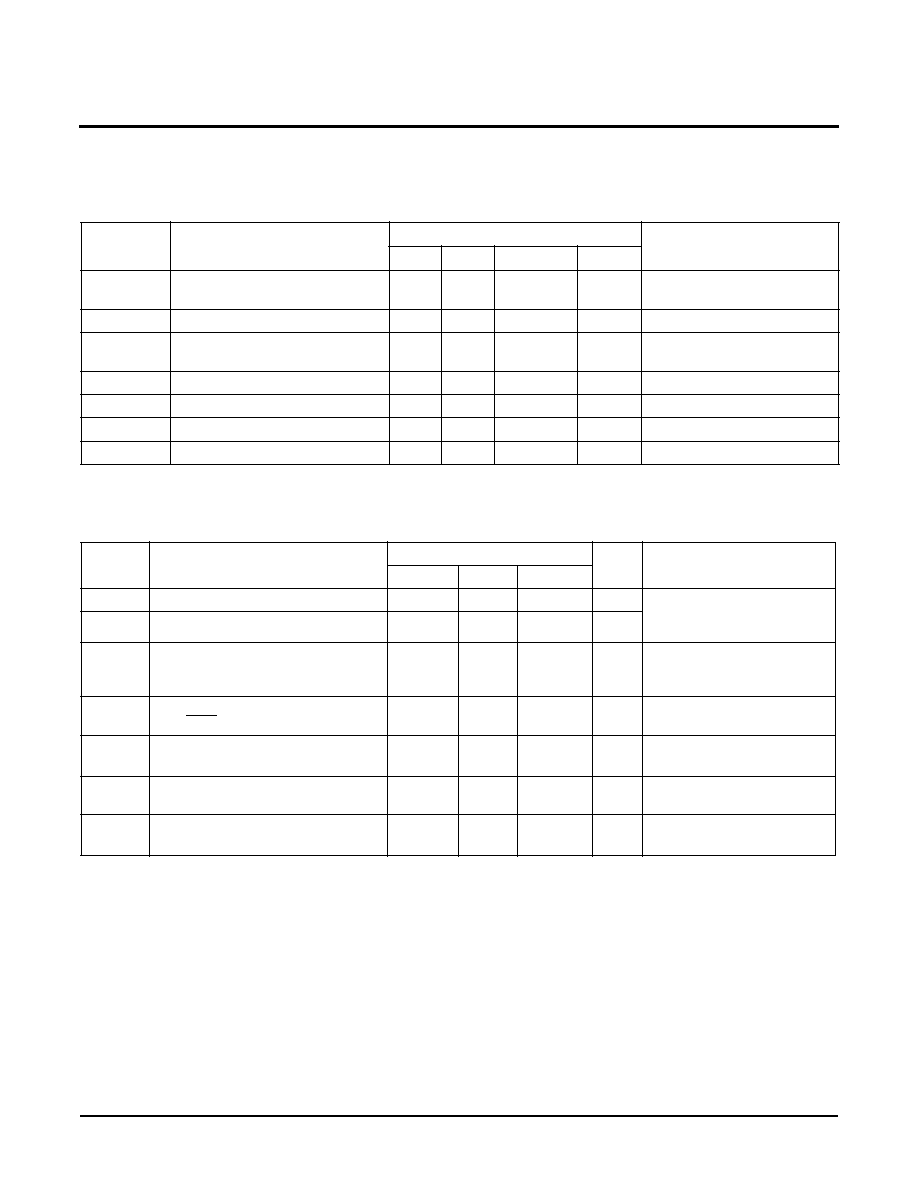

BIAS ADJUSTMENT DCP CIRCUIT BLOCK

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C, unless

otherwise noted.)

Resolution

(10)

1.6

%

Absolute Linearity

(6)

-0.2

+0.2

MI

(8)

Relative Linearity

(7)

-0.2

+0.2

MI

(8)

R

TOTAL

Temperature Coefficient

(10)

±300

ppm/∞C

Ratiometric Temperature Coefficient

(10)

-20

+20

ppm/∞C

C

IN

(10)

Potentiometer Capacitances on RH

REF

and RL

REF

10

pF

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max.

Units

R

TOTAL

End to End Resistance Variation

8

10

12

K

with ±20% variation

Number Taps or Positions

256

V

RH

Voltage at the RH

BIAS

Terminal Voltage

AGND

V

+

V

AGND

= 0V

V

RL

Voltage at the RL

BIAS

Terminal Voltage

AGND

V

+

V

AGND

= 0V

V

RW

Voltage at the RW

BIAS

Terminal Voltage

AGND

V

+

V

AGND

= 0V

Power Rating

(10)

2.5

mW

R

TOTAL

=10 K

Resolution

(10)

0.4

%

Absolute Linearity

(6)

-1.0

+1.0

MI

(8)

Relative Linearity

(7)

-1.0

+1.0

MI

(8)

R

TOTAL

Temperature Coefficient

(10)

±300

ppm/∞C

Ratiometric Temperature Coefficient

(10)

-50

50

ppm/∞C

C

IN

(10)

Potentiometer Capacitances on RH

BIAS

and RL

BIAS

10

pF

VBIAS OUTPUT VOLTAGE FOLLOWER

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max.

Units

V

OS

Input Offset Voltage

10

mV

V

OSDRIFT

(10)

Offset Voltage Temperature

Coefficient

10

µV/∞C

T

A

= -40 to +85∞C

SR

Output Slew Rate on

V

BIAS

0.5

V/

µS

R

L

= 10k

, 1nF, V

BIAS

=

20mV

V

BIAS

Voltage Output Swing

1.5

V

CC

≠ 0.5

V

I

OUT

= ±10mA

VREF DCP CIRCUIT BLOCK

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max.

Units

Preliminary Information

6 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

D.C. OPERATING CHARACTERISTICS

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C, unless

otherwise noted.)

Notes: (1) V

OUT

is a high impedance output intended for light loads only.

(2) Gain at V

OUT

is set to 20 by default.

(3) Value given is for V

OUT

. The V

BIAS

output will depend on the V

BIAS

potentiometer which is initially loaded with a zero value, then

followed by the loading of the final value from E

2

memory.

(4) Gain Error excludes the contribution of the input offset voltage error

(5) Total Error includes the contributions of gain error and input offset voltage error.

(6) Absolute Linearity is utilized to determine actual wiper voltage versus expected voltage = (V

w(n)

(actual) ≠ V

w(n)

(expected))

(7) Relative Linearity is a measure of the error in step size between taps = V

W(n+1)

≠ [V

w(n)

+ Ml]

(8) 1 Ml = Minimum Increment = R

TOT

/63 or R

TOT

/255.

(9) Typical values are for T

A

= 25∞C and nominal supply voltage, VCC = 5V

(10) This parameter is not 100% tested.

T

S

(10)

Settling Time

2

µs

Final value ±1%, R

L

= 10k

,

1nF,

V

BIAS

= 20mV

t

SHDN

Time for

SHDN

pin (delay) valid

0.1

1.0

µs

PSRR

Power Supply Rejection Ratio

45

55

dB

VCC supply V

CC

= 4.75 to

5.25V

Input Voltage Range

1.5

V

CC

≠ 0.5

V

C

L

(10)

Load Capacitance

1

nF

C

IN

(10)

Capacitances on Shutdown Pin

10

pF

R

OUT

(10)

Output Impedance

3

at 5MHz, 1nF load

Symbol

Parameter

Limits

Units

Test Conditions

Min.

Typ.

Max.

I

CC1

(9)

V+ Active Current

1

3

mA

CS

= V

CC

≠ 0.3V, and SCL

@ max. t

CYC, SDA =

V

CC

≠

0.3V, SHDN inactive

I

CC2

(9)(10)

V

CC

Active Current

5

25

mA

I

SB

(9)

Standby Supply Current

(V

CC

, V+)

1.5

mA

CS

= V

IL

, and SCL inactive

(no clock)

, SDA =

V

IL

, SHDN

active

I

LI

CS, SDA, SCL, SHDN RH, RL, RW,

INC/DEC VOUT, Input Leakage

-10

10

µA

V

IN

= VSS to V

CC

V

IH

(10)

CS, SDA, SCL, SHDN, A0, A1, A2

HIGH Voltage

V

CC

x 0.7

V

CC

+ 0.5

V

V

IL

(10)

CS, SDA, SCL, SHDN, A0, A1, A2

LOW Voltage

≠0.5

V

CC

x 0.3

V

C

IN

(10)

CS, SDA, SCL, SHDN, A0, A1, A2

Capacitance

10

pF

V

CC

= 5V, V

IN

= VSS,

T

A

= 25∞C, f = 1MHz

VBIAS OUTPUT VOLTAGE FOLLOWER

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C,

unless otherwise noted.)

Symbol

Parameter

Limits

Test Conditions/Notes

Min.

Typ.

Max.

Units

Preliminary Information

7 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

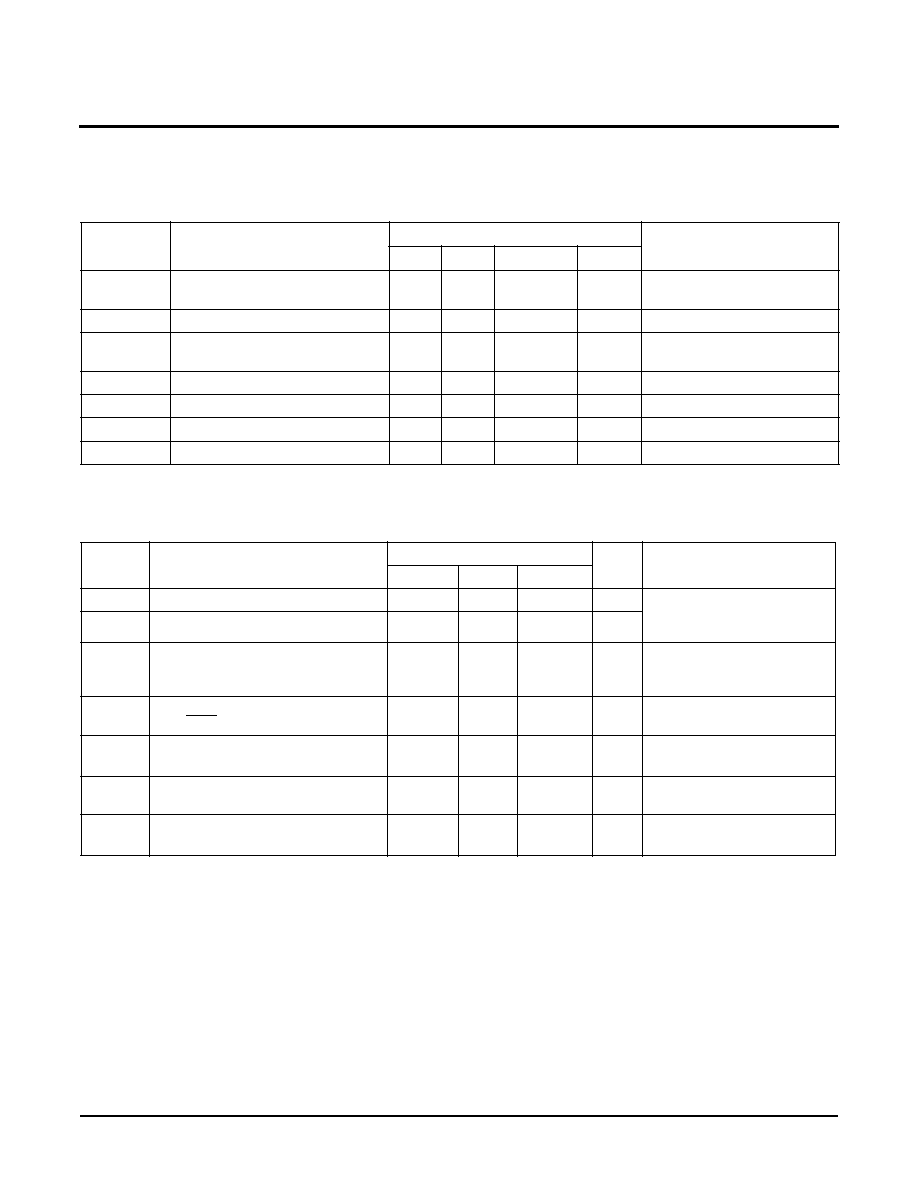

BIAS ADJUSTMENT CIRCUIT BLOCK

A.C. OPERATING CHARACTERISTICS

Recommended Operating Conditions: (Vcc, V+ = 4.75 to 5.25V; Vsense+, Vsense- = 26V; T

A

= -40∞C to +85∞C, unless

otherwise noted.)

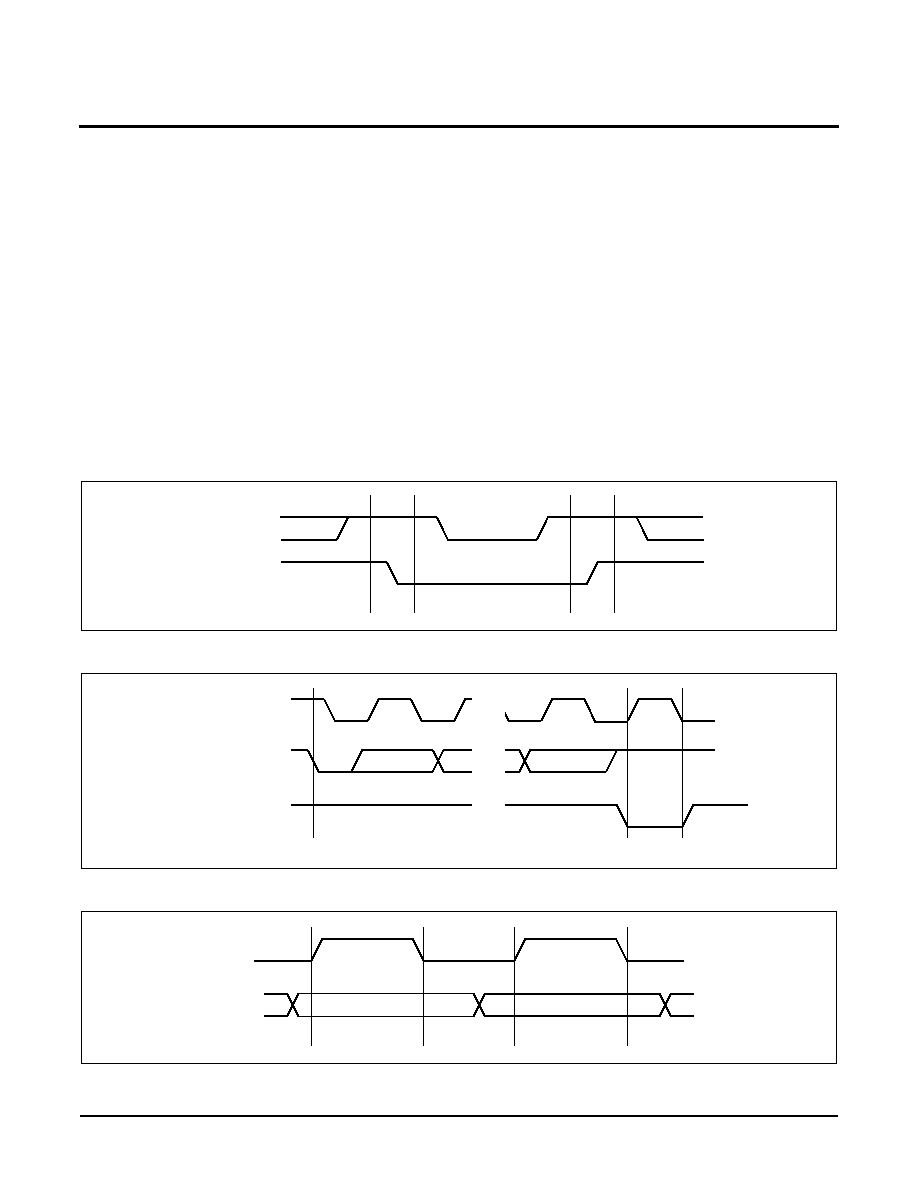

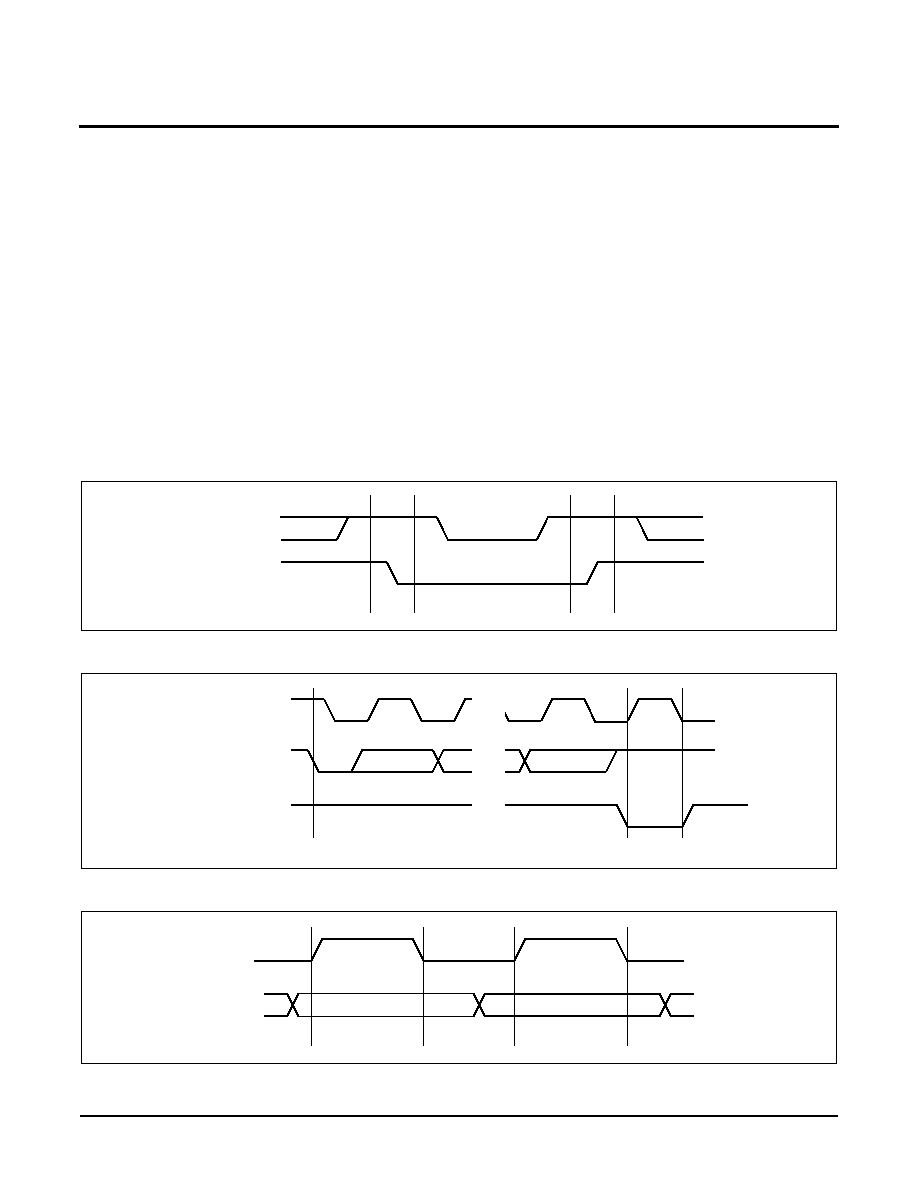

A.C. TIMING

Note:

(11) MI in the A.C. timing diagram refers to the minimum incremental change in the V

BIAS

output due to a change in the wiper position.

Symbol

Parameter

Limits

Units

Min.

Typ.

(9)

Max.

t

Cl

CS

to SCL Setup

100

ns

t

lD

Vsense Change to

INC/DEC

Change

5

µs

t

lL

SCL LOW Period

1.5

µs

t

lH

SCL HIGH Period

1.5

µs

t

lC

(10)

SCL Inactive to

CS

Inactive

100

ns

t

IW

(10)(11)

SCL to

V

BIAS

Change

3

µs

t

CYC

SCL Cycle Time

3

µs

t

R,

t

F

(10)

SCL Input Rise and Fall Time

500

ns

CS

SCL

INC/DEC

V

BIAS

t

CI

t

IL

t

IH

t

CYC

t

ID

t

IW

t

IC

t

F

t

R

10%

90%

90%

(Vsense+ ≠

Vsense-)

Preliminary Information

8 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

AC SPECIFICATIONS

Note:

(12) Cb = total capacitance of one bus line in pF.

TIMING DIAGRAMS

Bus Timing

Symbol Parameter

Min.

Max.

Unit

f

SCL

SCL Clock Frequency

0

400

kHz

t

IN

(10)

Pulse width Suppression Time at inputs

50

ns

t

AA

(10)

SCL LOW to SDA Data Out Valid

0.1

0.9

µs

t

BUF

(10)

Time the bus must be free before a new transmission can start

1.3

µs

t

LOW

Clock LOW Time

1.3

µs

t

HIGH

Clock HIGH Time

0.6

µs

t

SU:STA

Start Condition Setup Time

0.6

µs

t

HD:STA

Start Condition Hold Time

0.6

µs

t

SU:DAT

Data In Setup Time

200

ns

t

HD:DAT

Data In Hold Time

200

ns

t

SU:STO

Stop Condition Setup Time

0.6

µs

t

DH

(10)

Data Output Hold Time

50

ns

t

R

(10)

SDA and SCL Rise Time

20 +.1Cb

(12)

300

ns

t

F

(10)

SDA and SCL Fall Time

20 +.1Cb

(12)

300

ns

Cb

(10)

Capacitive load for each bus line

400

pF

t

SU:STO

t

DH

t

HIGH

t

SU:ST

t

HD:STA

t

HD:DAT

t

SU:DAT

SCL

SDA IN

SDA OUT

t

F

t

LOW

t

BUF

t

AA

t

R

Preliminary Information

9 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

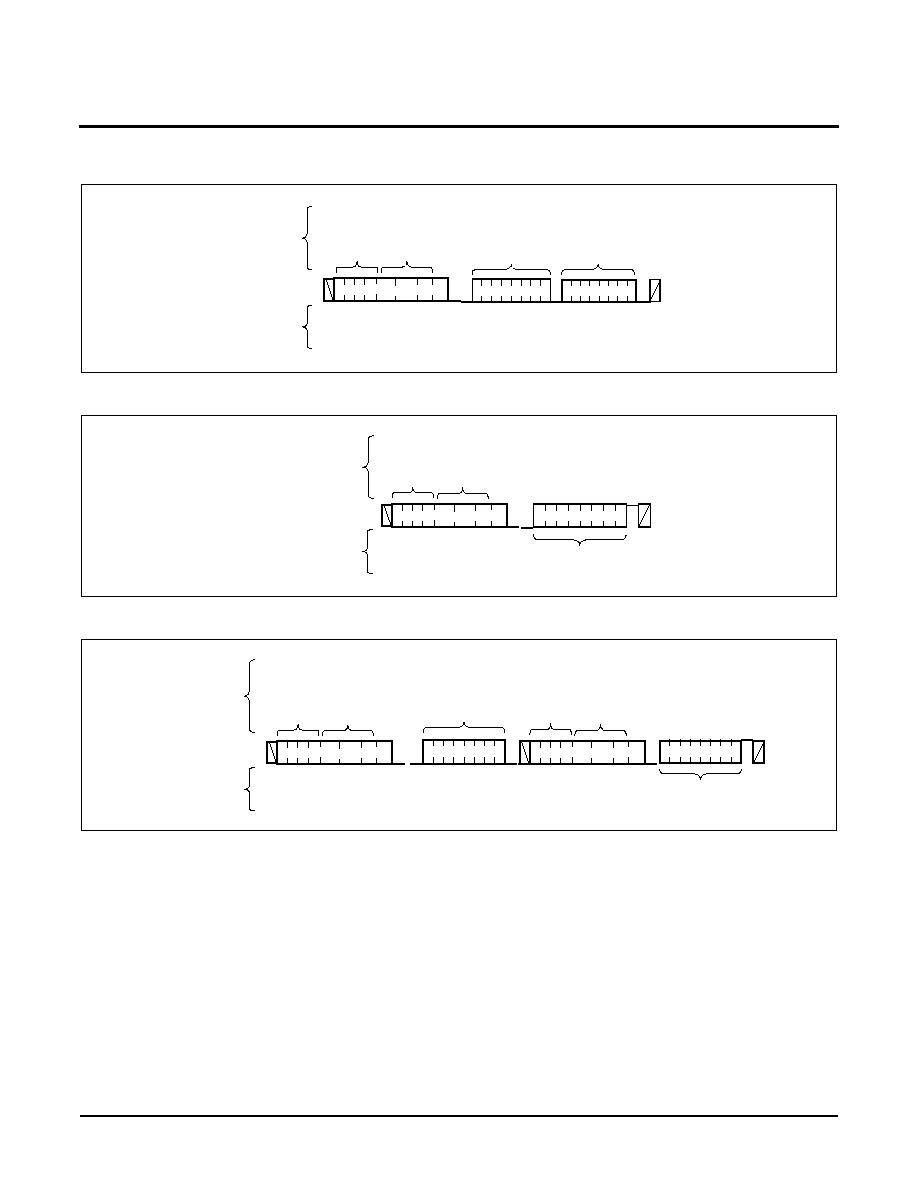

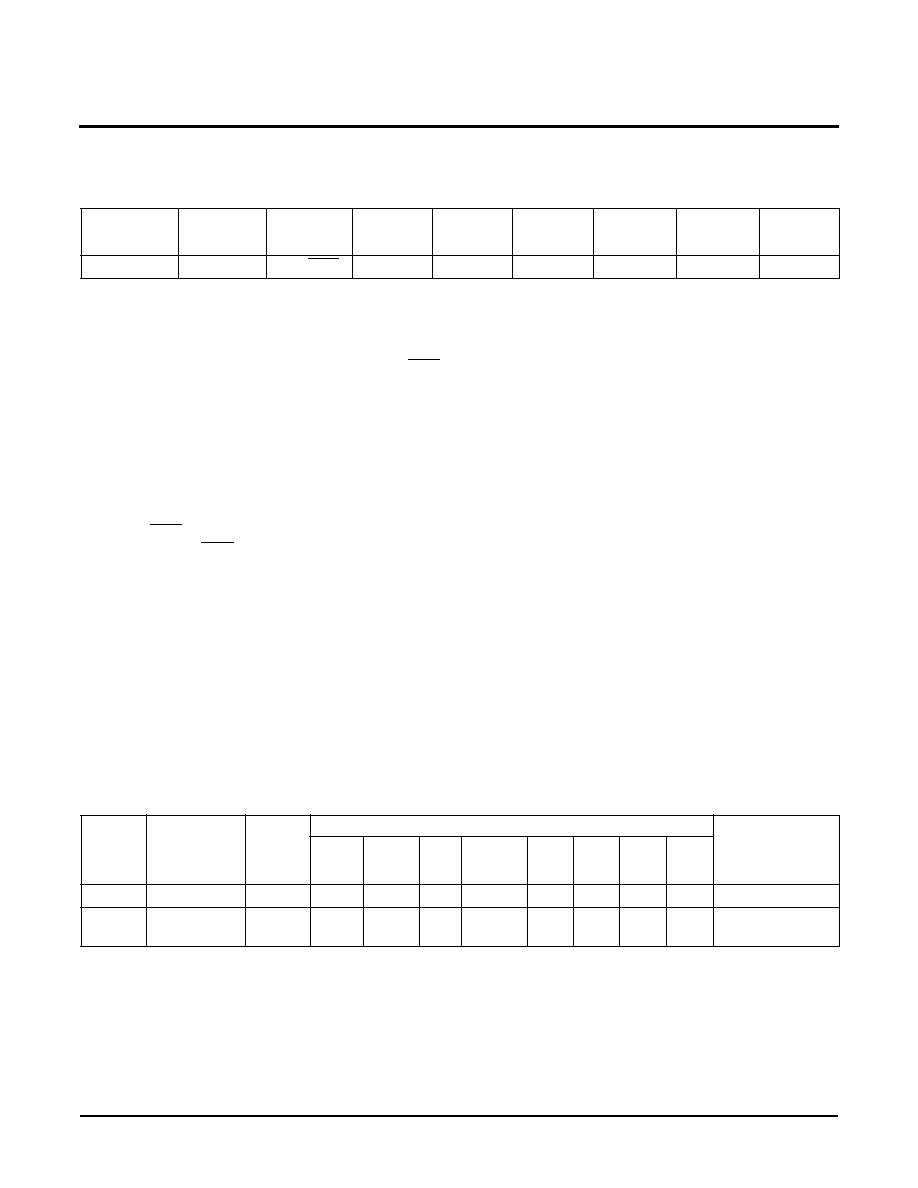

Write Cycle Timing

Power Up Timing

Note:

Delays are measured from the time V

CC

is stable until the specified operation can be initiated. These parameters are not 100% tested.

Proper recall of stored wiper setting requires a V

CC

power-up ramp that is monotonic and with noise or glitches < 100mV. It is important

to correctly sequence voltages in an LDMOS amplifier circuit. For the X9470 typical application, the V

CC

, then V+ pins should be pow-

ered before the V

DD

of the LDMOS to prevent LDMOS damage. Under no circumstances should the V

DD

be applied to the LDMOS

device before V

CC

and V+ are applied to the X9470.

DCP Default Power-up Tap Positions (shipped from factory)

Nonvolatile Write Cycle Timing

Note:

t

WC

is the time from a valid stop condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle. It is

the minimum cycle time to be allowed for any nonvolatile write by the user, unless Acknowledge Polling is used.

Symbol Parameter

Min.

Max.

Unit

t

r

V

CC

(10)

V

CC

Power-up rate

0.2

50

V/ms

VREF DCP

0

Bias Adjust DCP

0

Symbol Parameter

Min.

Typ.

(1)

Max.

Unit

t

WC

(10)

Write Cycle Time

5

10

ms

SCL

SDA

t

WC

8th Bit of Last Byte

ACK

Stop

Condition

Start

Condition

Preliminary Information

Preliminary Information

X9470

10 of 25

REV 11.16 3/20/03

www.xicor.com

DETAILED PIN DESCRIPTIONS

Supply Pins

Digital Supplies VCC, VSS

The positive power supply and ground for the DCP dig-

ital control sections. VSS is normally tied to digital

ground. The X9470 is provided with separate digital

and analog power supply pins to better isolate digital

noise from the analog section.

Analog Supplies V+, AGND

The positive analog supply and ground for the Instru-

mentation Amplifier (IA). The analog supply ground is

kept separate to allow an external single point connec-

tion. V+ can be a separate supply voltage from VCC, or

VCC can be filtered before connection to V+.

Bias Adjustment Circuit Block Pins

RH

BIAS

, RL

BIAS

, and RW

BIAS

for

VBIAS Adjust-

ments.

These pins are the connections to a Xicor Digitally

Controlled Potentiometer (XDCP

TM

) or R

BIAS

potenti-

ometer. RH

BIAS

is connected to the most positive refer-

ence, and the RL

BIAS

is connected to the least positive

reference voltage. The potentiometer has a resolution

of 256-taps and typical R

TOTAL

of 10kohm. So for

example, to provide 4mV resolution, the voltage differ-

ence applied to the RH

BIAS

and RL

BIAS

pins must be

1.024V. The RW

BIAS

value can be stored in non-vola-

tile memory and recalled upon power up.

Serial Clock (SCL).

This is a dual function input pin. The state of the CS pin

determines the functionality.

Function 1:

SCL

is a negative edge-triggered control

pin of the R

BIAS

potentiometer. Toggling

SCL

will

either increment or decrement the wiper in the

direction indicated by the logic level on the INC/DEC

pin. CS must be high for this function.

Function 2: SCL is the serial bus clock for serial bus

interface. CS must be low for this function.

Chip Select (CS). Calibration Enable.

The CS input is the enable bias adjustments. When the

CS is HIGH (enabled) and a SCL pulse is present, the

wiper position on the R

BIAS

potentiometer will auto-

matically update with either an increment or decrement

of one tap position according to INC/DEC signal from

the comparator.

When CS is LOW (disabled), the wiper counter of the

XDCP will hold the last wiper position until CS is

enabled again and the wiper position is updated.

INC/DEC Monitor Pin

The Up or Down Monitor pin (INC/DEC) indicates the

state of the comparator. This signal indicates that the

Instrumentation Amplifier output voltage is higher or

lower than the voltage level set by the RW

REF

pin. The

output is used to indicate the direction that the gate

bias voltage needs to move to reach the target bias

voltage.

Sense and Scale Block Pins

V

SENSE+

and V

SENSE-

These are the input pins to the IA circuit. These pins

are used to determine the change in voltage across the

the external drain sense resistor of an RF power ampli-

fier.

RH

REF

, RL

REF

, and RW

REF

. PA Bias Set Point.

The PA Bias reference voltage is controlled by a 64-tap

(10k ohm typical R

TOTAL

) potentiometer, called the

R

REF

potentiometer. The voltages applied to RH

REF

and RL

REF

will determine the range of adjustment of

the reference voltage level (VREF) for the Comparator.

The resolution of the comparator reference is the differ-

ence of the voltages applied to RH

REF

and RL

REF

divided by 63. The position of the wiper (RW

REF

) is

controlled via serial bus. The RW

REF

value can be

stored in non-volatile memory and recalled upon power

up.

RW

REF

is also an input signal used as a scaling volt-

age (VREF) to set the appropriate I

DQ

of an RF power

amplifier. V

REF

can be derived from an external voltage

divider or from a baseband processor or similar micro-

controller. V

REF

can be set permanently or changed

dynamically using the potentiometer for various PA

operating points.

Preliminary Information

11 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

V

OUT

This pin is the output of the IA, which reflects a 20x or

50x gain of the input signal (voltage across the Vsense

pins). It can be used to indicate the magnitude of the

drain current envelope when RF is present.

Output Block Pins

V

BIAS

The V

BIAS

is the gate bias voltage output. It is buffered

with a unity gain amplifier and is capable of driving 1nF

(typical) capacitive loads.

This pin is intended to be connected through an RF fil-

ter to the gate of an LDMOS power transistor. The volt-

age of V

BIAS

is determined by the XDCP's value of the

R

BIAS

resistor.

Other Pins

SHDN

SHDN is an input pin that is used to shutdown the

V

BIAS

output voltage follower. When the SHDN pin is

HIGH, the V

BIAS

pin is pulled to VSS. When the device

is shutdown, the current R

BIAS

wiper position will be

maintained in the wiper counter register. When shut-

down is disabled, the wiper returns to the same wiper

position before shutdown was invoked. Note that when

the device is taken out of shutdown mode (SHDN goes

from HIGH to LOW), the CS input must be cycled once

to enable calibration.

SDA

Serial bus data input/output. Bi-directional. External

pullup is required.

A0, A1, A2

Serial bus slave address pins. These pins are used to

defined a hardware slave address. This will allow up to

8 of the X9470's to be shared on one two-wire bus.

These are useful if several X9470's are used to control

the bias voltages of several LDMOS Power Transistors

in a single application. Default hardware slave address

is "000" if left unconnected due to internal pull-down

resistor.

TYPICAL APPLICATION

The X9470 can be used along with a microprocessor

and transmit control chips to control and coordinate

FET biasing (see Figure 1). The CS, SCL, and SDA

signals are required to control the X9470 Bias Adjust-

ment Circuit Block. An internal R

WREF

voltage is pro-

vided via a programmable voltage divider between the

RH

REF

and RL

REF

pins and is used to set the voltage

reference of the comparator. The shutdown (SHDN)

and bias voltage indicators (INC/DEC) are additional

functions that offer FET control, monitoring, and pro-

tection.

Typically, the closed loop setup of the X9470 allows for

final calibration of a power amplifier at production test.

The CS and SCL pins are used to perform this calibra-

tion function. Once in a base station, the amplifier can

then be re-calibrated any time that there is no RF sig-

nal present. The bias setting block can also be used

open loop to adjust gate bias or can be shutdown

using the SHDN pin. The sense and scale block can be

used for amplifier power monitoring diagnostics as

well.

The range of the drain bias current operating point of

the LDMOS FET is set by an external reference across

the reference potentiometer. The wiper of the potenti-

ometer sets the trip point for comparison with V

P

, the

amplified voltage across R

SENSE

, the drain resistor.

The output of the comparator causes the R

BIAS

poten-

tiometer to increment or decrement automatically on

the next SCL clock cycle. This R

BIAS

potentiometer is

configured as a voltage divider with a buffered wiper

output which drives the gate voltage of an external

LDMOS FET.

Once the optimum bias point is reached, the R

BIAS

value is latched into a wiper counter register. Again,

the V

BIAS

gate voltage can be updated continuously or

periodically depending on the system requirements.

Both terminals of the R

BIAS

potentiometer are access-

ible and can be driven by external reference voltages

to achieve a desired I

DQ

vs. gate voltage resolution, as

well as supporting temperature compensation circuitry.

In summary, the X9470 provides full flexibility on set-

ting the operating bias point and range of an external

RF power amplifier for GSM, EDGE, UMTS, CDMA or

other similar applications.

Preliminary Information

Preliminary Information

X9470

12 of 25

REV 11.16 3/20/03

www.xicor.com

Figure 1. Typical Application

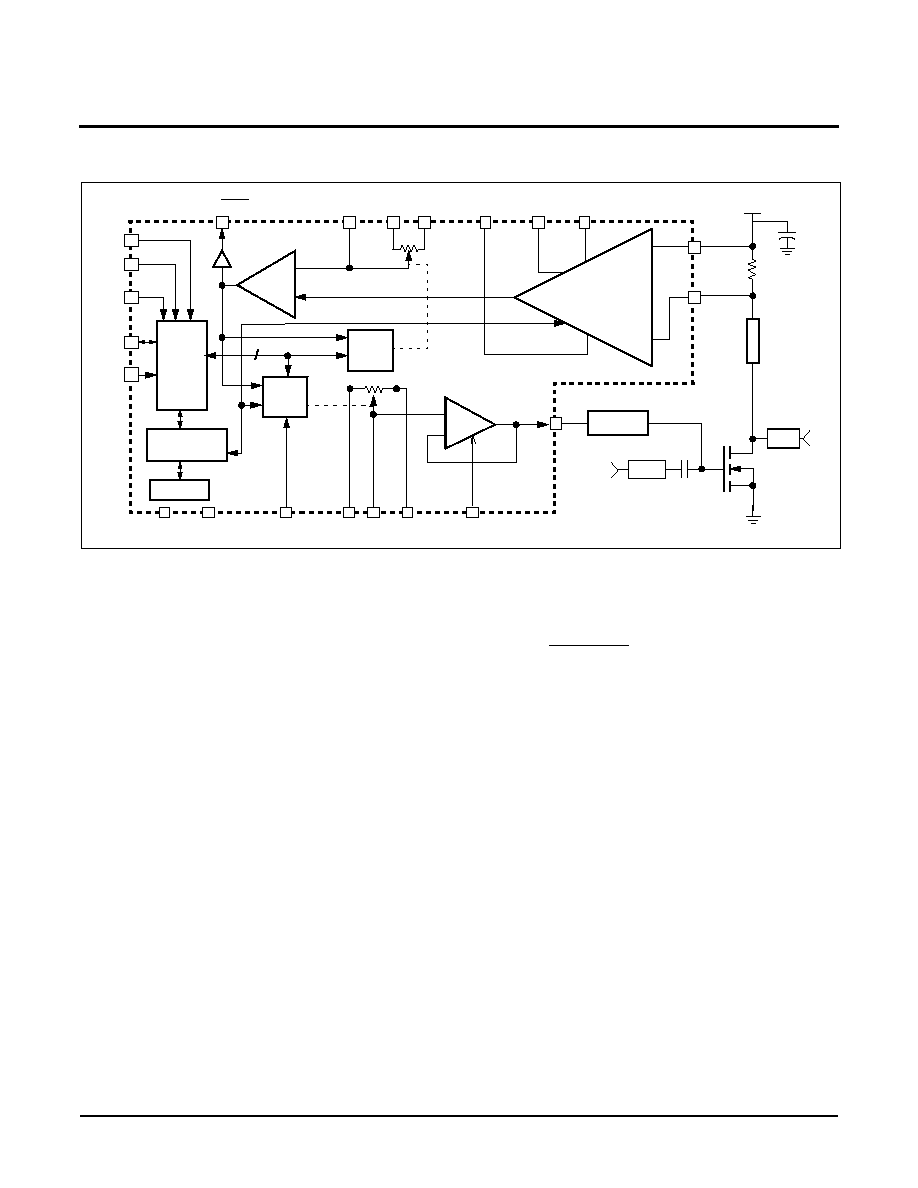

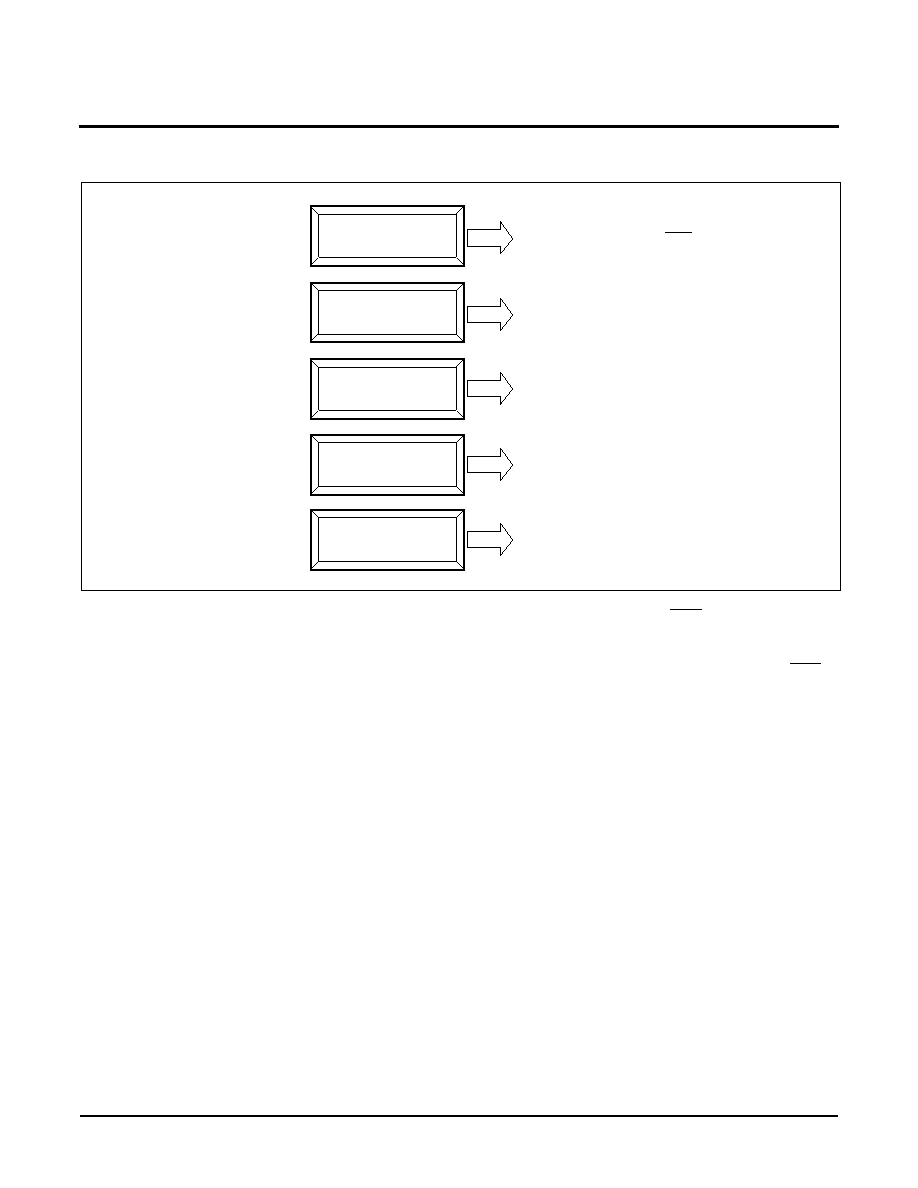

X9470 FUNCTIONAL DESCRIPTION

This section provides detail description of the following:

≠ Sense and Scale Block Description

≠ Bias Adjustment Control Block Description

≠ Output Block Description

≠ Bias Adjustment and Storage Description

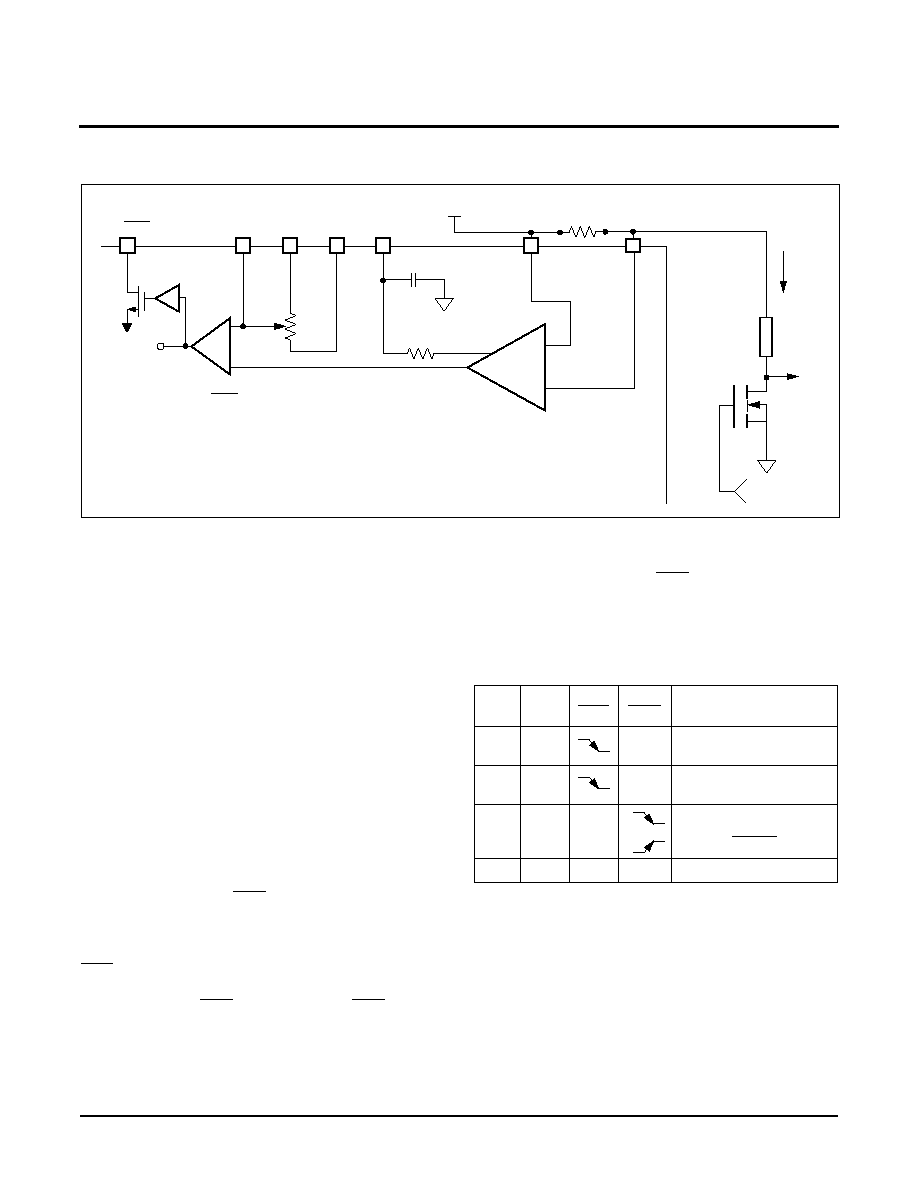

SENSE AND SCALE BLOCK

The Sense and Scale Circuit Block (Figure 2) implements

an instrumentation amplifier whose inputs (V

SENSE+

and

V

SENSE-

) are across an external sense resistor in the

drain circuit of an RF Power FET. V

SENSE+

is connected

to V

DD

, the drain voltage source for the RF power FET,

and V

SENSE-

pin is connected to the other end the exter-

nal sense resistor.

An internal instrumentation amplifier (IA) will sense the

V and amplify it by a gain factor of K

1

(see Equation

1). The resulting output is compared with V

REF

at the

comparator. V

REF

can be a fixed reference voltage or

adjusted by using the 64-tap digital potentiometer. The

output of the comparator is used to increment or decre-

ment the R

BIAS

potentiometer in the Bias Adjustment

Circuit Block. The gain factor K

1

is designed such that

the Sense and Scale Block will set the Bias Adjustment

Circuit Block to operate in a given voltage range (mV)

vs. drain current adjustment (mA).

The output of the IA is also available at the pin Vout to

enable drain current monitoring. The gain at Vout is

fixed at a factor of K

2

, lower than K

1

so that high I

DQ

currents will not cause saturation of the Vout signal.

The equation for Vout is given as:

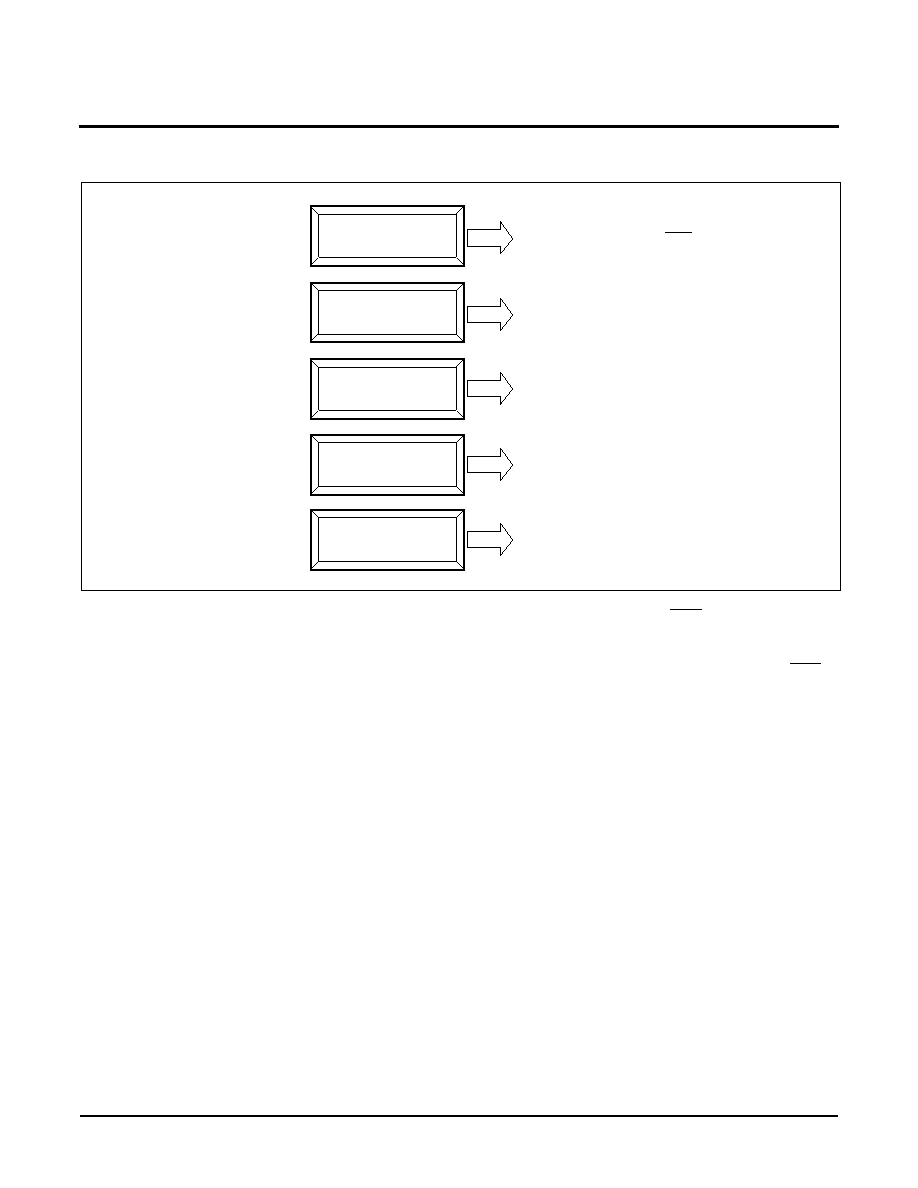

BIAS ADJUSTMENT CIRCUIT BLOCK

There are three sections of this block (Figure 3): the

input control, counter and decode section (1), the

resistor array (2); and the non-volatile register (3). The

input control section operates just like an up/down

counter. The input of the counter is driven from the out-

put of the comparator in the Sense and Scale Block

and is clocked by the SCL signal. The output of this

counter is decoded to select one of the taps of a 256-

tap digital potentiometer.

A0

A2

VCC

VSS

V+

AGND

Comparator

choke

RF PA in

R

SENSE

V

DD

V

REF

V

SENSE+

V

BIAS

INC/DEC

Instrumentation

Amplifier

V

CS

V

OUT

V

SENSE≠

R

REF

RW

REF

RL

REF

SHDN

+

≠

EEPROM

SCL

SDA

A1

Vbias

control

VREF

control

I2C

interface

Control &

Status Registers

RF

out

RH

REF

R

BIAS

VP

RH

BIAS

RL

BIAS

RW

BIAS

FILTER

V

BIAS (Unbuffered)

RF Impedance

Matching

C

BULK

Class A Example

I

DQ

V

REF

K

1

* R

SENSE

K

1

is fixed 50x for the internal comparator input.

(1)

V = I

DQ

* R

SENSE

V

OUT

= K

2

*

V

K

2

is fixed to 20x for the Vout pin

Preliminary Information

13 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

Figure 2. Sense and Scale Block Diagram

The wiper of the digital potentiometer acts like its

mechanical equivalent and does not move beyond the

last position. That is, the counter does not wrap around

when clocked to either extreme. The electronic

switches in the potentiometer operate in a "make

before break" mode when the wiper changes tap posi-

tions. If the wiper is moved several positions, multiple

taps are connected to the wiper for t

IW

(SCL to

RW

BIAS

change).

When the device is powered-up, the X9470 will load

the last saved value from the non-volatile memory into

the WCR. Note that the current wiper position can be

saved into non-volatile memory register by using the

SCL and CS pins as shown in Figure 4.

Important note: the factory setting of the wiper counter

register is the ZERO-position (0 of 255 taps). This is

the default wiper position.

Bias Adjustment Block Instructions and Program-

ming. The SCL, INC/DEC (internal signal) and CS

inputs control the movement of the wiper along the

resistor array. (See Table 1) With CS set HIGH, the

device is selected and enabled to respond to the INC/

DEC and SCL inputs. HIGH to LOW transitions on SCL

will increment or decrement R

BIAS

(depending on the

state of the INC/DEC input). The INC/DEC input is

derived from the output of the comparator of the Sense

and Scale Block.

Storing Bias Resistor Values in Memory. Wiper val-

ues are stored to VOLATILE memory automatically

when CS is HIGH and INC/DEC either transitions from

HIGH to LOW or from LOW to HIGH. Wiper values are

stored to NON-VOLATILE memory during Byte Write

or as described in the following section.

Table 1. Mode Selection

* When coming out of shutdown, the CS pin must be cycled once before bias

adjustment is enabled.

INC/DEC

RW

REF

RL

REF

RH

REF

V

OUT

V

DD

V

SENSE+

R

SENSE

V

SENSE≠

10k

64-tap

V

REF

Comparator

INC/DEC

~1kohm

Precision

I-Amp

Cint~2pF ±10%

}

V

I

DQ

RF

PA

Out

choke

V

gate

RF PA in

K

2

= 20X

K

1

= 50X

SDA

CS*

SCL

INC /

DEC

Mode

H

H

H

VBIAS is incremented

one tap position.

H

H

L

VBIAS is decremented

one tap position.

H

H

X

Lock Wiper Position.

Save to volatile

memory. (BiasLockTM)

X

L

X

X

Open Loop.

or

Preliminary Information

Preliminary Information

X9470

14 of 25

REV 11.16 3/20/03

www.xicor.com

Figure 3. Bias Adjustment Block Diagram

NON-VOLATILE STORE OF THE BIAS POSITION

The following procedure will store the values for the

Rref and Rbias wiper positions in Non-Volatile memory.

This sequence is intended to be performed after a

BiasLock calibration sequence to simplify storage. If

BiasLock has not been achieved, then the Rbias wiper

position may change when the CS pin is brought high

and SCL begins clocking. See Figure 4 for the actual

sequence.

1. Set the WEL bit with a write command (02h to regis-

ter 0Fh)

2. Peform a calibration and achieve BiasLock. Leave

CS pin high.

3. Write the address byte only (START, followed by

device/slave address and a 0 for a write, see page

20).

4. Perform a STOP command.

5. With SCL still low, bring the CS low. The falling edge

of the CS will initiate the NV write.

The WEL bit may be reset afterwards to prevent further

NV writes.

INC/DEC FUNCTION

The INC/DEC pin is an open-drain logic output that

tracks the activity of the increment/decrement compar-

ator. A logic HIGH at INC/DEC indicates that the I

DQ

did not rise up to the desired setting indicated by V

REF

while a logic LOW at the INC/DEC pin indicates that

the IDQ is higher than the desired setting.

INC/DEC is used as an internal control signal as well.

As an example, when INC/DEC is LOW, the Bias

Adjustment Circuit Block will start to move the Rbias

resistor wiper towards the RL

BIAS

terminal end when

CS is HIGH and SCL is clocking. Consequently, the

V

BIAS

voltage will decrease, and the I

DQ

decreases to

meet the desired V

REF

setting.

The INC/DEC signal can also be used to detect a dam-

aged RF power FET. For instance, If INC/DEC stays

HIGH during and after a calibration sequence it may

indicate that the RF power FET has failed. This indica-

tor can also be used with a level sense on the V

OUT

pin

to perform diagnostics.

SHUTDOWN MECHANISM

This hardware control shutdown pin (SHDN) will pull

the voltage of V

BIAS

to VSS with an internal pull down

resistor. When shutdown is disabled (V

BIAS

is active

when SHDN is LOW), the V

BIAS

voltage will move to

the previous desired bias voltage.

It will take less than a microsecond to enable the inter-

nal output buffer depending on the loading condition at

the V

BIAS

pin.

Gate Bias

Op Amp

+

≠

RW

BIAS

RH

BIAS

RL

BIAS

Legend

External pin/signal

Internal node/signal

SCL

CS

2

3

1

V

BIAS

(unbuffered)

V

BIAS

SHDN

to LDMOS gate

10Kohm

256-tap

R

BIAS

INC

U/D

CS

INC/DEC

XDCP

Memory and Control

WCR (Rbias)

Bias Register

non-volatile

Power On Recall

(POR)

Note:

1) WCR = Wiper Control Register

INC/DEC is logic HIGH or LOW

from Sense/Scale Block

and is used to increment or

decrement the Rbias resistor

(XDCP) to adjust the gate voltage.

Preliminary Information

15 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

OUTPUT (V

BIAS

)

V

BIAS

is a buffered output of RW

BIAS

(wiper output). It

can deliver a high current for driving up to typically 1nF

capacitive loading with stable performance and fast

settling time.

A single pole filter should be placed in between the

V

BIAS

output and the RF input signal to isolate any

high frequency noise.

Figure 4. Non-Volatile Store of the Bias Position

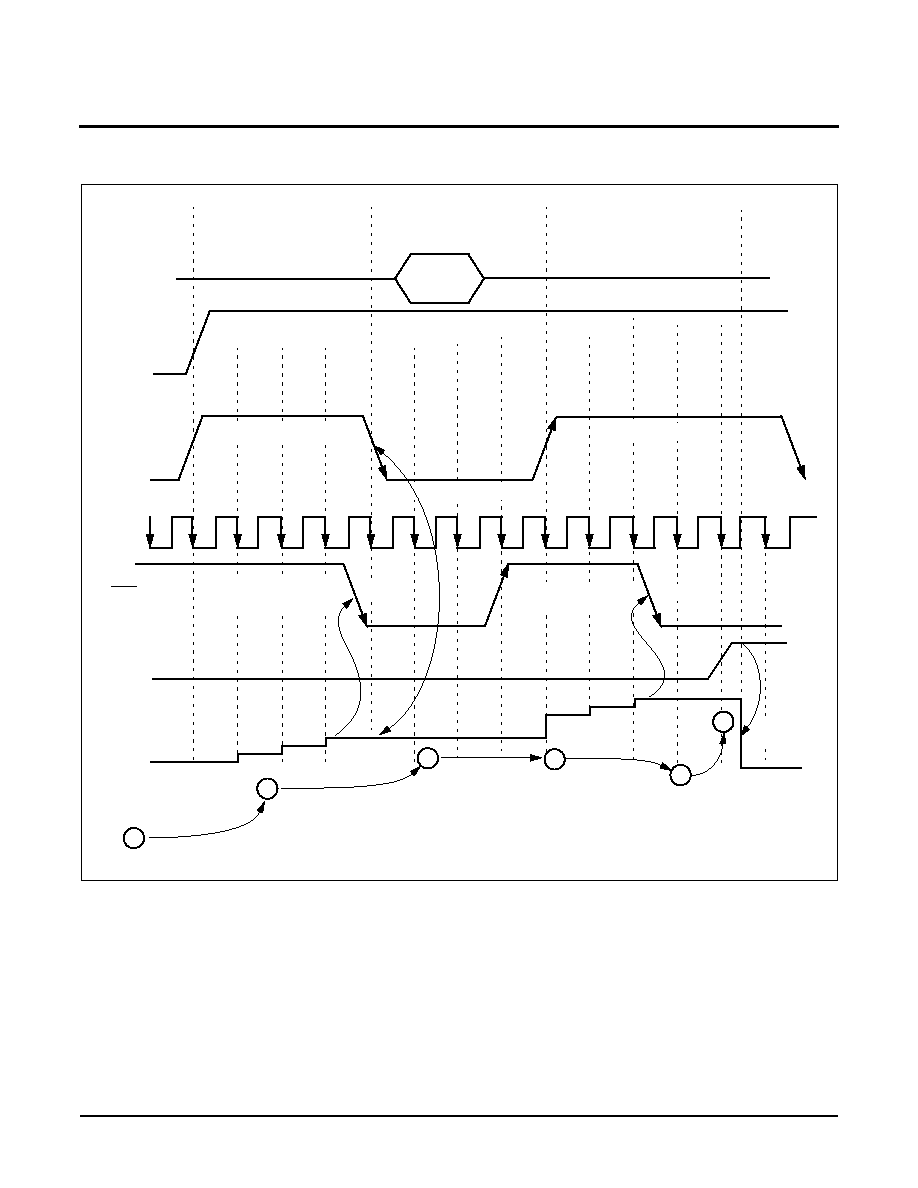

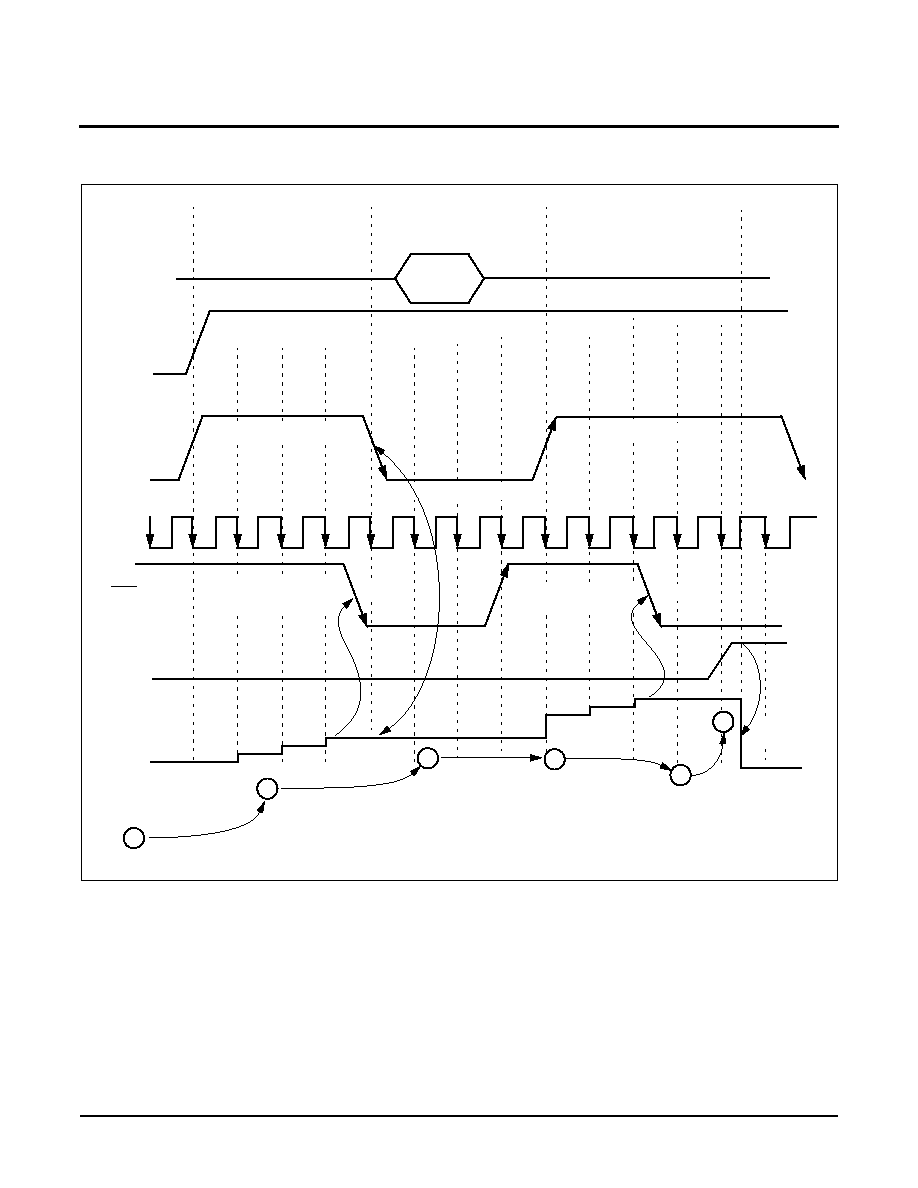

X9470 PRINCIPLES OF OPERATION

The X9470 is a Bias Controller that contains all the

necessary analog components for closed-loop DC bias

control of LDMOS Transistors in RF Applications. The

X9470 provides a mechanism to periodically set DC

bias operating points of Class A or AB-type amplifiers

to account for V

GS

drift and temperature variations.

The following is an example of X9470 operation.

The X9470 incorporates an instrumentation amplifier,

comparator and buffer amplifier along with resistor

arrays and their associated registers and counters. The

serial interface provides direct communication between

the host and the X9470. This section provides a

detailed example of how the X9470 can be used to cal-

ibrate and dynamically set the optimum bias operating

point of an RF power amplifier (see Figure 5):

≠ State 0: Power on Monitor Mode

≠ State 1: DC-bias Setting When No RF is Present

[Calibration]

≠ State 2: Calibration Disable When RF is Present

≠ State 3: PA Standby Mode. Dynamic Adjustment for

V

GS

drift and Temperature variation

≠ State 4: Power Off (Shutdown) Mode [Turn off the

Power Amplifier]

State 0: Monitor Mode

The V

OUT

and INC/DEC outputs of the X9470 can be

used for monitoring and diagnostic purposes. Since

V

OUT

has a lower gain (20x, default) than the internal IA

output, it can handle higher drain sense current while

keeping the output below the rail. This allows normal PA

power monitoring, and over-current sensing using an

external comparator. The INC/DEC pin can be moni-

tored during calibration to see if there is no change,

which indicates LDMOS functional problems. Note that

the INC/DEC status is also available in the status regis-

ter for software status reads.

State 1: DC-bias Setting When No RF is Present

[Calibration]

At calibration, the DC bias operating point of the

LDMOS Power Amplifier must be set. As soon as the

Bias Adjustment Circuit Block is enabled (CS enabled,

SDA high, and SCL pulse provided), the X9470 will

automatically calibrate the external Power Amplifier by

continually sampling the drain current of the external

Power Amplifier and make adjustments to the gate

voltage of the amplifier (See Figure 6).

Initiates

high voltage write

cycle

t

WR

Stored in

Non-volatile

memory

CS

SCL

SDA

Non-volatile Write of R

BIAS

and R

REF

value Using SDA, SCL and CS pins

R

BIAS

non-volatile register

Set WEL

bit

Calibration

and Bias Lock

Set

Address Byte

Stop

1

2

3

4

5

Preliminary Information

Preliminary Information

X9470

16 of 25

REV 11.16 3/20/03

www.xicor.com

Figure 5. Operating modes X9470

When no RF signal is present, the instrumentation

amplifier of the X9470 senses the drain current as a

voltage drop,

V, across an external drain R

sense

resis-

tor. The

V is amplified and compared to an external

scaling voltage, V

REF

. Any difference between

V and

V

REF

results in a resistive increment or decrement of

the internal R

BIAS

potentiometer.

The R

BIAS

potentiometer is used as a voltage divider

with the RH

BIAS

and RL

BIAS

terminals setting the

upper and lower voltage limits of the unbuffered

RW

BIAS

voltage. The resolution of the R

BIAS

potenti-

ometer resistor is 0.4% of the difference of voltage

across the RH

BIAS

and RL

BIAS

terminals. The R

TOTAL

is typically 10K

with 256-taps. So, for example, if the

difference between the RH

BIAS

and RL

BIAS

terminals

is 1.024V, then the step accuracy is 4mV.

The voltage at the RW

BIAS

pin is then fed into the

V

BIAS

voltage follower. The V

BIAS

pin is a buffered out-

put that is used to drive the gate of an LDMOS transis-

tor.

The scaling voltage, V

REF

, set by the R

REF

potentiom-

eter, sets the calibrated operating point of the LDMOS

Amplifier.

On edge transitions of the INC/DEC signal, the X9470 will

latch the current wiper position--this is known as "Bias

LockTM" mode. This is shown in Figure 6. When BiasLock

occurs, the comparator hysteresis will allow INC/DEC to

change state only after the IA output changes by more

than 20mV. This will prevent toggling of the V

BIAS

output

unless the drain bias current is constantly changing.

State 2: DC-bias Disable When RF is Present

(optional)

When an RF signal is present, the X9470 is put into

standby mode (open loop). The X9470 is in standby

mode when the CS pin is disabled so that the R

BIAS

potentiometer holds the last wiper position. The pres-

ence of an RF signal at the input of a Class A or AB

amplifier increases the current across the R

sense

resis-

tor. Over a period of time, the temperature of the

LDMOS also increases and the LDMOS also experi-

ences V

GS

drift. Therefore the DC biasing point that

was set during State 1 (calibration) is not optimal.

Adjustments to the gate voltage will need to be made

to optimize the operation of the LDMOS PA. This is

done in State 3.

Choose Vref to scale IDQ, perform calibration,

State 1

State 2

State 3

State 4

PA

Transmit Mode

PA

Calibration Mode

PA

Standby Mode

PA

Off Mode

Disable Bias Adjustment,

Recalibrate bias point for drift and temperature.

Rbias resistor will automatically increment or decrement

for optimal operating point continuously

Turn off PA

Latch bias point for DC bias current in wiper counter

PA Enabled, Vout and INC/DEC Monitored for status

State 0

PA

Monitor Mode

Preliminary Information

17 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

State 3: PA Standby Mode, DC Bias Adjustment

[Compensation for V

GS

Drift and Temperature

Variation]

When the Power Amplifier is in Standby Mode the

X9470 allows for dynamic adjustment of the DC bias-

ing point to take into account both V

GS

drift and tem-

perature variation. Dynamic biasing is achieved with

the X9470 by using the CS, and SCL pins. For exam-

ple, the SCL pin can be a steady clock and the CS pin

can be used as a control signal to enable/disable the

Bias Adjustment Block.

Figure 6 illustrates how the X9470 can be used for

dynamic biasing. Upon the presence of an RF signal,

the CS pin is pulled LOW. This will prevent the X9470

from changing the V

BIAS

voltage during I

DQ

peak cur-

rents. Once the RF signal is no longer present, the CS

pin can be enabled (closed loop), SDA high and the

X9470 Bias Adjustment Circuit moves the V

BIAS

volt-

age (the gate voltage of the FET) to meet the average

I

DQ

bias point for optimum amplifier performance.

State 4: Power Off Mode

During power saving or power-off modes the X9470

can be shut down via the SHDN pin. This pin pulls the

output of the V

BIAS

pin LOW.

Preliminary Information

18 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

Figure 6. Dynamic Biasing Technique: Automatic DC Bias Operating Point Adjustment

State 0

Monitor

Mode

State 1

Calibration

(no RF present)

State 2

RF present

State 3

Recalibrate bias

point for drift

and temperature

State 4

shut

down

Set Operating Range Scale for Bias Adjustment

RF signal

V

REF

CS

SCL

INC/DEC

SHDN

V

BIAS

1

2

3

4

5

6

R

bias

default is

zero point of R

total

Latch R

bias

DC point

in calibration vs V

REF

RF present

Turn off

Bias

Adjustment

R

bias

increase/decrease

after RF present due to

temperature increase &

V

GS

-threshold drift

IDQ vs. gate

voltage bias

optimized

Shut

down

BiasLock

Saves wiper position to

volatile memory

Bias Adjustment ON

Bias Adjustment OFF

Bias Adjustment ON

Automatic Bias Adjustment

BiasLock

Preliminary Information

19 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

X9470 STATUS REGISTER (SR) AND CONTROL REGISTER (CR) INFORMATION

Table 2. Status Register (SR)

STATUS REGISTER (SR)

The Status Register is located at address 0F<hex>.

This is a register used to control the write enable

latches, and monitor status of the SHDN, INC/DEC,

and CS pin. This register is separate from the Control

Register.

SR7: SHDN: Vbias SHDN Flag. Read Only--Volatile.

The bit keeps status of the shutdown pin, SHDN. When

this bit is HIGH, the SHDN pin is active and the V

BIAS

output is disabled. When this bit is LOW, the SHDN pin

is low and V

BIAS

output is enabled.

SR6: INC/DEC : Read Only--Volatile. This bit keeps

status of the INC/DEC pin. When this bit is HIGH the

counter is in increment mode, when this bit is LOW the

counter is in decrement mode.

SR4: CS: Read Only--Volatile. This bit keeps status

on the CS pin. When this bit is HIGH, the X9470 is in

closed loop mode (Rbias adjustment enabled). When

this bit is LOW the x9470 is in open loop mode (no

Rbias adjustments).

SR2, SR3, SR5: Read only

For internal test usage, should be set to 0 during SR

writes.

SR1: WEL: Write Enable Latch--Volatile

The WEL bit controls the access to the registers during

a write operation. This bit is a volatile latch that powers

up in the LOW (disabled) state. While the WEL bit is

set LOW, Nonvolatile writes to the registers will be

ignored, and all writes to registers will be volatile. The

WEL bit is set by writing a "1" to the WEL bit and

zeroes to the other bits of the Status Register. Once

this write operation is completed and a STOP com-

mand is issued, nonvolatile writes will then occur for all

NOVRAM registers and control bits. Once set, the,

WEL bit remains set until either reset to 0 (by writing a

"0" to the WEL bit and zeroes to the other bits of the

Status Register) or until the part powers up again.

SR0: Gain - NOVRAM

Selects V

OUT

and IA gain. When SR0=0, V

OUT

gain=20x,

IA gain=50x. When SR0=1, V

OUT

gain=50x, and IA

gain=20x. Default setting is 0.

CONTROL REGISTERS (CR)

The control registers are organized for byte operations.

Each byte has a unique byte address as shown in

Table 3 below.

Table 3. Control Registers (CR)

Note:

02H to 0EH are reserved for internal manufacturing use.

Byte

Addr

SR7

SR6

SR5

SR4

SR3

SR2

SR1

SR0

0F hex

SHDN

INC/DEC

0

CS

0

0

WEL

Gain

Byte

Addr.

<HEX>

Description

Reg

Name

Bit

Memory Type

7

6

5

4

3

2

1

0

00 hex

DCP for Vbias

Vbias

Vb7

Vb6

Vb5

Vb4

Vb3

Vb2

Vb1

Vb0

NOVRAM

01 hex

DCP for

VREF

Vref

X

X

Vr5

Vr4

Vr3

Vr2

Vr1

Vr0

NOVRAM

Preliminary Information

Preliminary Information

X9470

20 of 25

REV 11.16 3/20/03

www.xicor.com

X9470 BUS INTERFACE INFORMATION

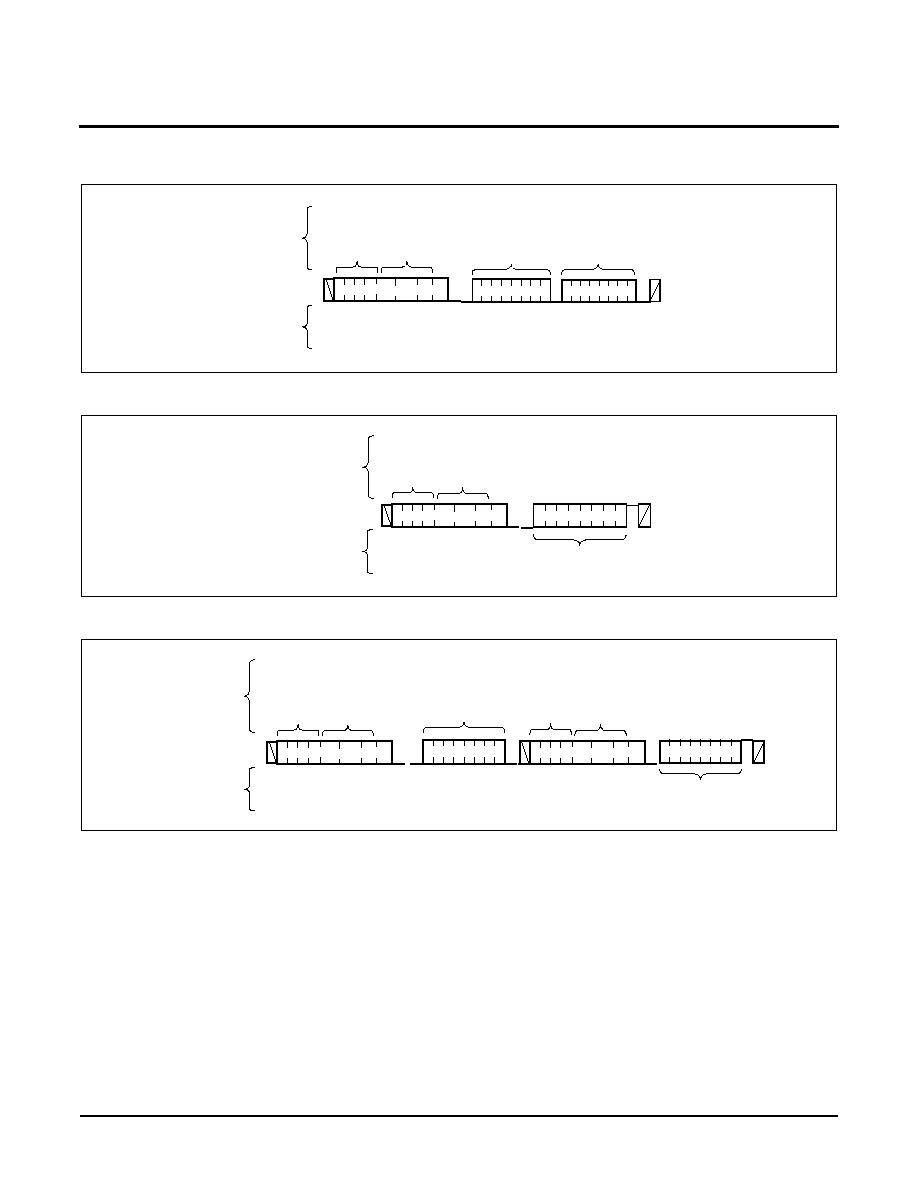

Figure 7. Slave Address, Word Address, and Data Bytes - Write Mode

Figure 8. Slave Address, Word Address, and Data Bytes - Read Mode

Slave Address, Byte Address, and Data Byte

The byte communication format for the serial bus is

shown in Figures 7 and 8 above. The first byte, BYTE

0, defines the device indentifier, 0101 in the upper half;

and the device slave address in the low half of the byte.

The slave address is determined by the logic values of

the A0, A1, and A2 pins of the X9470. This allows for

up to 8 unique addresses for the X9470. The next byte,

BYTE 1, is the Byte Address. The Byte Address identi-

fies a unique address for the Status or Control Regis-

ters as shown in Table 3. The following byte, Byte 2, is

the data byte that is used for READ and WRITE opera-

tions.

Start Condition

All commands are preceded by the start condition,

which is a HIGH to LOW transition of SDA when SCL is

HIGH. The device continuously monitors the SDA and

SCL lines for the start condition and will not respond to

any command until this condition has been met. See

Figure 9.

Slave Address Byte

Byte 0

D7

D6

D5

D2

D4

D3

D1

D0

A0

A7

A2

A4

A3

A1

Data Byte

Byte 2

A6

A5

0

1

0

S1

1

S0

R/W=0

S2

Device Identifier

Byte Address

Byte 1

Slave Address

0Fh : SR

00h : V

BIAS

01h : V

REF

Slave Address Byte

Byte 0

D7

D6

D5

D2

D4

D3

D1

D0

D0

D7

D2

D4

D3

D1

Data Byte

Byte 2

D6

D5

0

1

0

S1

1

S0

R/W

S2

Device Identifier

Data Byte

Byte 1

Slave Address

Preliminary Information

21 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

Stop Condition

All communications must be terminated by a stop con-

dition, which is a LOW to HIGH transition of SDA when

SCL is HIGH. The stop condition is also used to place

the device into the Standby power mode after a read

sequence. A stop condition can only be issued after the

transmitting device has released the bus. See Figure 9.

Acknowledge

Acknowledge is a software convention used to indicate

successful data transfer. The transmitting device, either

master or slave, will release the bus after transmitting

eight bits. During the ninth clock cycle, the receiver will

pull the SDA line LOW to acknowledge that it received

the eight bits of data. Refer to Figure 10.

The device will respond with an acknowledge after rec-

ognition of a start condition and if the correct Device

Identifier and Select bits are contained in the Slave

Address Byte. If a write operation is selected, the

device will respond with an acknowledge after the

receipt of each subsequent eight bit word. The device

will acknowledge all incoming data and address bytes,

except for:

≠ The Slave Address Byte when the Device Identifier

and/or Select bits are incorrect

≠ The 2nd Data Byte of a Status Register Write Opera-

tion (only 1 data byte is allowed)

Figure 9. Valid Start and Stop Conditions

Figure 10. Acknowledge Response From Receiver

Figure 11. Valid Data Changes on the SDA Bus

SCL

SDA

Start

Stop

SCL from

Master

Data Output

from Transmitter

Data Output

from Receiver

8

1

9

Start

Acknowledge

SCL

SDA

Data Stable

Data Change

Data Stable

Preliminary Information

Preliminary Information

X9470

22 of 25

REV 11.16 3/20/03

www.xicor.com

WRITE OPERATIONS

Byte Write

For a write operation, the device requires the Slave

Address Byte and the Word Address Bytes. This gives

the master access to any one of the words in the array.

Upon receipt of each address byte, the X9470

responds with an acknowledge. After receiving the

address bytes the X9470 awaits the eight bits of data.

After receiving the 8 data bits, the X9470 again

responds with an acknowledge. The master then termi-

nates the transfer by generating a stop condition. The

X9470 then begins an internal write cycle of the data to

the nonvolatile memory. During the internal write cycle,

the device inputs are disabled, so the device will not

respond to any requests from the master. The SDA out-

put is at high impedance. See Figure 12.

A write to a protected block of memory is ignored, but

will still receive an acknowledge. At the end of the write

command, the X9470 will not initiate an internal write

cycle, and will continue to ACK commands.

Stops and Write Modes

Stop conditions that terminate write operations must

be sent by the master after sending at least 1 full data

byte and it's associated ACK signal. If a stop is issued

in the middle of a data byte, or before 1 full data byte +

ACK is sent, then the X9470 resets itself without per-

forming the write. The contents of the array are not

affected.

Acknowledge Polling

Disabling of the inputs during nonvolatile write cycles

can be used to take advantage of the typical 5ms write

cycle time. Once the stop condition is issued to indi-

cate the end of the master's byte load operation, the

X9470 initiates the internal nonvolatile write cycle.

Acknowledge polling can begin immediately. To do this,

the master issues a start condition followed by the

Slave Address Byte for a write or read operation. If the

X9470 is still busy with the nonvolatile write cycle then

no ACK will be returned. When the X9470 has com-

pleted the write operation, an ACK is returned and the

host can proceed with the read or write operation.

Refer to the flow chart in Figure 15.

READ OPERATIONS

There are three basic read operations: Current

Address Read, Random Read, and Sequential Read.

Current Address Read

Internally the X9470 contains an address counter that

maintains the address of the last word read incre-

mented by one. Therefore, if the last read was to

address n, the next read operation would access data

from address n+1. On power up, the address is initial-

ized to 0h. In this way, a current address read immedi-

ately after the power on reset can download the entire

contents of memory starting at the first location. Upon

receipt of the Slave Address Byte with the R/W bit set

to one, the X9470 issues an acknowledge, then trans-

mits eight data bits. The master terminates the read

operation by not responding with an acknowledge dur-

ing the ninth clock and issuing a stop condition. Refer

to Figure 13 for the address, acknowledge, and data

transfer sequence.

Preliminary Information

23 of 25

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

Figure 12. Byte Write Sequence

Figure 13. Current Address Read Sequence

Figure 14. Random Address Read Sequence

S

t

a

r

t

S

t

o

p

Data

A

C

K

A

C

K

SDA Bus

Signals From

The Slave

Signals from

the Master

0

A

C

K

Byte

Address 0

A0

A1

A2

0

1

0

1

Slave

Address

Device

ID

S

t

a

r

t

S

t

o

p

Data

A

C

K

SDA Bus

Signals from

the Slave

Signals from the

Master

Slave

Address

1

A0

A1

A2

0

1

0

1

Device

ID

A

C

K

A

C

K

S

t

a

r

t

S

t

o

p

Data

S

t

a

r

t

SDA Bus

Signals from

the Slave

Signals from the

Master

Byte

Address 0

A

C

K

Slave

Address

0

A0

A1

A2

0

1

0

1

Device

ID

A

C

K

Slave

Address

1

A0

A1

A2

0

1

0

1

Device

ID

A

C

K

Preliminary Information

Preliminary Information

X9470

24 of 25

REV 11.16 3/20/03

www.xicor.com

Figure 15. Acknowledge Polling Sequence

It should be noted that the ninth clock cycle of the read

operation is not a "don't care." To terminate a read

operation, the master must either issue a stop condi-

tion during the ninth cycle or hold SDA HIGH during

the ninth clock cycle and then issue a stop condition.

Random Read

Random read operations allows the master to access

any location in the X9470. Prior to issuing the Slave

Address Byte with the R/W bit set to zero, the master

must first perform a "dummy" write operation.

The master issues the start condition and the slave

address byte, receives an acknowledge, then issues

the word address bytes. After acknowledging receipt of

each word address byte, the master immediately

issues another start condition and the slave address

byte with the R/W bit set to one. This is followed by an

acknowledge from the device and then by the eight bit

data word. The master terminates the read operation

by not responding with an acknowledge and then issu-

ing a stop condition. Refer to Figure 13 for the address,

acknowledge, and data transfer sequence.

In a similar operation called "Set Current Address," the

device sets the address if a stop is issued instead of

the second start shown in Figure 14. The X9470 then

goes into standby mode after the stop and all bus

activity will be ignored until a start is detected. This

operation loads the new address into the address

counter. The next Current Address Read operation will

read from the newly loaded address. This operation

could be useful if the master knows the next address it

needs to read, but is not ready for the data.

ACK

returned?

Issue Slave

Address Byte

(Read or Write)

Byte load completed

by issuing STOP.

Enter ACK Polling

Issue STOP

Issue START

NO

YES

Issue STOP

NO

Continue normal

Read or Write

command

sequence

PROCEED

YES

nonvolatile write

Cycle complete.

Continue command

sequence?

Preliminary Information

Characteristics subject to change without notice.

25 of 25

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc. makes no warranty,

express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the described devices from patent infringement.

Xicor, Inc. makes no warranty of merchantability or fitness for any purpose. Xicor, Inc. reserves the right to discontinue production and change specifications and prices

at any time and without notice.

Xicor, Inc. assumes no responsibility for the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents, or licenses are implied.

TRADEMARK DISCLAIMER:

Xicor and the Xicor logo are registered trademarks of Xicor, Inc. AutoStore, Direct Write, Block Lock, SerialFlash, MPS, BiasLock and XDCP are also trademarks of

Xicor, Inc. All others belong to their respective owners.

U.S. PATENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,326,134; 4,393,481; 4,404,475; 4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846;

4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829,482; 4,874,967; 4,883,976; 4,980,859; 5,012,132; 5,003,197; 5,023,694; 5,084,667; 5,153,880; 5,153,691;

5,161,137; 5,219,774; 5,270,927; 5,324,676; 5,434,396; 5,544,103; 5,587,573; 5,835,409; 5,977,585. Foreign patents and additional patents pending.

LIFE RELATED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with appropriate error detection

and correction, redundancy and back-up features to prevent such an occurrence.

Xicor's products are not authorized for use in critical components in life support devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, and whose failure to

perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiveness.

©Xicor, Inc. 2003 Patents Pending

REV 11.16 3/20/03

www.xicor.com

Preliminary Information

X9470

PACKAGING INFORMATION

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

24-Lead Plastic, TSSOP Package Type V

.169 (4.3)

.177 (4.5)

.252 (6.4) BSC

.026 (.65) BSC

.303 (7.70)

.311 (7.90)

.002 (.06)

.005 (.15)

.047 (1.20)

.0075 (.19)

.0118 (.30)

See Detail "A"

.031 (.80)

.041 (1.05)

0

∞ ≠ 8∞

.010 (.25)

.020 (.50)

.030 (.75)

Gage Plane

Seating Plane

Detail A (20X)